Why Marine Engine Performance Matters for Every Boat Owner

Marine rebuild specialists are the experts who restore your boat’s diesel engine to peak performance through comprehensive rebuilding services. Whether you’re dealing with decreased power, increased fuel consumption, or reliability issues, these professionals diagnose problems and rebuild engines using precision techniques and OEM parts.

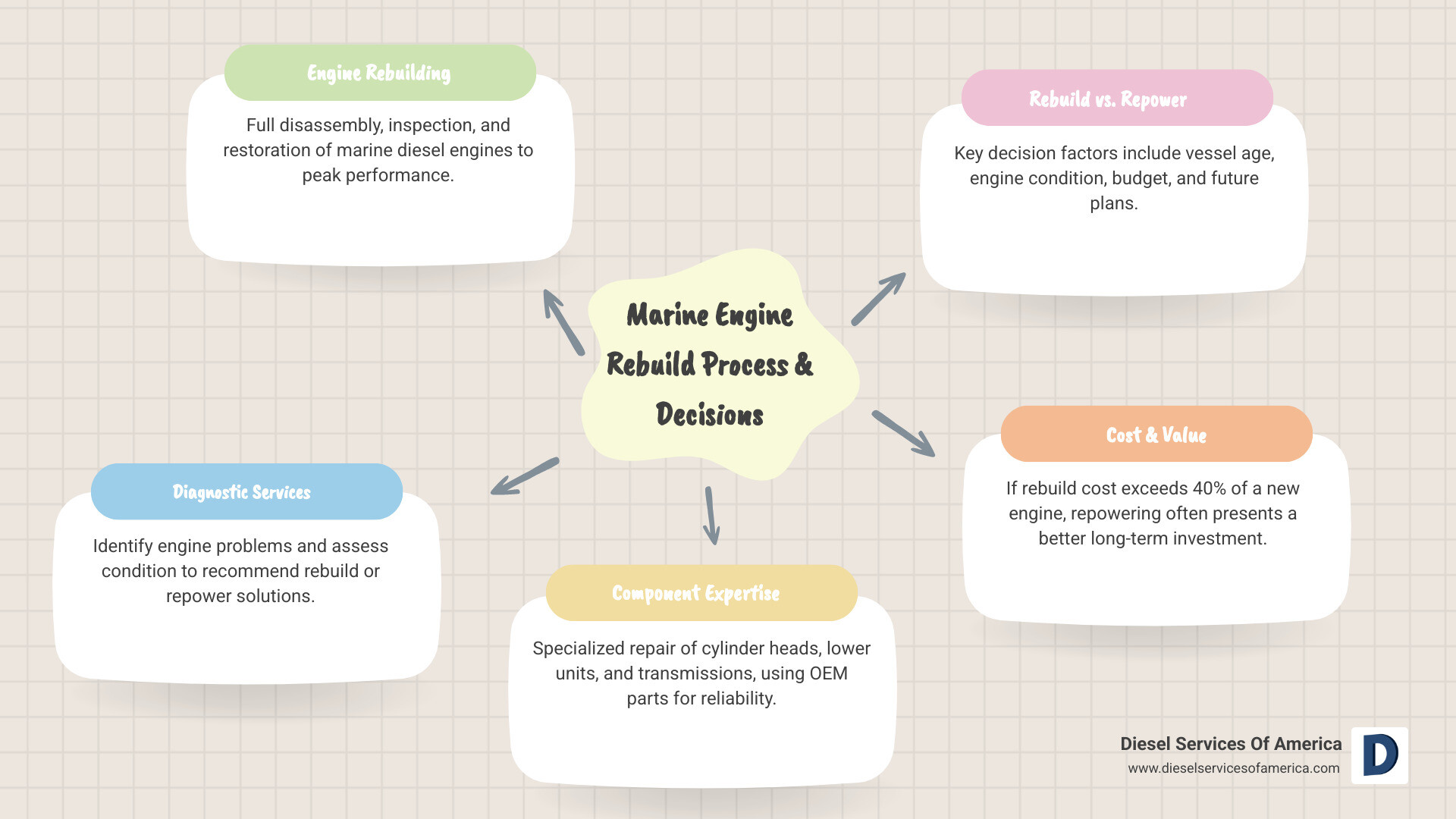

What Marine Rebuild Specialists Do:

- Engine Rebuilding – Complete disassembly, inspection, and restoration of marine diesel engines

- Component Repair – Cylinder head repair, lower unit rebuilds, and transmission services

- Diagnostic Services – Identifying engine problems and recommending rebuild vs. repower solutions

- OEM Parts Installation – Using genuine manufacturer parts for reliable, long-lasting repairs

- Testing & Tuning – Ensuring rebuilt engines meet or exceed original specifications

Your marine diesel engine serves as the heart and soul of your vessel, driving its performance, reliability, and overall safety. Marine engines face harsh operating conditions that automotive engines never encounter – constant saltwater exposure, high power demands, and continuous vibration that can wear down even the most robust components.

