Understanding Marine Diesel Water Pump Failures

Diesel engine water pump repair is a critical maintenance task for any marine vessel owner or fleet manager. When your cooling system fails, the entire operation comes to a standstill.

Here’s a quick guide to marine diesel water pump repair:

| Problem | Cause | Solution |

|---|---|---|

| No water flow | Air in pump housing or inlet pipe | Fill pump body with water, purge air from lines |

| No water flow | Damaged or worn impeller | Replace impeller (annually or every 1,000 hours) |

| No water flow | Loose coupling or mounting | Tighten connections to proper torque specs |

| No water flow | Clogged intake or blockage | Clear debris and inspect for marine growth |

| Leaking | Failed shaft seal | Replace seal kit or complete pump assembly |

| Leaking | Fluid from weep hole | Address immediately to prevent engine damage |

Your marine diesel engine’s water pump is the heart of its cooling system. Whether you’re dealing with a raw water pump (using seawater) or a closed-loop freshwater pump, proper function is essential for preventing catastrophic overheating.

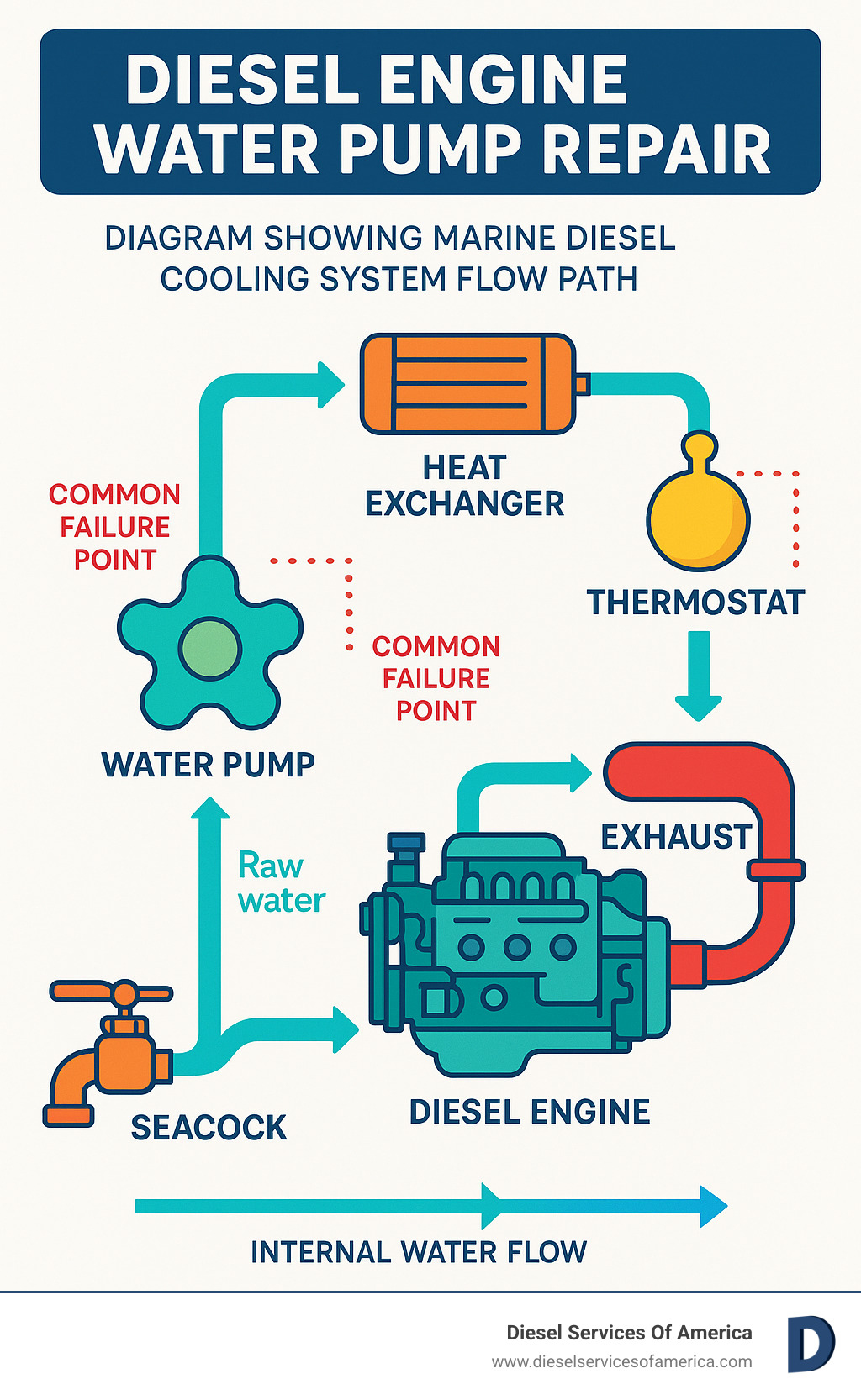

Marine diesel engines rely on effective cooling to maintain optimal performance and longevity. Unlike automotive applications, marine engines often use a dual cooling system: an internal freshwater circuit and an external raw water circuit that pulls water from the ocean, lake, or river.

As one maintenance expert noted, “Water pumps are touchy. Some only go 50k miles before they fail, and some are still running perfectly after a million.” This unpredictability makes regular inspection crucial.

For marine applications, specialists recommend inspecting and/or replacing impellers every year or every 1,000 hours of operation. This simple preventative step can save thousands in repairs and prevent being stranded on the water.

Diesel engine water pump repair word list:

– Diesel engine crankshaft repair

– Diesel engine timing adjustment

Water Pump Essentials: Functions, Failure Signs & Risks

Let’s talk about the heart of your marine diesel cooling system before we get our hands dirty with repairs. Your vessel’s water pump isn’t just another component—it’s what keeps your engine from becoming an expensive piece of modern art melted into your engine bay.

Marine diesel engines typically rely on two types of water pumps:

- Centrifugal pumps – These workhorses use spinning impellers to create water flow and are the most common choice for freshwater cooling circuits

- Gear pumps – Often found in older or specialized marine applications, these pumps use meshing gears to push water through the system

