Why Factory Authorized Marine Diesel Experts Matter for Your Fleet

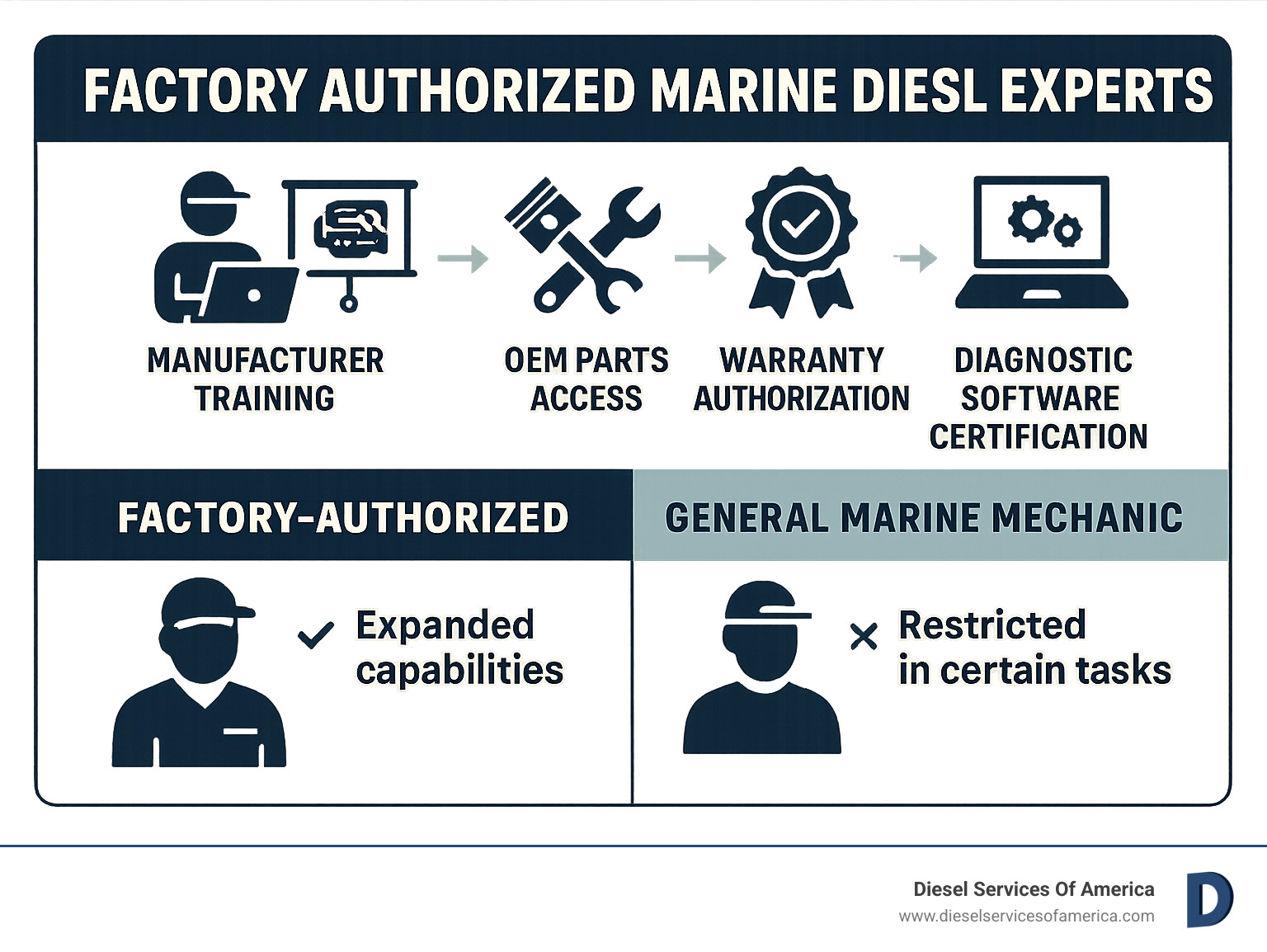

Factory Authorized Marine Diesel Experts are certified technicians who receive direct training from engine manufacturers like MAN, Volvo Penta, Cummins, and John Deere. These experts have exclusive access to OEM parts, factory software updates, and warranty repair authorization that general mechanics simply cannot provide.

