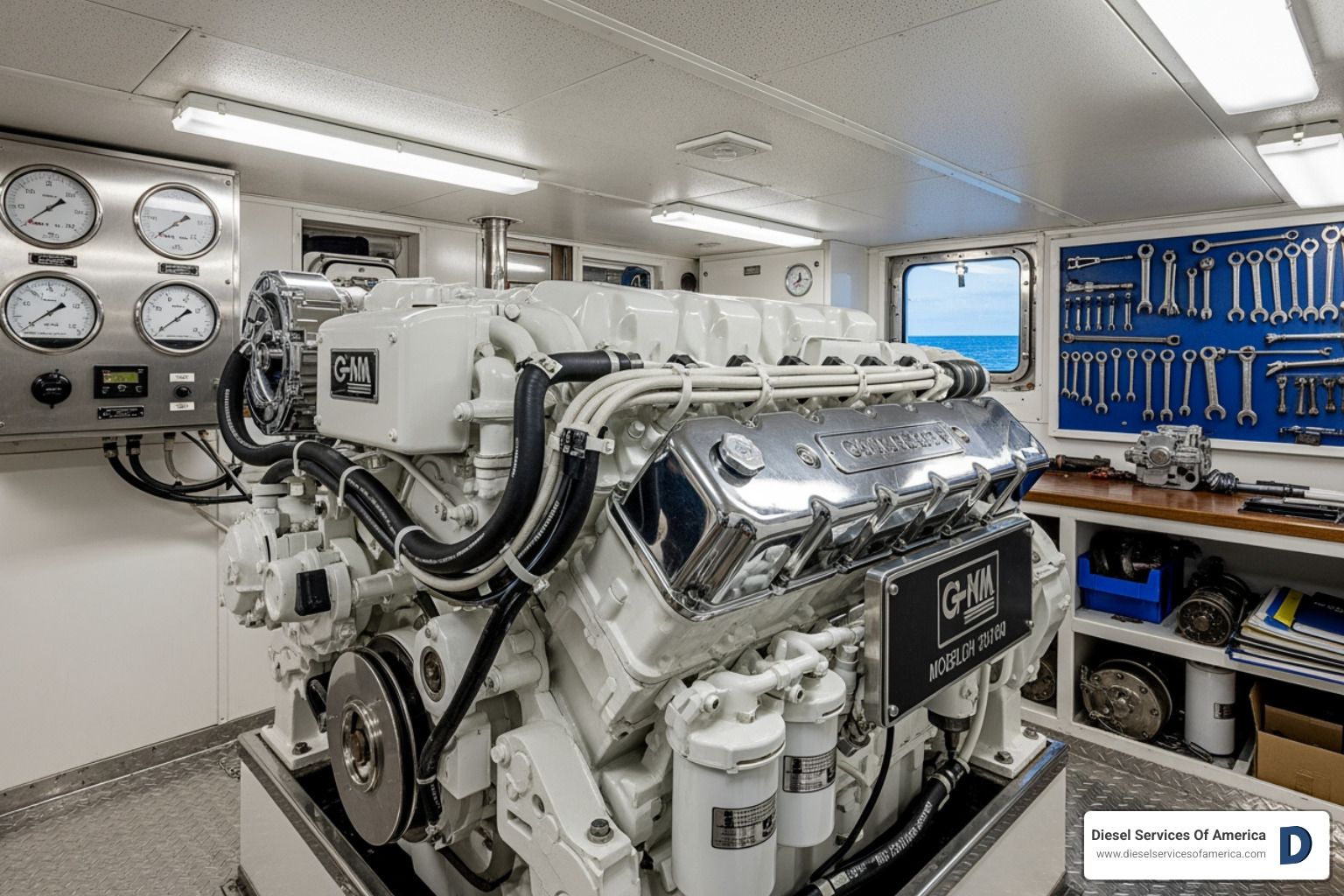

Why Understanding Diesel Engine Components Matters for Marine Operations

Diesel engine components work together in a precise system to convert fuel into reliable power for your vessel or industrial equipment. Whether you’re managing a fleet in the Caribbean or a single boat in South Florida, knowing your engine helps you catch problems early and make smarter maintenance decisions.

