Why Your Marine or Industrial Diesel Engine Cylinder Head Matters

Diesel engine cylinder head repair is a critical service that can restore power and prevent catastrophic engine failure in marine and industrial applications. Here’s what you need to know:

Quick Answer: Core Repair Services

- Crack Detection & Repair – Magnafluxing, pressure testing, stitching or welding

- Deck Resurfacing – Machining the head flat to ensure proper gasket seal

- Valve Work – Grinding, refacing, seat replacement, and guide installation

- Component Replacement – Injector tubes, cups, gaskets, and seals

- Testing & Quality Control – Pressure testing, vacuum testing, final inspection

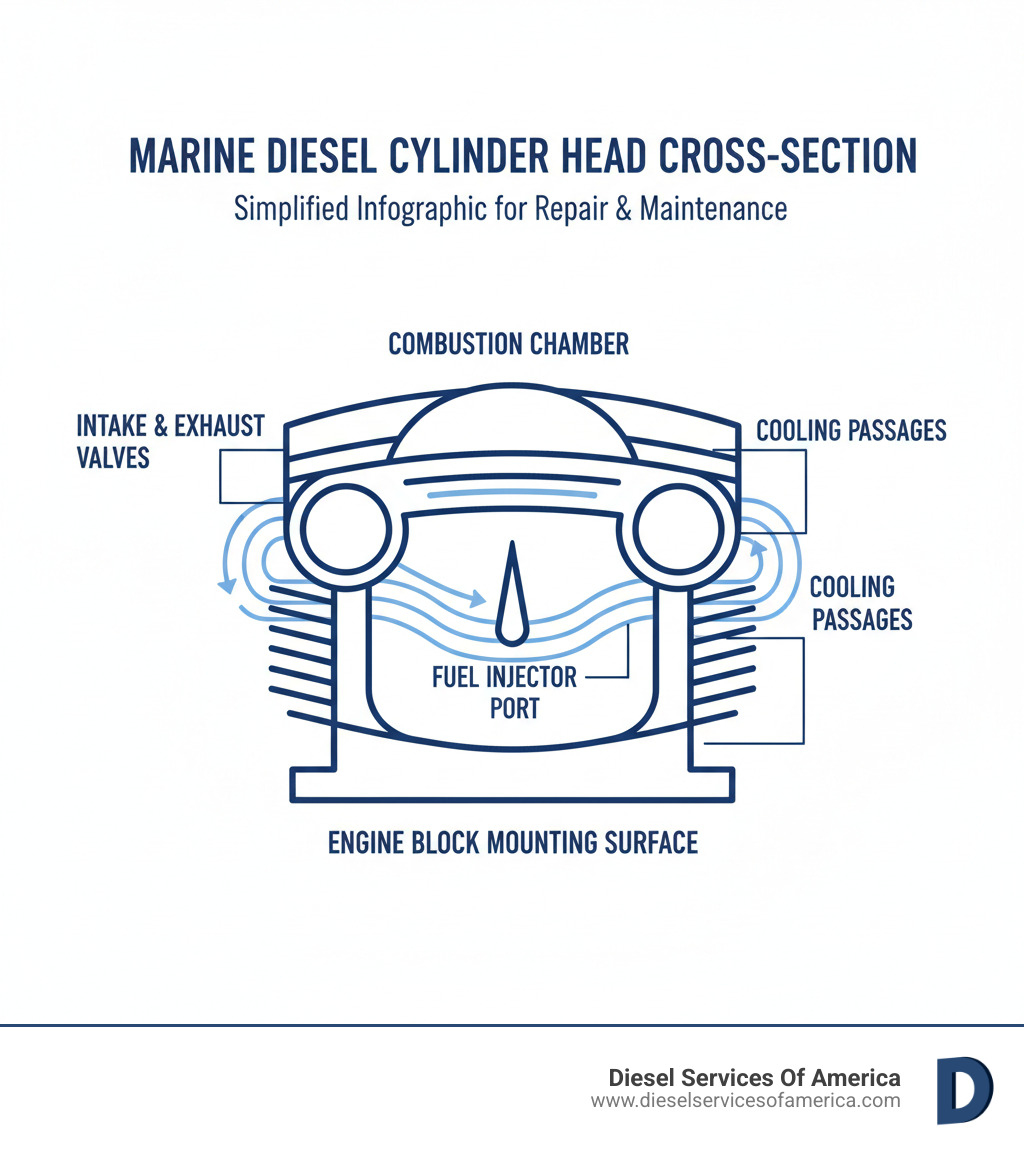

The cylinder head is the critical component that seals your combustion chamber. It controls air intake, fuel mixture, and exhaust gas removal – basically everything that makes your marine or industrial diesel engine run.

