Why Your Marine Diesel Engine Deserves the Right Tune-Up Products

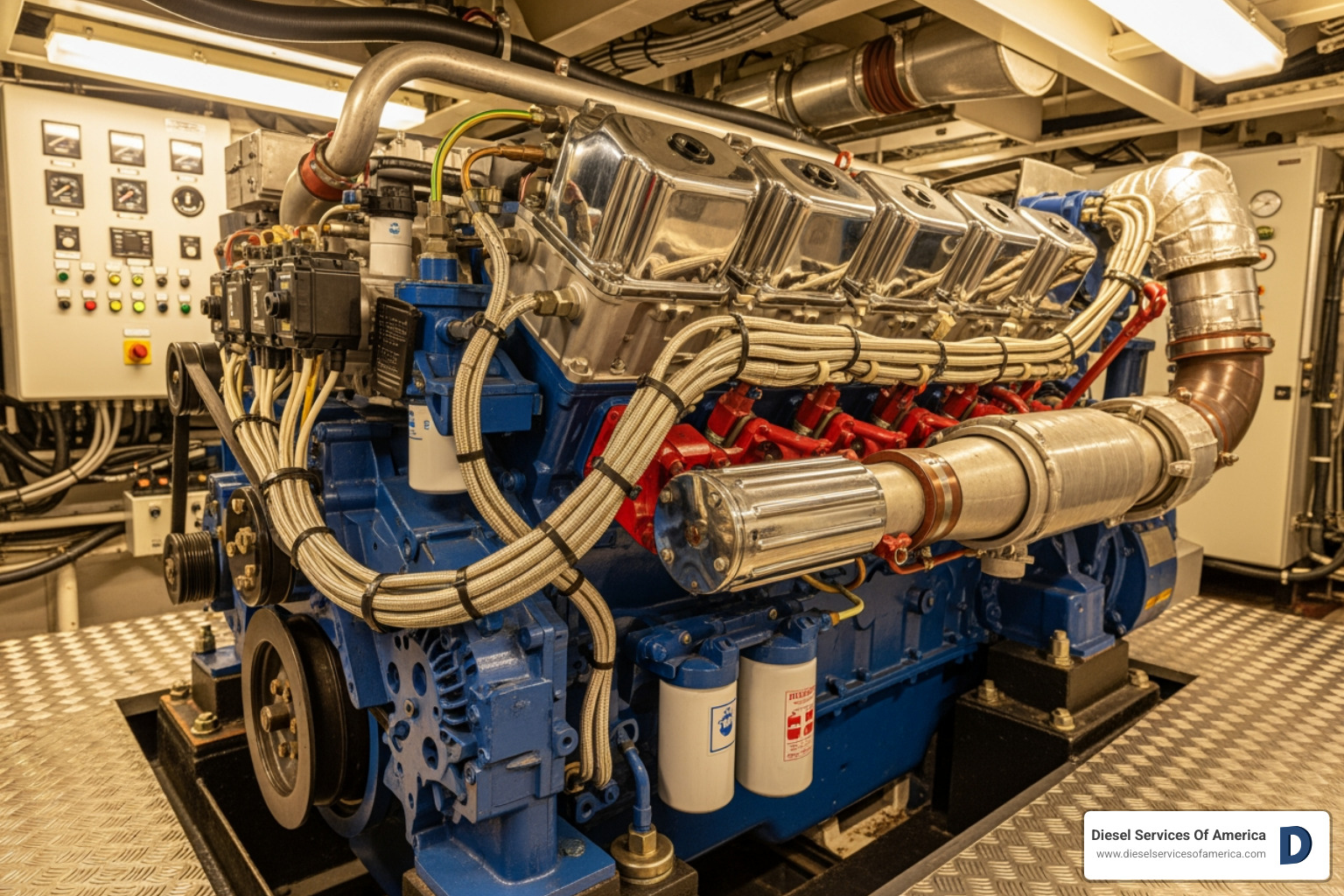

Tune up motor diesel engines require specialized products designed for the unique demands of marine and industrial applications. Unlike automotive diesels, marine engines face saltwater corrosion, constant vibration, and extended run times that demand superior maintenance products.

