Why Diesel Engine Fuel Efficiency Matters for Marine and Industrial Operations

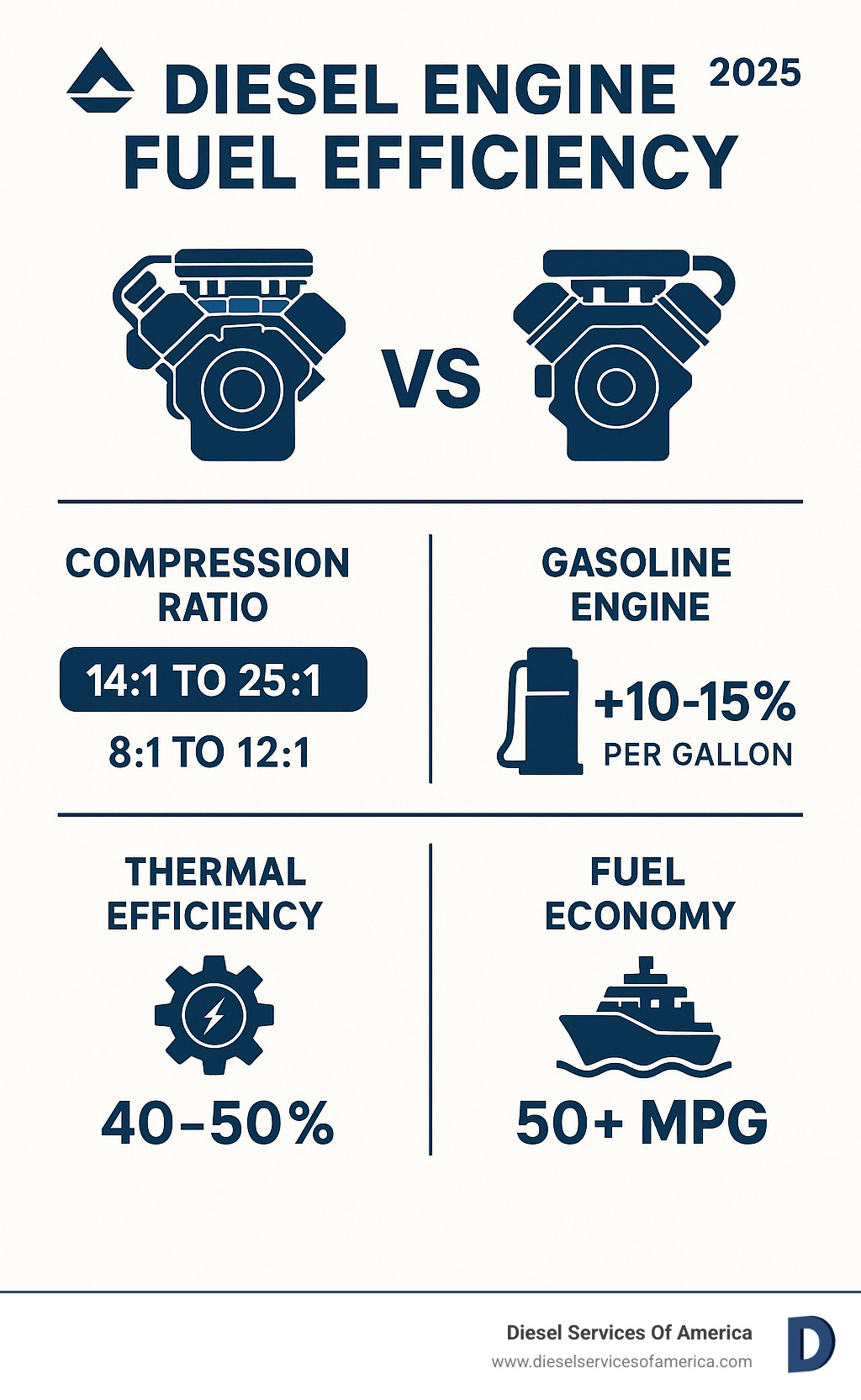

Diesel engine fuel efficiency is significantly superior to gasoline engines, delivering 20-35% better fuel economy through higher compression ratios and energy-dense fuel. Here’s what makes diesels the clear winner:

Key Efficiency Advantages:

- Energy Density: Diesel fuel contains 10-15% more energy per gallon than gasoline

- Compression Ratio: Diesel engines operate at 14:1 to 25:1 compression vs. gasoline’s 8:1 to 12:1

- Thermal Efficiency: Modern diesels achieve 40-50% efficiency compared to gasoline’s 35%

- Real-World Performance: Marine diesels can achieve up to 50+ MPG in optimal conditions

For marine fleet managers and boat owners in South Florida, this efficiency translates into extended range, lower fuel costs, and reduced downtime – critical factors when operating in demanding marine and industrial environments.

The numbers speak for themselves: diesel engines were 29% more efficient on the highway and 24% more efficient in city conditions compared to gasoline engines, according to research by The Motley Fool. For marine applications where engines run at sustained loads, these efficiency gains become even more pronounced.

But efficiency isn’t just about the fuel itself. Modern diesel technology has evolved dramatically since Rudolf Diesel unveiled his engine in 1892. Today’s marine and industrial diesels incorporate advanced fuel injection systems, turbocharging, and electronic controls that push thermal efficiency toward the theoretical limit of 55-60%.

Quick look at Diesel engine fuel efficiency:

The Science of Efficiency: Why Diesels Outperform Gasoline Engines

When we talk about diesel engine fuel efficiency, we’re diving into a fascinating world of physics, chemistry, and engineering. It’s not magic, but rather a clever design that leverages fundamental principles to extract more usable energy from every drop of fuel. At the heart of it, diesel engines are inherently more efficient than their gasoline counterparts, and understanding why helps us appreciate their enduring value in marine and industrial applications.