When it fails, you’re looking at overheating, coolant leaks, power loss, and potentially a destroyed engine block. That’s why fleet managers and boat owners in South Florida need to recognize the warning signs early.

With proper diagnosis and professional repair, most cylinder heads can be rebuilt to factory specifications. The average marine diesel engine runs 5,000 hours before needing major work, but with regular maintenance and timely repairs, some engines reach 8,000 hours or more.

Whether you’re running a commercial vessel in the Caribbean or managing power generation equipment, understanding the repair process helps you make informed decisions about rebuild versus replacement.

Diesel engine cylinder head repair terms to learn:

Is Your Cylinder Head Failing? Key Symptoms and Common Causes

Your marine or industrial diesel engine talks to you—you just need to know how to listen. When a cylinder head starts failing, it rarely happens without warning. The trick is catching those early signals before a minor issue becomes a major crisis that leaves your vessel dead in the water or shuts down your power generation system.

The most obvious red flag is engine overheating. When your temperature gauge climbs higher than normal, your cylinder head is literally being cooked from the inside. This excessive heat causes the metal to expand beyond its design limits, and when it cools back down, it doesn’t always return to its original shape. That’s when warping and cracking begin.

Coolant leaks are another telltale sign. Sometimes you’ll spot a puddle underneath your engine. Other times, the coolant just disappears without a trace—it’s leaking internally where you can’t see it. Either way, it’s bad news for your cylinder head.

Check your dipstick regularly. If your oil looks milky or discolored, that’s coolant mixing where it shouldn’t be. This contamination usually means the cylinder head or head gasket has developed a breach, allowing these fluids to mingle in ways that’ll damage your engine fast.

White smoke billowing from your exhaust isn’t always a cylinder head issue, but when it’s persistent, it often means coolant is sneaking into the combustion chamber and burning off. That’s a problem that won’t fix itself.

Pay attention to how your engine runs. Misfiring, rough idling, or a noticeable loss of power can all point to compression problems caused by a compromised cylinder head or valves that aren’t sealing properly anymore. Your engine should purr (well, as much as a big diesel can purr). If it’s stumbling or feels weak, something’s wrong.

Here’s a sneaky one: a pressurized cooling system even when the engine isn’t particularly hot. This usually means combustion gases are leaking into your coolant passages—a classic sign of head gasket failure or a cracked head. You might also notice your engine is burning more fuel or consuming oil faster than normal, especially if valve seals are worn.

Some symptoms are more dramatic. A popping noise from the intake or exhaust manifold often signals a bad valve or valve seat. And if you find contamination between fuel and coolant, drop everything and get professional help immediately. This serious condition, often caused by leaking injector cups or poor head casting, can destroy your entire engine.

The bottom line? Ignoring these warning signs leads to catastrophic engine failure, extended downtime, and repair bills that’ll make your eyes water. When you operate marine vessels in South Florida’s demanding conditions or manage critical industrial power generation, you can’t afford to let cylinder head problems slide.

Common Causes of Cylinder Head Damage

Understanding why cylinder heads fail helps you prevent it from happening again. In the marine and industrial world, engines don’t have it easy—they work hard, often in challenging environments.

Excessive heat is enemy number one. When your engine overheats, the cylinder head metal expands way beyond what the engineers intended. As it cools down, it shrinks unevenly, creating warps and cracks. Sometimes a single severe overheating event is all it takes to ruin a perfectly good cylinder head.

A blown head gasket doesn’t just cause leaks—it creates a domino effect. Escaping combustion gases cause localized hot spots, creating uneven thermal stress across the cylinder head. This uneven heating and cooling is a recipe for cracks. Plus, the mixing of coolant and oil that comes with a failed gasket causes its own set of problems.

Marine and industrial engines face stressful operating conditions that passenger car engines never see. Continuous heavy loads, sustained high RPMs, or running for hours on end without a break puts immense stress on the cylinder head. Over time, this constant punishment leads to metal fatigue and eventual failure.

