Understanding Marine Auxiliary Engines: Your Vessel’s Hidden Power Source

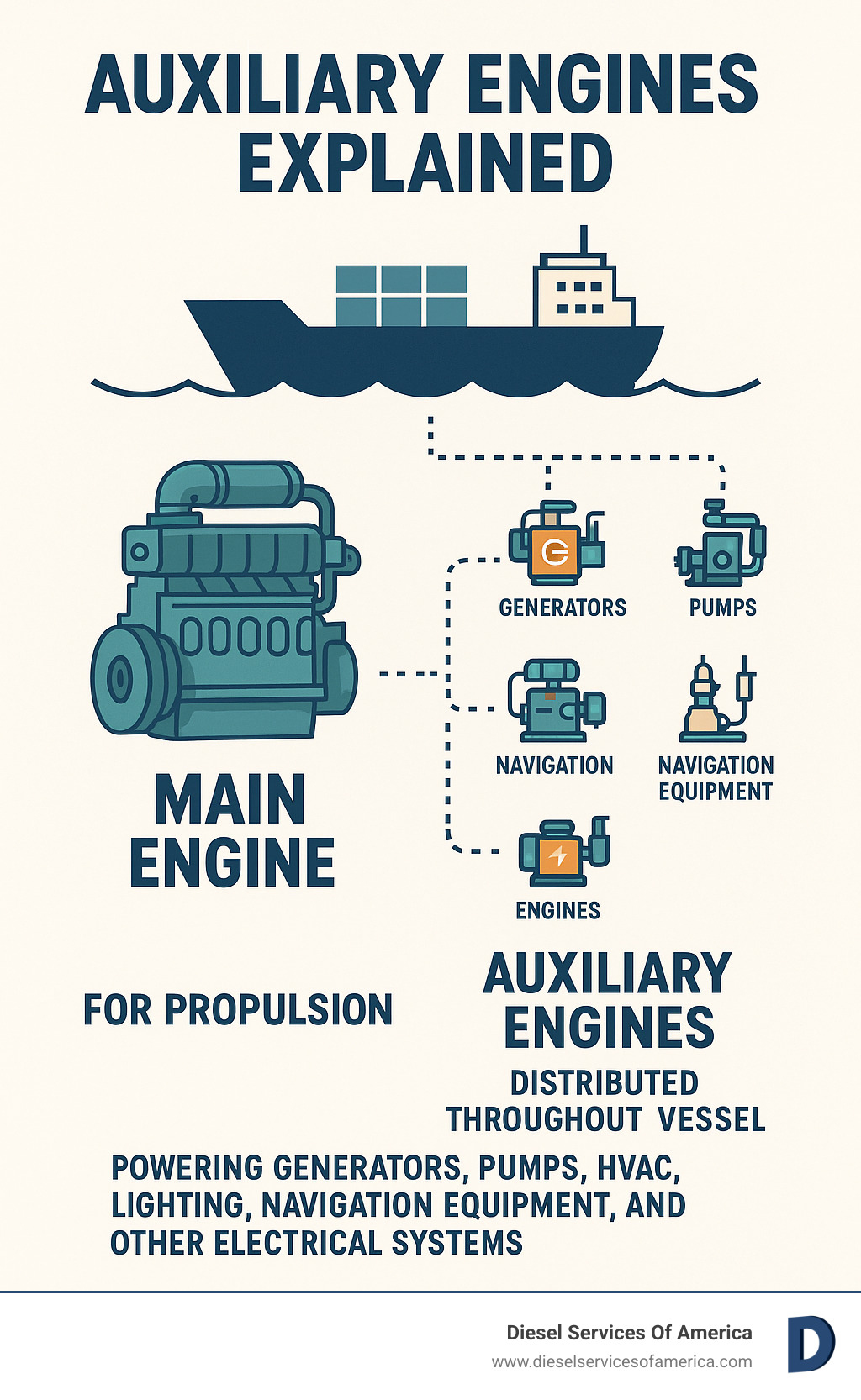

An auxiliary engine is a non-propulsion engine that provides electrical power for all the systems that keep your vessel running smoothly. Unlike your boat’s main engine that moves you through the water, auxiliary engines power everything from lights and navigation equipment to pumps and air conditioning.

Quick Answer: What is an Auxiliary Engine?