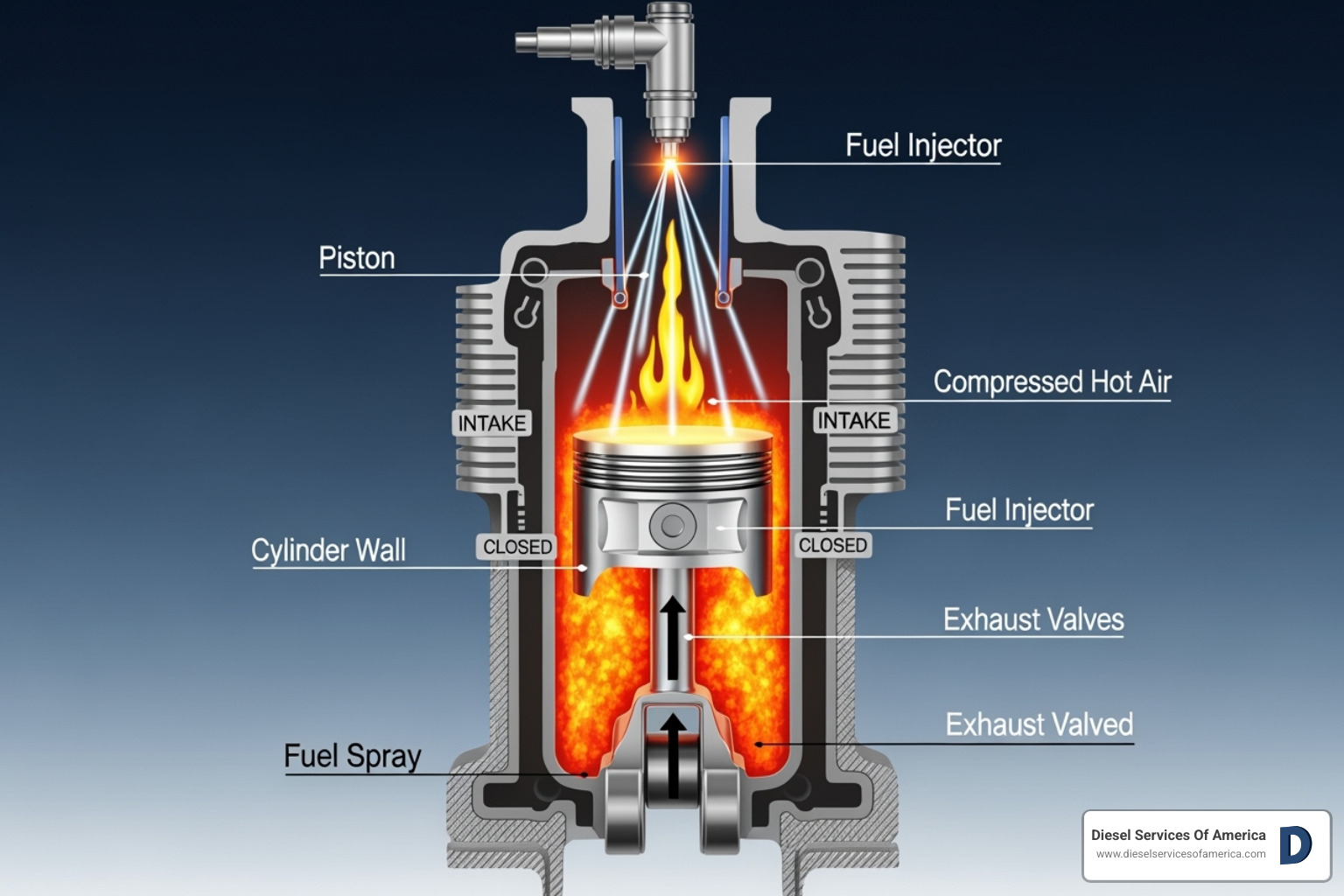

The Power of Compression

The primary reason for diesel’s superior efficiency lies in its unique combustion process, known as compression ignition. Unlike gasoline engines that rely on spark plugs to ignite a fuel-air mixture, diesel engines compress only air to incredibly high pressures (typically between 14:1 and 25:1 compression ratios). This extreme compression heats the air to temperatures so high that when fuel is injected, it ignites spontaneously. Think of it as a super-hot oven for your fuel!

This high compression ratio is a game-changer for thermal efficiency. It means that a greater percentage of the fuel’s energy is converted into mechanical work, reducing energy loss to heat. Because there are no spark plugs, there’s also no need for a throttle valve to regulate airflow (as in gasoline engines). This absence of “throttling losses” means diesel engines don’t waste energy pumping air against a restriction, leading to better fuel economy, especially at lower loads. This makes them ideal for marine vessels and industrial generators that often operate under varying loads but without the constant stop-and-go of city traffic.

Furthermore, diesel engines are built more robustly to withstand these higher compression forces. While this makes them heavier and initially more expensive, it also contributes to their legendary durability and longer lifespan, which is a huge benefit for heavy-duty applications. For more fascinating facts about how these powerhouses work, check out 7 things you might not know about diesel.

Fuel with More Force

Another key factor in diesel engine fuel efficiency is the fuel itself. Diesel fuel is a true powerhouse, containing roughly 10% to 15% more energy per gallon by volume than gasoline. This higher energy density means you simply get more bang for your buck with every fill-up. Imagine two identical jugs: one filled with a light, fizzy drink, and the other with a rich, dense smoothie. The smoothie, like diesel, packs more nutritional punch per sip.

This density allows diesel engines to travel farther on the same amount of fuel. While gasoline can resist a compression ratio of between 8:1 and 10:1 before pre-ignition (that dreaded “knocking”), diesel’s higher compression resistance allows it to operate at 18:1 or even higher. This allows for a more complete and efficient burn of the fuel.

