Why Marine Cummins Engine Repair Matters for Your Vessel

Marine Cummins engine repair is crucial for keeping your vessel operational and avoiding costly breakdowns. For both commercial fleets and recreational boats, understanding your repair options can save thousands in downtime and emergency service calls.

Quick repair options for marine Cummins engines:

- In-frame rebuild – Engine stays in vessel, replaces pistons, rings, bearings ($8,000-$15,000)

- Complete overhaul – Engine removed for full restoration ($15,000-$30,000)

- Cummins ReCon™ engine – Factory remanufactured exchange unit (varies by model)

- Component replacement – Individual parts like injectors, turbo, water pump

- Emergency field service – On-site repairs to get you back to port

As one marine mechanic noted in our research: “Maintaining a Cummins marine diesel engine is crucial for ensuring reliable performance, fuel efficiency, and longevity on the water.”

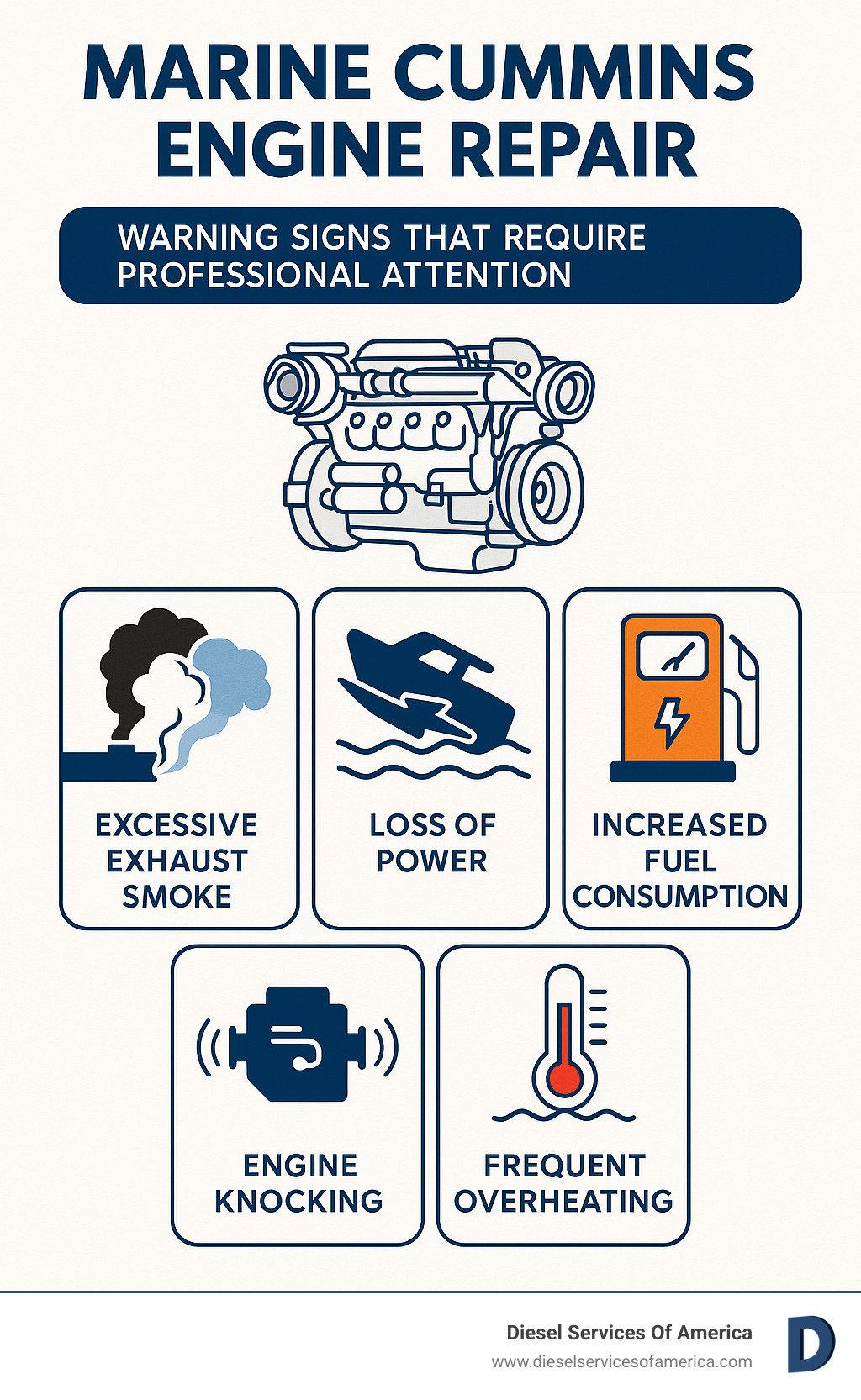

Common warning signs that demand immediate attention include excessive smoke, loss of power, increased fuel consumption, engine knocking, and frequent overheating. Early detection of these symptoms can mean the difference between a simple repair and a complete engine replacement.

Knowing when to act is key. A timely, professional rebuild can significantly extend your engine’s life by addressing problems before they cause catastrophic internal damage.

Glossary for marine cummins engine repair:

Recognizing the Signs: When Does Your Cummins Marine Engine Need Repair?

Even the toughest Cummins marine engines eventually show signs of needing attention. Learning to recognize these signals—through performance, sounds, and exhaust—is key to preventing minor issues from becoming major, costly repairs. Acting early keeps you on the water and saves money.

Common Symptoms Demanding Attention

When something’s not right with your marine Cummins engine repair needs, your engine usually makes it pretty obvious. Here’s what to watch for:

Loss of performance is a primary red flag. A sluggish boat that struggles to reach top speed or maintain RPMs under load often points to fuel delivery problems or internal wear causing low compression.

Excessive smoke analysis is like reading your engine’s mood ring. The color of your exhaust is a diagnostic tool:

- Black Smoke: Indicates too much fuel or not enough air, pointing to issues like clogged air filters, faulty injectors, or turbo problems.

- White Smoke: Thick, sweet-smelling smoke suggests coolant is burning, a sign of a bad head gasket or cracked cylinder head. (Thin, dissipating white smoke is likely just condensation).

- Blue Smoke: Signals that the engine is burning oil, usually due to worn piston rings, valve guides, or cylinder liners.

Engine knocking diagnosis is critical. Persistent knocking, rattling, or clanking sounds often indicate serious internal issues like worn bearings or crankshaft problems. These noises typically worsen under load, and ignoring them can lead to catastrophic failure.

Overheating causes can be simple or serious. Frequent overheating can stem from low coolant or a clogged strainer, but it can also signal a failing water pump, blocked heat exchanger, or a bad head gasket. Address overheating immediately to prevent warped heads or a cracked block.

Oil consumption issues tell their own story. Excessive oil consumption, especially with blue smoke, points to internal wear. Milky oil indicates coolant contamination, while a fuel smell suggests fuel dilution—both are serious issues requiring immediate attention.

Poor fuel economy is an early warning sign of inefficiency. A sudden drop can be caused by injector problems, fuel pump issues, or internal wear.

Diagnostic First Steps

Before calling for professional help, these simple checks can provide valuable information to your technician.

Fluid and leak checks are a must. Ensure engine oil, coolant, and transmission fluid are at proper levels. Visually inspect hoses, connections, and engine components for any oil, fuel, or coolant leaks.

Monitor sounds and gauges. Listen for any new or unusual noises and note their location. Regularly check engine gauges for temperature, oil pressure, and RPMs, investigating any readings outside the normal range.

Keep an engine logbook. Record service hours, maintenance, fuel consumption, and any unusual observations. This log is an invaluable diagnostic tool for tracking patterns, catching problems early, and helping technicians quickly identify issues.

Staying observant and proactive is key to ensuring your Cummins engine provides years of reliable service.