- Primary Function: Generates electrical power for ship systems (not propulsion)

- Common Types: Diesel generators, air compressors, hydraulic pumps

- Typical Power: 850kW for bulkers, 1-1.5MW for large tankers

- Operation: Usually 2 running (1 at sea, 2 in port), 1 spare for redundancy

- Voltage: Most ships use 440V, larger installations up to 6600V

Think of your vessel as a floating city. Just like any city needs reliable electricity, your boat depends on auxiliary engines to keep the lights on, pumps running, and critical systems operational. Without these hardworking engines, even the most powerful main engine becomes useless – you’d have no navigation, no communication, and no way to operate essential safety equipment.

Whether you’re managing a commercial fleet or maintaining your own vessel in South Florida waters, understanding these engines is crucial for safe and efficient operations. A single auxiliary engine failure can mean the difference between a successful voyage and a costly emergency.

Related content about auxiliary engine:

What is an Auxiliary Engine? A Cross-Industry Look

When we talk about an auxiliary engine, we’re describing something pretty straightforward: an engine that handles everything except moving your vessel forward. Think of it as the behind-the-scenes hero that keeps all your systems humming while your main engine focuses on propulsion.

The definition stays consistent across industries, though the applications vary wildly. According to SEC filings, an auxiliary engine is “a diesel engine in a vessel, which provides power for functions other than propulsion or emergencies.” Simply put, it’s your reliable workhorse that generates power for all those essential systems that make life aboard possible.

This concept of auxiliary power becomes crucial wherever you have a primary power source dedicated to one job and need independent energy for everything else. It’s like having a backup generator for your house, but much more sophisticated.

Marine Applications

In the marine world, auxiliary engines are absolutely essential. They’re the heart of your vessel’s electrical system, powering everything from navigation lights to complex radar equipment. Without them, even the most powerful main engine becomes practically useless.

These engines typically drive generators that create your ship’s electrical grid. They power pumps for bilge water, fire suppression, and ballast operations. Your winches for mooring and cargo handling? That’s auxiliary power too. Even your galley equipment and air conditioning depend on these hardworking engines.

For vessels using diesel-electric propulsion, the lines blur a bit since these engines actually contribute to movement by generating electricity for electric motors. However, they’re still considered auxiliary because their direct output is electrical power, not mechanical propulsion.

The beauty of modern marine auxiliary engines is their flexibility. They can handle both 50Hz and 60Hz frequencies depending on your vessel’s needs, and they’re designed to work together seamlessly. Most ships run with multiple units – typically one at sea, two in port, with a spare for redundancy.

For more insights into these crucial systems, check out our expertise with Marine Diesel Generator applications.

Aviation Applications

While our expertise lies in marine and industrial applications, it’s fascinating how the Auxiliary Power Unit (APU) concept works in aviation. Aircraft use small gas turbine engines to provide ground power, pneumatic power, and electrical power (typically 115V AC at 400Hz) when the main engines aren’t running.

The history is pretty cool too. It started with WWI blimps using tiny ABC auxiliary engines, evolved through WWII bombers with their “putt-putt” generators, and really took off with the Boeing 727 in 1963 – the first jetliner with a gas turbine APU. This allowed planes to operate independently without ground support equipment, revolutionizing airport operations.

Land and Industrial Applications

The auxiliary engine concept extends well beyond marine applications into non-road mobile machinery and commercial vehicles. In industrial settings, these engines power everything from hydraulic systems on construction equipment to air conditioning on refrigerated trailers.

Unlike marine applications where we focus on constant power generation, land-based auxiliary engines often handle intermittent loads. A truck might use its auxiliary engine to power hydraulic lifts, air compressors, or refrigeration units – all while the main engine handles transportation.

One key difference in land applications is maintenance scheduling. While your truck gets serviced based on mileage, the auxiliary engine needs attention based on operating hours – just like marine engines. This is why proper service tracking becomes so important for reliable operation.

These engines also serve as critical backup power for facilities like water treatment plants, ensuring essential services continue during power outages. It’s the same reliability principle we see in marine applications, where redundancy can mean the difference between safe operations and emergency situations.

The Heart of the Ship: The Role of the Marine Auxiliary Engine

Picture this: you’re standing on the deck of a massive cargo ship at night, watching the lights twinkle across the harbor. That vessel beneath your feet is essentially a floating city – complete with its own power grid, water systems, and all the electrical demands of a small town. At the heart of keeping this maritime metropolis alive and running sits the marine auxiliary engine.