As one industry expert notes: “From mega yachts to dive boats, and just about everything in between, marine engine specialists have the time-tested technical experience and practical knowledge you can depend on for virtually any level of repair.”

The decision between rebuilding your current engine or repowering with a new one often comes down to a simple rule of thumb from the industry: if a rebuild costs 40% or more than installing a new engine, repowering may be the better investment.

Marine rebuild specialists further reading:

The Comprehensive Marine Engine Rebuilding Process

Your marine diesel engine faces relentless saltwater exposure, constant vibration, and high power demands. We advocate a proactive approach to engine care. Instead of waiting for a breakdown at sea, smart boat owners work with marine rebuild specialists to prevent problems. The harsh marine environment corrodes metal and creates unique wear patterns, requiring specialized knowledge that only experienced marine professionals possess.

For comprehensive information about our approach to marine engine care, visit our marine diesel engine services page.

Warning Signs: When Your Marine Engine Needs Attention

Your marine diesel engine has its own way of asking for help. Recognizing these distress signals is key to preventing major failures.

- Increased fuel consumption: Burning more fuel for the same trips indicates declining efficiency.

- Excessive smoke: Black smoke suggests fuel issues, blue smoke means burning oil, and white smoke often points to coolant problems.

- Loss of horsepower: Your boat feels sluggish or struggles to reach normal speeds.

- Unusual noises: Knocking, grinding, or hissing are clear warning signs.

- Oil pressure changes: Fluctuations or low pressure signal serious internal problems.

- Overheating: This often indicates cooling system failures or internal damage.

- High maintenance costs: Constant small repairs can point to deeper issues that a rebuild can solve.

When you notice these warning signs, consult with experienced marine professionals who understand the unique demands of marine diesel engines.

