Why a Checklist is Your Engine’s Best Friend

A diesel engine inspection checklist is a vital tool for anyone who relies on these powerful machines. Whether you’re managing a fleet of commercial vessels or you’re a local boat owner in South Florida, knowing what to check and how often can save you a world of trouble.

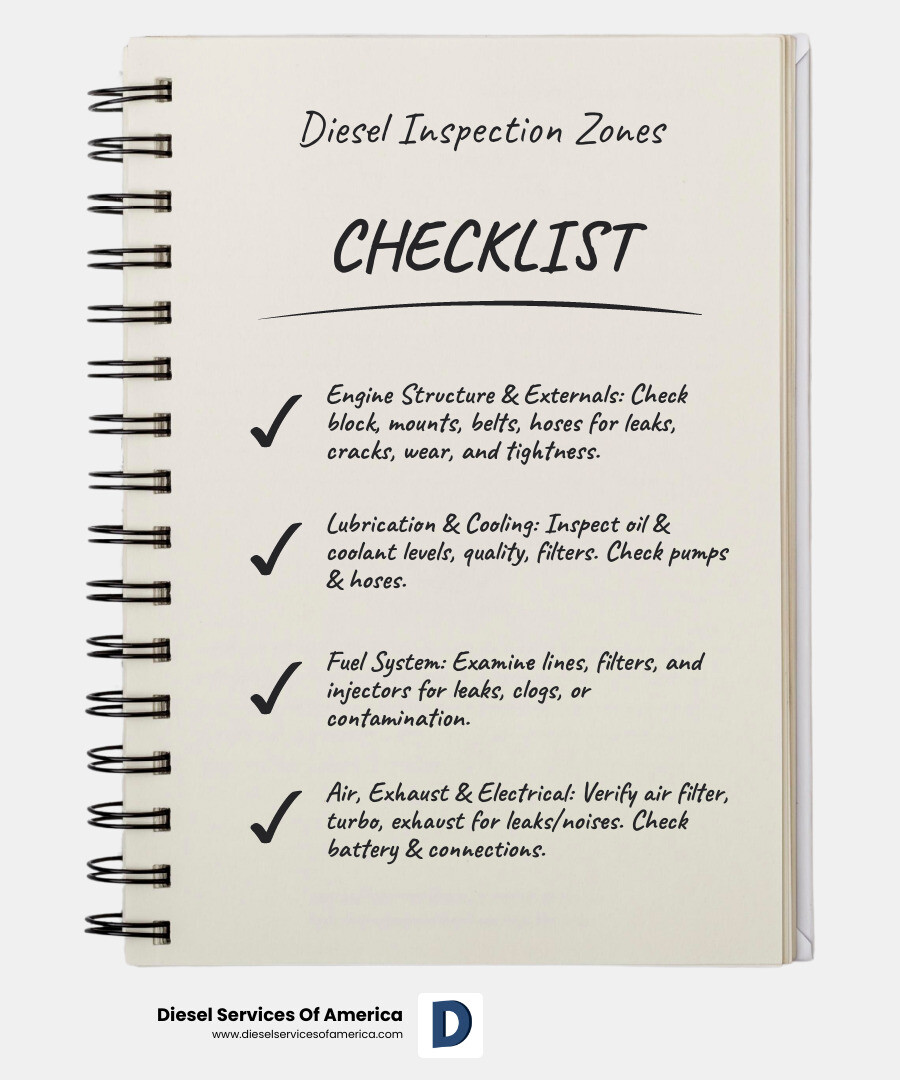

To get straight to the point, here are the core areas a comprehensive diesel engine inspection covers:

- Engine Block, Mounts, and Externals: Look for leaks, wear, and proper alignment.

- Lubrication System: Check oil levels, quality, and filter condition.

- Cooling System: Inspect coolant levels, radiator, water pump, and hoses.

- Fuel System: Examine filters, lines, and injectors for leaks or clogs.

- Air Intake & Exhaust Systems: Check air filter, turbocharger, and exhaust components.