The quality of diesel fuel is also crucial. Its cetane rating, which measures its ignition quality, plays a vital role in how smoothly and efficiently the engine runs. A higher cetane number generally means faster, more complete combustion. Understanding your fuel is just as important as understanding your engine; you can learn More info about Diesel Engine Fuel on our website.

Real-World Diesel Efficiency by Application

Here’s where the rubber meets the road—or in our case, where the propeller meets the water. Understanding diesel engine fuel efficiency in theory is one thing, but seeing how it performs in the real world of marine and industrial applications is what truly matters to our customers in South Florida and beyond.

Understanding Real-World Diesel Engine Fuel Efficiency

Picture this: you’re cruising the Intracoastal Waterway on a beautiful Saturday morning, or your industrial generator is humming along at a remote job site. These scenarios represent the perfect playground for diesel engines to show off their efficiency prowess.

Marine engines face a completely different world than automotive engines. While cars deal with traffic lights, stop signs, and rush hour gridlock, your boat engine settles into a steady rhythm for hours at a time. This consistent operation is where diesel engine fuel efficiency really shines.

The Motley Fool study on efficiency found that diesel engines achieved 29% better efficiency on highways compared to gasoline engines. In marine terms, think of open water cruising as your “highway driving”—and the efficiency gains are even more impressive because there’s no traffic to slow you down.

For industrial applications, the story is equally compelling. A diesel generator powering a construction site or backup power system operates under steady, predictable loads. Unlike gasoline engines that struggle with sustained heavy-duty work, diesels actually become more efficient as they settle into their work rhythm. This translates into lower fuel costs and fewer refueling interruptions—exactly what you need when deadlines matter.

Our customers regularly tell us about the dramatic difference they notice when switching from gasoline to diesel power. Whether it’s a yacht owner extending their range between fuel stops or a contractor reducing their generator fuel bills, the real-world benefits are undeniable. For more insights into how these engines perform in marine environments, check out our page on Marine Engine Performance.

Optimal Conditions for Peak Efficiency

Every diesel engine has a “happy place” where everything clicks into perfect harmony. Understanding these optimal conditions can help you squeeze every mile out of every gallon.

Sustained operation is the golden rule of diesel efficiency. These engines love routine—they prefer to warm up once, settle into their optimal operating temperature, and stay there for hours. Think of it like a long-distance runner who hits their stride and maintains it, versus a sprinter who constantly starts and stops.

The “sweet spot” RPM range varies by engine, but it’s typically where your engine produces maximum torque with minimal fuel consumption. For most marine diesels, this falls somewhere in the middle of the RPM range—not the lowest setting, but not wide-open throttle either. Our factory-trained technicians can help identify this range for your specific engine and application.

Here’s something that surprises many people: diesel engines often become more efficient under heavy loads. While a gasoline engine might struggle and guzzle fuel when working hard, a well-maintained diesel settles into its work with impressive grace. This is why they’re the go-to choice for towing heavy loads or powering through challenging sea conditions.

Avoiding excessive idling is crucial, even though modern diesels don’t need lengthy warm-up periods like their older cousins. Extended idling burns fuel without doing useful work and can lead to carbon buildup over time. In marine applications, this means not letting your engine idle at the dock longer than necessary.

Temperature and environmental factors also play a role. Diesel engines perform best when they can maintain their optimal operating temperature, which is why proper cooling system maintenance is so critical in our South Florida climate.

The beauty of marine and industrial diesel applications is that they naturally align with these optimal conditions. Whether you’re on a day-long fishing trip or running a generator for extended periods, you’re operating in diesel’s efficiency wheelhouse. For more detailed information about maximizing power and efficiency, visit our insights on Power and Speed.