A Step-by-Step Guide to a Professional Rebuild

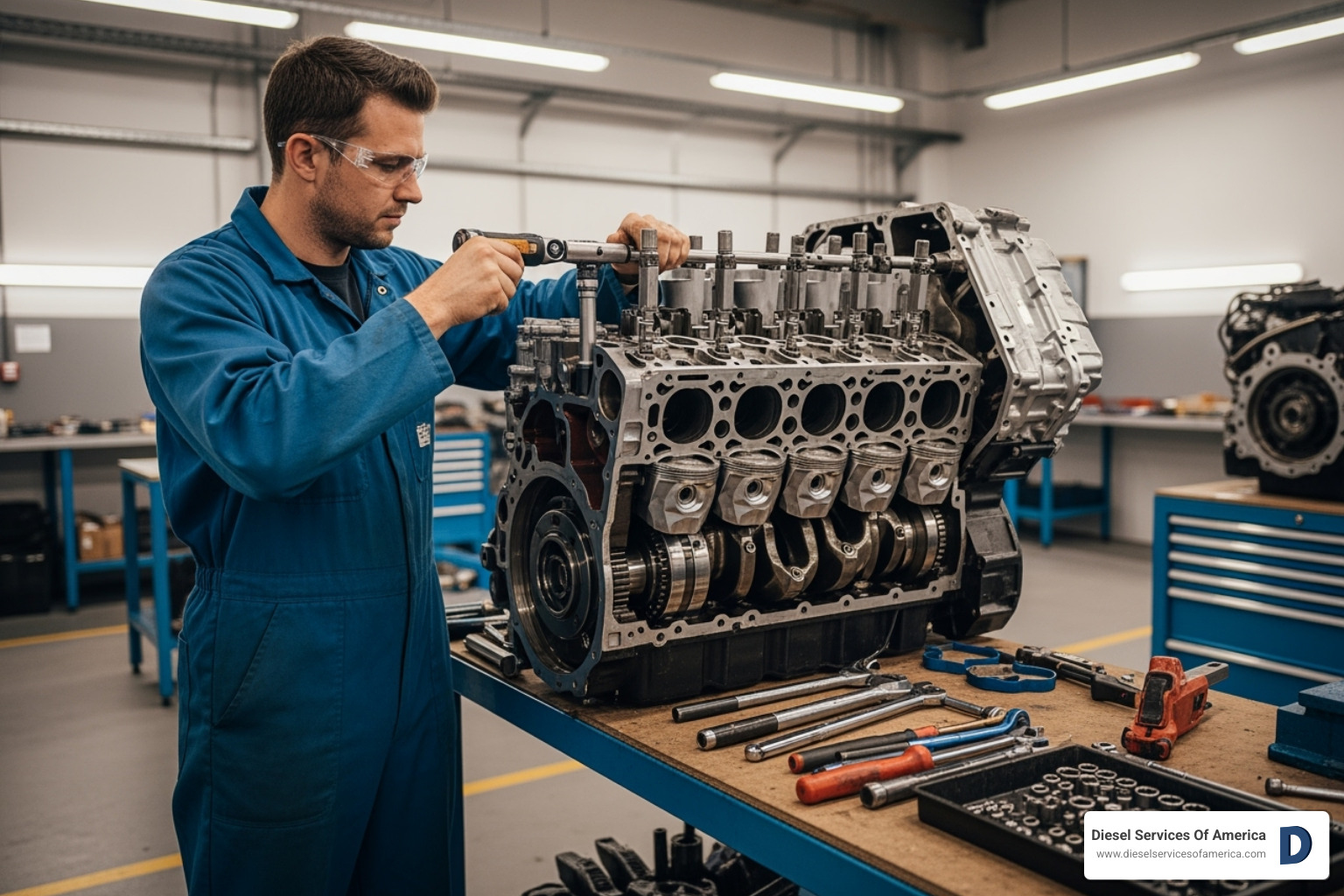

A professional marine engine rebuild requires precision, experience, and the right tools. Our factory-trained technicians follow a meticulous process to restore your engine.

- Disassembly and inspection: We completely disassemble your engine, examining every component for wear, cracks, or corrosion using advanced diagnostic tools to identify hidden problems.

- Component cleaning: This crucial step removes carbon, sludge, and contaminants, ensuring accurate measurements and proper seating of new parts.

- Component replacement or repair: We address every worn or damaged part, replacing critical components like pistons and bearings with high-quality marine-grade parts. Restorable components are returned to original specifications with precision machining.

- Fuel injection system servicing: We service and recalibrate injection systems and replace filters to ensure optimal power and efficiency.

- Cooling system checks: We inspect all cooling system components, including water pumps and heat exchangers, to prevent overheating.

- Electrical system evaluation: This covers all electrical components for reliable starting and operation.

- Precise reassembly: Our experienced technicians torque every bolt to exact specifications and set timing perfectly.

- Final testing and tuning: The rebuilt engine undergoes rigorous load testing that simulates real-world operation. We fine-tune performance to meet or exceed original specifications before returning it to service.

Our experienced team ensures your marine diesel engine receives the specialized care it deserves.

Rebuild vs. Repower: Making the Right Choice for Your Vessel

When your marine diesel engine ages, you face a key decision: rebuild or repower? Like renovating a home versus buying new, the right choice depends on your situation. Key factors include your vessel’s age, engine condition, budget, and future plans for the boat. Considering whether you’ll keep or sell the vessel and if you need modern features will guide you to the best choice for your lifestyle and wallet.

Key Differences Explained

Let’s break down what each option really means for you and your vessel:

| Feature | Rebuilding an Engine | Repowering a Vessel |

|---|---|---|

| Process | Restores the original engine by replacing worn components. | Replaces the entire engine (and often transmission/drives). |

| Components | Mix of original, repaired, and new replacement parts. | All new engine components, often with latest technology. |

| Cost | Generally less expensive than repowering upfront. | Higher upfront cost, but potentially lower long-term. |

| Warranty | Typically a limited warranty on the rebuild work. | Full manufacturer’s warranty on the new engine. |

| Performance | Restored to original (or slightly improved) specs. | Often significantly improved power, efficiency, and quietness. |

| Technology | Limited to the original engine’s design. | Access to the latest advancements (e.g., common rail, electronic controls). |

| Installation | Fits existing engine mounts and connections. | May require modifications to engine room, mounts, or systems. |

| Environmental | Extends life of existing components. | New engines are often more emissions-compliant and fuel-efficient. |

Rebuilding gives your engine a second life. Marine rebuild specialists restore it by replacing worn parts, maintaining the original design and fit. It’s cost-effective for specific failures. Repowering is like a heart transplant for your vessel, installing a new engine with the latest technology, warranties, and efficiency improvements. This often means better performance and emissions compliance.