Unlike your car or truck, your boat’s cooling system faces unique challenges. Salt water, constant moisture, and the sobering reality that when you’re miles offshore, you can’t just call a tow truck.

“When a diesel water pump fails, the consequences can be swift and severe,” explains one of our veteran technicians at Diesel Services Of America. “Unlike automotive applications where you can pull over, a marine engine failure can leave you stranded miles offshore in potentially dangerous conditions.”

Ever wonder what happens when your cooling system starts to fail? Here’s a comparison that might keep you up at night:

| System Condition | Normal Operation | Overheating Sequence |

|---|---|---|

| Engine Temperature | 160-190°F (71-88°C) | Rapidly climbing above 200°F (93°C) |

| Coolant Pressure | 12-15 PSI | May spike then drop as coolant boils |

| Oil Viscosity | Maintains proper film | Breaks down, loses lubricating properties |

| Metal Components | Normal thermal expansion | Excessive expansion, potential warping |

| Exhaust Color | Clean or light smoke | White steam (coolant burning) |

| Engine Performance | Steady power output | Power loss, rough running |

| Warning Systems | All clear | Temperature alarms, shutdown imminent |

Core Functions of a Marine Diesel Water Pump

Your marine diesel water pump isn’t just pushing water around—it’s performing several critical jobs that keep your engine happy and healthy.

Heat Rejection is the primary mission. Your diesel generates enormous heat through combustion and friction. Without proper cooling, temperatures skyrocket to destructive levels in minutes, not hours.

The Jacket-Water Loop Circulation is like your engine’s personal bloodstream. In closed cooling systems, the freshwater pump moves coolant through the engine block and cylinder heads, absorbing heat along the way.

For Sea-Water Exchange, your raw water pump draws water from outside the vessel, circulates it through heat exchangers to cool the jacket water, then sends it back overboard. It’s like having the ocean as your personal radiator.

Lubrication Integrity might not seem related to cooling, but temperature directly affects your oil’s performance. Proper cooling ensures your engine oil maintains its viscosity and lubricating properties—critical for long engine life.

Emissions Compliance matters too. Proper cooling helps maintain optimal combustion temperatures, reducing harmful emissions and ensuring you stay compliant with increasingly strict regulations.

“The cooling system doesn’t just prevent catastrophic failure—it’s essential for optimal performance, fuel economy, and emissions control,” notes our marine specialist at Diesel Services Of America. “A properly functioning water pump is the cornerstone of this entire system.”