Key Diesel Engine Components:

- Core Mechanical Parts – Engine block, pistons, crankshaft, connecting rods, cylinder head, camshaft, and valvetrain

- Fuel Injection System – Fuel pumps, filters, high-pressure lines, and injectors

- Air Intake System – Air filters, turbocharger (compressor and turbine), and intercooler

- Exhaust System – Exhaust manifold, valves, and components that drive the turbocharger

- Support Systems – Lubrication system (oil pump, filter, cooler) and cooling system (heat exchanger, coolant pump, thermostat)

Diesel engines have powered marine vessels since 1903. They convert chemical energy into mechanical energy through compression ignition—air inside the cylinder is compressed to just 6% of its original volume, heating it over 1,000°F. When fuel sprays into this superheated air, it ignites instantly without spark plugs.

This fundamental process, invented by Rudolf Diesel, remains, but modern marine and industrial diesels are far more sophisticated, with turbochargers spinning at up to 250,000 rpm and high-pressure fuel injection systems. Understanding these components is the foundation for preventing costly breakdowns and extending your engine’s service life.

The Heart of the Machine: Core Mechanical Components

Every marine or industrial diesel engine is built around heavy-duty mechanical parts that turn fuel into power. These diesel engine components face extreme temperatures, pressures, and constant motion. Understanding them highlights why proper maintenance is critical.

The engine block is the foundation, a massive casting of cast iron or compacted graphite iron that houses the cylinders. It’s the structural backbone supporting every other component. Inside the block, replaceable cylinder liners take the brunt of heat and wear, protecting the block itself.

Inside each cylinder, pistons move up and down with tremendous force. Modern marine diesel pistons often have combustion chambers designed to help fuel burn efficiently. Piston rings create an airtight seal against the cylinder wall, keeping combustion gases in and oil out of the combustion chamber.

Connecting rods link each piston to the crankshaft, transferring the up-and-down motion into rotation. Bolted to the crankshaft, the flywheel is a heavy spinning disc that smooths out power delivery and stores rotational energy between power strokes.

