Why Diesel Engine Optimization Matters for Marine and Industrial Operations

Diesel engine optimization services transform how your marine vessel or industrial equipment performs by fine-tuning engine software, upgrading critical components, and customizing calibration for your specific operational needs.

Core Optimization Services Include:

- ECM/ECU Tuning – Reprogramming the engine’s computer to optimize fuel delivery, timing, and boost pressure

- Performance Hardware Upgrades – Installing aftermarket turbochargers, intercoolers, fuel injectors, and exhaust systems

- Fuel System Optimization – Improving fuel delivery and combustion efficiency

- Custom Calibration – Tailoring engine parameters to your specific duty cycle

- Component Blueprinting – Restoring components to factory specs or better

Expected Results:

- Up to 71% less downtime

- 55%+ reduction in repair costs

- Up to 2.1 MPG better fuel efficiency

- Increased power and torque

- Extended engine longevity

For marine vessels and industrial diesel equipment in Southeast Florida and the Caribbean, downtime directly impacts your bottom line. Modern diesel engines rarely leave the factory optimized for a specific application, leaving significant performance and efficiency on the table.

Professional diesel engine optimization is a comprehensive approach combining advanced diagnostics, custom software calibration, and precision hardware upgrades by certified technicians. The result is an engine that runs cleaner, stronger, and more efficiently while reducing wear and tear. This guide covers what you need to know about diesel engine optimization for marine and industrial applications.