What makes a marine diesel expert “factory authorized”:

– Direct manufacturer training on specific engine models and systems

– Certified access to OEM diagnostic software and technical bulletins

– Authorized warranty work – only they can perform covered repairs

– Genuine parts sourcing with 95% availability within 48 hours

– Factory specifications for rebuilds, overhauls, and failure analysis

Key benefits for fleet managers:

– Maintains manufacturer warranty coverage

– Reduces downtime with proper diagnostics

– Prevents costly repeat repairs from incorrect procedures

– Provides expert witness support for insurance claims

The difference between factory authorized and general marine mechanics is stark. As one industry expert notes: “Factory-scheduled maintenance is often overlooked and is the root cause of the majority of boat engine problems.”

Even experienced marine diesel technicians make costly mistakes when they skip manufacturer protocols or use non-OEM parts. The average marine diesel engine lasts 5,000 hours before major overhaul, but proper factory-authorized maintenance can extend this to 8,000 hours – potentially adding decades to engine life.

This expert roundup reveals the biggest mistakes that even certified technicians regret, and how factory authorization prevents these expensive errors.

Factory Authorized Marine Diesel Experts: Definition & Credentials

Here’s something that might surprise you: not every marine mechanic can legally work on your diesel engine under warranty. The difference between a good mechanic and a Factory Authorized Marine Diesel Expert could save you thousands of dollars – or cost you even more.

Factory Authorized Marine Diesel Experts earn their credentials through rigorous manufacturer-specific training programs. We’re talking about intensive courses directly from companies like MTU, Detroit Diesel, and John Deere. These aren’t weekend workshops – they’re comprehensive programs that can take weeks to complete and require ongoing education to maintain certification.

At our facility, our Expert Marine Diesel Technicians regularly attend factory training because marine engines face unique challenges. Unlike their land-based cousins, marine diesels deal with constant vibration, salt air, and varying load conditions that demand specialized knowledge.

The factory training process is thorough and unforgiving. Technicians must demonstrate mastery of OEM certification requirements, understand complex warranty support protocols, and pass rigorous testing on diagnostic procedures. They also learn the detailed survey process that manufacturers require for warranty claims and major repairs.

Factory Authorized Marine Diesel Experts vs. General Mechanics

The gap between factory authorized experts and general mechanics isn’t just about credentials – it’s about access to critical resources. Factory Authorized Marine Diesel Experts work with proprietary diagnostic tools that aren’t available to the general public. These tools can pinpoint problems in minutes that might take others hours to find.

When it comes to genuine parts, factory authorized facilities have established relationships with manufacturers. We can source authentic components quickly, while general mechanics often struggle with availability and authenticity. There’s nothing worse than installing a “compatible” part only to have it fail during your next voyage.

The compliance records we maintain are another crucial difference. Every repair, every part replacement, every diagnostic test gets documented according to manufacturer specifications. This paperwork trail becomes essential when warranty claims arise or when insurance companies investigate major failures.

General mechanics, no matter how skilled, simply can’t access manufacturer databases or technical bulletins. They’re working without the manufacturer’s playbook, which puts your engine and your wallet at risk.

Why Manufacturers Require Factory Authorization for Warranty Work

Manufacturers didn’t create factory authorization requirements to make your life difficult – they did it to protect everyone involved. When a marine diesel engine costs as much as a luxury car, proper procedures become absolutely critical.

Warranty claims require meticulous documentation and adherence to exact specifications. Factory authorized facilities know precisely what paperwork manufacturers need and how to present failure analysis data. We’ve seen vessel owners lose warranty coverage because a well-meaning mechanic used the wrong torque specification or skipped a documentation step.

Recall repairs present another challenge that only factory authorized experts can handle. When manufacturers issue safety recalls or technical service bulletins, only authorized facilities receive the notifications and proper repair procedures. Missing a recall repair can create serious safety hazards and void your warranty entirely.

The documentation requirements alone justify working with factory authorized experts. Insurance companies increasingly demand proof that repairs followed manufacturer protocols. Without proper documentation, even legitimate claims can be denied, leaving you responsible for expensive repairs that should have been covered.