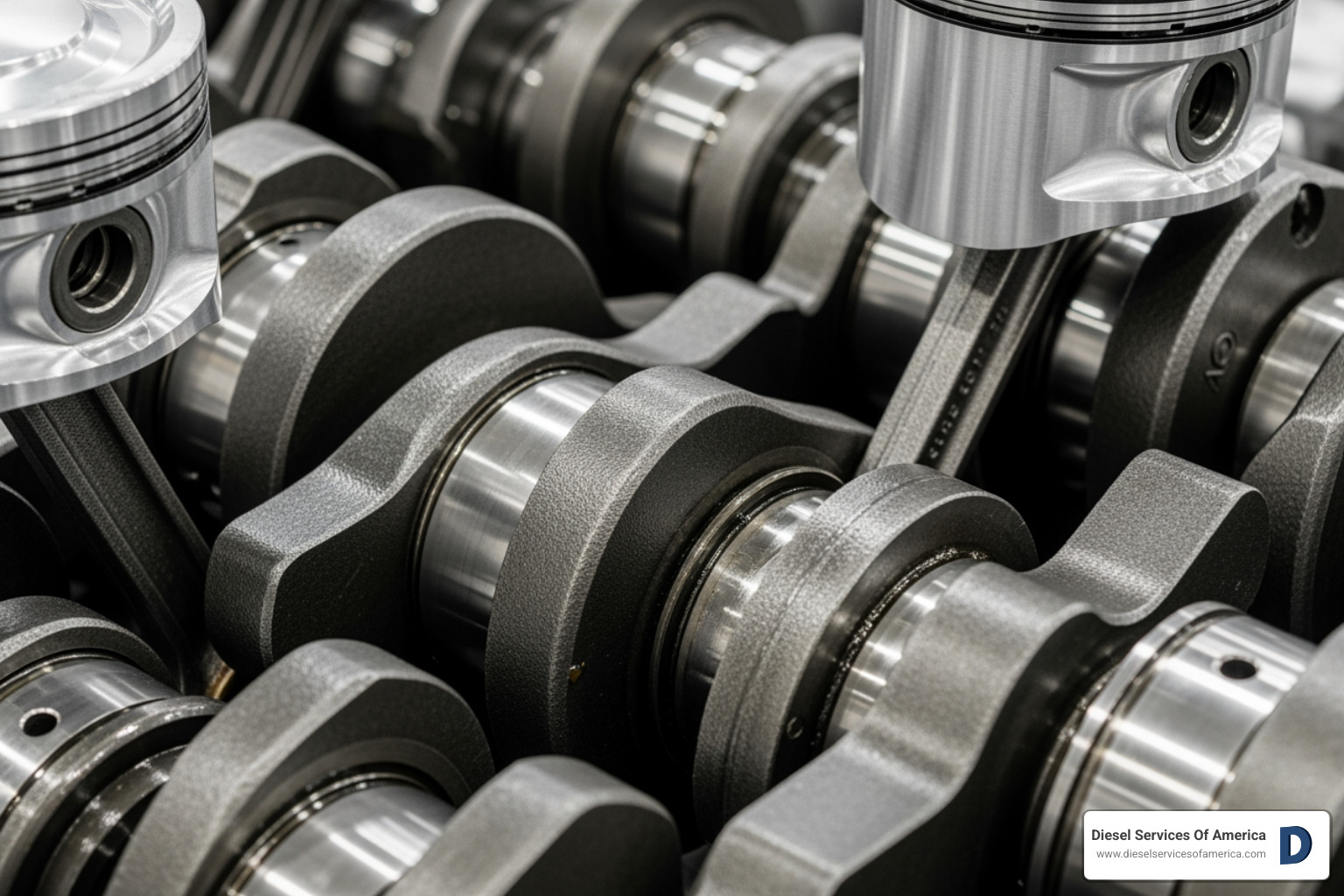

The Rotating Assembly: Creating Power

The rotating assembly converts explosive combustion into the steady rotational power that drives your propeller or generator. At its center is the crankshaft, one of the engine’s most precisely engineered parts.

The crankshaft converts the reciprocating (up-and-down) motion from the pistons into rotation. As pistons fire in sequence, they push the crankshaft around in a continuous circle. This occurs inside the crankcase, which houses the crankshaft and directs oil for lubrication. The crankshaft spins on precisely machined bearings made from special alloys to handle enormous loads with minimal friction. Thrust washers control side-to-side movement, keeping the crankshaft centered.

In marine applications, these components face brutal conditions, making crankshaft damage a serious issue. If you suspect problems, our Diesel Engine Crankshaft Repair services can diagnose and fix the issue before it becomes catastrophic. For a deeper dive, check out More about diesel engine fundamentals.

The Valvetrain: Breathing and Exhausting

The valvetrain controls the engine’s breathing with split-second precision. Fresh air enters, combustion occurs, and exhaust gases exit before the next cycle. If timing is off by even a few degrees, performance suffers.

The cylinder head bolts to the engine block, sealing the cylinders. This complex casting houses the intake and exhaust valves, provides passages for air and exhaust, and often holds the fuel injectors. Between the block and head, the head gasket is a critical seal preventing compression loss and the mixing of coolant, oil, and gases.

The camshaft, driven by the crankshaft, is the conductor. Its lobes push against pushrods and rocker arms, which open the valves at the exact moment. Valve springs snap the valves shut, creating a tight seal.