- Electrical System: Assess battery health, connections, and critical components like glow plugs.

Let’s be real: unexpected breakdowns are a nightmare. They eat into your budget, sideline your operations, and create headaches you don’t need. This is especially true for marine and industrial diesel engines, where reliability isn’t just a convenience – it’s a necessity.

That’s where a thorough inspection checklist comes in. It’s your proactive shield against costly surprises. Think of it as a roadmap to keeping your engine humming smoothly, mile after mile, or hour after hour.

Diesel engines are legendary for their durability. With proper care, they can last for 500,000 miles, or even over 1,000,000 miles. That’s a lifespan far beyond what gasoline engines typically offer. But this incredible longevity isn’t just a given; it’s earned through consistent maintenance. Regular inspections catch small issues before they snowball into major, expensive repairs. They minimize downtime, keep your operations efficient, and protect your significant investment.

Explore more about Diesel engine inspection checklist:

The Ultimate Marine & Industrial Diesel Engine Inspection Checklist

This section breaks down the inspection into key systems, providing a step-by-step guide for operators and owners. Regular checks ensure safety, efficiency, and longevity.

Engine Block, Mounts, and Externals

Our journey begins with a good old-fashioned visual inspection. Sometimes, your nose knows best! What does the place smell like? Diesel, damp, or oil? Each can indicate potential leaks or issues. A clean engine basin helps reveal any new leaks easily. We even recommend placing a pet training sheet beneath the engine to soak up leaks and keep bilges clean – a little trick we’ve learned over the years.

Here’s what we look for:

- Visual Inspection for Leaks: Scan the entire engine block, manifold, and oil pan. Are there any puddles of water, oil, or fuel? Check for cracks, water/oil mixture, or moisture spots. Even a small drip can become a big problem.

- Oil Leaks: Look for drips or residue around seals, gaskets, and connections.

- Coolant Leaks: Pink, green, or orange fluid often indicates a coolant leak, possibly from hoses, clamps, or the radiator.

- Fuel Leaks: The smell of diesel is a dead giveaway, but visually inspect fuel lines, filters, and connections for any wet spots.

- Engine Mounts for Cracks and Alignment: These are the unsung heroes holding your powerful engine in place. Examine the mounts for cracks, misalignment, or distortions. They should be properly aligned, bolted, and their fasteners in good condition. Misaligned mounts can lead to excessive vibration and premature wear.

- Belts for Tension and Cracks: Engine belts, typically driven by the crankshaft, transfer power to crucial components like the alternator and water pump. Depress each engine belt gently with your thumb. If the depression is over 1/4″ (about 6mm), or if a V-belt deflects by more than 1/2 inch (12mm), it’s too loose. A loose belt can lead to an uncharged battery (alternator inefficiency) or an overheating engine (water pump inefficiency). Also, look for signs of a slipping belt, like black belt dust around the pulleys. Inspect them for cracks, fraying, or excessive wear. A belt adjusted too tight can also put undue stress on pulley wheel shafts and bearings.

- Hoses for Bulges and Softness: Hoses are critical for carrying fluids. They should feel soft and pliable, free of wear and cracks. Check for any bulges, which indicate internal damage, or hard, brittle spots. Ensure hose ends are clamped securely, and clamps are free of corrosion, wear, and not too tight.

- Fasteners and Bolts for Tightness: Give a quick check to visible bolts and fasteners. Are they all present and accounted for? Are they tight? Loose fasteners can lead to vibrations and component damage.

- Signs of Corrosion: Especially in marine environments, corrosion is a constant threat. Look for rust or pitting on metal surfaces. This can compromise structural integrity and electrical connections.

If you spot any issues with belts or hoses, it’s best to address them promptly. We can help you replace worn belts and other components to keep your engine running smoothly.

Lubrication and Cooling Systems

These systems are the lifeblood of your diesel engine, preventing friction and overheating.