Biggest Mistakes Even Certified Technicians Regret

Here’s something that might surprise you: even our most experienced Factory Authorized Marine Diesel Experts have made mistakes that still keep them up at night. After thirty years in this business, we’ve learned that the best technicians are the ones who admit their errors and learn from them.

The pressure on marine technicians is unlike anything in automotive or general mechanical work. When a yacht charter is losing $5,000 per day or a commercial vessel is stuck at dock, the temptation to take shortcuts becomes overwhelming. We’ve been there, and we’ve learned some expensive lessons.

One of our senior technicians still talks about the time he skipped a proper cooling system pressure test during what seemed like a simple emergency repair. The boat owner was desperate to get back on the water, and everything looked fine. Three days later, that engine overheated catastrophically, requiring a complete rebuild that could have been prevented with twenty minutes of proper testing.

Dockside shortcuts under pressure have taught us that there’s never a good reason to skip manufacturer protocols. The marine environment is simply too harsh and unpredictable. What works fine on land can fail spectacularly when you add salt air, constant vibration, and dynamic loading conditions.

Skipped service intervals represent another painful lesson. “Just this once” has a way of becoming “just this twice” and then a dangerous pattern. We’ve seen technicians defer oil changes by 50 to 100 hours because the oil still looked clean. Marine diesel engines operating under constant load simply can’t tolerate this kind of neglect.

The most heartbreaking mistakes involve misdiagnosed overheating issues. When an engine runs hot, it could be anything from a $50 thermostat to catastrophic internal damage. Rushing to conclusions without systematic diagnosis has cost our clients tens of thousands in unnecessary repairs. We learned to slow down and follow the diagnostic tree, even when everyone’s breathing down our necks.

Improper torque specifications might sound technical, but this mistake has real-world consequences. Using automotive specs on marine applications is asking for trouble. Marine engines face different thermal cycling and vibration loads than their land-based cousins. We’ve witnessed head gasket failures within months because someone used “close enough” torque values instead of exact manufacturer specifications.

Factory Authorized Marine Diesel Experts Reveal Top 3 Errors

After honest conversations with our Factory Authorized Marine Diesel Experts across Fort Lauderdale and Southeast Florida, three mistakes emerged as the most costly and common.

Coolant system neglect tops our list of regrets. Marine engines work harder than virtually any land-based application, and coolant chemistry breaks down faster in this environment. The biggest mistake we see is treating marine coolant like automotive coolant. Salt contamination accelerates corrosion in ways that surprise even experienced technicians. We learned the hard way to test coolant chemistry every 250 hours, not just check fluid levels.

Non-OEM filter substitutions have cost our clients dearly over the years. Those “equivalent” aftermarket filters might save $20 upfront, but we’ve seen them cause $50,000 engine rebuilds. Marine applications demand filters specifically designed for constant vibration and moisture exposure. The failure modes are different, and the consequences are severe.

Ignoring software updates represents a modern mistake that catches many technicians off guard. Today’s marine diesels rely heavily on electronic engine management systems. Skipping manufacturer software updates can cause everything from poor fuel economy to complete engine shutdown. We now make software updates a standard part of every major service because we’ve learned that prevention beats emergency repairs every time.

Factory Authorized Marine Diesel Experts on Rebuild Timing

The 5,000-hour benchmark for marine diesel overhaul isn’t some arbitrary number dreamed up by manufacturers. It’s based on real-world failure data from thousands of engines operating in harsh marine conditions.

However, our experience shows this timeline varies dramatically based on maintenance quality and operating conditions. Oil analysis has become our crystal ball for predicting engine health. We’ve seen engines need complete rebuilds at 3,000 hours due to poor maintenance, while others with religious care run smoothly past 8,000 hours.

The rebuild versus repower decision often catches boat owners by surprise. When engine blocks show cracking, severe corrosion, or excessive wear, replacement frequently costs less than rebuilding. The mistake many people make is attempting to rebuild engines that are beyond economical repair. We’ve learned to be honest about when it’s time to say goodbye to an old engine, even when the news isn’t what owners want to hear.

Our failure analysis process now includes detailed documentation of what went wrong and why. This isn’t just for warranty claims – it’s how we prevent the same mistakes from happening again.