When a head gasket fails, coolant displacement becomes a serious issue. Combustion gases push coolant out of the way, creating hot spots within the cylinder head that aren’t getting the cooling they desperately need. These areas experience rapid, severe thermal stress—and they crack.

Finally, metal expansion and warping from repeated heating and cooling cycles gradually takes its toll. This is especially true if your cooling system isn’t maintained properly or if thermostats stick. The cylinder head warps just enough that the head gasket can’t seal effectively anymore, and the whole cycle of problems begins.

Initial Diagnostic Checks

When your marine or industrial diesel engine shows symptoms of cylinder head trouble, guessing won’t cut it. Professional diagnosis is the foundation of effective diesel engine cylinder head repair.

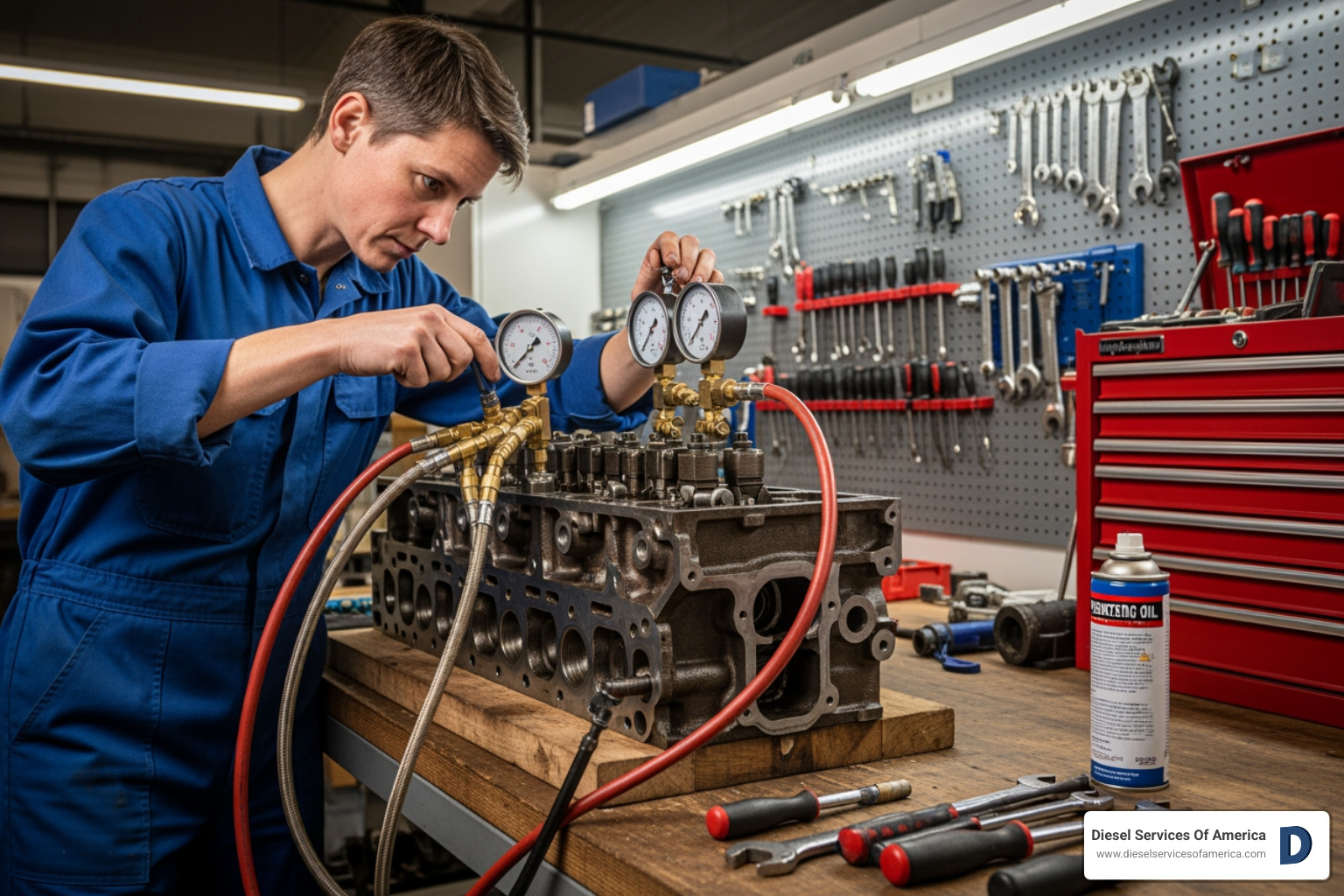

We start with a coolant system pressure test, which pressurizes your cooling system and watches for pressure drops. This quickly reveals leaks caused by a faulty head gasket or cracked cylinder head, even ones you can’t see with the naked eye.