- Checking Oil Level and Quality: This is a daily ritual for a reason. Read the dipsticks of the oil sump and transmission gearbox. A pro tip: don’t clean the dipstick with a cloth; use your hand. Check the color and reading in the second sounding of the dipstick.

- Milky or Gritty Oil: If the lubricant smells burned or appears milky or bubbly, it could signal a cracked engine block or head gasket, allowing coolant to mix with the oil. If the oil feels gritty or has particles, it’s a sign of serious engine wear.

- Oil Filter Condition: While you’re at it, note the condition of your oil filter. A clogged filter restricts oil flow, which is terrible for your engine. Regular oil and filter changes are paramount. On average, change the oil every 10,000–15,000 miles or according to the manufacturer’s guidelines. For marine and industrial engines, this is often based on operating hours.

- Coolant Level in Reservoir and Heat Exchanger: Ensure coolant is at the correct level in the reservoir. For marine engines, check the heat exchanger as well.

- Coolant Condition and Color: Coolant should be clean and brightly colored. Discoloration or presence of oil indicates a problem. Also, check coolant acidity – an often-overlooked detail.

- Raw Water Strainer Cleanliness: (Marine specific) This is crucial for engines with raw water cooling. Check the raw water strainer and ensure it is free from debris. Use gloves when checking strainers, as some sea creatures can sting! Make sure your engine sea-cocks are open before starting.

- Water Pump for Leaks: Inspect the water pump for any leaks and excessive shaft end play.

- Zinc Anode Condition: (Marine specific) These sacrificial anodes protect your engine and drivetrain from galvanic corrosion. Inspect the zinc anodes on the propeller shaft or hull, and in the engine heat exchange. A fully compromised shaft zinc can’t perform its function, leading to serious corrosion of the drivetrain.

- Radiator/Heat Exchanger: Ensure the radiator (or heat exchanger for marine engines) isn’t clogged or leaking. Keep it clean to prevent blockages.

It’s vital to ensure the cooling system is functioning properly to prevent severe engine damage from overheating. Overheating can damage gaskets, cylinder heads, and pistons. Regular flushing and replacement of coolant are also critical. Learn more about your oil’s health with a Diesel Engine Oil Analysis.

Fuel System Inspection

The fuel system is the heart of combustion. Even minor issues here can drastically affect performance.

- Checking for Fuel Leaks: Examine seals on the injectors, fuel lines, and lift pumps. Check for leaks around the fuel tanks and fuel filters. The smell of diesel is a strong indicator of a leak.

- Fuel Lines and Connections: Ensure all fuel lines are secure and free from cracks or wear. Loose connections can lead to air ingress or fuel leaks.

- Fuel Filters and Water Separator: Diesel fuel is prone to water contamination and microbial growth. Regularly replace fuel filters and check the fuel/water separator.

- Draining Water from Separator: If equipped, drain the fuel/water separator daily or before each significant operation. Water in diesel fuel can cause rust in steel and iron components, leading to clogged filters and damaged injectors.

- Algae or Sediment in Fuel Bowl: Inspect the fuel filter bowl for any signs of algae (often looks like black slime) or sediment. These contaminants can clog your system and starve the engine of fuel.

- Fuel Injector Seals: Look for any leaks around the injector seals. Faulty injectors can lead to poor performance, rough idling, and reduced fuel efficiency.

- Fuel Pump Operation: While more complex to test without specialized tools, ensure there are no obvious leaks or unusual noises coming from the fuel pump.

We can help you replace fuel filters and address other fuel system concerns, ensuring your engine gets clean, consistent fuel.

Air Intake and Exhaust Systems

Your diesel engine needs to breathe! Clean air in, clean exhaust out.