The Overhaul Deep Dive: In-Frame vs. Complete Rebuilds

When major marine Cummins engine repair is needed, you have two main options: an in-frame rebuild or a complete overhaul. The right choice depends on your engine’s condition and your long-term plans for the vessel, not just the cost.

| Feature | In-Frame Rebuild | Complete Overhaul (Out-of-Frame) |

|---|---|---|

| Engine Removal | No, engine remains in the vessel. | Yes, engine is removed from the vessel. |

| Scope of Work | Focus on cylinder kit (pistons, rings, liners), main & rod bearings, gaskets, seals. | Complete disassembly, all wear components replaced, extensive cleaning, machining. |

| Components | Pistons, rings, cylinder liners, main bearings, rod bearings, gaskets, seals. | All in-frame components PLUS cylinder head rebuild, camshaft, lifters, oil pump, water pump, turbocharger (if applicable). |

| Best Use Case | Engine has good block/crankshaft, needs refreshed top-end and bearings. Good for high oil consumption or low compression on healthy bottom end. | Severe wear, internal damage, high hours, or when the entire engine needs to be brought back to ‘like-new’ condition. |

| Downtime | Generally shorter. | Generally longer due to engine removal and comprehensive work. |

| Cost-Effectiveness | More affordable for specific issues; less labor. | Higher initial cost, but can offer better long-term value for severely worn engines. |

| Testing | Limited testing on board. | Can be hot-tested on a dynamometer to original manufacturing standards. |

What is an ‘In-Frame’ Rebuild?

An in-frame rebuild is performed with the engine still in the vessel. It’s the ideal solution when the engine block and crankshaft are in good condition, but key internal components are worn. Technicians remove the cylinder head and oil pan to access the engine’s internal components, addressing specific wear points without the complexity of removing the entire engine.

Key components replaced include:

- Pistons, rings, and cylinder liners to restore compression and control oil consumption.

- Main and rod bearings to ensure smooth operation.

- All necessary gaskets and seals to prevent leaks.

This approach is best for issues like high oil consumption or low compression when the engine’s bottom end is still healthy.

What is a ‘Complete Overhaul’ (Out-of-Frame) Rebuild?

A complete overhaul involves removing the engine from the vessel for a full restoration. This comprehensive approach is necessary for engines with severe wear, internal damage, or very high hours. In our shop, the engine is completely disassembled, and every component is cleaned, inspected, and measured against factory specifications.

This process includes all the work of an in-frame rebuild, plus:

- A full cylinder head rebuild (valves, guides, seats).

- Inspection and replacement of the camshaft and lifters.

- Rebuilding or replacing the oil and water pumps.

- A full inspection and rebuild of the turbocharger.

Precision machining can restore the block, crankshaft, and heads to factory tolerances. A key advantage is the ability to test the rebuilt engine on a dynamometer, verifying it meets or exceeds OEM standards before reinstallation.

Key Components in a Marine Cummins Engine Repair Overhaul

Whether it’s an in-frame or complete overhaul, we focus on critical systems using genuine Cummins parts to ensure quality and reliability. Our approach is to inspect and replace components as needed to restore the engine to factory specifications.

- Cylinder Head and Valve Train: We inspect the head for cracks or warping and replace worn valves, guides, seats, and springs. A new head gasket is essential for a perfect seal.

- Pistons, Rings, and Liners: Replacing these parts restores compression and eliminates blow-by, which is crucial for engine power.

- Bearings and Crankshaft: New main, rod, and thrust bearings are installed. The crankshaft is inspected and, if necessary, reground to ensure smooth rotation.

- Fuel System: Injectors and the fuel pump are tested and replaced if they are not performing optimally, ensuring efficiency and proper power delivery.

- Cooling and Lubrication Systems: The water pump, thermostat, heat exchanger, and oil pump are inspected for corrosion and wear to prevent overheating and ensure proper lubrication.

