Why Large Diesel Engine Overhaul Costs Matter to Your Bottom Line

Whether it’s a marine vessel or an industrial generator, a major diesel engine overhaul is one of the most significant investments you can make. We work exclusively on marine and industrial diesel engines and do not service automotive or on-road trucks. If you arrived here searching for “semi truck engine overhaul cost,” use the figures below as a scale reference—cost principles are similar for heavy-duty marine and industrial engines.

Quick Answer: What Does a Major Marine/Industrial Diesel Overhaul Cost?

The following table shows typical costs for large marine and industrial diesel engines:

| Service Type | Typical Cost Range | Downtime | Warranty |

|---|---|---|---|

| Engine Overhaul | $20,000 – $40,000 | 7-14 days | 1-3 years |

| Engine Rebuild | $20,000 – $40,000 | 10-21 days | 2-4 years |

| Engine Replacement (New) | $40,000 – $50,000 | 3-7 days | 3-5 years |

| Engine Replacement (Reman) | $25,000 – $35,000 | 3-7 days | 2-3 years |

Final costs depend on engine make and model, scope of work, the shop you choose, and any hidden issues discovered during disassembly. For marine and industrial applications, related components (coolers, turbochargers, mounts, and hoses) often influence the total bill and downtime.

This guide breaks down the key considerations for a major diesel engine overhaul, helping you make smart financial decisions for your critical equipment.