Timing is everything. The intake valve opens for air, seals for compression and combustion, and then the exhaust valve opens to release spent gases. This dance happens thousands of times per minute. If timing drifts, you’ll notice reduced power, rough running, or increased fuel consumption. That’s why proper Diesel Engine Timing Adjustment is so critical. Our factory-trained technicians have the specialized tools to ensure your valvetrain operates with the precision your diesel demands.

Power and Precision: Fuel, Air, and Exhaust Systems

While mechanical components provide the foundation, the fuel, air, and exhaust systems bring your diesel engine to life. These diesel engine components orchestrate a timed dance of delivery, compression, combustion, and expulsion. Understanding these systems helps you recognize problems before they become expensive failures.

The Fuel Injection System

The diesel fuel injection system atomizes fuel for efficient combustion. The journey begins in the fuel tank. A fuel pump draws fuel forward through fuel filters that catch contaminants. Quality filtration is vital, as even a speck of dirt can ruin a precision injector.

The fuel then enters a high-pressure pump, which pressurizes it to over 30,000 psi. This high-pressure fuel travels through high-pressure fuel lines to the fuel injectors. The injectors atomize the fuel into a microscopic mist, spraying it directly into the superheated, compressed air inside each cylinder.

This atomization is key to diesel efficiency; a finer spray means more complete combustion. This is why injection pressures have climbed dramatically in modern marine diesels. Understanding your Diesel Engine Fuel system and maintaining it prevents most performance issues.

The Air Intake and Turbocharger System

Your engine needs roughly 14 parts of air for every part of fuel. The air intake system starts with air filters that keep salt spray, dust, and contaminants out of the engine—critical protection in the marine environment.

Atmospheric pressure alone can’t supply enough air for high power. The turbocharger solves this by using exhaust gas energy. A turbo has two wheels on a shaft: the turbine wheel in the exhaust stream and the compressor wheel in the intake. As exhaust spins the turbine, the compressor crams fresh air into the engine at speeds from 80,000 to 250,000 rpm.

This forced induction, or boost pressure, packs more air into each cylinder. Marine diesels typically operate at 25-35 psi of boost. More air allows more fuel to be burned, creating more power.

Compressing air heats it, which is where the intercooler comes in. This heat exchanger cools the compressed air, making it denser and allowing even more oxygen into each cylinder. If you’ve wondered How Does a Turbo Diesel Intercooler Work?, it’s essentially a radiator for your intake air. For specifics, see our guide on Marine Diesel Turbocharger systems.

The Exhaust System

After combustion, spent gases must exit efficiently. The exhaust system handles this final stage.

As the power stroke completes, exhaust valves open, and hot gases rush into the exhaust manifold. This manifold collects exhaust from all cylinders. In turbocharged engines, these gases then drive the turbine side of the turbocharger, harvesting energy that would otherwise be wasted. After the turbo, the gases flow through a muffler or silencer to reduce noise.

The exhaust system is also crucial for heat management. It safely channels gases exceeding 1,200°F away from sensitive components. All these Marine Diesel Engine Parts work together for efficient operation and long service life.

Essential Support Systems for Diesel Engine Components

Your engine’s power-generating components would self-destruct in minutes without two critical support systems. The lubrication and cooling systems are the unsung heroes that keep your marine or industrial diesel running strong. One keeps parts moving smoothly while removing heat and contaminants; the other prevents the entire assembly from melting down.

Lubrication System

Without proper lubrication, the high-speed, high-pressure metal surfaces inside your engine would quickly fail. The lubrication system prevents this.

It starts at the oil sump (or oil pan), a reservoir holding the engine’s oil. An oil pump creates 40-70 psi of pressure, pushing oil through passages in the engine block and cylinder head. This pressurized lubrication delivers a microscopic film of oil to every critical surface: crankshaft bearings, connecting rod bearings, camshaft lobes, and more. This film reduces friction by up to 90% compared to dry metal contact.