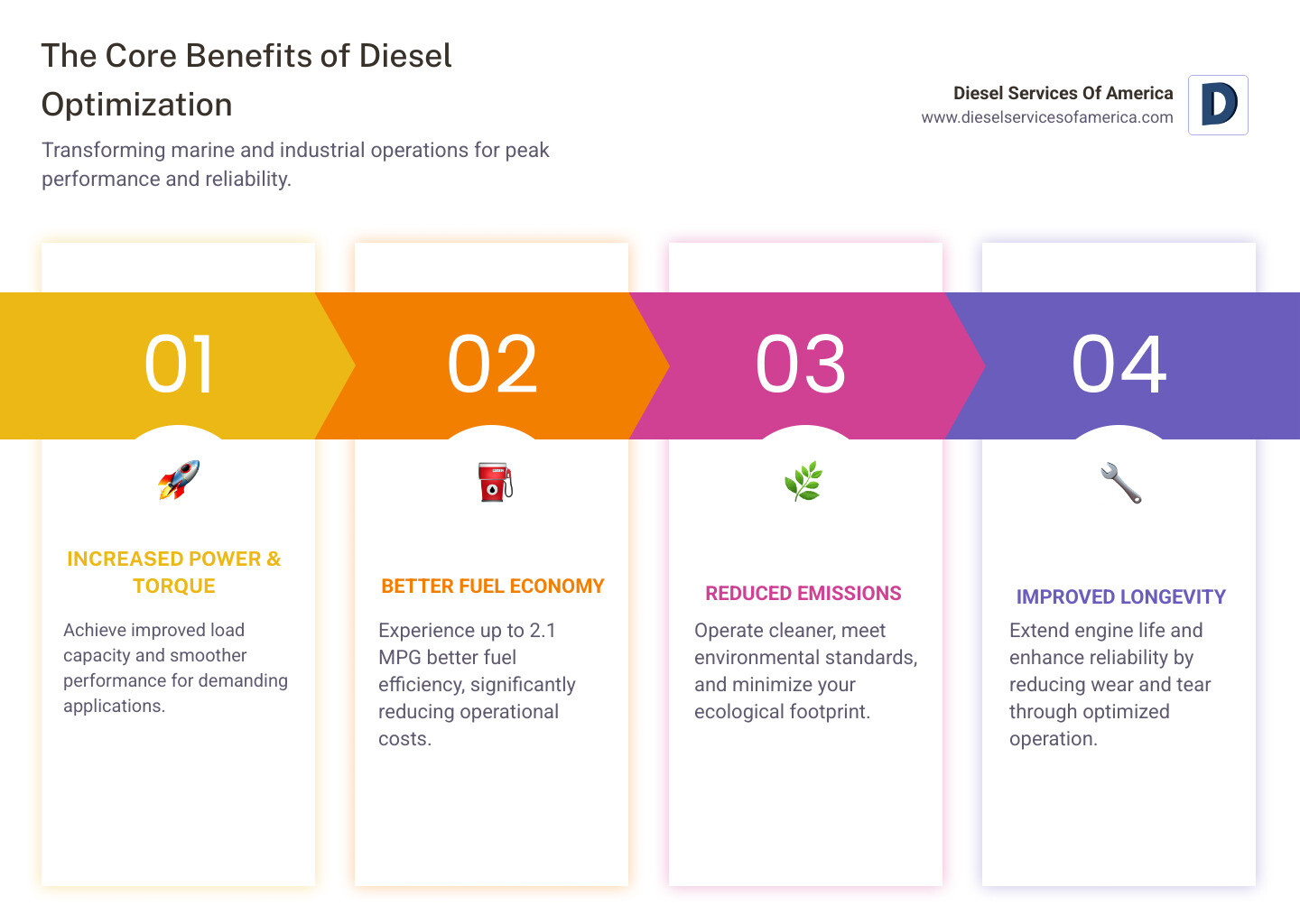

The Core Benefits: Why Optimize Your Marine or Industrial Diesel Engine?

Investing in professional diesel engine optimization services delivers tangible benefits that impact every corner of your operation. You’ll see increased power, lower fuel costs, longer engine life, and fewer breakdowns, all while meeting environmental standards. For operators in Southeast Florida and the Caribbean, these advantages directly translate to improved daily operations and annual profits.

Maximizing Power and Torque

Increased power and torque improve maneuverability in tight marina spaces and the ability to push through rough seas. You’ll notice smoother acceleration and improved load-carrying capacity. Industrial equipment also benefits, handling peak loads without strain. For example, a CAT C13 engine can be expertly calibrated to deliver up to 520 horsepower of reliable performance. Our Engine Power Enhanced with DSOA services focus on open uping this hidden potential within safe parameters.

Boosting Fuel Efficiency and Reducing Costs

Optimization proves its worth in fuel savings. Our clients regularly see efficiency improvements of up to 2.1 MPG. For a commercial fleet operating between Fort Lauderdale and the Caribbean, annual savings can exceed $36,000. Better fuel efficiency also extends your operational range, meaning more time working and less time refueling. Less fuel burned per hour equals more profit. Learn more about our Diesel Engine Fuel Efficiency services.

Improving Engine Longevity and Reliability

An optimized engine lasts longer. By operating within its optimal parameters, every component experiences less stress and wear. This balance helps prevent costly aftertreatment failures, with clients achieving up to 71% less downtime and over a 55% reduction in repair costs. Think of optimization as preventive medicine for your engines. Regular Diesel Engine Maintenance combined with proper calibration keeps small issues from becoming major problems. Understanding the Importance of Diesel Marine Engine Maintenance is crucial. When engines run cleaner and cooler, reliability becomes a certainty. Whether you need better Diesel Engine Performance or specific Marine Diesel Engine Performance, the principle is the same: engines perform best when perfectly dialed in.

Understanding the Spectrum of Diesel Engine Optimization Services

Diesel engine optimization services encompass a range of techniques, from sophisticated software calibration to precision hardware upgrades, designed to help your engine reach its full potential. For commercial vessels in Southeast Florida or industrial generators, the right combination of services can transform equipment performance. Our Diesel Engine Efficiency Improvements approach covers everything from ECM tuning to custom solutions for your exact operational profile.

The Brains of the Operation: The Role of the Electronic Control Module (ECM)

Every modern diesel engine’s brain is the Electronic Control Module (ECM). It constantly monitors sensors and adjusts key parameters like fuel injection timing, air-to-fuel ratios, and turbocharger boost pressure. Without a properly programmed ECM, even the best hardware upgrades won’t deliver their full potential. Using advanced Diesel Engine Diagnostic Tools, we communicate with the ECM to identify exactly where improvements can be made.

Basic ECU Tuning vs. Advanced Custom Calibration

Not all tuning is equal. Basic ECU remapping, or “chip tuning,” involves loading pre-made software maps. These generic solutions offer some improvement but don’t account for your engine’s unique history or operating conditions. Advanced custom calibration is a bespoke solution developed for your specific engine and its use. A marine vessel at cruising speed needs different optimization than an industrial generator at a constant load. Custom calibration begins with comprehensive diagnostics, leading to a custom “blueprint” that is implemented and verified through real-world testing, such as sea trials. This is true Performance Tuning that respects your engine’s limits while maximizing its output.