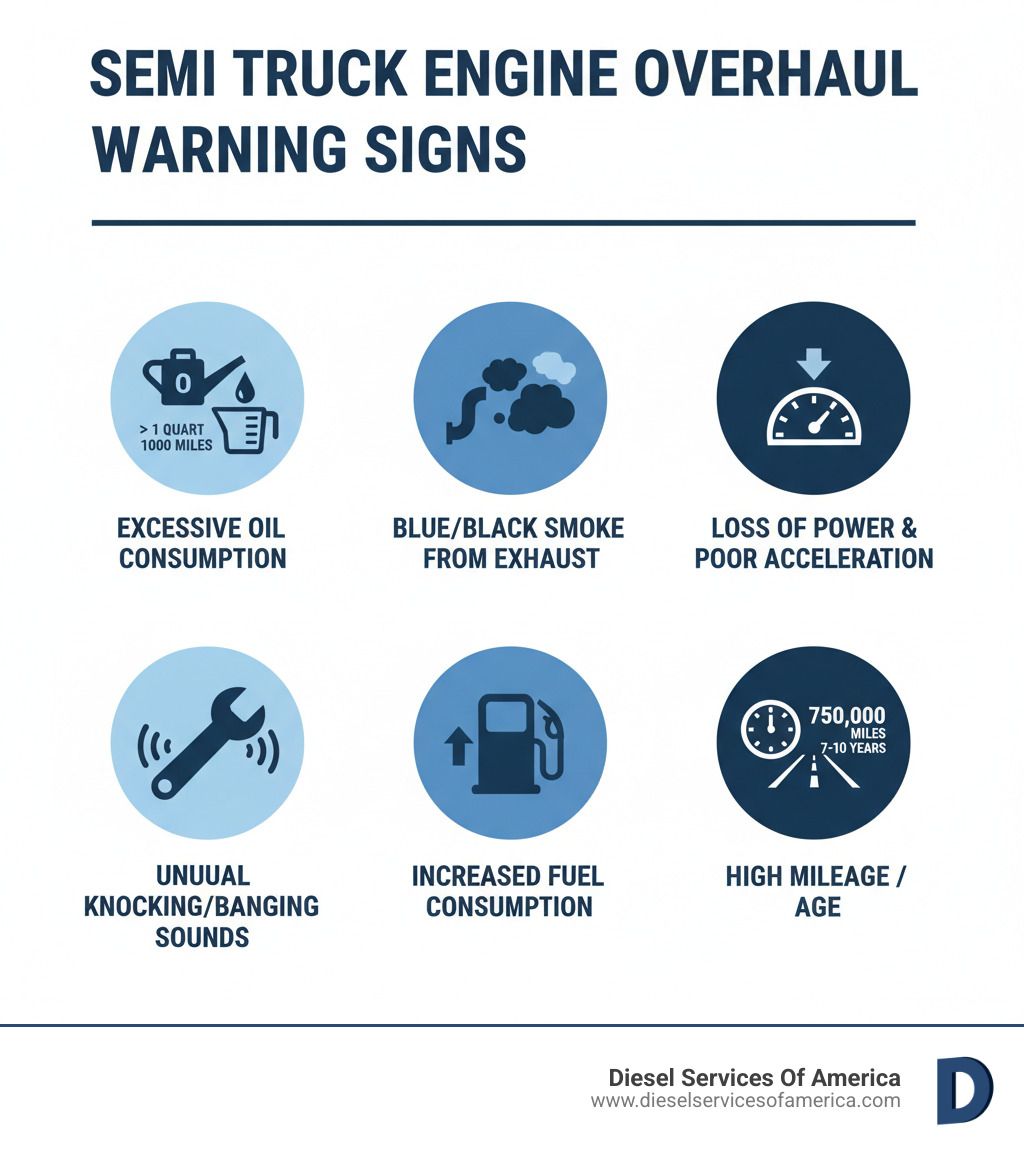

Is Your Engine Crying for Help? Signs You Need an Overhaul

Your heavy-duty diesel engine is the heart of your operation. Ignoring warning signs can lead to catastrophic failure, costly downtime, and expensive repairs. These symptoms apply to marine and industrial engines alike.

Key indicators that your engine may need an overhaul include:

- Excessive Oil Consumption: Are you adding oil more frequently than the manufacturer recommends? This is a classic sign of internal wear.

- Increased Exhaust Emissions: Blue smoke often signals burning oil, while black smoke can indicate fuel combustion problems.

- Loss of Power: If the engine feels sluggish or struggles under load, its internal components might be wearing out, causing reduced compression.

- Increased Fuel Usage: A noticeable drop in fuel efficiency without a change in operating habits points to a loss of engine performance.

- Unusual Engine Noises: Knocking, banging, or grinding sounds can indicate serious internal damage, such as worn bearings, and require immediate attention.

Beyond these symptoms, overhauls are often part of a proactive maintenance strategy. For marine and industrial engines, intervals are based on operating hours, duty cycle, oil analysis trends, and age. A scheduled overhaul is a wise investment to extend an engine’s life and prevent unexpected failures.

The Bottom Line: Breaking Down the Overhaul Cost

For large marine and industrial diesel engines, a major overhaul typically costs between $20,000 and $40,000. This significant investment covers the complex process of disassembling, inspecting, replacing worn components, and rebuilding a massive diesel engine to manufacturer specifications. Parts alone can range from $10,000 to $30,000.

While we specialize in marine and industrial diesel engines, the cost principles are similar across heavy-duty platforms. The final price for any heavy-duty diesel overhaul will vary based on the factors below.

Factors That Influence the Final Price Tag

No two overhauls cost the same. Key variables include:

- Engine Model: A Paccar engine has different parts and costs than a Cummins, Detroit, MAN, or MTU engine. Complexity and parts availability are major drivers.

- Extent of Damage: A top-end overhaul is far less expensive than a complete rebuild involving the crankshaft and other bottom-end components. The more damage found, the higher the cost.

- OEM vs. Aftermarket Parts: Original Equipment Manufacturer (OEM) parts cost more but offer guaranteed compatibility and strong warranties. Aftermarket parts can save money, but quality varies.

- Labor Rates: Labor costs differ by geographic location and a shop’s expertise. Specialized technicians may have higher rates but can prevent costly mistakes.

- Warranty Level: A comprehensive parts-and-labor warranty costs more upfront than a basic parts-only warranty but provides greater long-term protection.

- “While You’re In There” Repairs: It’s often cost-effective to address related components like turbochargers, coolers, engine mounts, and hoses during an overhaul to save on future labor costs.