Warning Signs You Can’t Ignore

Your engine will usually tell you when the water pump is struggling—if you know what to look for. These warning signs aren’t just suggestions—they’re urgent calls to action:

Coolant Leaks might seem obvious, but they’re easy to miss in a damp engine room. Look for colorful puddles or drips beneath the engine, especially around the pump housing.

Salt Crust Formation is a telltale sign in marine engines. Those white, crusty deposits around seals or gaskets aren’t just cosmetic—they indicate seawater has leaked and evaporated, leaving salt behind.

If you see Steam in Exhaust, pay attention. Excessive white smoke or steam from the exhaust often means coolant is finding its way into the combustion chambers—never a good thing.

When those High Temperature Alarms start sounding, it’s not the time to “wait and see.” Temperature warning systems are designed to give you just enough time to react before damage occurs.

Noisy Bearings create a distinctive grinding, whining, or squealing noise from the pump area. This sound means bearing failure is imminent or already happening.

A Wobbling Pulley is something you can actually see during a visual inspection. If the pump pulley wobbles during operation, the shaft or bearings are already failing.

Perhaps most important is any Fluid from Weep Hole. “The weep hole is your early warning system,” explains our marine technician. “It’s designed to allow fluid to escape before it can damage internal components. If you see anything coming from that weep hole, it’s time to service the pump immediately.”

Catching these warning signs early can mean the difference between a simple repair in port and a costly emergency at sea. At Diesel Services Of America, we’ve seen too many catastrophic failures that started as small, ignored symptoms. Don’t let your next fishing trip or cruise become a cautionary tale about deferred maintenance.

Diesel Engine Water Pump Repair: Diagnostics & Root Causes

When your vessel’s engine starts running hot, proper diagnosis becomes your best friend before jumping into any diesel engine water pump repair. Understanding what’s really happening can save you hours of frustration and a locker full of unnecessarily replaced parts.

“I can’t tell you how many boat owners I’ve seen who’ve replaced three or four parts without proper diagnosis,” says our lead technician at Diesel Services Of America. “They end up with lighter wallets but the same overheating problem. A methodical approach almost always pays off.”

Marine diesel cooling problems typically stem from four common no-flow causes: air locks, worn impellers, loose couplings, or clogged intakes. Each leaves its own distinctive clues that can help you pinpoint the true culprit.

According to research on preventative replacement, addressing these issues before complete failure can prevent catastrophic engine damage and extend the life of your marine diesel significantly.

“Diesel engine water pump repair” Troubleshooting Flowchart

When diagnosing cooling system issues, our marine technicians follow a systematic approach that you can adopt too:

Start by verifying actual overheating with your temperature gauges and checking for steam or unusual exhaust. Don’t skip testing your thermostat – a sticky valve here can perfectly mimic pump failure symptoms while being much easier to fix.

Your cooling system’s pressure cap deserves attention too. These caps maintain precise pressure that raises the boiling point of your coolant. A simple pressure tester can confirm it’s working correctly.

For a more thorough investigation, use an infrared thermometer to trace your cooling system. Cold spots often indicate blockages, while hot spots suggest flow issues. Adding fluorescent dye to your coolant can reveal even the most elusive leaks.

“The borescope has become one of our most valuable diagnostic tools,” our technician explains. “It lets us peek inside without tearing everything apart. You wouldn’t believe what we sometimes find – from broken impeller pieces to marine life that’s made itself at home.”

For more detailed information about our comprehensive diagnostic approach, visit our diesel engine diagnostic tools page.

The Four Big Reasons Your Pump Stops Moving Water

After diagnosing thousands of marine cooling issues, we’ve found that most water flow problems boil down to four primary causes:

Air in the pump housing or inlet pipe is probably the most common issue we encounter. Your pump might be running perfectly, but if it’s fighting an air lock, it won’t move water effectively. The solution is refreshingly simple: fill the pump body with water before starting, check all inlet connections for tiny air leaks, and thoroughly purge air from your system.

Impeller damage or wear creates a cascade of problems. Those rubber vanes are designed to flex thousands of times per minute, but they don’t last forever. Running dry for even a few minutes can destroy them. We recommend replacing rubber impellers annually or every 1,000 hours – whichever comes first. When they fail, watch out for fragments that can migrate to your heat exchanger.