- Turbocharger: On turbocharged models, the turbo is inspected for blade damage and shaft play to guarantee correct air-to-fuel ratios and power output.

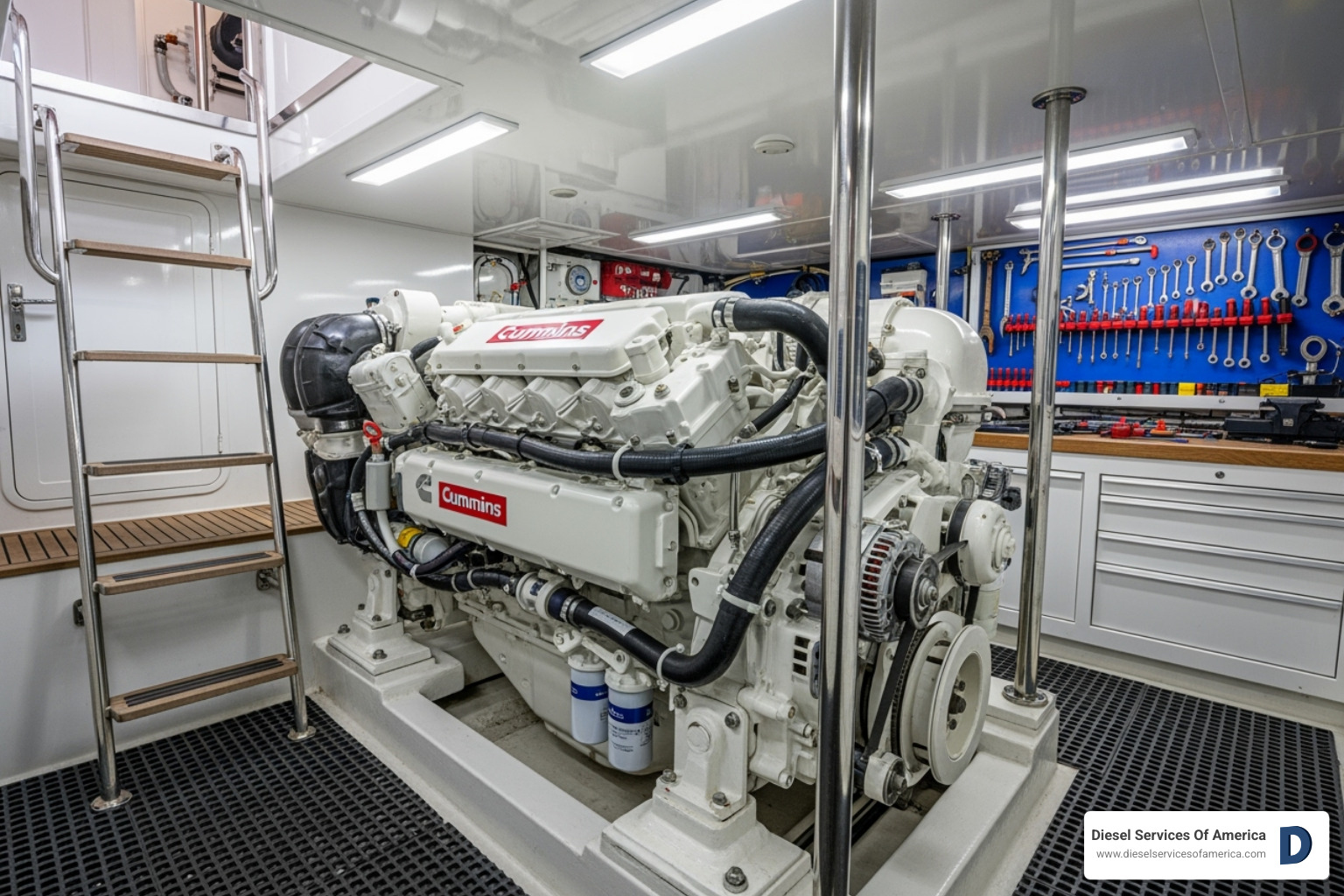

The Anatomy of a Professional Marine Cummins Engine Repair

A professional marine Cummins engine repair is a meticulous process that restores your engine’s reliability and performance. At Diesel Services Of America, our factory-trained technicians understand that your vessel’s engine is its heart. We don’t just swap parts; we follow a proven, step-by-step process to ensure every repair is done right the first time. You can learn more about our comprehensive approach at Professional Marine Diesel Engine Repair.