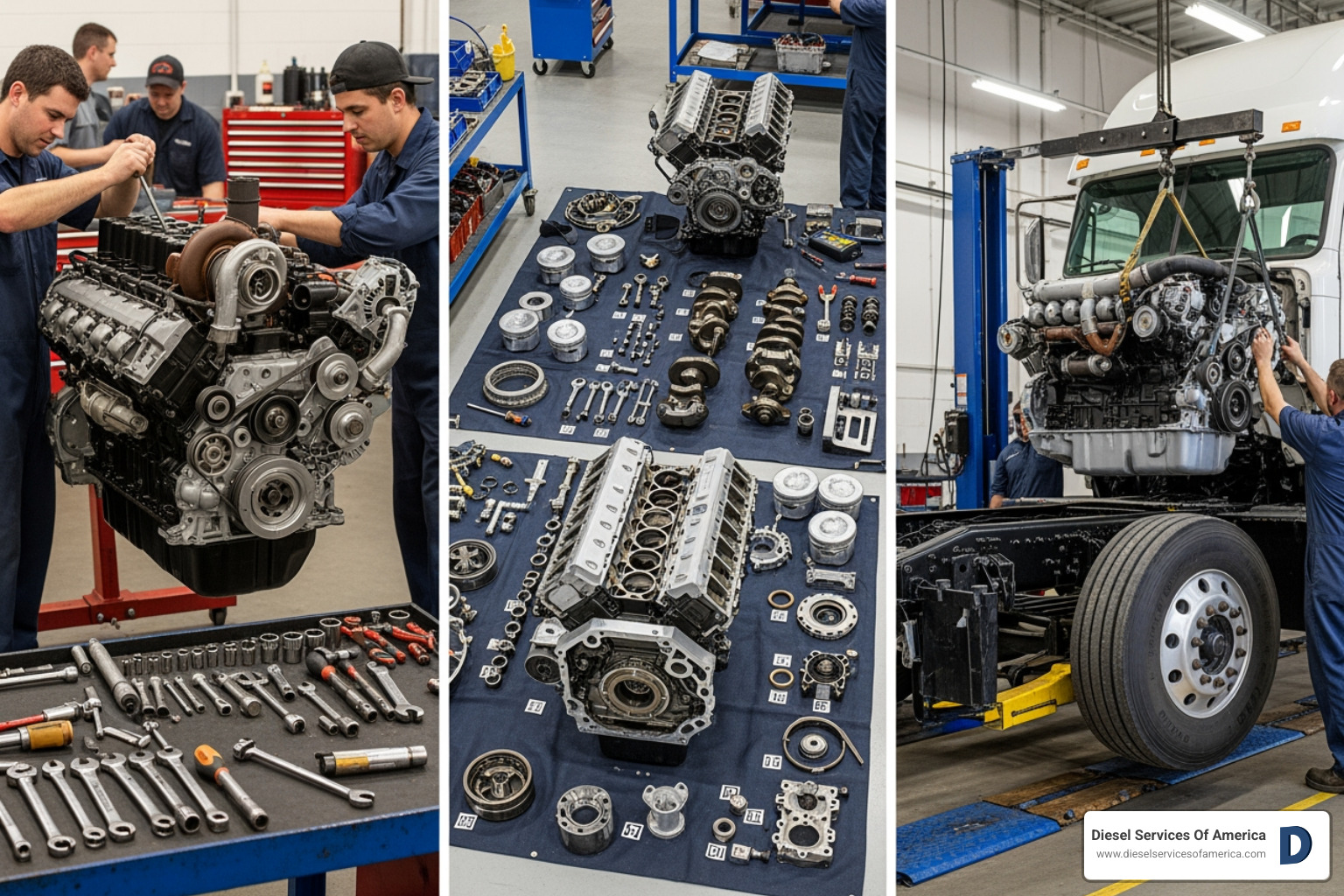

Understanding Labor Costs

Labor is a huge portion of the final bill. Overhauling a large diesel engine is intricate work requiring dozens of hours of skilled labor, specialized tools, and diagnostic equipment. Reinstalling an engine alone can take 15-30 hours. The entire process—from removal and disassembly to inspection, reassembly, and calibration—is a massive undertaking. Labor rates for heavy-duty diesel experts typically range from $60 to over $150 per hour.

Potential Hidden Costs

An initial estimate can change once the engine is disassembled. Be prepared for potential surprises that add to the total overhaul cost on large marine and industrial diesel engines:

- Unexpected Damage: A technician may find a cracked engine block or damaged crankshaft, which are often beyond economical repair and may necessitate a full replacement.

- Seized or Broken Parts: Corrosion can cause bolts to snap during removal, requiring time-consuming extraction.