Shaft seal failure announces itself with telltale leakage from the weep hole or around the shaft. This small drip might seem minor, but it demands immediate attention. If you spot coolant in your engine oil, you’re already facing a serious situation that requires prompt professional intervention.

Drive-belt issues or coupling failure might be the easiest to spot visually but still cause plenty of headaches. A loose, squealing belt or a pump that’s not turning despite the engine running points to mechanical drive problems rather than internal pump issues.

“I always remind boaters about the importance of proper torque,” our marine specialist emphasizes. “I’ve seen too many pumps damaged by overtightening. Following manufacturer specs isn’t just being fussy – it’s the difference between a repair that lasts years and one that fails next week.”

For marine diesel owners who want to stay ahead of potential problems, our technicians at Diesel Services Of America offer comprehensive inspections that can catch these issues before they leave you stranded miles offshore.

From Repair to Prevention: Rebuild, Replacement & Maintenance

Once you’ve pinpointed the problem, it’s time to roll up your sleeves and tackle the diesel engine water pump repair process. Whether you’re facing a minor issue or a major failure, having the right approach makes all the difference between a quick fix and a recurring headache.

“The difference between a repair that lasts five years and one that fails next month often comes down to the little details,” says our shop foreman at Diesel Services Of America. “Taking your time and doing it right the first time pays dividends when you’re 20 miles offshore.”

“Diesel engine water pump repair” Step-by-Step Rebuild Guide

Rebuilding a marine diesel water pump isn’t rocket science, but it does require attention to detail and a methodical approach. Here’s how to get it done right:

Start with proper preparation and safety – always disconnect battery cables and ensure the engine is cool before beginning. Wear those safety glasses and gloves – they’re not just suggestions when you’re working with coolant and sharp edges.

When draining the cooling system, position a clean container to catch the coolant. If it’s relatively fresh and clean, you might be able to reuse it. If not, coolant requires proper disposal – it’s toxic to wildlife and pets.

Removing the water pump takes patience. Document everything with your phone camera before disconnecting hoses and electrical connections. Those photos will be lifesavers during reassembly. Remove mounting bolts carefully, keeping track of their exact positions – they might have different lengths depending on location.

During disassembly, maintain the order of components and note their orientation. Use proper pullers for bearings and pulleys – hammering or prying can damage components that might otherwise be reusable.

The inspection phase is crucial and often overlooked. “I’ve seen plenty of folks rebuild a pump only to have it fail because they missed hairline cracks in the housing,” notes our senior technician. Check the housing for corrosion, the shaft for scoring, and all water passages for scale buildup or blockages.

When installing new components, cleanliness is next to godliness. Remove all old gasket material with a proper scraper (not a metal file that could damage mating surfaces). Apply blue Loctite to threads where specified, but don’t overdo it – excess compound can break loose and clog passages.

Before reinstallation, perform a quick bench test by manually rotating the shaft. It should turn smoothly without catching or binding. This simple check can save hours of frustration later.

When reinstalling the pump, follow the torque sequence in your service manual. Over-tightening isn’t better – it can warp housings and create leaks. Under-tightening is just as bad, allowing gaskets to blow out under pressure.

The refill and purge process requires patience. Add the correct 50/50 coolant mixture slowly to minimize air pockets. Many marine engines have specific air bleed points – use them. Running an engine with air in the cooling system is asking for trouble.

Finally, perform thorough checks with the engine running. Monitor temperatures, look for leaks, and verify proper coolant flow. Top off the coolant after the system has cycled through its full temperature range.

For quality maintenance parts for your marine diesel engine, visit our diesel engine maintenance parts page.

Selecting the Right Replacement or Kit

Choosing the correct replacement pump or rebuild kit isn’t just about finding something that looks similar. It’s about ensuring precise compatibility with your specific engine.

Always start with your engine serial number lookup. Marine diesel engines often have variations even within the same model year, and the serial number is your golden ticket to getting exactly the right parts.

Cross-reference verification adds an extra layer of certainty. Part numbers sometimes change over the years as manufacturers make improvements. A good parts supplier (like us at Diesel Services Of America) can help steer these changes and ensure you’re getting the current, correct component.