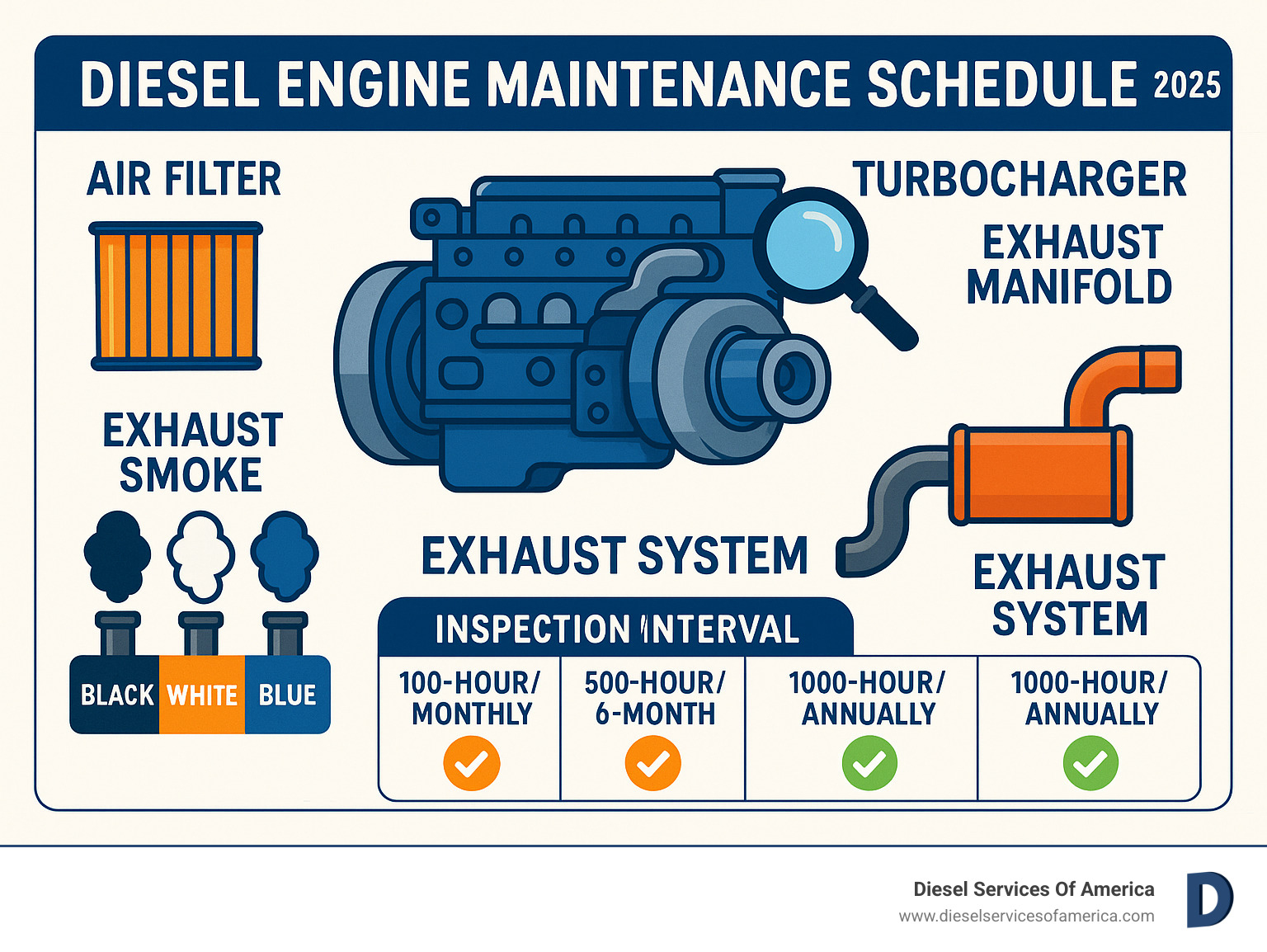

- Air Filter Condition: Check the air filter for dirt and debris. A clogged air filter can significantly reduce engine efficiency, increase fuel consumption, and cause damage. Replace air filters every 12,000 miles or sooner if operating in dusty or dirty conditions. Inspect the intake manifold for leaks and ensure it is securely fastened. We can help you check the air filter and ensure optimal airflow.