Without these hardworking engines, even the most powerful main propulsion system becomes useless. The lights go dark, the pumps fall silent, and suddenly your vessel transforms from a sophisticated machine into a drifting hulk. The electrical load on a modern ship is staggering – from the bridge electronics keeping you on course to the galley equipment feeding your crew.

That’s why we take power generation and distribution so seriously here in South Florida’s marine industry. Every system depends on reliable auxiliary power, and there’s simply no room for failure when you’re miles from shore. Understanding the Importance of Marine Generators isn’t just technical knowledge – it’s about keeping vessels safe and operational.

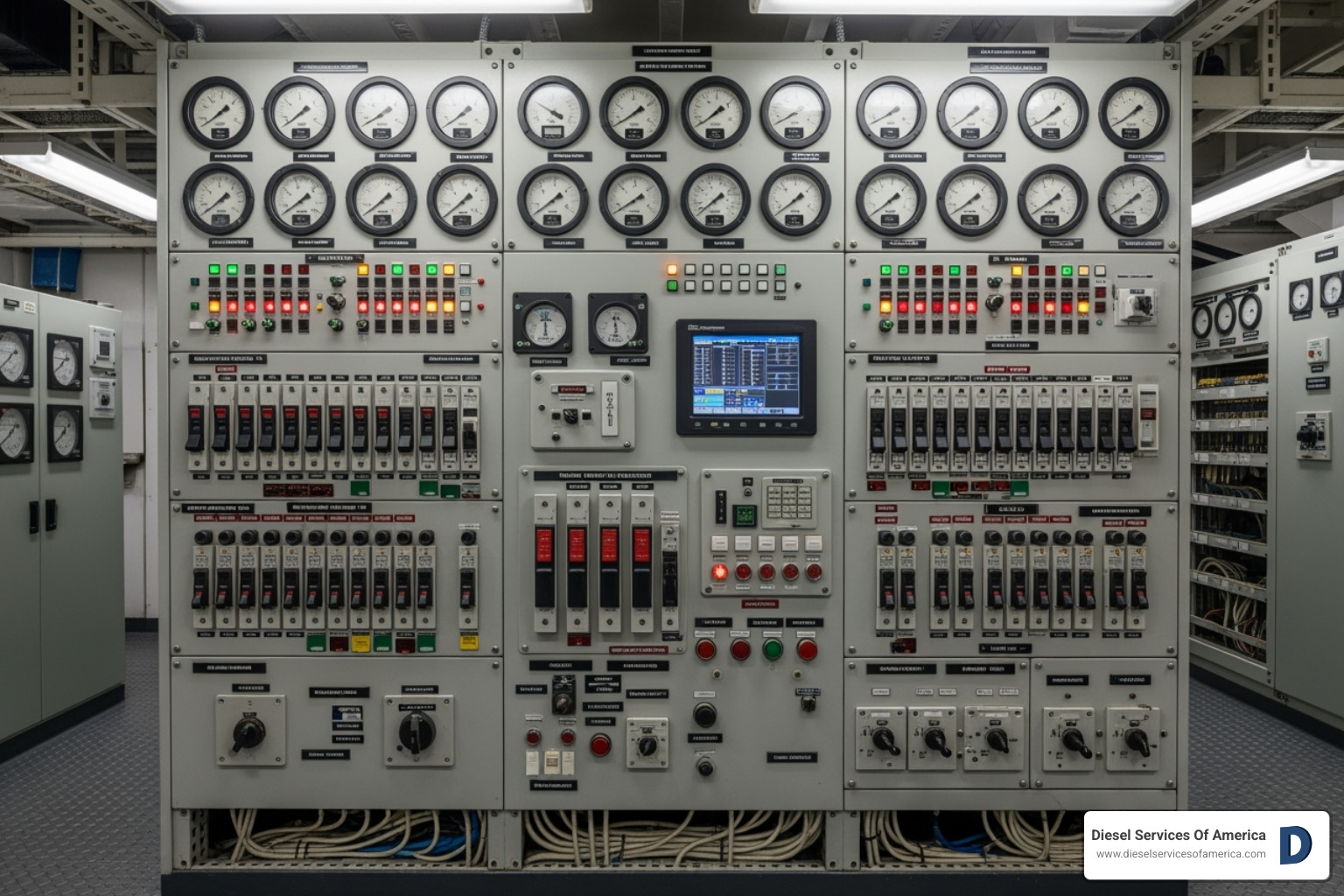

Power Generation and Distribution

The magic happens when your auxiliary engine serves as the prime mover, spinning an alternator that converts raw mechanical energy into the electrical power your vessel craves. Most ships rely on three-phase AC power because it delivers smooth, efficient energy that keeps motors running happily and electrical loads balanced.