Quick Guide: Essential Tune-Up Products for Marine Diesel Engines

| Product Category | Purpose | Replacement Interval |

|---|---|---|

| Fuel Additives & Filters | Prevent contamination, water buildup, and microbial growth | Every 250-500 hours |

| Cooling System Products | Combat saltwater corrosion, prevent overheating | Annually or 250-500 hours |

| Air & Oil Filters | Protect combustion and internal components | Every 250-500 hours |

| Belts, Hoses & Gaskets | Prevent catastrophic failures at sea | Inspect every service |

A well-maintained marine diesel can run for over 1,000,000 hours before major repairs. But that legendary longevity depends entirely on using the right products during regular tune-ups.

The harsh marine environment presents unique challenges. Salt air accelerates corrosion. Humidity causes fuel contamination. Vibration loosens connections. These factors mean that generic automotive products simply won’t cut it for your marine or industrial diesel engine.

The difference between a $500 tune-up and a $10,000 engine rebuild often comes down to catching small problems early—and using quality products designed specifically for marine diesel applications.

This guide covers the essential product categories you need for a comprehensive diesel tune-up. From fuel treatments that prevent the dreaded “diesel bug” to cooling system components that combat saltwater’s corrosive effects, you’ll learn what to look for when maintaining your marine or industrial diesel engine.

Fuel System Treatments: The First Line of Defense

Your diesel engine’s fuel system is vital. For marine and industrial engines, especially in humid climates like Southeast Florida and the Caribbean, maintaining fuel system integrity is a major challenge. It’s essential for preventing costly repairs and ensuring reliability when you need it most.

How can you tell if your tune up motor diesel needs fuel system attention? Watch for performance issues like reduced power, sluggish acceleration, hard starts, or decreased fuel efficiency. These often point to clogged injectors or restricted fuel flow.

Your exhaust smoke also tells a story:

- Black smoke often indicates incomplete combustion from issues like dirty injectors. Find out more about how to reduce black smoke in diesel engines.

- Blue smoke suggests burning oil, pointing to internal wear. Learn more about what blue smoke coming from your car might mean.

- White smoke can mean incomplete combustion or a coolant leak. Explore why you might see white smoke from a diesel engine.

For marine diesels, fuel contamination is a major preventable problem. Water in diesel fuel allows microbes—the “diesel bug”—to grow. This clogs filters, corrodes lines, and can destroy fuel injection components. Neglecting the fuel system is a common and costly mistake.

Choosing Fuel Additives and Stabilizers

In a humid environment, fuel additives are not optional—they are crucial for protecting your fuel system and ensuring smooth operation.

When looking for quality fuel additives, here’s what to look for:

- Injector Cleaners: Removes deposits from your fuel injectors to ensure a fine spray for efficient combustion, preventing excess smoke and wear.

- Water Eliminators: Help demulsify water, separating it from fuel so it can be drained. This is essential for marine engines where condensation is a constant issue.

- Biocides (Anti-Diesel Bug): Critical for fighting microbial growth (“diesel bug”), which thrives in water at the bottom of the fuel tank. A quality biocide is non-negotiable for marine and industrial diesels.

- Lubricity Improvers and Fuel Stabilizers: Modern low-sulfur diesel has less lubricity; additives that add lubricity extend fuel pump and injector life. Fuel stabilizers prevent fuel degradation in engines that sit idle. Other additives can prevent fuel gelling in cold climates or act as cetane boosters to improve ignition quality, power, and efficiency.

For modern high-pressure common rail systems, clean fuel is paramount. These systems have tight tolerances and are highly sensitive to contaminants. While they require less frequent injector servicing than older mechanical systems, pristine fuel is non-negotiable. Using a high-quality fuel additive proactively protects your investment.

Essential Fuel Filters for your tune up motor diesel

Proper filtration is as important as fuel additives. Fuel filters are the unsung heroes of a tune up motor diesel, catching debris, contaminants, and water before they reach sensitive components like the fuel injection pump and injectors.