- Additional Machining: Components like cylinder heads or crankshafts may need precision machining to be brought back into spec, adding cost.

- Progressive Damage: An issue like a failed injector can cause collateral damage to pistons, cylinder walls, and bearings, increasing the scope of the repair.

- Towing/Transport: For non-mobile equipment or vessels that break down far from a shop, transport fees can be substantial.

Overhaul vs. Rebuild vs. Replace: Making the Right Decision

When your heavy-duty diesel engine needs major work, you face a critical business decision: overhaul, rebuild, or replace? The right choice affects not just the immediate cost, but also your equipment’s future performance, reliability, and value. If the engine’s core components (like the block and crankshaft) are sound, repair is often the most economical path. If not, replacement may be necessary.

This table compares the options for marine and industrial engines:

| Service Type | Average Cost | Downtime | Typical Warranty | Expected Lifespan |

|---|---|---|---|---|

| Engine Overhaul | $20,000 – $40,000 | 7-14 days | 1-3 years | 5,000-10,000 operating hours |

| Engine Rebuild | $20,000 – $40,000 | 10-21 days | 2-4 years | 5,000-10,000 operating hours |

| Engine Replacement (New) | $40,000 – $50,000 | 3-7 days | 3-5 years | 10,000-20,000+ operating hours |

| Engine Replacement (Reman) | $25,000 – $35,000 | 3-7 days | 2-3 years | 5,000-12,000 operating hours |

Engine Overhaul vs. Engine Rebuild: What’s the Difference?

Though often used interchangeably, “overhaul” and “rebuild” are different.

- An engine overhaul (often an “in-frame” repair) focuses on replacing common wear items like piston rings, bearings, gaskets, and seals to restore the engine to factory specifications. It’s a targeted, cost-effective restoration.

- An engine rebuild is more extensive. The engine is removed, completely disassembled, and every component is inspected. Critical surfaces are machined back to precise OEM standards, and all worn or out-of-spec parts are replaced. The goal is to return the engine to a like-new condition.

Top Overhaul vs. Complete Overhaul

An overhaul can be further broken down by scope:

- A top overhaul addresses the upper half of the engine: cylinder heads, pistons, and valve components. It’s a good option for issues like low compression or high oil consumption if the bottom end is healthy.

- A complete overhaul addresses both the top and bottom ends. It’s a comprehensive restoration that includes replacing pistons, rings, gaskets, seals, timing components, main and connecting rod bearings, valves, and the oil pump.

The Replacement Option: When to Start Fresh

Sometimes, repair isn’t the best option. Engine replacement, while more expensive upfront, can be the smarter long-term choice.

- New Engine ($40,000 – $50,000+): This premium option provides the latest technology, maximum reliability, and the best warranty (typically 3-5 years).

- Remanufactured Engine ($25,000 – $35,000): A factory-rebuilt engine restored to new specifications. It offers a balance of near-new performance and a more manageable price, with a solid warranty (usually 2-3 years).

Replacement is often necessary in cases of a cracked engine block, severe internal damage, or if you need to meet modern emissions standards. For mission-critical operations where downtime is unacceptable, the reliability of a new or remanufactured engine can be worth the investment.

Maximizing Your Investment: Shops, Warranties, and Insurance

A major engine overhaul is a substantial investment. To maximize its value, you must carefully consider the repair shop, the warranty, and your insurance coverage. These decisions are critical for ensuring long-term reliability and protecting your asset.

Certified vs. Non-Certified Repair Shops: A Critical Choice

Choosing the right shop is paramount. While a low price is tempting, it’s not the only factor.

Certified repair shops, recognized by engine manufacturers (like Caterpillar, Cummins, MTU, etc.), offer significant advantages. Their technicians receive continuous, factory-direct training and use state-of-the-art diagnostic equipment. This expertise ensures the job is done right. Crucially, they often provide nationwide or even worldwide warranty coverage, which is invaluable for mobile equipment. A certified overhaul also adds verifiable service history, boosting resale value.

Non-certified shops can offer competitive pricing, but quality varies. Their warranties are often local-only, and they may lack the specialized tools for modern, electronically controlled engines. While you might save money upfront, the risk of improper repairs and limited warranty support can be costly in the long run.