How Factory Training, OEM Parts, and Warranty Support Prevent Costly Errors

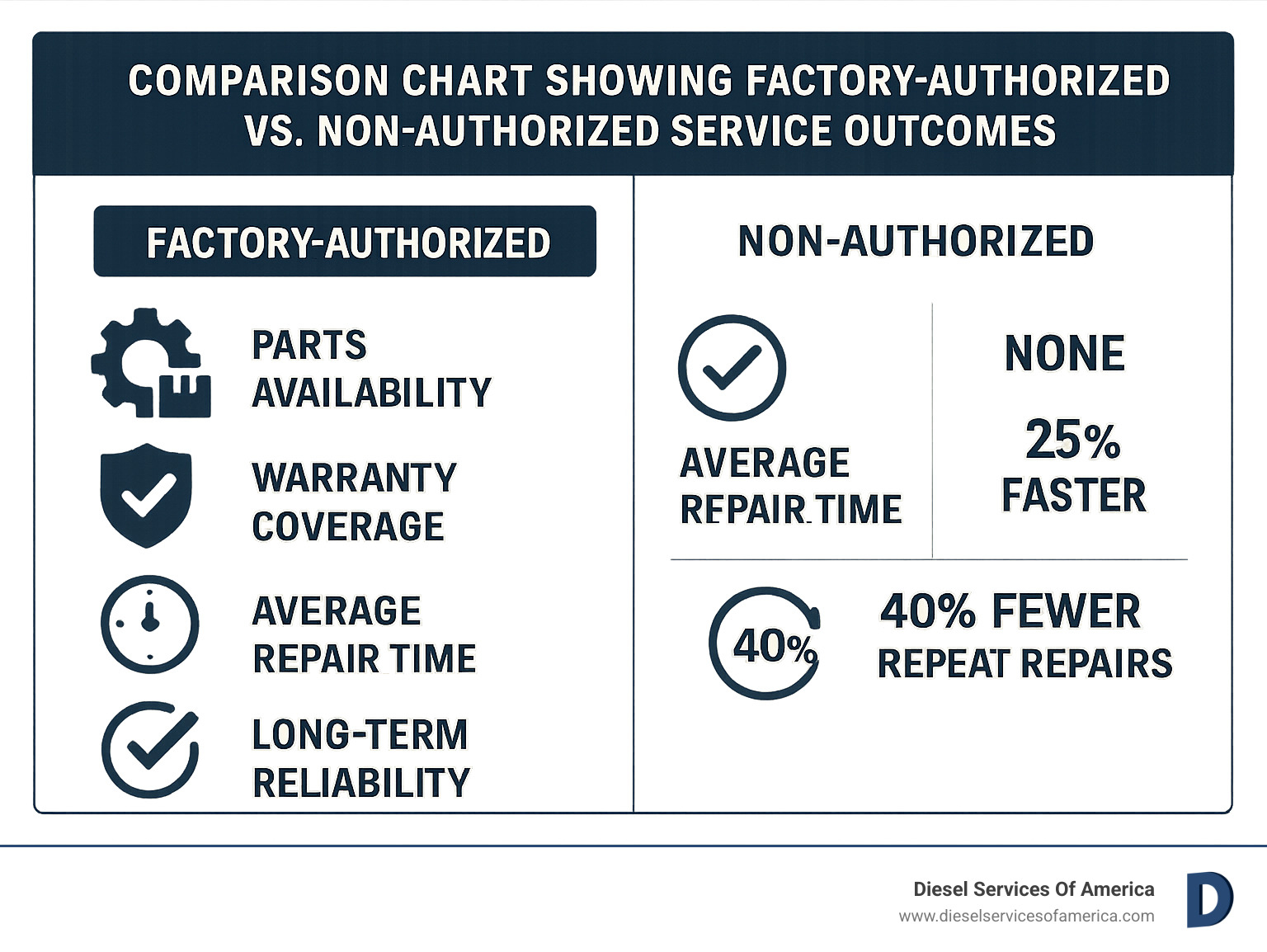

The difference between Factory Authorized Marine Diesel Experts and regular mechanics becomes crystal clear when you look at real-world outcomes. After decades in the marine diesel business, we’ve tracked the results, and they’re eye-opening.

Factory authorized service delivers 95% parts availability within 48 hours compared to the weeks you might wait for aftermarket alternatives. When your charter boat is losing $3,000 per day, that speed matters enormously.