You’ll typically find shipboard systems running at 440V, though larger installations might step up to 6600V for heavy-duty applications. The nerve center of this entire operation is the Main Switchboard (MSB) – think of it as mission control for your vessel’s electrical universe.

From the MSB, electricity travels through bus bars – essentially electrical highways – controlled by circuit breakers that act like traffic cops, preventing dangerous overloads. Transformers step voltage up or down depending on what each system needs, ensuring your navigation equipment gets clean power while your cargo cranes get the muscle they require.

Essential Ship Systems Powered

Here’s where the rubber meets the road – or should we say, where the propeller meets the water. Your marine auxiliary engine doesn’t just generate power; it breathes life into every corner of your vessel.

Lighting systems throughout the ship depend on auxiliary power, from the engine room work lights to the navigation lights that keep you visible to other vessels. Your HVAC systems work around the clock, maintaining comfortable temperatures for crew quarters and protecting sensitive cargo from temperature swings.

Navigation equipment like radar, GPS, and electronic chart systems are absolutely critical for safe passage – and they’re all powered by auxiliary engines. The same goes for communication systems that keep you connected to shore, other vessels, and emergency services when needed.

Down in the galley, auxiliary power keeps equipment running so your crew stays well-fed during long voyages. Meanwhile, essential pumps work tirelessly: bilge pumps remove unwanted water, fire pumps stand ready for emergencies, and ballast pumps help maintain your vessel’s stability and trim.

For cargo operations, cranes and winches powered by auxiliary engines make efficient loading and unloading possible. Without reliable auxiliary power, these systems simply can’t function.

The bottom line? Every one of these systems directly impacts your vessel’s safety and operational efficiency. That’s exactly why we focus on delivering top-quality Boat Generator and Engine Services – because when your auxiliary power systems are running strong, everything else falls into place.

Choosing, Operating, and Maintaining Your Marine Auxiliary Engine

When it comes to your vessel’s auxiliary engine, getting the selection, operation, and maintenance right isn’t just about keeping the lights on – it’s about ensuring your floating home stays safe, efficient, and profitable for years to come. These hardworking engines face some of the toughest conditions imaginable, from salt spray to constant vibration, which is why we at Diesel Services of America take their care so seriously. Our comprehensive Diesel Engine and Generator Services are designed to keep your power systems running smoothly, no matter what Mother Nature throws at you.

Key Considerations for Selecting a Marine Auxiliary Engine

Choosing the right auxiliary engine is like picking the perfect heart for your vessel – get it wrong, and you’ll feel the consequences every day you’re on the water. The most critical factor is power requirements, measured in kilowatts (kW). We start by calculating your vessel’s total electrical load, including those peak demands when everything’s running at once.

A typical bulker might need around 850kW of auxiliary power, while larger tankers often require 1-1.5MW. But here’s where it gets interesting – massive container ships like the Emma Maersk demand as much as 30MW from five large auxiliary engines, largely due to all those refrigerated containers that need constant power.

Your vessel type dramatically affects these calculations. A fishing vessel’s power needs look nothing like a luxury yacht’s requirements, and both are worlds apart from a cargo ship’s demands. We work closely with you to understand exactly what systems you’ll be running and when.

Fuel type is another crucial decision. Your auxiliary engine can run on Marine Diesel Oil (MDO) or Heavy Fuel Oil (HFO), but fuel quality can make or break your engine’s performance. Poor fuel leads to costly repairs and efficiency losses – something we see far too often in South Florida waters.

Emissions standards aren’t just paperwork – they’re your ticket to operating globally. You’ll need to comply with IMO Tier I/II/III standards, and depending on where you operate, various regional requirements too. The regulations are complex, but you can dive deeper into USA: Marine Diesel Engines – Emission Standards for the full picture.

Space is always at a premium in any engine room, so we consider the engine footprint carefully. But it’s not just about physical size – noise and vibration levels (what we call “sociability”) matter too. Your crew needs to live and work around these engines, and excessive noise or vibration can make life miserable.

For fleet operators, standardization is golden. Using similar engines across your fleet simplifies maintenance, parts inventory, and crew training. When you need new power solutions, we’re here to guide you through New Generators and Engines Through DSOA.