Oil analysis done in a laboratory can detect even tiny amounts of coolant contamination in your engine oil, confirming internal leaks that might not be obvious otherwise. Meanwhile, a compression test measures the pressure in each cylinder, revealing worn valves, damaged piston rings, or a compromised cylinder head that’s preventing proper sealing.

Our technicians perform thorough visual inspections, carefully examining the cylinder head, block, and surrounding components for any signs of oil, fuel, or coolant leaks. Sometimes the evidence is right there on the surface, telling us exactly what’s going wrong.

But here’s what separates a good diagnosis from a great one: identifying the root cause. We don’t just find the damage—we figure out why it happened. If overheating caused your cylinder head to crack, we need to investigate your cooling system. If it’s a recurring problem, there’s an underlying issue that needs fixing, or you’ll be right back in the shop a few months down the road.

That’s the approach that keeps commercial vessels running reliably and industrial power generation systems online when you need them most.

The Professional Diesel Engine Cylinder Head Repair Process

When your marine or industrial engine needs attention, our team at Diesel Services Of America is here to help. We pride ourselves on a thorough and meticulous approach to diesel engine cylinder head repair. Our comprehensive services ensure that your cylinder head is restored to optimal condition, ready to tackle the demanding environments of marine and industrial applications.

You can trust us for expert services including precise valve grinding to restore proper shape and seal, careful deck resurfacing for a perfectly flat mating surface, and specialized injector tube replacement to prevent leaks and ensure optimal fuel delivery. We also handle valve seat replacement for superior valve sealing and performance. Every job begins with a thorough professional assessment by our factory-trained technicians, ensuring we know exactly what your engine needs.

Step 1: Diagnosis, Disassembly, and Cleaning

The diesel engine cylinder head repair process begins long before any tools touch the component. It’s all about thoroughness from the start.

First, our factory-trained technicians perform a detailed visual inspection. This helps us spot any obvious cracks, damage, or signs of wear that might need extra attention. After this initial check, the cylinder head is completely disassembled. All components – like valves, springs, retainers, and seals – are carefully removed and carefully labeled. This makes sure everything goes back exactly where it belongs later!

Next, the cylinder head casting gets a deep clean. It’s immersed in a specialized hot tank solution. This process thoroughly strips away stubborn carbon deposits, grease, oil, and other contaminants. This crucial cleaning step is vital because it allows us to perform a much more accurate inspection afterward. Depending on the cylinder head’s material and condition, we might also use soda blasting or glass beading for an even finer, more precise cleaning, ensuring all surfaces are free from any lingering residue.

Step 2: Crack Detection and Integrity Testing for a Diesel Engine Cylinder Head Repair

Once your cylinder head is sparkling clean, the real detective work begins. This is where we carefully test for any hidden flaws, which is a critical phase for effective diesel engine cylinder head repair.

For cast iron cylinder heads, we use Magnafluxing. This magnetic particle inspection technique can detect even microscopic surface and subsurface cracks that are invisible to the naked eye. It’s an essential step to ensure no hidden issues are missed.

Then, we perform pressure testing. The cylinder head is pressurized with air while submerged in water. This allows us to identify internal gallery cracks or leaks in the fuel injection tubes and cups. This test is crucial for ruling out internal coolant or oil leaks that might otherwise go unnoticed and cause problems down the line. We also conduct vacuum testing to confirm the complete seal of the valves and valve seats after our initial inspections. We pay particular attention to areas prone to cracking, such as between valve seats, which are common failure points due to the intense thermal stress they endure.