Marine and industrial diesels typically use two filter types:

- Primary fuel filters/water separators: Located before the engine, they remove large particles and separate water from fuel. Regularly drain accumulated water, especially in humid climates.

- Secondary on-engine fuel filters: Mounted on the engine, these fine filters are the final defense, ensuring only the cleanest fuel reaches the injectors.

Regular filter replacement is critical. A clogged filter restricts fuel flow, causing reduced power and acceleration, hard starts, or stalling. We recommend replacing fuel filters every 500 to 1000 operating hours or annually. This simple step helps avoid costly fuel injection system repairs.

A clogged fuel filter is a common cause of reduced power. Don’t let this simple part compromise your engine’s longevity. For more details, explore our resources on More info about marine diesel engine maintenance.

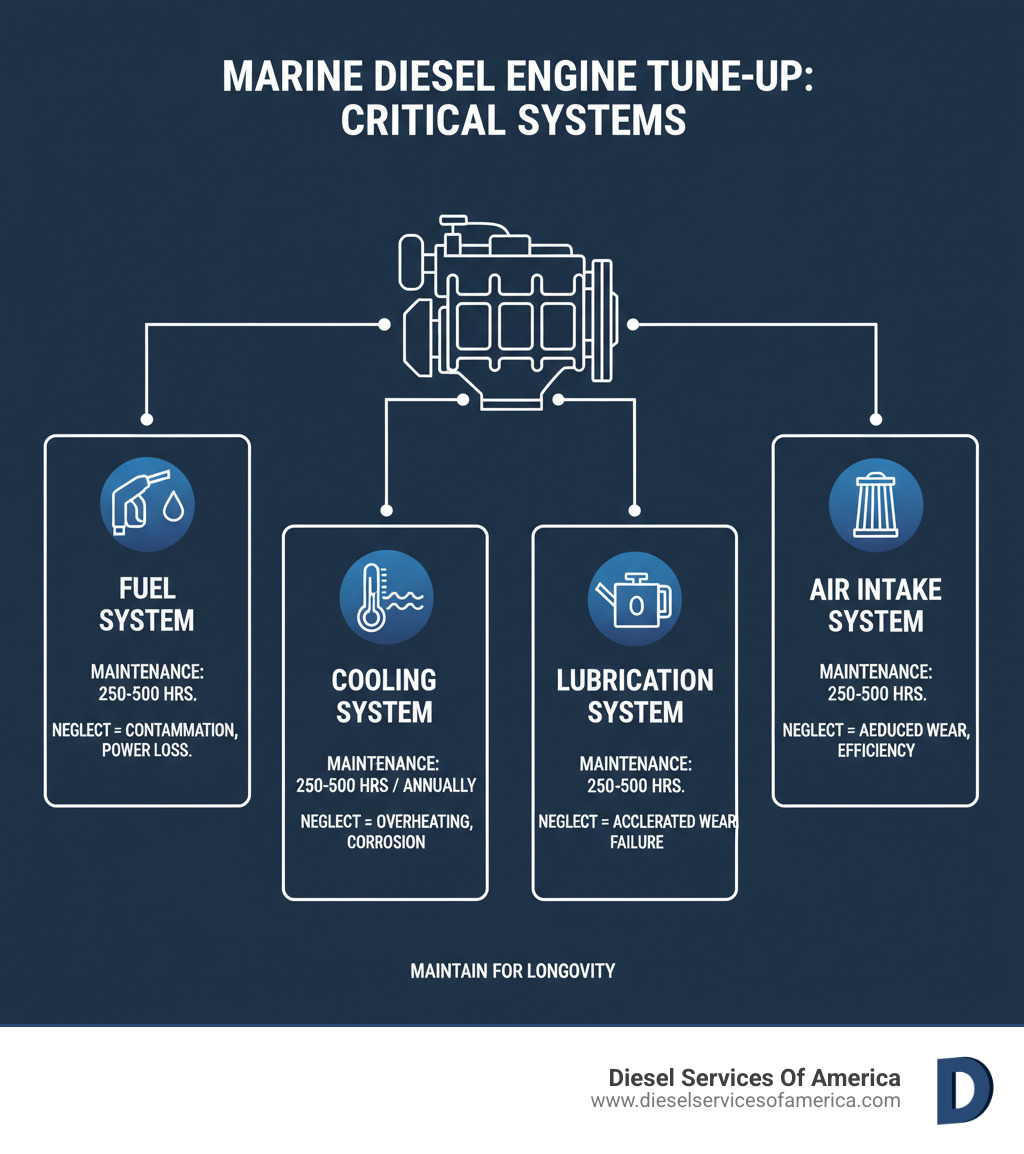

Cooling System Products for the Harsh Marine Environment

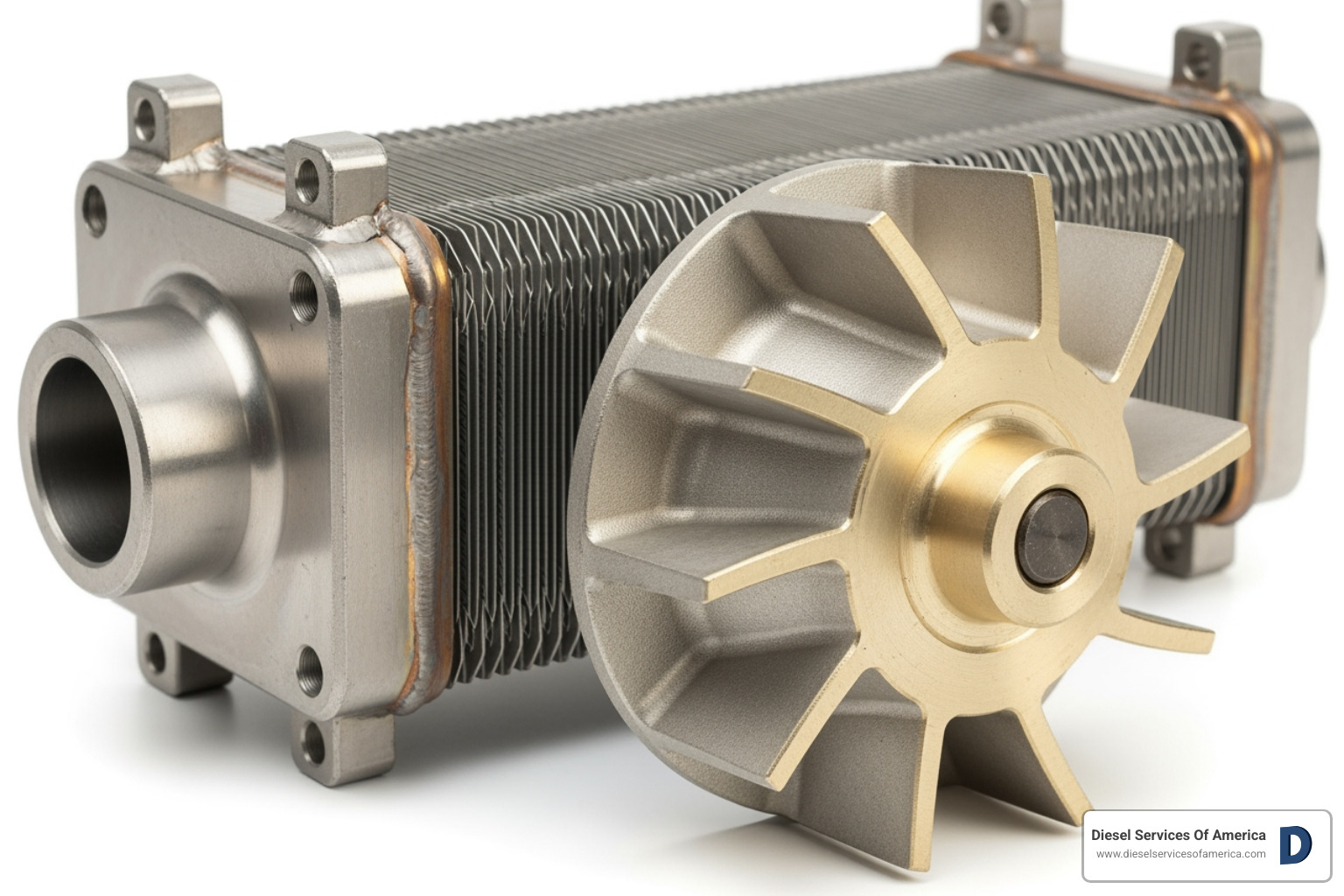

The marine environment is tough on your engine. A marine diesel’s cooling system constantly battles saltwater corrosion, humidity, and the risk of overheating. Unlike automotive engines, marine diesels often use heat exchangers with raw seawater to cool the internal coolant. This direct saltwater contact makes specialized care and products vital.