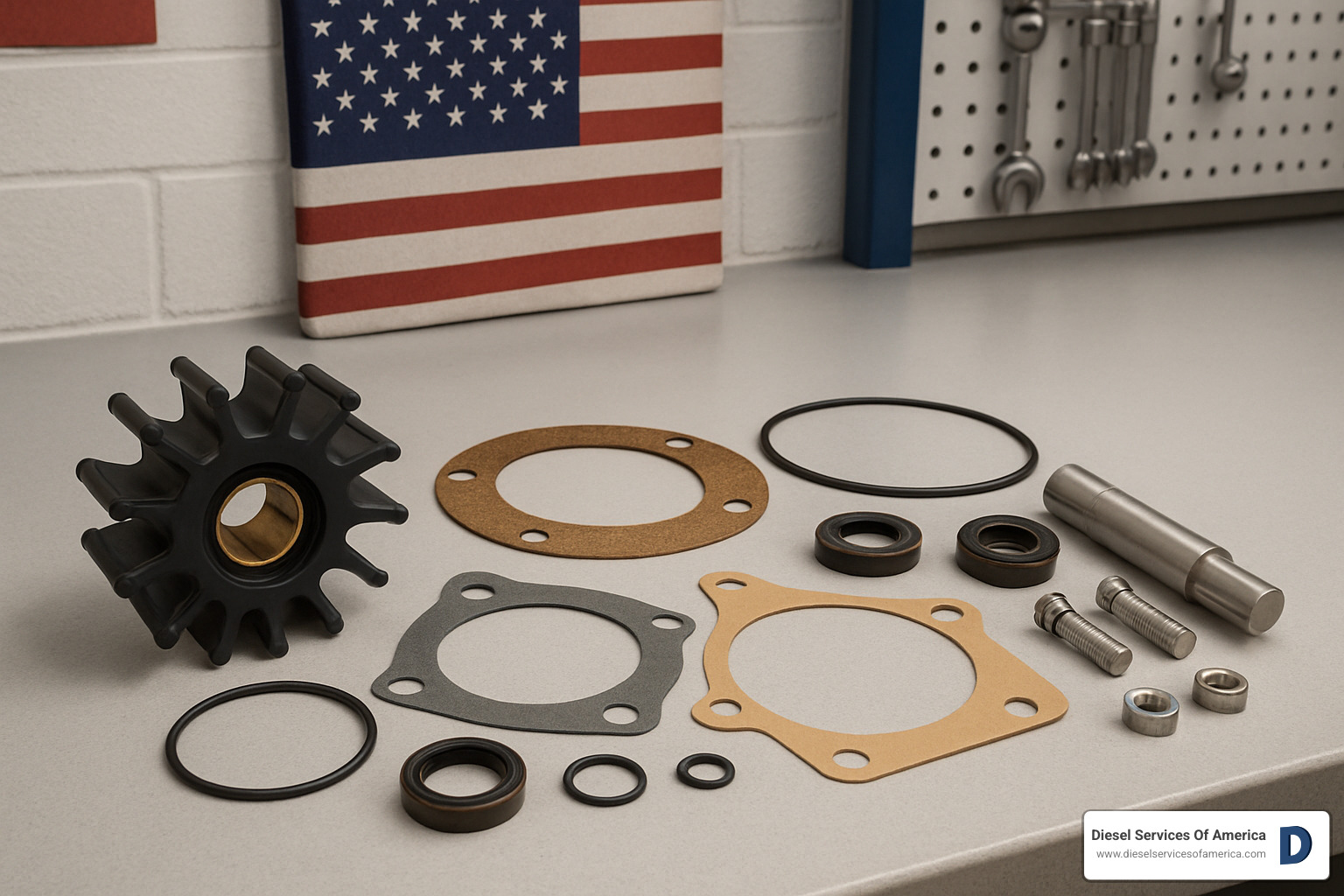

Standard rebuild kits typically include the essentials: shaft seals, gaskets, O-rings, and for raw water pumps, a new impeller. More comprehensive kits might add bearings, a shaft, or even housing components. The age and condition of your pump will help determine whether a basic kit will suffice or if you need the works.

The OEM versus aftermarket debate deserves serious consideration. While aftermarket parts often come with an attractive price tag, they can vary wildly in quality. OEM parts typically cost more but offer the assurance of proper materials, exact fitment, and manufacturer warranty support. For critical systems like cooling, that peace of mind is often worth the premium.