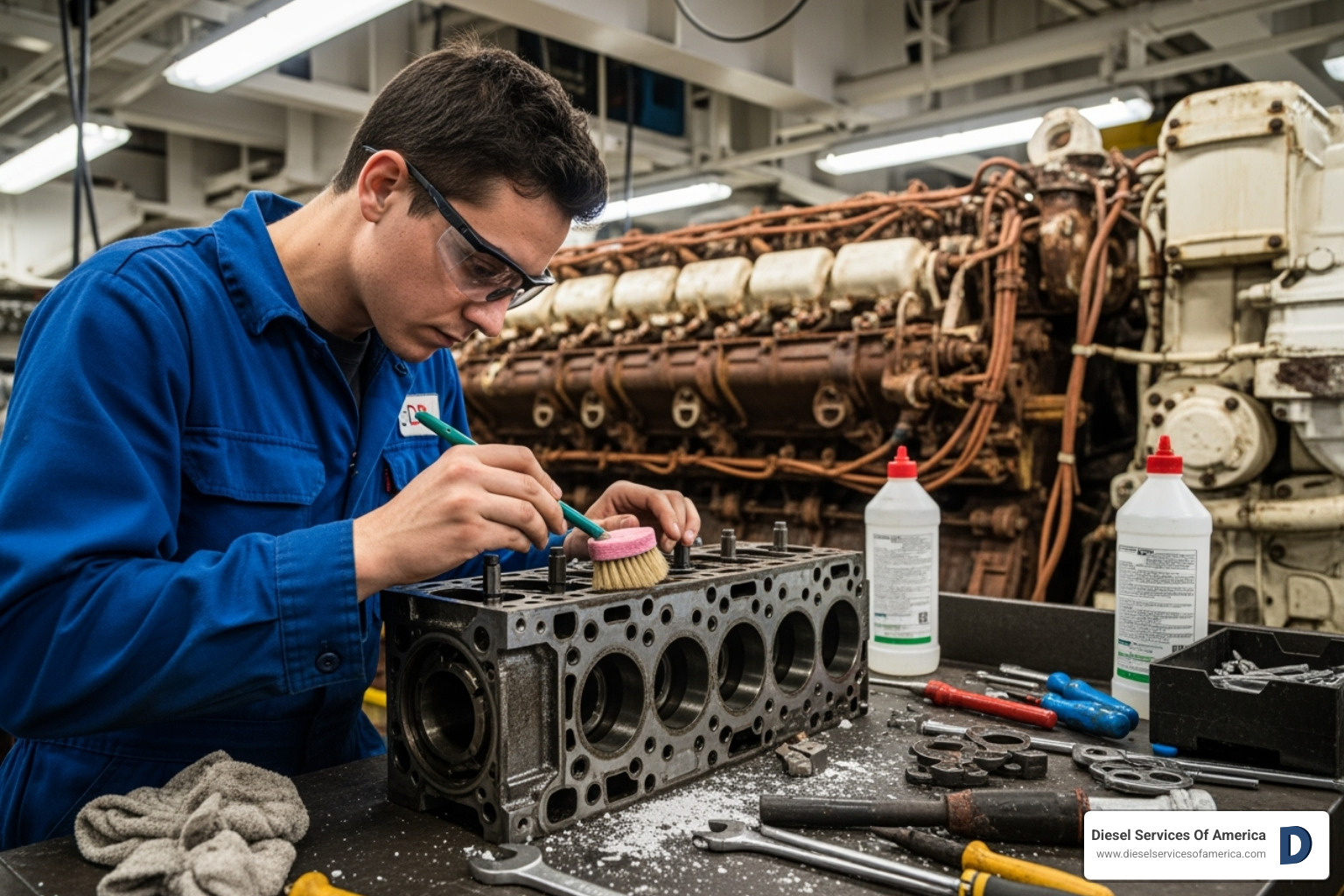

The Step-by-Step Rebuild Process

A successful marine Cummins engine repair follows a precise process that leaves nothing to chance. Here’s our approach:

- Draining and Analysis: The process begins by draining all fluids. We analyze the oil and coolant for signs of internal problems.

- Systematic Disassembly and Labeling: We follow a precise sequence, carefully labeling and organizing every part to ensure accurate reassembly and prevent damage.

- Inspection and Measurement: After a thorough cleaning, each part is inspected for wear or damage. We use micrometers to check critical tolerances against Cummins’ factory specifications.

- Precision Cleaning: Before reassembly, all components, oil passages, and mating surfaces are cleaned to surgical standards to ensure a perfect fit and prevent contamination.

- Reassembly to OEM Specs: We reassemble the engine following Cummins’ service manuals precisely, using calibrated torque wrenches to tighten every fastener to exact specifications for optimal reliability.

- Testing and Break-in: The rebuilt engine undergoes comprehensive testing to verify oil pressure, temperature, and performance, including dynamometer testing for complete overhauls. We provide detailed break-in instructions for the first 50-100 hours to ensure new components seat correctly for long-term durability.

The Importance of Genuine Parts for Your Marine Cummins Engine Repair

Using genuine Cummins parts is non-negotiable for a reliable marine Cummins engine repair. Aftermarket components often lead to premature failure and costly rework. Here’s why we insist on genuine parts:

- Perfect Fit: Genuine parts are made to exact OEM specifications, ensuring they function perfectly in the demanding marine environment.

- Best Reliability: You can’t afford a failure at sea. Genuine parts are rigorously tested to withstand the vibration, temperature changes, and corrosion of marine use.