A marine diesel’s robustness comes from its compression-ignition design. Its legendary lifespan depends on a perfectly working cooling system. Ignoring cooling system maintenance is a common, costly mistake that can lead to severe damage, like a cracked engine block from a failed impeller. A proper tune up motor diesel always includes a thorough check of this critical system.

So, what parts of your cooling system need extra attention?

- Heat exchangers are where the engine’s fresh coolant meets raw seawater. They are magnets for saltwater corrosion and can get clogged.

- Raw water pumps pull in that seawater to move it through the heat exchanger. Their impellers are parts that wear out over time.

- Impellers themselves are made of rubber and naturally break down from heat and friction. A failing one can quickly cause your engine to overheat.

- Zinc anodes are special metal pieces that sacrifice themselves to prevent corrosion on more important parts.

- The coolant/antifreeze inside your engine must be the right kind and strength. Even if you’re not worried about freezing in sunny places like Fort Lauderdale, it still provides crucial protection against internal corrosion.

- Thermostats are like the engine’s temperature regulators. A faulty one can cause your engine to run too hot or too cold.

Coolants and Corrosion Inhibitors

Choosing the right coolant is critical; it protects the engine’s interior from corrosion and heat. Always follow your manufacturer’s guide to avoid chemical incompatibilities and engine damage. Extended life coolants are often a smart choice for their longevity and superior protection. Coolant degrades over time, losing its anti-corrosive properties. We recommend a full flush and replacement every two to three years, or as your manual specifies, as a key part of your tune up motor diesel routine.

High-quality coolants contain special ingredients called inhibitors. These stop rust, scale, and other gunk from building up inside the cooling passages. Such buildup can block heat transfer and cause your engine to overheat. A thorough flushing of the cooling system removes old, worn-out coolant and any deposits. This prepares the system for fresh coolant and ensures your engine runs at its best.

Sacrificial Anodes and Impellers

These two small but mighty parts are absolutely vital for preventing big, costly problems in your marine diesel’s cooling system.

Let’s talk about zinc anodes. They play a big role in stopping galvanic corrosion. This happens when two different metals touch in saltwater. The zinc anodes are put there to “sacrifice” themselves. They corrode instead of more important parts like your heat exchangers or engine block. We recommend checking and replacing these zinc anodes annually, or anytime they’re more than half eaten away.

Then there are impellers. The raw water pump impeller is a part that will wear out. It’s not a question of if it will fail, but when. That’s why we strongly suggest annual impeller replacement, or every 250 to 500 operating hours, whichever comes first. This simple, affordable step is cheap insurance against a much more expensive problem down the line.

How do you know if an impeller is failing? Keep an eye out for signs of a failing water pump impeller: you might see less water coming out of your exhaust, your engine temperature gauge might read higher than usual, or you might hear strange noises from the raw water pump. If you notice any of these, check your impeller right away. Replacing impellers regularly and checking zinc anodes are incredibly effective ways to prevent catastrophic failure from overheating. An overheated engine can suffer permanent damage, like a cracked block or warped cylinder heads, leading to a very expensive repair.

Essential Replacement Parts for a Tune Up Motor Diesel

A proper tune up motor diesel involves replacing physical components that allow the engine to breathe clean air, circulate clean oil, and drive accessories. These parts are critical, especially in the harsh marine environment where vibration, humidity, and salt air take a heavy toll.

Some of these tasks are straightforward enough for experienced boat owners to tackle themselves. Changing an air filter or inspecting a belt doesn’t require a marine engineering degree. But knowing when to call in the professionals is just as important as knowing how to check your oil. For marine and industrial diesels, we typically recommend service intervals measured in operating hours rather than miles—usually every 250 to 500 hours, or at least annually.