“In the marine environment, we’re particularly cautious about aftermarket parts,” explains our parts manager. “Salt water is merciless, and inferior materials can deteriorate rapidly. What seems like a bargain now can become very expensive when you’re calling for a tow back to port.”

Best-Practice Maintenance Schedule

An ounce of prevention truly is worth a pound of cure when it comes to marine diesel water pumps. Following a consistent maintenance schedule can help you avoid unexpected failures and costly emergency repairs.

Raw-water impellers should be replaced annually or every 1,000 hours – whichever comes first. These rubber components are designed as wear items, and they degrade even when not in use. The peace of mind from a fresh impeller is well worth the modest cost and effort.

Bronze impellers in closed cooling systems last much longer but still need inspection every 1,000 hours. Look for corrosion, erosion, or excessive wear. The weep hole is your early warning system – any fluid seeping from it means your seal is starting to fail.

Belt condition directly affects pump performance. Check tension and condition monthly, looking for cracks, glazing, or fraying. A belt that looks “good enough” probably isn’t. When in doubt, replace it – a spare belt costs far less than the consequences of a failure.

Hoses and clamps often get overlooked until they fail catastrophically. Inspect them quarterly, looking for softening, hardening, or cracking of the rubber. Clamps should be corrosion-free and tight enough to prevent leaks without crushing the hose.

Regular oil analysis can detect coolant contamination before it causes major damage. The presence of coolant in your oil sample is a red flag that demands immediate attention – it likely indicates a failing water pump seal or cracked heat exchanger.

Coolant testing every six months helps ensure your cooling system is providing proper protection. Check pH levels and additive concentrations, and replace the coolant entirely every two years. Old coolant becomes acidic and can damage internal components.

A comprehensive system flush every two years helps remove scale buildup and deposits that can restrict flow and reduce cooling efficiency. This is especially important in sea-water applications where mineral deposits can accumulate quickly.

Detailed record-keeping might seem tedious, but it’s invaluable for tracking component lifespans and anticipating replacement needs. Note dates, hours, and observations with each service – this information becomes a roadmap for preventative maintenance.

“The weep hole on a water pump is your early warning system,” our technician emphasizes. “Check it regularly during engine inspections. Any fluid there means the seal is beginning to fail, and you should plan for service before it becomes an emergency.”

For more information about maintaining raw-water systems, visit our raw-water cooling systems page.

Frequently Asked Questions about Marine Diesel Water Pump Repair

How risky is it to run with a leaking pump?

Let’s be honest—running your marine diesel with a leaking water pump is like sailing into a storm with torn sails. It’s not just risky; it’s inviting disaster.

When your water pump leaks, you’re facing a countdown to potentially catastrophic damage. Even a small drip can lead to coolant loss and engine overheating. Before you know it, you’re looking at warped cylinder heads, cracked blocks, or blown gaskets—all expensive problems that could have been avoided.

Internal leaks are particularly sneaky villains. When coolant seeps past a failed seal into your engine oil, it creates a nasty cocktail that destroys lubrication. Your bearings and journals start wearing faster, and suddenly your simple pump repair becomes a complete engine rebuild.

“I’ve seen too many boaters ignore a small leak, only to call us later with a towing bill and a seized engine,” shares one of our technicians at Diesel Services Of America. “A leaking water pump never gets better on its own—it only gets worse, and usually at the worst possible time.”

Don’t forget the electrical damage that can occur when coolant reaches sensitive components, causing shorts and corrosion. And perhaps most concerning is the safety risk—being stranded miles offshore with an overheated engine isn’t just inconvenient; it can be dangerous.

Should I replace the pump preventively during haul-out?

Smart boat owners think ahead, and replacing your water pump during scheduled haul-out often makes good financial and practical sense.

Consider your pump’s age and operating hours. Just like we humans show our age eventually, water pumps have a finite service life. If yours is approaching the typical lifespan for your engine model, replacing it while your boat is already out of the water is simply good planning.

Your operational patterns matter too. If you frequently venture far from shore or take extended voyages, the peace of mind from a fresh water pump is worth its weight in gold. Our service manager puts it perfectly: “Preventative maintenance is much easier to manage than unplanned repairs. The cost of replacing a water pump during scheduled maintenance is negligible compared to towing fees and lost wages from breakdowns.”