The Evolution and Future of Diesel Engine Fuel Efficiency

The story of diesel engine fuel efficiency is one of continuous innovation. From Rudolf Diesel’s first successful prototype in 1893, which achieved a then-impressive 26.2% efficiency, to today’s sophisticated powerhouses, the drive for greater efficiency has been relentless. In the 1980s, diesel engines typically achieved around 35% efficiency. Today, that figure has soared to 50%, with theoretical limits pushing towards 55-60%. This remarkable progress is a testament to engineering ingenuity and the enduring relevance of diesel technology.

Key Technological Leaps

How did we get here? A series of critical technological advancements have transformed diesel engines into the highly efficient machines we know today, especially in marine and industrial applications:

- Common Rail Direct Injection (CRDI): This system allows for extremely precise control over fuel injection. Instead of a single, blunt injection, CRDI systems can deliver multiple, finely atomized fuel sprays at incredibly high pressures (up to 270 MPa or 39,000 psi!). This leads to more complete combustion, reduced emissions, and significant improvements in fuel efficiency and power.

- Turbocharging: Turbochargers use exhaust gases to spin a turbine, which in turn drives a compressor to force more air into the engine’s cylinders. More air means more power and more efficient combustion, especially at higher altitudes or under heavy loads. For marine engines, a Marine Diesel Turbocharger is crucial for extracting maximum power and efficiency.

- Intercooling: Often paired with turbochargers, intercoolers cool the compressed air before it enters the engine. Cooler air is denser, meaning even more oxygen can be packed into the cylinders, further enhancing combustion efficiency and power output. Learn more about the benefits of a Diesel Intercooler.

- Electronic Engine Controls (ECU): The “brain” of the modern diesel engine, the Electronic Control Unit (ECU), precisely manages everything from fuel injection timing and pressure to turbocharger boost and emissions controls. This real-time optimization ensures the engine operates at peak efficiency across its entire operating range.

These technological leaps have not only boosted efficiency but also made diesel engines quieter, smoother, and cleaner than ever before. For a deeper dive into these advancements, explore our page on Diesel Engine Efficiency Improvements.

The Next Frontier: Pushing the Boundaries

The quest for even greater diesel engine fuel efficiency continues. Engineers are constantly exploring new avenues to push the boundaries of what’s possible:

- Advanced Materials and Designs: Lighter, stronger materials reduce engine weight and friction, while innovative designs (like low heat rejection engines) aim to capture more waste heat and convert it into usable energy.

- Hybrid Diesel-Electric Systems: For marine applications, combining a diesel engine with electric motors offers exciting possibilities. The diesel engine can operate at its most efficient “sweet spot” to generate electricity, while the electric motors provide propulsion, especially at lower speeds. This approach allows for further downsizing of the diesel engine and significant fuel savings.

- Alternative and Renewable Fuels: The development and adoption of alternative fuels like biodiesel and renewable diesel are critical. These “drop-in” fuels can often be used in existing diesel engines with minimal or no modifications, offering a path to reduced carbon emissions while maintaining diesel’s superior efficiency. Electro-fuels (E-fuels) derived from renewable energy sources also hold immense promise for carbon-neutral operation.

- Waste Heat Recovery: Capturing and reusing the heat typically lost through the exhaust or cooling system is a significant area of research. Technologies that convert this waste heat back into mechanical or electrical energy could dramatically increase overall system efficiency.

These ongoing developments ensure that diesel engines, particularly in demanding marine and industrial roles, will remain a vital and highly efficient power source for the foreseeable future.

Maximizing Your Investment: Factors That Impact Efficiency

Getting the most from your marine or industrial diesel engine isn’t just about having great technology under the hood. Diesel engine fuel efficiency in the real world depends on dozens of factors that can either boost your performance or quietly drain your fuel tank. For boat owners and industrial operators in South Florida, understanding these variables is the difference between a profitable operation and watching your investment disappear one gallon at a time.

When we talk to customers at our Fort Lauderdale facility, we often hear the same question: “Why is my fuel consumption higher than expected?” The answer usually isn’t the engine itself—it’s everything around it. Think of your diesel engine as a world-class athlete. Even the best runner won’t perform well in the wrong shoes, on a rough track, or without proper nutrition.