Step 3: Machining, Resurfacing, and Component Restoration

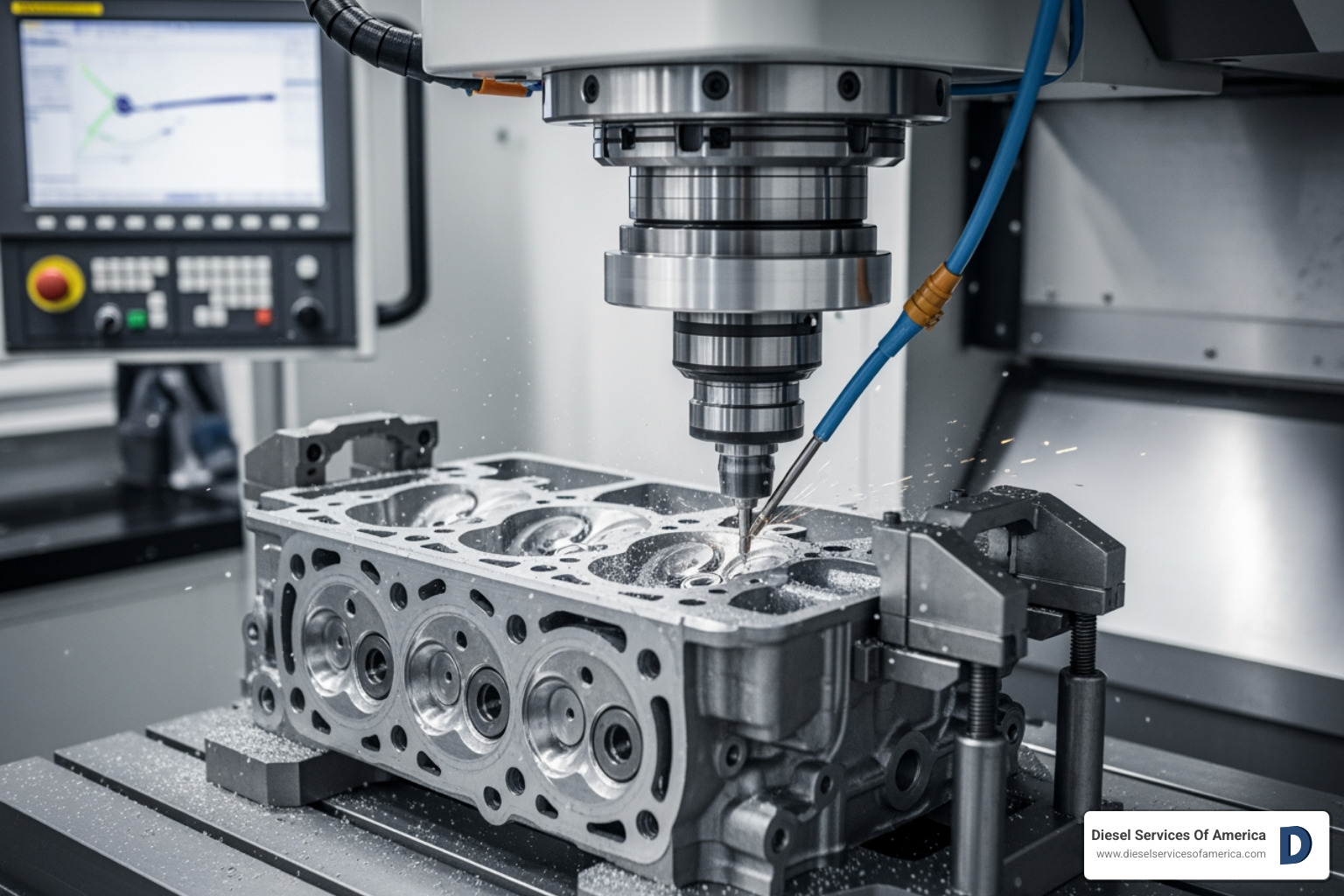

With any cracks addressed and integrity confirmed, it’s time for precision work. Precision machining is truly at the heart of effective diesel engine cylinder head repair, as it restores critical tolerances and surfaces to like-new condition.

We use advanced CNC machining to precisely resurface the deck of the cylinder head. This ensures it’s perfectly flat and true, which is absolutely vital for a proper, leak-free seal with the engine block and head gasket. If needed, we also resurface the manifold sides.