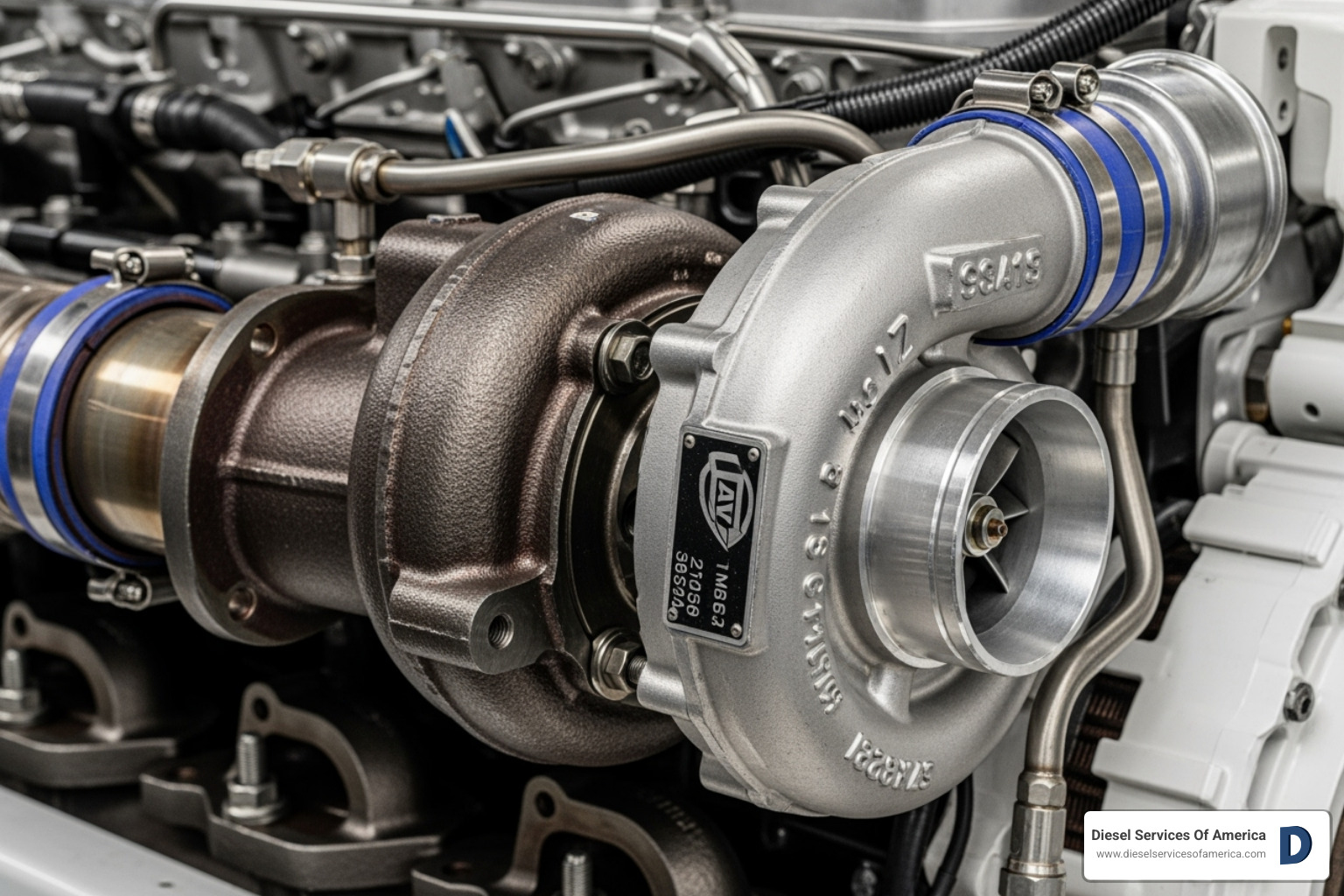

- Turbocharger for Leaks or Unusual Noises: Many marine and industrial diesel engines are turbocharged. Listen for any unusual whistling or grinding noises. Inspect for oil leaks around the turbocharger housing. Ensure it’s securely mounted.