The reality is that diesel fuel costs have been fluctuating significantly, and according to average price difference for diesel fuel, every gallon counts more than ever. This makes understanding efficiency factors not just helpful, but essential for your bottom line.

Key Factors Influencing Diesel Engine Fuel Efficiency

Your engine’s appetite for fuel depends heavily on the conditions it operates under. Engine load plays a huge role—while diesels love to work hard, there’s a sweet spot. Push too hard consistently, and you’ll see fuel consumption climb. Run too light, and you’re not getting the efficiency benefits diesel engines are famous for.

For marine applications, your hull condition is absolutely critical. We’ve seen boats burn 30% more fuel simply because the owner skipped a few hull cleanings. Those barnacles and marine growth might look harmless, but they’re creating drag that forces your engine to work overtime. It’s like trying to run through thick mud instead of on a smooth track.

Propeller selection and condition can make or break your fuel economy. A damaged prop with even small nicks or the wrong pitch can turn your efficient diesel into a fuel-guzzling monster. We regularly see boats where a simple propeller adjustment saves hundreds of dollars in fuel costs over a season.

Environmental factors matter too. Ambient temperature affects how your engine breathes and how efficiently fuel burns. Altitude changes the air density, which impacts combustion—though this is more relevant for our industrial generator customers operating in varied locations. And never underestimate fuel quality. Cheap fuel often costs more in the long run through reduced efficiency and increased maintenance needs.

The Critical Role of Maintenance

Here’s where we get passionate at Diesel Services of America: maintenance isn’t just about preventing breakdowns—it’s about protecting your fuel budget. A well-maintained engine is an efficient engine, and we’ve seen the numbers to prove it.

Clean fuel injectors are absolutely essential for optimal diesel engine fuel efficiency. When these precision components get clogged or dirty, your fuel spray pattern becomes uneven, leading to incomplete combustion and wasted fuel. Our Marine Diesel Fuel Injectors service can restore efficiency you didn’t even know you’d lost.

Your air filter condition directly impacts how well your engine can breathe. A clogged filter is like putting a pillow over your engine’s face—it has to work much harder to get the air it needs. Oil quality reduces friction throughout the engine, and fresh, clean oil keeps everything running smoothly. Our Diesel Engine Oil Analysis service can tell you exactly what’s happening inside your engine.

Cooling system performance keeps your engine at the perfect operating temperature for maximum efficiency. For marine engines, this includes maintaining your Raw Water Cooling Systems to prevent overheating and efficiency loss.

The beauty of diesel engines is that they reward good care with exceptional performance. Regular fuel filter replacement protects your entire fuel system, while proper valve adjustments ensure optimal airflow. Don’t forget your turbocharger inspection—a healthy turbo is essential for maintaining the power and efficiency your engine was designed to deliver.

A comprehensive Preventative Diesel Maintenance program isn’t an expense—it’s an investment that pays for itself through improved fuel economy, reduced downtime, and extended engine life. Our factory-trained technicians have seen how proper maintenance can restore efficiency levels that owners thought were gone forever.

Frequently Asked Questions about Diesel Efficiency

When we talk with marine and industrial operators here in South Florida, the same questions about diesel engine fuel efficiency come up time and again. Whether you’re considering your first diesel-powered vessel or looking to squeeze every bit of performance from your existing industrial generator, these are the answers you need.

How much more fuel-efficient are diesel engines?

Here’s the straightforward answer: diesel engines are typically 20-35% more fuel-efficient than comparable gasoline engines. That’s not just marketing fluff – it’s real-world performance you can count on.

This efficiency comes from two main factors: diesel fuel packs more energy per gallon (about 10-15% more than gasoline), and the compression ignition process simply does a better job converting that energy into useful work. For marine applications, this translates into something every boat owner loves: significantly extended range and lower fuel bills.