Warranty coverage tells an even more dramatic story. Factory authorized work maintains full manufacturer backing, while non-authorized repairs often void warranties entirely. We’ve seen vessel owners lose $100,000+ in warranty claims because they chose cheaper, non-authorized service.

| Service Type | Parts Availability | Warranty Coverage | Average Repair Time | Long-term Reliability |

|---|---|---|---|---|

| Factory Authorized | 95% within 48 hours | Full manufacturer backing | 25% faster completion | 40% fewer repeat repairs |

| Non-Authorized | Limited aftermarket | Voided warranty | Extended downtime | Higher failure rates |

Factory software access alone prevents countless diagnostic nightmares. When we encounter unusual problems, we can call manufacturer engineering teams directly. Last month, this connection helped us solve a mysterious fuel system issue in two hours that had stumped another shop for three weeks.

Modern marine diesels are incredibly sophisticated machines. Our Latest insights on marine control automation show just how complex these systems have become. Without factory training and software access, technicians are essentially flying blind.

Step-by-Step OEM Rebuild & Overhaul Workflow

Our factory authorized rebuild process isn’t just thorough – it’s methodical in ways that save money down the road.

Complete tear-down documentation starts every rebuild. We photograph and measure every component, creating a detailed failure analysis record. This documentation has saved our clients thousands when insurance companies questioned claims.

Factory measurement standards guide every decision. We don’t use “close enough” – every clearance and dimension gets compared to original specifications. This precision prevents the premature failures we’ve seen from sloppy rebuilds.

Dynamometer testing catches problems before they reach the water. We’ve finded assembly errors during dyno testing that would have caused catastrophic failures within hours of launch. Better to find problems in our shop than 50 miles offshore.

Complete documentation packages accompany every rebuild. These records satisfy warranty requirements and provide the paper trail that insurance companies demand for major claims.

Genuine Parts Supply Chain & Overnight Shipping

Our Complete Source for Marine Diesel Services includes something that general mechanics simply cannot offer – direct access to manufacturer inventories worldwide.

Global inventory access means we can source parts from factories in Germany, Sweden, or Japan and have them in Fort Lauderdale within 24-48 hours. We’ve shipped emergency parts to vessels in the Caribbean, Bahamas, and remote locations throughout the Americas.

Remanufactured components offer significant savings while maintaining factory specifications. These aren’t aftermarket rebuilds cobbled together in someone’s garage – they’re factory-restored components with full warranties. A remanufactured injector costs 60% less than new but performs identically.

Dockside delivery eliminates the hassle of parts pickup. Our mobile service fleet brings parts directly to your vessel, whether you’re at a marina in Miami or anchored in the Keys. We’ve delivered parts to vessels at anchor using everything from service boats to helicopters when time was critical.

The genuine parts supply chain makes the difference between a quick repair and weeks of downtime. When you’re dealing with marine applications, aftermarket parts are often a costly gamble that rarely pays off.

Finding and Working with the Right Factory Authorized Expert

Finding the right Factory Authorized Marine Diesel Expert is like finding a good doctor – credentials matter, but so does experience and availability when you need them most. After thirty years in the marine diesel business, we’ve learned what separates truly qualified experts from those who just claim the title.

Service area coverage should extend beyond just having a shop. Real factory authorized experts offer both permanent facilities and mobile service capabilities. We cover Southeast Florida and the Caribbean because marine engines don’t break down conveniently close to repair shops. Our 24/7 emergency response teams carry fully equipped mobile units because a fuel leak at 2 AM can’t wait until Monday morning.

Engine surveys require specialized training that goes beyond basic repair work. Whether you’re buying a yacht or filing an insurance claim, the surveyor’s factory authorization gives their findings legal weight. We regularly provide expert witness testimony and insurance claim support because our manufacturer backing makes our assessments credible in court.

Mobile service makes all the difference in the marine world. While your neighbor’s car can be towed to any shop, your 60-foot sportfish needs experts who come to the water. Our Factory Authorized Diesel Shop combines shore-based facilities with a mobile fleet that brings factory expertise directly to your slip.

How to Verify Factory Authorized Status

Don’t assume someone is factory authorized just because they say so. We’ve seen too many vessel owners get burned by mechanics who stretched the truth about their credentials.