- Exhaust Manifold for Cracks or Leaks: Look for cracks or leaks in the exhaust manifold, which can lead to reduced engine performance and dangerous fumes.

- Exhaust Smoke Color Analysis: The color of your exhaust smoke tells a story about your engine’s health.

- Black Smoke: Often indicates incomplete combustion due to too much fuel or not enough air. Possible causes include damaged fuel injectors, blocked air filters, a defective turbocharger, or incorrect injector timing.

- White Smoke: Suggests unburnt fuel or water/coolant in the combustion chamber. This could be due to faulty injection timing, low cylinder compression, water in the diesel fuel, or a damaged head gasket.

- Blue Smoke: A clear sign of burning oil. This can be caused by worn piston rings, cylinders, valve guides, or an engine overfilled with oil.

Understanding the color of the smoke is a critical diagnostic tool.

- Exhaust System Security and Mounting: Ensure the muffler and entire exhaust system are secure and free from rust or holes. Loose exhaust components can be a safety hazard and indicate underlying issues.

Inspection Frequency and Common Warning Signs

Adhering to a schedule is crucial for engine health. Knowing the warning signs allows for early intervention before minor issues become major failures.

Your Pre-Operation Diesel Engine Inspection Checklist

Think of your pre-operation check as a conversation with your engine before you ask it to work. Just like a good friend, your diesel will tell you if something’s wrong – you just need to know how to listen.

Before you even think about turning that key, take five minutes to give your engine a quick once-over. Check your fluid levels first – oil, coolant, and fuel should all be within the manufacturer’s recommended range. It’s amazing how many problems start with something as simple as low oil.

Next, do a visual scan for leaks around and under the engine. Fresh drips or puddles are like breadcrumbs leading to bigger problems. While you’re there, give your belt tension a quick thumb test – they should be snug but not guitar-string tight.

For our marine friends, here’s a critical step that can save your engine: ensure your sea cocks are open. We’ve seen too many engines overheat because someone forgot this simple step after winter storage. It’s an easy mistake that leads to expensive consequences.

Don’t forget to check your battery connections for cleanliness and tightness, and if you have a fuel/water separator, drain any accumulated water. These small steps take minutes but can prevent hours of downtime.

Advanced Diesel Engine Inspection Checklist for Scheduled Maintenance

While daily checks keep you running, it’s the deeper, scheduled maintenance that builds true engine longevity. For marine and industrial engines, we base these intervals on operating hours rather than calendar time – your engine doesn’t care if it’s been sitting for six months!

| Inspection Task | 100-Hour / Monthly | 500-Hour / 6-Month | 1000-Hour / Annually |

|---|---|---|---|

| Oil and Filter Changes | X | X | X |

| Fuel Filter Replacement | X | X | |

| Air Filter Inspection/Replacement | X | X (replace if needed) | X (replace) |

| Coolant Level/Condition Check | X | X | X |

| Coolant Flush & Replacement | X | ||

| Belt & Hose Inspection | X | X | X |

| Battery Load Test & Terminal Clean | X | X | |

| Valve Adjustment | X | ||

| Compression Test | X (if performance issues) | ||

| Injector Inspection/Service | X (if performance issues) | ||

| Turbocharger Inspection | X | X | |

| Raw Water Impeller Inspection/Replacement (Marine) | X | X (replace annually) | |

| Zinc Anode Inspection/Replacement (Marine) | X | X | |

| Transmission Fluid Check/Change | X | X |

The 100-hour checks are your bread and butter – oil changes, filter inspections, and basic system checks. Think of these as your engine’s regular health checkup.

500-hour maintenance digs deeper. This is where we replace fuel filters, test batteries under load, and for marine engines, check that crucial raw water impeller. A failed impeller can destroy an engine in minutes, so we don’t take chances.