Essential Procedures for Operating Your Auxiliary Engine

Operating a marine auxiliary engine properly requires precision and respect for established procedures. Our factory-trained technicians have mastered these operations through years of hands-on experience.

Starting and stopping might seem straightforward, but there’s an art to it. For a manual start, we always check all valves, open indicator cocks, and give a small “air kick” to check for water leakage. Once started, the engine runs on no load for about five minutes – think of it as a warm-up stretch before the real work begins. Only then do we put it in remote mode and gradually take on load.

Stopping is equally important. We gradually reduce the load, take the generator off-load (usually below 100kW), and let it idle for about five minutes. This cool-down period prevents thermal shock and extends engine life.

Synchronization becomes critical when running multiple generators in parallel. This means matching the incoming generator’s voltage, frequency, and phase angle with the running generator. The synchroscope is our primary tool here – that circular gauge with a pointer that shows phase difference. We aim to close the breaker just before the pointer reaches the 12 o’clock position, ensuring the incoming generator is slightly faster. In emergencies, we can use the three-bulb method, watching the brightness of bulbs to indicate proper alignment.

Once synchronized, load sharing ensures your generators work together efficiently, preventing any single unit from being overloaded.

Now, let’s talk about every engineer’s nightmare – blackout management. A ship-wide blackout means complete power loss, and your vessel essentially becomes a floating paperweight. But stay calm – we’ve developed proven recovery procedures. First, inform the bridge and chief engineer immediately. Secure main propulsion and running purifiers, shut down the auxiliary boiler if running, then identify and fix the blackout’s cause.

The recovery sequence is methodical: start the pre-lubrication priming pump, get the emergency generator running and loaded, then restart main engine support systems like lube oil and jacket water pumps. Finally, reset breakers and restart other machinery following the preferential tripping sequence. It takes skill and patience, but knowing your engine room well is your best asset. Our Generator Maintenance services ensure your systems are ready for such emergencies.

Maintenance and Major Manufacturers

Regular maintenance is what separates reliable auxiliary engines from expensive boat anchors. These engines work hard in harsh conditions, so they deserve – and require – diligent care.

Daily checks are non-negotiable: oil levels, coolant levels, fuel quality, and visual inspections of belts and radiators. Proper ventilation and keeping protective covers closed might seem basic, but these simple steps prevent countless problems.

Performance monitoring helps us catch issues before they become expensive repairs. Whether through online systems or manual reports, we track your engine’s health and optimize its parameters. We believe strongly in proactive maintenance based on hours run, not just calendar dates. This approach prevents costly at-sea failures and extends equipment life significantly.

The marine auxiliary engine market includes several respected manufacturers. Yanmar leads globally with their comprehensive range supporting various frequencies and fuel types. Caterpillar builds heavy-duty engines perfect for large commercial vessels, offering custom generator set solutions. Wärtsilä provides broad spectrum engines for both propulsion and auxiliary applications, while Cummins offers constant speed marine power solutions with emphasis on customization and emissions compliance.

Here’s something we can’t stress enough: authorized service matters. Our factory-trained technicians understand the intricacies of these major brands, ensuring your auxiliary engine gets precisely the care it needs. When you’re dealing with complex marine power systems, experience and proper training make all the difference. That’s why we’re your trusted experts for Diesel Engine Generator Maintenance Services throughout Fort Lauderdale, Southeast Florida, and the Caribbean.

Frequently Asked Questions about Marine Auxiliary Engines

Over the years, we’ve heard just about every question you can imagine about auxiliary engines. Whether you’re docked in Fort Lauderdale or anchored somewhere in the Caribbean, these are the questions that keep coming up. Let’s clear the air on some of the most common ones.

What is the difference between a ship’s main engine and an auxiliary engine?

Think of your vessel’s main engine as the legs that get you where you’re going, while the auxiliary engine is like the heart that keeps everything else alive. The differences are pretty dramatic when you break them down.

Function is the big one – your main engine has one job: push the boat forward. Your auxiliary engine handles literally everything else by generating electricity. We’re talking about powering your navigation equipment, keeping the lights on, running your pumps, and making sure your galley equipment works so the crew can eat.

The size difference is honestly impressive. Main engines are these massive beasts – we’re talking several meters in diameter and over ten meters tall. An auxiliary engine is much more manageable, though still substantial enough that a person would only come up to about half its height.