Decoding Overhaul Packages and Warranties

Certified facilities often offer tiered overhaul packages (e.g., Bronze, Silver, Gold, Platinum). These reflect different levels of service and warranty coverage.

- Lower-tier packages (Bronze/Silver) are less expensive, covering essential components to fix immediate problems. They come with shorter warranties and are suitable for equipment nearing retirement.

- Higher-tier packages (Gold/Platinum) are more comprehensive, replacing a wider range of parts to prevent future failures. They include longer, more robust warranties (e.g., multi-year, unlimited hour/mileage) and typically offer the best long-term value.

When choosing, consider the total cost of ownership, not just the initial price. A cheap package that leads to future downtime and repairs isn’t a bargain.

Don’t Forget Your Insurer: Updating Your Policy Post-Overhaul

After investing tens of thousands of dollars in an overhaul, you have significantly increased your equipment’s value. You must inform your insurance provider.

Failure to do so can lead to underinsurance. If the equipment is totaled, the insurance payout may only reflect its pre-overhaul value, leaving you with a major financial loss. Contact your agent with all documentation from the overhaul (invoices, warranty) and ask to adjust your policy’s stated value. The small increase in your premium is crucial protection for your larger investment.

How to Afford a Major Engine Overhaul

Facing an overhaul cost of $20,000 to $40,000 or more can be daunting for any business. Fortunately, several financing solutions exist to help you cover these major expenses without halting your operations.

- Specialized Lenders: Look for lenders who understand heavy equipment and industrial/marine businesses. They often offer more flexible terms than traditional banks because they grasp the unique cash flow and collateral involved.

- Business Loans: If you have solid credit, a traditional business loan from a bank or credit union can be a good option for financing major equipment repairs.

- Invoice Factoring: This option provides immediate cash by selling your outstanding invoices to a factoring company. It’s a way to access funds you’ve already earned without taking on new debt, which is ideal for covering unexpected repairs.

- Working Capital Loans: These short-term loans are designed to cover operational expenses and emergencies. They provide quick access to cash to get your equipment back in service.

- Equity Loans: Using property as collateral for an equity loan can be another way to secure funds, often at a lower interest rate.

Exploring these options before a crisis hits will allow you to make a clear-headed decision when the time comes.

Frequently Asked Questions about Heavy-Duty Engine Overhauls

How long does a heavy-duty engine last after an overhaul?

A quality overhaul can significantly extend an engine’s life. For marine and industrial engines, this often means another 5,000 to 10,000+ operating hours, depending on duty cycle, fuel quality, and maintenance practices. Results depend on the quality of work, the scope of components replaced, and post-overhaul care.

What is the typical lifespan of a heavy-duty diesel engine?

Many marine and industrial heavy-duty diesels are engineered for 10,000 to 20,000+ operating hours between new and major overhaul when maintained properly. Achieving the upper end requires consistent maintenance, proper loading, clean fuel, and proactive service.

Is it cheaper to rebuild or replace a heavy-duty engine?

Upfront, rebuilding or overhauling is almost always cheaper. A major overhaul commonly runs $20,000 to $40,000, while a new replacement engine can be $40,000 to $50,000 or more.

However, the decision shouldn’t be based on the initial price alone. A new engine offers a longer warranty, the latest technology, and maximum reliability. The best approach is to consider the total cost of ownership, factoring in potential downtime, future repairs, and warranty coverage. If the engine’s core is sound, a rebuild is often the best financial choice. If there is major damage (like a cracked block) or you require absolute reliability, replacement may be more cost-effective in the long run.

Conclusion: Keeping Your Business in Service

Understanding the cost of a major diesel overhaul is about making a smart investment in your operation. Whether you’re facing a $20,000 repair or a $50,000 replacement, the decision impacts your bottom line for years to come. By understanding the options—overhaul, rebuild, or replace—and the factors that influence cost, you can make an informed choice.

Choosing a certified shop, selecting the right warranty package, and updating your insurance are all critical steps to protect your investment. With proper planning and financing, a major overhaul can be a manageable expense that adds years of life to your equipment.

If you found us while researching “semi truck engine overhaul cost,” please note we service marine and industrial diesel only. At Diesel Services of America, our factory-trained technicians provide expert service for critical diesel equipment throughout Fort Lauderdale, Southeast Florida, and the Caribbean.