Annual or 1000-hour service is the comprehensive physical. We’re talking valve adjustments, coolant system flushes, and compression tests if needed. For marine engines, we always replace zinc anodes annually – they’re cheap insurance against expensive corrosion damage.

These are general guidelines. Your specific engine might have different requirements, so always consult your manufacturer’s manual. When it’s time for major work, our team handles complete Diesel Engine Overhauls with the expertise you need.

Recognizing Early Warning Signs

Your diesel engine is constantly communicating with you – the trick is learning its language. Ignore these signals, and you’ll likely face much bigger problems down the road.

Unusual noises are your engine’s way of shouting for help. Knocking or pinging sounds often point to fuel system issues or worn components. Rattles, squeals, or grinding sounds are never good news and deserve immediate attention.

Excessive vibration is another red flag. While diesels naturally vibrate more than gas engines, any sudden increase or change in vibration pattern could signal problems with engine mounts, rotating components, or even misfiring cylinders.

When your engine experiences loss of power – feeling sluggish, struggling under load, or unable to reach normal RPMs – it’s telling you something’s restricting its performance. This could be anything from clogged filters to faulty injectors or turbocharger issues.

Difficulty starting, especially in cold weather, might indicate problems with glow plugs, fuel delivery, or low compression. Don’t just keep cranking – investigate the cause.

Overheating is a critical warning that demands immediate attention. Rising temperature gauges or warning lights usually stem from cooling system problems, low coolant, or blockages. Never ignore an overheating engine.

Pay attention to changes in exhaust smoke color. As we discussed earlier, the color tells a story about your engine’s internal health. Any deviation from clear exhaust warrants investigation.

Modern diesel engines come equipped with sophisticated Electronic Control Units (ECUs) that store fault codes when problems arise. These systems are incredibly helpful for diagnosing issues quickly and accurately. We’re experts with Diesel Engine Diagnostic Tools and can interpret these codes to pinpoint problems before they become catastrophic failures.

The key is catching these warning signs early. A diesel engine inspection checklist isn’t just about preventing breakdowns – it’s about listening to your engine and responding before small problems become expensive disasters.

Frequently Asked Questions about Diesel Inspections

When it comes to diesel engine inspection checklists, we get a lot of questions from boat owners and industrial operators. Let’s tackle the most common ones to help you better understand your marine or industrial diesel engine.

How does a diesel engine inspection differ from a gasoline engine inspection?

While both are internal combustion engines, diesel and gasoline engines are like cousins who grew up in different neighborhoods – related, but with distinct personalities and needs.

The biggest difference lies in how they ignite fuel. Diesel engines use compression ignition – they squeeze the air so hard it gets hot enough to ignite the fuel on its own. Gasoline engines, on the other hand, rely on spark plugs to create that initial flame. This fundamental difference shapes everything about how we inspect them.

Higher compression ratios in diesel engines mean they operate under much more stress. We’re talking about pressures that would make a gasoline engine cry uncle. This means we pay extra attention to signs of wear, cracking, or fatigue in components like cylinder heads, pistons, and engine blocks.

Instead of spark plugs, many marine and industrial diesel engines use glow plugs to help with cold starting. These little heating elements warm up the combustion chamber, and their condition is crucial for reliable starts – especially important when you’re miles offshore or in the middle of an industrial operation.

Turbochargers are practically standard on modern diesel engines. While some gasoline engines have them, they’re almost universal in the diesel world. This means our inspection checklist always includes checking the turbocharger, intercooler, and all those associated pipes and hoses for leaks or damage.

The fuel system maintenance needs are completely different too. Diesel fuel is thicker, more prone to water contamination, and can actually grow algae if conditions are right (sounds gross, but it happens!). This means we’re constantly checking fuel/water separators, draining water, and replacing fuel filters more frequently than you would with gasoline.

How often should I perform a detailed inspection?

This is where the rubber meets the road – or in our case, where the propeller meets the water! The honest answer is: it depends on how hard you work your engine and where you operate it.