Weight and fuel consumption follow the same pattern. That main engine is incredibly heavy and burns through fuel like there’s no tomorrow because it’s producing enormous power. Your auxiliary engines are relatively lighter and much more fuel-efficient for their power output.

Here’s where it gets interesting: most ships have just one main engine but typically carry three auxiliary engines. Why three? Simple redundancy. Usually two are running (one at sea, both in port when power demand is higher) and one stays as a spare. This setup means you’re never left in the dark if one fails – quite literally.

Why are four-stroke engines commonly used for auxiliary power on ships?

This is a great technical question that comes down to how these engines actually work in real-world conditions. While those massive two-stroke engines are perfect for main propulsion because they’re designed to run at constant, high power, auxiliary engines face a completely different challenge.

Flexibility is the name of the game here. Your auxiliary engine needs to handle everything from quiet nighttime power loads to the full electrical demand when you’re loading cargo in port. Four-stroke engines excel at this kind of variable load operation, maintaining good fuel efficiency whether they’re running at 30% or 80% capacity.

The operating costs work out better too. At the typical loads an auxiliary engine sees, four-strokes generally burn less fuel per kilowatt-hour than their two-stroke cousins, which are optimized for constant high-power operation.

Start-up time is crucial, especially in emergencies. Four-stroke engines can get up and running much faster than large two-strokes. When you need power back online quickly – whether for a planned generator swap or an emergency situation – those faster start-up times can make all the difference.

What happens during a ship-wide blackout?

A ship-wide blackout is every marine engineer’s nightmare, and honestly, it’s as serious as it sounds. Imagine your entire vessel going completely dark – no lights, no pumps, no navigation equipment, no communication. The ship literally becomes dead in the water.

Complete power loss means everything stops at once. Your bilge pumps quit working, your navigation goes dark, and even basic lighting disappears. If you’re in restricted waters or bad weather, this becomes a safety emergency very quickly.

The good news is that your emergency generator should kick in automatically (or can be started manually). This smaller unit – usually around 200-300kW – provides enough power to restore essential lighting, emergency communications, and most importantly, the systems needed to restart your main auxiliary engines.

Safety risks multiply fast during a blackout, especially if you’re maneuvering near other vessels or in challenging waters. That’s why the restoration procedures we follow are so precise and well-practiced.

The restoration process follows strict steps: inform the bridge immediately, secure the main propulsion and any running equipment, identify what caused the blackout, get the emergency generator stable, then systematically restart your auxiliary engines and restore power throughout the ship.

Modern ships use something called preferential trips to prevent complete blackouts in the first place. These systems automatically shed non-essential loads in stages if a generator gets overloaded, keeping power to critical systems and hopefully avoiding a total shutdown.

We’ve seen our share of blackout situations over the years, and proper preparation makes all the difference. Our Marine Generator Repair Shop services are designed to help you prevent these situations and get back online fast when they do occur.

Your Partner for Reliable Marine Power

When you think about your vessel’s auxiliary engine, it’s not just another piece of equipment tucked away in the engine room. It’s the beating heart that keeps your floating city alive, ensuring every light stays on, every pump keeps running, and every critical system remains operational when you need it most.

Without a reliable auxiliary engine, even the most powerful main engine becomes useless. You’d lose navigation, communication, and all the safety equipment that keeps your crew protected. That’s why we take auxiliary power so seriously here at Diesel Services of America.

We’ve been keeping South Florida’s marine and industrial diesel engines running strong from our Fort Lauderdale headquarters for years. Our factory-trained technicians understand that when your auxiliary engine goes down, it’s not just an inconvenience – it’s a serious safety issue that needs immediate attention.

What sets us apart is our complete focus on marine and industrial diesel applications. We don’t dabble in automotive work – we’re specialists who live and breathe the unique challenges of marine power systems. From routine maintenance that prevents problems before they start to emergency repairs that get you back on the water quickly, we’ve got the expertise you need.

Our service area covers all of Southeast Florida and extends throughout the Caribbean. Can’t make it to our shop? No problem. We provide dockside service because we know your vessel can’t always come to us. And with our worldwide parts delivery, we can get the components you need no matter where your travels take you.

The ocean doesn’t wait for business hours, and neither do we. When your auxiliary engine needs attention, we’re ready to respond with the urgency and expertise your situation demands.

Contact us for expert marine generator repair and let us help keep your vessel’s heart beating strong. After all, reliable auxiliary power isn’t just about convenience – it’s about getting you home safely every time you head out on the water.