Cost vs. Value: A Financial Breakdown

The 40% rule of thumb is crucial: if a rebuild costs 40% or more than a new engine, repowering is often the smarter financial move. The math extends beyond the initial price. A rebuild saves money upfront but doesn’t fix the limitations of older designs. A new engine offers long-term financial benefits.

Modern engines deliver better fuel economy, potentially 20-30% more efficient than older models. For frequent boaters, these savings add up. You can see modern engine specs in resources like this example engine specifications.

New engines also come with comprehensive manufacturer warranties for peace of mind. They also deliver improved performance: more power, better acceleration, and quieter operation. From a long-term investment perspective, repowering increases your boat’s value and marketability, making it more attractive to buyers than one with a rebuilt older engine.

When to Seriously Consider Repowering

Repowering makes the most sense when dealing with chronic reliability issues. If your engine is unreliable, constantly breaking down, its useful life may be over. Frequent downtime costs money and time on the water. Obsolete parts are another reason to repower. Finding replacements for older engines can be difficult and expensive as manufacturers discontinue them.

Many boat owners also want modern performance features. Today’s marine diesels offer common rail technology for better efficiency, reduced emissions, and quieter operation. The difference is dramatic. Emissions compliance is also key, as newer engines meet current standards.

If these situations sound familiar, explore your repowering options. Our team can help you understand what’s possible for your vessel. Learn more about all our capabilities here: More info about our services.

The Value of Professional Marine Rebuild Specialists

When your marine diesel engine needs serious attention, choosing the right professionals can make all the difference between a repair that lasts and one that leaves you stranded. Marine rebuild specialists aren’t your typical mechanics – they’re craftsmen who understand the unique challenges that marine engines face every day on the water.

Think about it: your marine diesel engine operates in conditions that would make an automotive engine cry for mercy. Constant saltwater exposure, endless vibration, and the demanding power requirements of moving a heavy vessel through water require a special kind of expertise. That’s exactly what professional marine rebuild specialists bring to the table.

The marine industry has built its reputation on experience, and for good reason. Some of the most respected names in our field have been perfecting their craft for decades. Here at Diesel Services of America, our team has been providing marine and industrial diesel expertise for over 20 years, contributing to a collective pool of knowledge that ensures your engine receives the skilled attention it deserves.

Why to Choose Professional marine rebuild specialists

When your marine diesel engine starts showing its age, you have choices. You could try to patch things up with quick fixes, or you could trust your investment to professionals who live and breathe marine diesel technology every day.

Specialized knowledge is perhaps the most compelling reason to work with marine diesel experts. Marine engines operate in a completely different world from their automotive cousins. The materials, systems, and operating environments require specialized understanding. We know which components are most vulnerable to saltwater corrosion, how to properly seal systems against water intrusion, and which rebuild techniques work best in marine applications.

Industry-leading techniques separate the professionals from the amateurs. The best marine rebuild shops invest heavily in the latest diagnostic equipment, precision measuring tools, and rebuilding techniques. This means your engine benefits from methods that simply weren’t available even a few years ago. Advanced honing machines, computerized balancing equipment, and precision torque systems ensure your rebuilt engine performs like new.

Our commitment to customer satisfaction goes beyond just fixing what’s broken. We believe in transparency throughout the rebuild process. You’ll understand exactly what we’re doing, why we’re doing it, and what you can expect from the finished product. This commitment shows in our warranties – we stand behind our work because we’re confident in our craftsmanship.

Factory-trained technicians make a real difference in rebuild quality. We invest heavily in training our team directly with engine manufacturers, from MAN to Caterpillar. This specialized training means our technicians understand the specific quirks, common issues, and best practices for each engine brand. It’s knowledge you simply can’t get from general diesel repair manuals.

Quality assurance runs through every step of our process. From the moment your engine arrives at our facility, strict quality control measures guide every decision. We use precise measurements, conduct material testing, and perform comprehensive post-rebuild testing to ensure your engine meets or exceeds original manufacturer specifications.

Specialized Services Beyond the Standard Rebuild

While a complete engine rebuild addresses most issues, sometimes your marine diesel needs more targeted attention. Marine rebuild specialists often excel at specific services that can solve problems without a full rebuild.