Oil also acts as a coolant, carrying heat from areas like piston crowns that the main cooling system can’t reach. An oil cooler, a small heat exchanger, removes this heat before the oil returns to the sump. The oil filter catches metal particles and contaminants. On marine and industrial diesels, these filters are robust, as filter failure can have serious consequences offshore.

Marine Cooling System

A diesel engine converts about 40% of fuel energy into work; the other 60% becomes heat that must be removed. Without effective cooling, diesel engine components warp, gaskets fail, and pistons seize.

Marine cooling systems use a two-circuit design to handle massive heat loads in a corrosive saltwater environment.

The freshwater circuit is a closed loop of coolant (water and antifreeze). A coolant pump circulates this mix through the engine block and cylinder head, absorbing heat. This hot coolant then flows to the heat exchanger.

The seawater circuit handles heat rejection. A pump draws raw water from outside the vessel, pushes it through the heat exchanger to absorb heat from the freshwater circuit, and discharges the warm seawater overboard. This design keeps corrosive salt water out of the engine block.

A thermostat regulates coolant flow to maintain an optimal operating temperature, typically 160°F to 190°F. Running too cool reduces efficiency, while running too hot risks catastrophic failure. Proper maintenance of your Raw Water Cooling Systems is essential, especially in South Florida and the Caribbean. Components like pumps, heat exchangers, and zinc anodes need regular inspection to prevent costly failures.

Diagnosing Common Issues with Diesel Engine Components

Your marine or industrial diesel engine communicates through subtle changes in vibration, sound, or smoke. Catching these early warnings can be the difference between a quick fix and a catastrophic failure.

Recognizing Signs of Component Failure

Pay attention to these common symptoms of engine trouble.

Vibration: An increase in vibration can point to an imbalance in the rotating assembly, worn engine mounts, or a misfiring cylinder. Our Diesel Engine Vibration Analysis service can pinpoint the cause before it worsens.

Unusual noises: A knocking sound often signals issues with fuel injection timing or worn bearings. Squealing may indicate belt problems, while grinding sounds always signal a serious issue.

Performance loss: A sluggish feel, failure to reach normal RPMs, or increased fuel consumption often means compromised engine efficiency. This could stem from worn injectors, a failing turbocharger, or a restricted air intake.

Exhaust smoke analysis: The color of your exhaust is a diagnostic tool.

- Black smoke typically means a fuel issue—too much fuel or not enough air, often from faulty injector pumps or a clogged air filter.

- White smoke is usually water or coolant vaporizing in the combustion chamber, suggesting a blown head gasket or cracked cylinder head. It can also indicate unburnt fuel on cold starts.

- Blue smoke is the telltale sign of burning oil, likely from worn piston rings, valve seals, or turbocharger seals.

Engine knocking: This metallic rattling sound is concerning and often indicates problems with combustion timing or excessive wear in critical diesel engine components.

Overheating: An overheating engine is an emergency. Causes include a faulty thermostat, a clogged heat exchanger, low coolant, or a failing raw water pump. It demands immediate attention to prevent self-destruction.

The Importance of Professional Service

Modern marine and industrial diesels are sophisticated machines that require professional expertise. When your livelihood or safety depends on your engine, professional service is a necessity.

Our factory-trained technicians understand the intricate relationships between all diesel engine components. They have the specialized diagnostic tools and experience to distinguish symptoms from root causes. For example, high-pressure fuel systems and turbochargers demand precision tools and deep expertise. A misdiagnosis can lead to unnecessary repairs and further damage.

Quality parts are as important as quality service. Substandard components can fail prematurely and damage your engine. Our Diesel Engine Parts Sourcing Guide explains why genuine parts are crucial for longevity.

For commercial vessels or industrial power generation, the cost of downtime far exceeds the investment in professional service. Our team serves Fort Lauderdale and the Caribbean, offering dockside service to minimize downtime. For a guide to professional service, see The Ultimate Guide to Diesel Engine Repair Services. Trust experts to keep your engine running strong.