Pay attention to even minor symptoms. That occasional drip from the weep hole or slight temperature fluctuation isn’t going to fix itself. And if your engine configuration makes the water pump difficult to access, take advantage of haul-out when other components are already removed.

The math is simple: scheduled replacement costs significantly less than emergency repairs, not to mention the potential towing fees and lost boating time.

Why does my new pump still overheat the engine?

You’ve installed a brand new water pump, but your temperature gauge is still climbing into the red zone. Frustrating, isn’t it? Before you question your repair skills, know that several common culprits might be at work.

Air in the cooling system is the most frequent offender. Those stubborn air pockets prevent proper coolant circulation, essentially creating “dry spots” in your engine. Thorough bleeding after installation is critical—sometimes it takes multiple cycles to get all the air out.

Installation details matter tremendously. Did you torque the bolts to specification in the correct sequence? Is the gasket properly seated? Even small mistakes can lead to big problems.

Your thermostat might be playing tricks on you. A stuck thermostat will restrict coolant flow regardless of how powerful your new pump is. While you have the system open, replacing this inexpensive part is often wise.

“A new pump is only one component in a complex system,” explains our diagnostic specialist at Diesel Services Of America. “We often find that overheating persists because related issues weren’t addressed during the pump replacement.”

Don’t overlook your heat exchangers and internal cooling passages. Years of marine operation can leave them clogged with scale, salt deposits, or debris. Similarly, exhaust restrictions in wet exhaust systems can prevent proper water flow.

Sometimes the issue is as simple as improper belt tension causing the pump to spin slower than required, or as complex as having installed a pump with different flow characteristics than the original.

If you’re still struggling with overheating issues after a diesel engine water pump repair, it might be time to call in the professionals. At Diesel Services Of America, our systematic troubleshooting approach can identify and resolve even the most puzzling cooling system problems.

Conclusion

Proper diesel engine water pump repair is essential for maintaining the reliability and longevity of your marine diesel engine. Throughout this guide, we’ve explored how these pumps serve as the beating heart of your engine’s cooling system, and how their failure can lead to serious consequences if not addressed quickly.

Let’s take a moment to revisit what we’ve learned:

Marine diesel engines depend on two critical pump types – freshwater pumps handling closed cooling circuits and raw water pumps that circulate seawater for heat exchange. These components work together in a delicate balance to keep your engine running at optimal temperature.

We’ve seen that regular maintenance – particularly the annual replacement of impellers in raw water pumps – costs far less than emergency repairs or complete engine rebuilds following overheating damage. An ounce of prevention truly is worth a pound of cure when it comes to marine cooling systems.

The four main culprits behind pump failures – air in the system, impeller damage, seal failure, and drive issues – can all be addressed through proper diagnosis and repair procedures. Knowing these common issues helps you catch problems early, before they escalate into more serious concerns.

Following proper rebuild procedures and using quality parts isn’t just about fixing current problems – it’s about ensuring reliable operation and extending your engine’s service life. The small premium paid for quality components pays dividends in reliability when you’re miles offshore.

A thoughtful, comprehensive maintenance schedule with regular inspections of all cooling system components serves as your best defense against unexpected failures. Those routine checks might seem tedious, but they’re your best insurance policy against being stranded at sea.

At Diesel Services Of America, our factory-trained technicians specialize in marine diesel engine cooling systems. Based in Fort Lauderdale, we provide dockside service throughout South Florida and the Caribbean, along with worldwide parts delivery when you need them most.

“We’ve seen how proper maintenance prevents catastrophic failures,” says our service director with a knowing smile. “The most expensive repair is always the one you didn’t plan for. Regular inspection and timely intervention save not just money, but potentially dangerous situations at sea.”

Whether you’re facing an emergency repair, planning scheduled maintenance, or simply seeking advice on keeping your marine diesel cooling system in top condition, our team stands ready to help. For more information about our comprehensive vessel services, visit our diesel marine vessel service page.

Remember: when it comes to marine diesel engines, prevention isn’t just better than cure—it’s your ticket to safety, reliability, and peace of mind while on the water. Don’t wait until you’re drifting with an overheated engine to think about your cooling system’s health.