- Long-Term Durability: Genuine parts last longer, saving you money on labor, downtime, and repeat repairs over the life of your engine.

- Warranty Protection: Using genuine parts protects your Cummins factory warranty and allows us to stand behind our repair work with our own guarantee.

- Optimal Performance: Cummins parts are designed as an integrated system to deliver the fuel efficiency, power, and emissions control you expect.

- Avoiding Aftermarket Risks: Inferior materials and incorrect specs in aftermarket parts can lead to catastrophic failure. The small initial savings aren’t worth the risk at sea.

For genuine Cummins parts and expert guidance, you can explore options at Find genuine parts here. When your engine’s reliability matters, genuine parts aren’t an expense – they’re an investment in your peace of mind.

Prevention is Key: Your Cummins Marine Engine Maintenance Schedule

A consistent preventative maintenance schedule is the most cost-effective way to ensure your Cummins marine engine’s longevity and reliability, preventing costly emergency marine Cummins engine repair. Proper care can be the difference between an engine lasting 5,000 hours versus one lasting over 20,000. Regular maintenance allows technicians to catch small issues before they become catastrophic failures, while a detailed logbook helps track your engine’s health over time.

Daily and Hourly Maintenance Checks

Simple, consistent checks are key to catching problems early and avoiding expensive repairs. Always consult your OEM service manual for model-specific requirements.

Daily (or every 10 hours):

- Check engine oil and coolant levels.

- Drain the fuel-water separator.

- Check marine transmission oil level.

- Inspect drive belts for tension and wear.

Annually (or every 300 hours):

- Change engine oil and filter.

- Replace primary and secondary fuel filters.

- Inspect the raw water pump impeller (replace every 1-2 years as a precaution).

Every 2 Years (or 600 hours):

- Flush the cooling system.

- Perform a valve lash adjustment.