Beyond the Code: Hardware and Performance Upgrades

Software tuning is powerful, but sometimes an engine needs better hardware. Performance upgrades involve installing aftermarket components—like upgraded turbochargers, high-flow intercoolers, precision fuel injectors, and optimized exhaust systems—that improve physical capabilities. The magic happens when hardware upgrades are combined with custom tuning. An ECM calibrated to take advantage of a new turbocharger’s increased airflow yields remarkable gains in both power and efficiency. Quality Diesel Engine Parts matched with expert tuning create a reliable and efficient powerhouse for your application.

Key Components Addressed in Optimization

In diesel engine optimization services, every component must work in harmony. When software optimization meets precision hardware, performance soars. When repairs are needed, we use high-quality Diesel Engine Replacement Parts to keep your engine running strong.

Forced Induction Mastery: Turbocharger and Intercooler Optimization

A turbocharger uses exhaust gases to force more air into the combustion chambers, increasing power and fuel efficiency. Over time, especially in the harsh marine environment of Southeast Florida, performance can degrade. Turbo blueprinting, a precision machining process, restores or exceeds factory specifications by optimizing clearances. The results are reduced black smoke, increased horsepower, and improved throttle response. For even more power, we specialize in Diesel Turbo Installation and Services. The intercooler is also critical. It cools the hot, compressed air from the turbo, making it denser and more oxygen-rich for better combustion. Optimizing the intercooler is key to great performance. Learn How Does a Turbo Diesel Intercooler Work on our blog.

Precision Fueling: Injector and Fuel System Improvements

Fuel delivery is a critical aspect of diesel performance. Fuel injectors atomize diesel into a fine mist for efficient combustion. When injectors wear out, power drops and fuel economy suffers. Upgrading to high-performance injectors can transform an engine’s capabilities with more precise fuel delivery. The entire fuel system, including pumps and lines, must also support the engine’s improved performance. Our expertise in Diesel Engine Fuel systems ensures every component works together for results you can feel and measure.

Ignition and Support Systems

While diesels use compression ignition, glow plugs are vital for cold starts and smooth operation, preheating the combustion chambers. Worn glow plugs cause hard starting, rough idling, and white smoke. A Diesel Engine Glow Plug Replacement can solve these issues. Optimizing an engine for more power also generates more heat, making a robust cooling system essential. We ensure your cooling system can manage this increased thermal load, sometimes by upgrading components or performing routine maintenance like a Diesel Engine Coolant Flush. This comprehensive approach ensures every part works together to deliver the performance, efficiency, and reliability you demand.

The Optimization Process: From Diagnosis to Implementation

Diesel engine optimization services follow a proven, methodical approach for marine and industrial applications.

| Step | Description |

|---|---|

| 1. Diagnosis | Comprehensive assessment of current engine performance and health using advanced diagnostic tools. |

| 2. Consultation | Discussion of operational needs, desired outcomes, and potential solutions. |

| 3. Custom Blueprint | Development of a detailed optimization plan, including ECM calibration and hardware upgrades. |

| 4. Implementation | Expert execution of the optimization plan by certified technicians. |

| 5. Testing & Verification | Rigorous testing (e.g., sea trials, load testing) to confirm performance gains and reliability. |

Identifying the Need: Signs Your Engine Requires Attention

Your engine communicates when it needs help. Key signs to watch for include:

- Excessive smoke: Black smoke often indicates fuel system issues, while blue or white smoke can point to oil or water problems.

- Loss of power or RPMs: The engine struggles to reach cruising speed or hold its rated load.

- Increased fuel consumption: A sudden drop in efficiency often points to inefficient combustion.

- Hard starting or rough running: Suggests issues with glow plugs, fuel delivery, or compression.

- Frequent check engine lights: The ECM is signaling a problem that requires professional diagnosis.

Our Diesel Engine Inspection Checklist and The Ultimate Guide to Diesel Engine Repair Services offer more details.

The Professional Approach to Diesel Engine Optimization Services

Our process is comprehensive. We start with comprehensive diagnostics, using advanced tools to analyze thousands of data points from your ECM. Our proprietary ECM P.A.S.S. Audit then examines your engine’s real-world duty cycle to identify specific opportunities for improvement. Based on this data, we create a custom blueprint with precise fuel maps and parameters for your application. Expert implementation is handled by our factory-trained, certified technicians. Finally, verification through sea trials or load testing confirms the performance gains are real and reliable. This commitment to excellence defines our Diesel Engine Service.