Cylinder head repair deserves special attention because the cylinder head houses so many critical components. Valves, camshafts, and combustion chambers all live here, and damage from overheating or normal wear can devastate engine performance. Professional cylinder head services include resurfacing, valve seat replacement, guide repair, and pressure testing to eliminate leaks.

Lower unit rebuilds become essential for outboard marine diesels. These units take a beating – they’re constantly submerged and exposed to the harshest conditions your engine faces. A proper lower unit rebuild involves complete disassembly, thorough inspection, and replacement of gears, bearings, and seals to restore smooth power transfer.

Marine transmission rebuilding often costs half as much as buying new while ensuring your original unit fits perfectly back into your boat. The rebuild process includes complete disassembly, inspection, cleaning, and replacement of all seals, rings, and gaskets. Many professional shops offer substantial warranties on transmission rebuilds because they’re confident in their work.

When your transmission comes out for service, it’s the perfect time to address related components. Damper plates absorb engine vibrations that could damage your transmission. Oil coolers keep transmission fluid at optimal temperatures. Fresh hoses and fittings ensure the entire drivetrain system works together harmoniously.

Beyond engines and transmissions, marine diesel systems often include generators that need specialized attention. For comprehensive information about our generator services, visit our page on marine generator repair.

The Critical Role of OEM Parts in a Quality Rebuild

Here’s where many rebuild projects succeed or fail: the quality of replacement parts. When it comes to marine diesel rebuilds, Original Equipment Manufacturer (OEM) parts aren’t just preferred – they’re essential for a rebuild that will serve you well for years to come.

Ensuring proper fit might sound basic, but it’s absolutely critical. OEM parts are manufactured to exact specifications, guaranteeing perfect integration with existing components. This eliminates the guesswork and compatibility issues that plague aftermarket alternatives. When you’re dealing with the precision tolerances of modern marine diesels, “close enough” simply isn’t good enough.

Performance specifications matter enormously in marine applications. Using OEM parts ensures your rebuilt engine will deliver the power, efficiency, and reliability that the manufacturer designed into the original engine. There’s no compromise on the engineering integrity that makes your engine perform properly in demanding marine conditions.

Reliability and longevity become even more important when you’re miles from shore. OEM parts typically use superior materials and manufacturing processes, translating directly into improved reliability and longer engine life. The small additional cost of genuine parts pays dividends in reduced maintenance and fewer unexpected failures.

Manufacturer guidelines aren’t suggestions – they’re requirements for maintaining your engine’s integrity. Professional marine rebuild specialists follow these guidelines religiously, which includes using genuine OEM parts throughout the rebuild process. This adherence to manufacturer standards is often essential for any post-rebuild warranty coverage.

While aftermarket parts might tempt you with lower upfront costs, the potential risks to fit, performance, and durability can create much larger expenses down the road. Investing in genuine OEM parts is really an investment in your engine’s long-term health and your peace of mind on the water.

The Impact of Emissions Regulations and Maintenance

The world of marine engines has changed dramatically in recent years. Environmental regulations are tighter than ever, and boat owners are finding that staying compliant isn’t just about following rules – it’s about enjoying better performance and efficiency on the water.

At the same time, we’ve learned that the secret to getting the most from any marine diesel engine, whether rebuilt or brand new, lies in consistent, thoughtful maintenance. It’s like the difference between a weekend warrior and a seasoned captain – both might reach their destination, but one does it with far less stress and expense.

How Emissions Regulations Affect Your Decision

Modern emissions standards have fundamentally shifted how we think about marine engine choices. These aren’t just bureaucratic problems – they represent real opportunities to upgrade your boating experience while protecting the waters we all love to explore.

When you’re weighing rebuild versus repower options, emissions compliance becomes a major decision factor. Older marine diesel engines, even when perfectly rebuilt, may not meet current environmental standards. This matters especially if you operate in controlled waters or plan to sell your vessel down the line.

Today’s compliant engines offer remarkable advantages that go far beyond just meeting regulatory requirements. Better fuel efficiency tops the list – modern marine diesels are engineered for optimal combustion, which translates directly to more money in your pocket and fewer fuel stops during long cruises.

Advanced electronic controls represent another game-changer. These sophisticated systems provide precise tuning, real-time diagnostics, and performance optimization that older engines simply cannot match. Imagine having detailed engine data at your fingertips, helping you spot potential issues before they become expensive problems.