- Inspect engine mounts for deterioration.

Every 3 Years (or 1500 hours):

- Clean the aftercooler core.

- Replace engine coolant.

- Test and clean fuel injectors.

For expert guidance custom to your engine, check out our comprehensive resource: Marine Diesel Engine Repair Service Tips.

Essential Systems Requiring Regular Service

Your engine has five critical systems that require regular attention to avoid major marine Cummins engine repair.

- Fuel System: Clean fuel is vital. Regularly drain the water separator and change filters on schedule to protect expensive injectors from contamination.

- Lubrication System: Clean oil and quality filters are essential for protecting internal components. Follow recommended oil change intervals without fail.

- Cooling System: Both the raw water and freshwater circuits must be maintained. Keep strainers clean, replace impellers proactively, and flush the system to prevent salt buildup and corrosion, which can lead to catastrophic overheating.

- Air Intake System: A clean air filter is crucial for power and efficiency. On turbocharged engines, the turbo also requires periodic inspection.

- Exhaust System: Inspect the exhaust system for leaks and corrosion. A failed riser or manifold can allow water into the engine, causing catastrophic damage.

Regular maintenance keeps these systems in harmony, extending engine life. Don’t overlook your auxiliary power; we also provide expert service for Cummins Onan Generator Repair.

Frequently Asked Questions about Marine Cummins Engine Repair

Here are answers to the most common questions we receive about marine Cummins engine repair, helping you make informed decisions for your vessel.

What’s the difference between a rebuild and a Cummins ReCon™ engine?

A rebuild involves overhauling your specific engine. We disassemble it, replace worn parts with genuine Cummins components, and reassemble it to factory specs. A Cummins ReCon™ engine is a unit that has been completely remanufactured in a Cummins factory. You exchange your old engine (the “core”) for a factory-remanufactured one. The primary advantage of a ReCon™ engine is significantly reduced downtime, as you don’t have to wait for your original engine to be rebuilt. ReCon™ engines also come with a factory warranty. A rebuild restores your existing engine using new and inspected parts, while a Cummins ReCon™ engine is a unit completely remanufactured in a factory to meet or exceed original specifications, often available for a quick exchange to minimize downtime.

How long can a properly rebuilt Cummins marine engine last?

While mileage is used for on-road engines, a professionally rebuilt marine engine, with proper break-in and consistent preventative maintenance, can provide thousands of additional service hours, often restoring it to a like-new service life. The key factors for longevity are the quality of the workmanship, the use of genuine parts, and adherence to proper maintenance schedules.

Can I perform major repairs on my Cummins marine engine myself?

While owners can and should perform routine maintenance like fluid checks and filter changes, major repairs and overhauls require specialized tools, a controlled environment, and in-depth knowledge of Cummins systems. Mistakes with critical procedures can lead to catastrophic engine failure. For safety, reliability, and warranty protection, using certified technicians for any major marine Cummins engine repair is highly recommended.

Conclusion

Understanding marine Cummins engine repair—from recognizing warning signs to choosing between a rebuild and an overhaul—is essential for every Cummins-powered vessel owner. The most important takeaway is that preventative maintenance is your most powerful tool against costly downtime and repairs.

When repairs are necessary, making an informed decision and insisting on genuine Cummins parts and certified technicians is critical for reliability at sea. Quality work isn’t a luxury; it’s a necessity for navigating the harsh marine environment.

At Diesel Services Of America, our factory-trained technicians specialize exclusively in marine and industrial diesel engines. From our Fort Lauderdale location, we provide dockside service throughout South Florida and deliver genuine parts worldwide. We understand your vessel is more than just machinery; it’s an investment in your passion or livelihood.

Trusting our experts for your marine Cummins engine repair needs is an investment in reliability, performance, and peace of mind. Don’t wait for a minor issue to become a major problem.

Contact us for expert marine diesel engine services today, and let us help you keep your Cummins engine running strong for years to come!