Frequently Asked Questions about Marine Diesel Engines

We’ve worked on marine and industrial diesels for years, and our clients in South Florida and the Caribbean often ask the same great questions. Here are the answers to the most common ones.

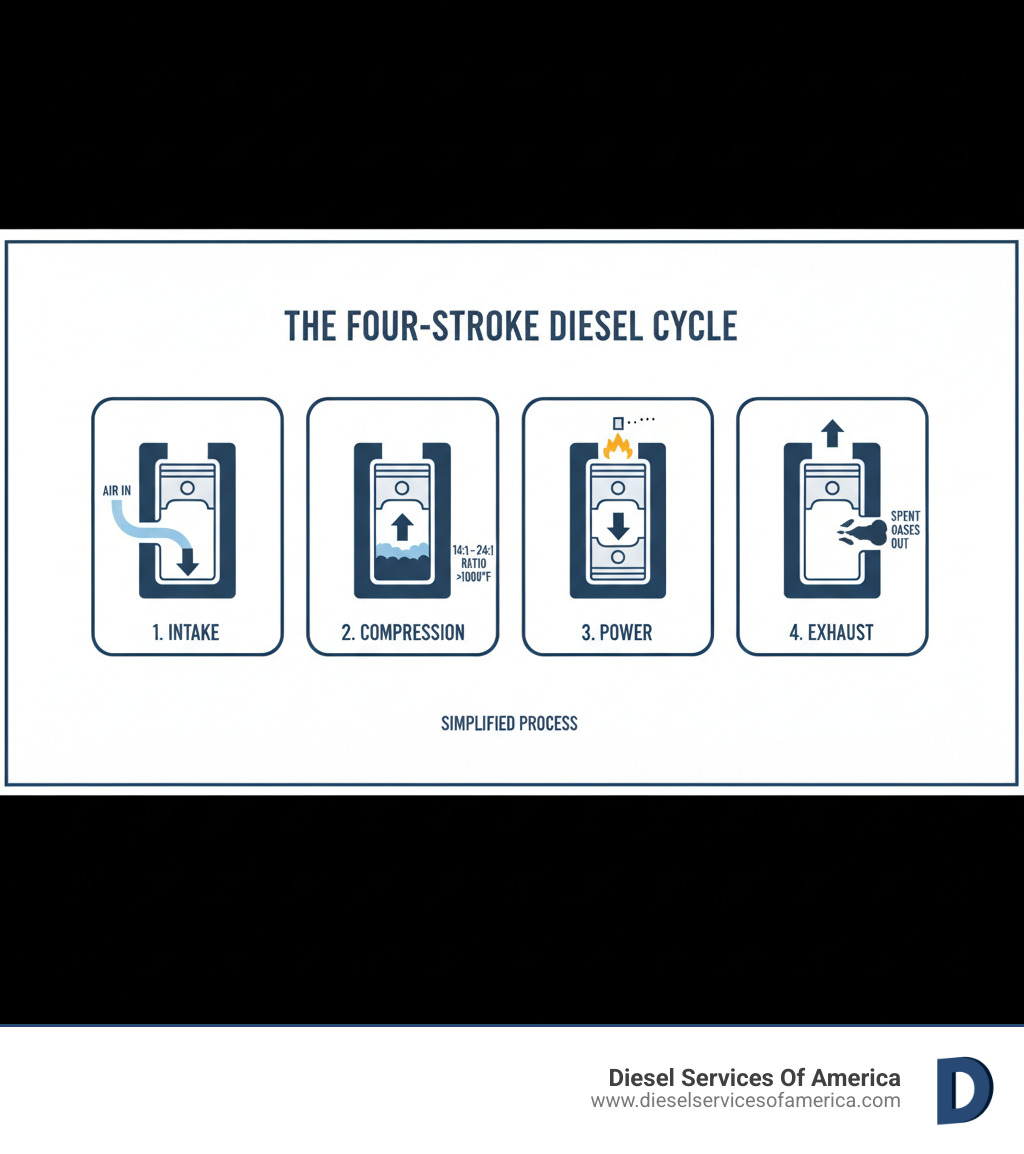

What’s the difference between 2-stroke and 4-stroke marine diesels?