Follow your manufacturer’s recommendations first and foremost. They built the engine, so they know it best. But here’s what we typically see in the real world:

For daily or pre-operation checks, you should be doing a quick walk-around every time you fire up that engine. Check your fluid levels, listen for anything that sounds off, and give everything a visual once-over. This takes maybe five minutes but can save you thousands.

Monthly or every 100 operating hours, step it up a notch. This is when you’re checking belt tension more carefully, cleaning that raw water strainer (if you’re marine), and really looking at fluid quality – not just levels.

Every six months or 500 operating hours brings the bigger maintenance items. Oil changes, fuel filter replacements, battery testing, and a thorough inspection of all your belts and hoses. For marine engines, this is also when we check those zinc anodes and raw water impellers.

The annual or 1000-hour service is the big kahuna. Coolant flushes, valve adjustments, compression tests if needed, and basically going through your engine with a fine-tooth comb.

Now, here’s the kicker: harsh environments change everything. If you’re operating in saltwater (which most of our South Florida customers are), extreme temperatures, or dusty industrial conditions, you might need to double the frequency of these checks. Saltwater is particularly brutal – it’s like your engine’s arch-nemesis, accelerating corrosion and causing problems faster than you’d expect.

For more guidance on timing, check out our recommendations for Regular Maintenance for Your Diesel Engine.

Can I perform all these checks myself?

We love this question because it shows you care about your engine! The short answer is: some yes, some definitely no.

Basic daily checks are absolutely within your wheelhouse. Anyone can check fluid levels, look for obvious leaks, test belt tension with their thumb, and make sure those sea cocks are open before starting. These are your first line of defense and honestly, the most important thing you can do for your engine.

Intermediate maintenance tasks like changing oil and filters, draining fuel/water separators, or even replacing belts and hoses can be handled by mechanically inclined folks. Just make sure you’re using the right parts and fluids – using the wrong oil viscosity or a cheap filter can cause more harm than good.

But here’s where we draw the line: complex diagnostics and repairs need professional hands. Compression tests require specialized gauges and the knowledge to interpret the results. Injector service involves working with pressures that can literally cut through skin. Turbocharger work requires precision and specific tools. Electrical diagnostics on modern engines often need proprietary software that only factory-trained technicians have access to.

Think of it this way – you wouldn’t perform surgery on yourself, right? Same principle applies to major engine work. The stakes are too high, and the specialized knowledge too important.

If you’re wondering about a specific task, our guide on DIY or Professional Diesel Maintenance can help you decide which side of the fence it falls on.

The bottom line? Stay involved in your engine’s care with daily checks and basic maintenance, but don’t hesitate to call in the professionals when things get complex. Your engine – and your wallet – will thank you for it.

Trust the Experts with Your Diesel Engine

You’ve now seen how powerful a diesel engine inspection checklist can be. Following it regularly is truly the best way to keep your engine running strong, avoiding those sudden, unwelcome surprises. We believe in empowering owners and operators to handle those vital daily checks – you’re the first line of defense for your marine or industrial powerhouse!

However, there comes a point where comprehensive service calls for more than just a keen eye and a quick glance. Those intricate diagnostic procedures, complex repairs, and in-depth maintenance tasks demand a level of expertise that goes beyond routine checks. It’s about specialized tools, deep knowledge of specific engine models, and years of hands-on experience. This proactive approach ensures your marine or industrial diesel engine doesn’t just run, but thrives, reliably and efficiently for many years to come.

When that time comes, you deserve to trust your valuable investment to the very best. At Diesel Services of America, we’re ready to step in. Our team of expert marine diesel technicians provides professional, factory-authorized service right here in Fort Lauderdale. We’re dedicated specialists in marine and industrial diesel engine sales, service, and maintenance. Whether you need dockside service throughout South Florida and the Caribbean, or worldwide parts delivery, our focus is always on your satisfaction. We leverage our factory-trained experts to ensure your engine stays in peak condition, allowing you to focus on what you do best.