Key Considerations and Potential Risks

Warranty concerns are common, but professional tuning from a reputable provider protects your warranty. We work within the engine’s designed capabilities using manufacturer-recommended parameters. Our solutions are CARB and EPA compliant and will not void manufacturer warranties. The danger of improper tuning is serious, potentially leading to catastrophic engine failure. Generic tunes don’t account for your engine’s specific condition or operating environment. Choosing a reputable provider with certified technicians and proper diagnostic equipment is critical. When considering any Diesel Engine Repair or optimization, expertise is everything.

Specialized Applications and Advanced Solutions

The demands on a generator in Fort Lauderdale are different from those on a yacht in the Caribbean, which is why diesel engine optimization services must be custom to the specific application.

Custom for the Task: Optimizing for Marine, Industrial, and Fleet Use

Optimization strategies vary by use case. For marine vessels, we focus on responsive power curves for maneuverability and sustained cruising efficiency. Our Marine Diesel Engine Services are built around these realities. For industrial generators, which run at constant speeds, optimization targets rock-solid reliability and maximum fuel economy. Our Diesel Engine Generator Maintenance approach emphasizes predictable performance. For fleet managers, the benefits multiply, with potential downtime reductions of up to 71% and maintenance cost savings over 55%.

Meeting Regulations with Smarter Diesel Engine Optimization Services

A common myth is that performance optimization compromises emissions compliance. In reality, professional optimization often makes engines run cleaner. By improving combustion efficiency, less unburnt fuel escapes as smoke, and fewer harmful particles are produced. Our solutions are 100% compliant with regulations from bodies like the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB). This is especially important in sensitive areas like Southeast Florida and the Caribbean. Our compliant Optimization Services deliver performance gains without environmental or legal headaches.

The Role of Fuel Science and Additives

Fuel quality directly impacts performance, efficiency, and longevity. High-quality fuel, combined with scientifically formulated additives, can clean injectors, prevent harmful deposits, and improve fuel lubricity. These solutions can restore lost power and improve cost-effectiveness by addressing issues like injector fouling. Regular oil analysis also helps inform the right fuel and additive strategy. Our guide on Oil Odyssey: Understanding Diesel Engine Health Through Oil Analysis explains this essential diagnostic tool. Quality fuel and smart additives are investments in your engine’s future.

Frequently Asked Questions about Diesel Engine Optimization

When considering diesel engine optimization services for your marine or industrial equipment, it’s natural to have questions. Here are answers to the ones we hear most often from our clients in Southeast Florida and the Caribbean.

How much power can I gain from engine tuning?

The exact power gain depends on your engine model, its condition, and its original factory tune. However, our focus is on delivering usable power and torque across the entire RPM range, not just a peak horsepower number. This translates to better real-world performance, like stronger acceleration for a marine vessel. That said, clients often see improvements of 10-20% in both horsepower and torque, especially when combining software optimization with hardware upgrades.

Will tuning my marine diesel engine void its warranty?

This is a primary concern, but the answer is no—when performed by certified professionals using manufacturer-approved parameters, optimization will not void your warranty. Our solutions are 100% CARB & EPA compliant and use the adjustment capabilities built into the engine by the manufacturer. We work within the engine’s safe design limits to deliver impressive results without compromising your warranty protection.

Is engine optimization just for high-performance applications?

Not at all. While we serve high-performance clients, a primary goal for most of our industrial and marine clients is improved fuel efficiency, reliability, and longevity. A commercial fishing vessel needs better fuel economy to reduce costs, while a backup generator needs improved reliability to ensure uninterrupted power. Our diesel engine optimization services are designed to make your engine work smarter, not just harder, leading to measurable reductions in operational costs and downtime for any application.

Conclusion: Your Partner in Peak Diesel Performance

For marine vessels in the Caribbean or industrial equipment in Southeast Florida, your diesel engines are the heartbeat of your operation. That’s why diesel engine optimization services are a fundamental investment in your success. The benefits are clear: up to 71% less downtime, repair costs cut by over 55%, and fuel efficiency gains of up to 2.1 MPG. These results represent real money saved and greater operational reliability.

True optimization requires factory-trained technicians, advanced diagnostic technology, and custom calibrations that match your specific duty cycle—not a generic, one-size-fits-all approach. Your engines deserve to be optimized for your world, your challenges, and your goals, all while staying compliant and preserving your warranty.

At Diesel Services of America, we are your partners in keeping your engines running stronger, cleaner, and more efficiently. Your engines have untapped potential for power, fuel economy, and longevity. All of this is within reach with the right partner.

Ready to see what your engines are truly capable of? Contact us today to schedule your expert diesel engine services and let’s open up peak performance for your operation.