Think of it this way – where a gasoline engine might take you three nautical miles on a gallon of fuel, a comparable diesel will often take you four miles or more. Over a long cruise or a full season of operation, those extra miles really add up.

What are the best operating conditions for diesel fuel efficiency?

Diesel engines are like marathon runners – they excel at sustained, consistent operation rather than sprinting and stopping. For marine vessels cruising the waters off Fort Lauderdale or industrial generators powering remote sites, this is fantastic news.

The sweet spot for diesel engine fuel efficiency happens when your engine runs within its optimal RPM range for extended periods. This allows the engine to reach its ideal operating temperature and maintain the most efficient combustion cycle. Frequent start-stop cycles are efficiency killers, while steady loads at cruising RPM are where diesels truly shine.

For marine operators, this means planning longer runs rather than short hops between marinas. For industrial applications, it means sizing your generator correctly so it operates at a consistent load factor rather than cycling on and off constantly.

Can regular maintenance really improve my diesel’s fuel economy?

Absolutely – and this might be the most important answer in this entire article. Proper maintenance isn’t just about preventing breakdowns; it’s about optimizing every drop of fuel your engine burns.

Consider clean fuel injectors – when they’re clogged or dirty, they can’t create the fine fuel mist needed for complete combustion. That means wasted fuel going right out your exhaust. Similarly, dirty air filters choke your engine, forcing it to work harder for the same power output.

High-quality engine oil reduces friction between moving parts, while a properly functioning cooling system ensures your engine operates at its ideal temperature. Even something as simple as fresh fuel filters can make a measurable difference in fuel consumption.

We’ve seen engines gain 10-15% better fuel economy just from thorough maintenance. For more details on keeping your marine diesel running at peak efficiency, check out our insights on Marine Diesel Engine Maintenance.

The bottom line? Regular maintenance is one of the most cost-effective ways to improve fuel efficiency – often paying for itself in fuel savings within a single season of operation.

Your Partner in Peak Diesel Performance

After diving deep into diesel engine fuel efficiency, one thing becomes crystal clear: these powerhouses aren’t just more efficient by accident. They’re engineering marvels that, when properly understood and maintained, deliver optimal performance for marine and industrial applications.

Think about it – we’ve explored how diesel engines achieve that impressive 20-35% efficiency advantage through clever compression ignition, energy-dense fuel, and decades of technological refinement. We’ve seen how modern innovations like common rail injection and turbocharging have pushed efficiency from 35% in the 1980s to an impressive 50% today. And we’ve found that the secret to open uping this efficiency isn’t just in the engine design – it’s in understanding how to operate and maintain these machines properly.

For marine operators cruising the waters off Fort Lauderdale or industrial facilities across South Florida, this efficiency translates into real dollars saved and extended operational capability. When your yacht’s diesel engine is running in its “sweet spot” during those long coastal cruises, or when your industrial generator is humming along under consistent load, you’re experiencing diesel efficiency at its finest.

But here’s the thing – even the most efficient engine in the world won’t deliver on its promise without proper care. Those fuel injectors need regular cleaning, air filters require replacement, and cooling systems demand attention. It’s like having a high-performance athlete who needs the right nutrition and training to perform at their peak.

That’s where the expertise of factory-trained technicians becomes invaluable. Understanding the intricacies of marine and industrial diesel systems – from raw water cooling challenges to the specific demands of saltwater environments – makes all the difference between an engine that merely runs and one that delivers exceptional fuel economy year after year.

The future of diesel efficiency is bright, with hybrid systems and alternative fuels on the horizon. But today’s technology, when properly maintained and operated, already offers remarkable efficiency that can dramatically impact your bottom line and operational range.

At Diesel Services of America, we’ve seen how proper maintenance and expert service can transform an engine’s performance. Our dockside service throughout South Florida and worldwide parts delivery ensure that your diesel investment continues delivering the fuel efficiency and reliability you depend on. Learn more about our comprehensive marine diesel services.