Certification cards should be current and displayed prominently. Real factory authorized experts are proud of their credentials and keep them visible. Ask to see the actual certificates – they’re hard to fake and easy to verify.

Manufacturer databases don’t lie. Most engine manufacturers maintain online dealer locators where you can verify authorization status. If a shop isn’t listed as an authorized dealer, they’re not truly factory authorized, regardless of what their business cards say.

Customer testimonials tell the real story. Ask for references from recent major overhauls or warranty work. Factory authorized experts should have extensive documentation of complex repairs and happy customers willing to vouch for their work.

Questions to Ask Factory Authorized Marine Diesel Experts

Before you commit to major work, ask the right questions. These conversations often reveal more about a shop’s capabilities than their marketing materials.

Labor rates should be transparent and reasonable. Industry standard rates for certified marine diesel technicians range from $135-165 per hour. Emergency work costs more, but you should know the rates upfront. Ask about overtime charges and travel time for mobile service calls.

Turnaround time depends heavily on parts availability. True factory authorized experts should give you realistic timelines based on actual parts inventory, not wishful thinking. Ask how quickly they can source parts and what their typical rebuild timeline looks like.

Warranty extensions beyond manufacturer coverage often indicate strong manufacturer relationships. Shops that stand behind their work with extended warranties are confident in their capabilities.

Failure analysis support separates the real experts from basic mechanics. Can they provide expert witness services for insurance claims? This capability demonstrates the highest level of factory authorization and technical expertise.

When You Need Dockside vs. In-Shop Repairs

Understanding when to call for dockside service versus bringing your vessel to the shop can save time, money, and frustration.

Emergency situations like fuel leaks, cooling system failures, or electrical problems often require immediate dockside attention. Our mobile units carry diagnostic equipment and common repair parts to handle urgent issues on the spot. Sometimes a quick dockside fix gets you safely to port where more extensive work can be done properly.

Scheduled overhauls need proper shop facilities with lifting equipment, clean assembly areas, and dynamometer testing capabilities. Major rebuilds simply can’t be done properly in a boat’s engine room. The precision required for measuring clearances and assembling components demands a controlled environment.

Voyage planning should coordinate major service with your cruising schedule. We often perform surveys and minor repairs dockside, then schedule major work during planned lay-up periods. This approach minimizes disruption to your boating season while ensuring your engines get the attention they need.

Conclusion

Your marine diesel engine isn’t just another piece of equipment – it’s the heart of your vessel and often represents your largest single investment after the boat itself. After decades in the marine diesel industry, we’ve learned that the difference between factory authorized service and “good enough” repairs can literally make or break your boating experience.

The costly mistakes we’ve shared throughout this guide – from that $50,000 engine rebuild caused by a $20 filter substitution to the warranty claims voided by improper torque specifications – happen every day in marinas across the country. These aren’t abstract examples. They’re real failures that cost real boat owners real money.

What makes Factory Authorized Marine Diesel Experts different isn’t just the training certificates on the wall. It’s having the manufacturer’s engineering team on speed dial when something unusual happens. It’s knowing that the parts we install are exactly what the engine was designed for. It’s the confidence that comes from following procedures developed by the people who actually built your engine.

The marine environment is unforgiving. Salt air, constant vibration, and variable loads push engines harder than any land-based application. Your engine deserves technicians who understand these unique challenges and have the factory backing to address them properly.

When you’re dealing with a marine diesel engine that should last 5,000 to 8,000 hours – potentially decades of service – cutting corners on maintenance and repairs simply doesn’t make financial sense. The few hundred dollars you might save using non-authorized service can easily turn into tens of thousands in premature failures.

At Diesel Services Of America, we’ve built our reputation on being your reliable partner for factory-authorized marine diesel expertise. Whether you need emergency dockside service in Fort Lauderdale or a complete engine overhaul, our factory-trained technicians bring the same attention to detail that your investment deserves.

Your time on the water is precious. Don’t let preventable engine problems rob you of those perfect days when the weather’s right and the fish are biting. Choose Factory Authorized Diesel Marine Shop services that keep your engines running strong for decades to come.

Because when it comes to marine diesel engines, there’s no such thing as “close enough.”