Quieter operation might be the most immediately noticeable improvement. New compliant engines run with significantly less noise and vibration, changing the on-board experience. Conversations become easier, and the overall comfort level increases dramatically.

For detailed guidance on navigating these regulations, manufacturers provide comprehensive resources like this Information on repower exhaust regulations to help boat owners make informed decisions.

The environmental benefits extend beyond just cleaner emissions. Even the rebuilding process itself contributes to sustainability by recycling and reusing major engine components, reducing waste and resource consumption. It’s a win-win approach that marine rebuild specialists have acceptd wholeheartedly.

The Contribution of Regular Maintenance to Engine Longevity

Here’s something we tell every boat owner: the most expensive marine diesel engine is the one that leaves you stranded. The best insurance against breakdowns isn’t just a quality rebuild or new engine – it’s consistent, proactive maintenance.

Preventative care forms the foundation of engine longevity. Regular oil changes, filter replacements, and fluid level checks might seem mundane, but they’re your engine’s daily vitamins. These simple tasks prevent the vast majority of serious problems we see in our shop.

Routine inspections catch problems early, often before you even notice symptoms. A trained eye can spot a loose belt, a weeping seal, or a corroded connection long before it causes a breakdown. We always tell our customers: it’s much cheaper to replace a $20 belt during routine maintenance than to rebuild an engine after that belt snaps and causes overheating.

Oil analysis provides incredible insights into your engine’s internal health. This laboratory testing can detect wear metals, contamination, and coolant leaks months before they become visible problems. It’s like having X-ray vision into your engine’s condition.

Cooling system maintenance deserves special attention in marine applications. Saltwater is incredibly corrosive, and overheating remains one of the leading causes of marine diesel engine failure. Regular coolant checks, heat exchanger cleaning, and system flushes are absolutely critical for engine survival.

The goal of all this maintenance work is simple: maximizing your time on the water. Every hour spent on routine care saves multiple hours in the repair yard later. As we always say, engines that receive regular professional attention run smoother, last longer, and give their owners far fewer headaches.

Professional maintenance also allows experienced technicians to troubleshoot future issues before they become emergencies. During routine service, we’re constantly looking for early warning signs – unusual wear patterns, slight temperature variations, or minor performance changes that could indicate developing problems.

The marine environment is unforgiving, but with proper maintenance, your diesel engine can provide decades of reliable service. Whether you choose to rebuild your current engine or repower with a new one, establishing a solid maintenance routine is the best investment you can make in your vessel’s future.

Conclusion

Navigating marine engines doesn’t have to feel overwhelming. Throughout this guide, we’ve walked through the essential decisions every boat owner faces when their engine starts showing signs of wear.

Rebuilding your existing engine makes perfect sense when you’re dealing with specific component failures and want to restore your trusted powerplant to its original glory. It’s often the most cost-effective path, especially for engines that have served you well but just need some mechanical attention. The comprehensive rebuild process we outlined – from careful disassembly to precision reassembly – can breathe new life into your marine diesel.

Repowering with a modern engine becomes the smarter choice when you’re looking at frequent breakdowns, obsolete parts, or simply want to accept the latest technology. 40% rule of thumb: if your rebuild costs approach nearly half the price of a new engine, it’s time to seriously consider repowering. The benefits go beyond just reliability – you’ll enjoy better fuel economy, quieter operation, and often improved performance that makes every day on the water more enjoyable.

What ties both options together is the critical importance of working with experienced marine rebuild specialists. The harsh marine environment – with its saltwater exposure, constant vibration, and high power demands – requires expertise that goes far beyond general mechanical knowledge. Our factory-trained technicians understand these unique challenges and have the specialized tools and knowledge to handle everything from cylinder head repairs to complete engine overhauls.

At Diesel Services of America, we’ve been helping South Florida boat owners make these important decisions for over two decades. Whether you’re dealing with a beloved older engine that deserves a careful rebuild or you’re ready to upgrade to the latest emissions-compliant technology, our Fort Lauderdale team brings the expertise and commitment to quality that your vessel deserves.

The key is not to wait until you’re stranded at sea or facing emergency repairs. Regular maintenance, early attention to warning signs, and thoughtful planning can keep you enjoying the water instead of worrying about your engine.

For expert consultation on your marine diesel engine needs, from routine maintenance to complete overhauls, contact our team today. We’re here to help you make the right choice for your vessel and get you back to what matters most – enjoying your time on the water.