Worn valves are refaced (ground) using specialized equipment to restore their proper geometry, ensuring a complete seal when closed. Similarly, worn valve seats are precisely machined, often using sophisticated 3-angle cutters. This guarantees optimal concentricity and contact width with the refaced valves, significantly improving your engine’s efficiency and compression. If necessary, worn valve guides are replaced to ensure proper valve alignment and reduce oil consumption. Throughout this entire process, all critical measurements are rigorously compared against Original Equipment Manufacturer (OEM) specifications to ensure your cylinder head performs exactly as it was designed.

Find more info about our comprehensive engine services here.

Step 4: Specialized Repairs and Reassembly for a Diesel Engine Cylinder Head Repair

Sometimes, a cylinder head needs a little more than just standard machining. Our expertise extends to these specialized repairs and the meticulous reassembly that follows.

While simple welding isn’t always the best solution for complex cracks, some can be repaired using highly specialized crack repair methods like stitching or intricate welding techniques. The success of these repairs depends heavily on the crack’s location, size, and the cylinder head material. It’s often a much more involved process than many might think, and we approach it with extreme care. Another common specialized repair is injector tube and cup replacement, which is crucial for preventing fuel-coolant contamination and ensuring proper fuel atomization in your marine or industrial engine.

Once all repairs, machining, and component replacements are complete, the cylinder head is carefully reassembled with new valve seals, springs, and any other necessary components. We then perform a precise valve lash adjustment to ensure optimal valve timing and engine performance. Finally, before the cylinder head ever leaves our facility, it undergoes a final battery of quality control checks, including further vacuum testing, to absolutely guarantee its integrity and readiness for installation back into your hard-working diesel engine.

Rebuild or Replace? Making the Right Decision for Your Engine

Alright, so you’ve got a cylinder head problem. Now comes the big question: do we fix it up, or is it time for a brand-new one? This is a really important decision for anyone running a marine vessel or industrial equipment. It’s not just about money; it’s about how long your engine will reliably serve you and how much downtime you can afford.

Our expert technicians at Diesel Services Of America are here to help you weigh all the options. We’ll look closely at your specific cylinder head, your operational needs, and help you decide if a diesel engine cylinder head repair (a rebuild) is the smart move, or if replacement makes more sense in the long run.

Here’s a quick comparison to help you understand the core differences when making this choice with Diesel Services Of America:

| Feature | Rebuilding a Cylinder Head (Repair) | Replacing a Cylinder Head (New or Remanufactured) |

|---|---|---|

| Cost-effectiveness | Generally more cost-effective for minor to moderate damage. | Higher initial investment, but can be more cost-effective long-term for severe damage. |

| Turnaround time | Can be quicker if parts are readily available and damage is minor. | Potentially faster if a new/remanufactured head is in stock, but can vary. |

| Engine lifespan | Extends engine life significantly when core components are sound and repairs are done to OEM specs. | Maximizes engine lifespan and reliability, essentially giving your engine a fresh start. |

| Severity of damage | Ideal for minor warping, repairable cracks, and worn valve components. | Necessary for severe cracks, extensive corrosion, or damage beyond repair limits. |

| Cracked engine block | Not directly related, but a new head might be considered if the block is also compromised (rarely). | Prevents further damage to the engine block by ensuring a perfect seal and integrity. |

When to Rebuild Your Cylinder Head

A diesel engine cylinder head repair (rebuild) is often a fantastic option, especially when the core of your cylinder head is still solid. Think of it like giving a good engine a new lease on life. It’s usually the more cost-effective choice and can significantly extend your engine’s life without breaking the bank.

We typically recommend a rebuild when we see things like minor warping, repairable cracks that aren’t too severe, or just worn valve components. If the head hasn’t suffered catastrophic damage and its main structure is sound, rebuilding can save you money and get you back to work or out on the water faster.

When Replacement is Necessary

Sometimes, though, even the best repair efforts just aren’t enough. There are times when replacing the cylinder head completely is the only way to ensure long-term reliability. This usually comes into play when we find severe cracks that are too deep or in critical areas, or if there’s extensive corrosion that has compromised the head’s structure.

Another key factor is if the head has been machined too many times and has reached its minimum thickness, making it unsafe for further use. Also, if warping is beyond repair limits, a new head is the safer bet. While it’s a bigger upfront investment, a new cylinder head ensures maximum performance and peace of mind, especially when the integrity of your entire engine (and potentially preventing a cracked engine block) is on the line.