The fundamental difference is the number of piston strokes per combustion cycle.

In a 4-stroke engine, you get the whole show in four distinct acts: intake, compression, power, and exhaust. The crankshaft makes two complete rotations (720 degrees) to finish one cycle. These engines are what you’ll find in most marine and industrial applications. They’re known for better fuel efficiency and cleaner operation, though they do tend to be larger and heavier for the same power output.

2-stroke engines are the speed demons of the diesel world. They complete their combustion cycle in just two strokes—one full crankshaft rotation. Instead of having separate intake and exhaust strokes, they combine these functions through a clever process called uniflow scavenging. Fresh air enters through ports at the bottom of the cylinder and pushes exhaust gases out through valves in the head. This design makes them remarkably compact and powerful for their size, which is why you’ll see them powering massive cargo ships and large marine vessels where space is at a premium.

| Feature | 4-Stroke Engine | 2-Stroke Engine |

|---|---|---|

| Cycle Completion | 4 strokes (Intake, Compression, Power, Exhaust) | 2 strokes (combined functions) |

| Crankshaft Rotations | 2 full rotations (720°) per cycle | 1 rotation (360°) per cycle |

| Size & Weight | Heavier and larger for equivalent power | Lighter and more compact |

| Efficiency | Generally better fuel economy | High power density, but less efficient |

| Complexity | More complex valvetrain with camshafts | Simpler design with fewer moving parts |

| Typical Applications | Most marine vessels, industrial generators | Large marine propulsion systems |

Why are diesel engines heavier than gasoline engines?

Diesel engines are heavier due to their much higher compression ratios—typically 14:1 to 24:1, compared to a gasoline engine’s 10:1. This extreme compression generates the intense heat (over 1,000°F) needed for compression ignition.

This process requires incredibly robust construction. The diesel engine components must be built to handle forces that would destroy a lighter gasoline engine. This includes reinforced cast-iron engine blocks, heavy-duty crankshafts, and beefier connecting rods. This rugged construction is what gives diesel engines their legendary durability and high torque output, essential for marine propulsion and industrial power.

How is speed controlled on a large diesel engine?

Unlike gasoline engines, diesels don’t use a throttle plate; they always draw in a full charge of air. Speed is controlled by regulating the amount of fuel injected.

This is handled by a device called a governor, which acts as the engine’s automatic cruise control. The governor’s job is to maintain a constant RPM as the engine’s load changes. If the engine slows under increased load (e.g., rough seas), the governor senses the speed drop and increases fuel delivery via the fuel rack. When the load decreases, it cuts back fuel to prevent overspeeding. This system, whether mechanical or electronic, is critical for stable propulsion and consistent power generation.

Keep Your Engine Running Strong with Expert Care

We’ve journeyed through the core diesel engine components—from the massive crankshaft to the precision fuel injectors and vital cooling systems. Understanding these parts is about recognizing when something is wrong, knowing why maintenance matters, and trusting the right people to keep your engine reliable.

Marine and industrial diesel engines are built to last for decades under punishing conditions like constant vibration, salt spray, and 24/7 operation. But even the toughest engine needs expert care.

At Diesel Services of America, we believe your engine’s reliability is our responsibility. Our factory-trained technicians don’t just fix problems; they understand the why behind every symptom. We have the specialized tools, genuine parts, and experience that comes from years of working exclusively on marine and industrial diesels throughout Fort Lauderdale, Southeast Florida, and the Caribbean.

Whether you run a commercial vessel, manage a fleet, or operate critical industrial equipment, you need a reliable partner. For expert maintenance and marine diesel engine services that keep your operation running smoothly, trust our team to deliver the professional service your investment deserves.