Air and Oil Filtration Products

Clean air is everything for proper combustion. A diesel engine needs massive amounts of clean air for an efficient air-to-fuel ratio. A clean air filter ensures this, but when clogged with debris, the engine gasps for air. This results in reduced power, higher fuel consumption, and often black smoke from the exhaust.

A clogged air and fuel filters affects performance in ways you’ll definitely notice. Your engine has to work harder to pull in the air it needs, which means it’s burning more fuel to produce less power. In dusty or dirty operating environments—like construction sites or boats operating in sandy coastal areas—air filters need checking and replacing more frequently than you might expect.

High-quality oil filters are your engine’s kidneys, cleaning contaminants from combustion and friction. They trap metallic particles, carbon, and dirt before they can damage cylinder walls, bearings, or oil passages. We recommend oil and filter changes every 250 operating hours or annually as cheap insurance against internal engine damage.

For operators who want to go beyond basic maintenance, oil analysis kits offer a window into your engine’s soul. These diagnostic tools analyze a small sample of your used oil, revealing things you can’t see with the naked eye. Abnormal wear metals might indicate bearing problems. Coolant in the oil could mean a head gasket issue. Fuel dilution suggests injection problems. Catching these issues early, before they become catastrophic failures, can save you thousands of dollars and prevent being stranded at sea.

Belts, Hoses, and Gaskets for your tune up motor diesel

Belts and hoses might seem minor, but their failure can cause an emergency at sea. A failed alternator belt can leave you without power, while a burst coolant hose can lead to rapid overheating. These are not hypothetical scenarios; they happen regularly when inspections are neglected.

During every comprehensive tune up motor diesel, we inspect all engine belts for signs of trouble. Cracks, fraying, glazing, or improper tension are all red flags. Some engines use traditional V-belts, while others have serpentine belts. Serpentine belts generally last longer and transfer power more efficiently, but both types need regular attention.

Hoses face their own set of challenges in the marine environment. We’re looking for bulging (a sign of internal breakdown), softening or hardening (both indicate aging rubber), cracks, or any signs of leakage. The constant vibration from engine operation and wave action accelerates hose deterioration in ways that automotive applications never experience.

Here’s a professional tip that saves headaches: when we’re already in there replacing other components during a tune-up, we replace the associated gaskets too. It’s not about the gasket being bad; it’s about prevention. Once you’ve broken the seal on a gasket by removing a component, that gasket has been compromised. The small cost of a new gasket is nothing compared to dealing with an oil, coolant, or fuel leak later.

Fresh gaskets ensure tight seals and prevent those annoying drips that can lead to reduced fluid levels, contamination, and potential engine damage. In the marine world, where everything corrodes faster and access can be difficult, an ounce of prevention really is worth a pound of cure.

The bottom line? These replacement parts aren’t exciting, but they’re essential. They’re the difference between a reliable engine and an expensive tow bill.

Frequently Asked Questions about Diesel Tune-Ups

We get a lot of questions from boat owners and industrial equipment operators here in Fort Lauderdale and throughout the Caribbean. When it comes to tune up motor diesel maintenance, people want to know what’s really necessary versus what’s just nice to have. Here are the answers to the questions we hear most often.

How often do marine diesel engines need a tune-up?

Unlike cars, marine and industrial diesel maintenance is measured in operating hours, not miles. This reflects how long the engine has been running, which is the critical factor for wear.

The general rule we follow is pretty straightforward. Basic service should happen every 250 to 500 operating hours, or at least once a year, whichever comes first. This includes your oil and filter changes, fuel filter replacements, and a thorough inspection of belts, hoses, and fluid levels.

More comprehensive tune-ups happen at bigger milestones. Around the 1000-hour mark, you’re looking at a deeper service that might include valve adjustments, injector servicing (especially for older mechanical systems), and more extensive system checks.

Your owner’s manual is your best friend here. It contains the specific service schedule for your particular engine model, and honestly, it’s worth following to the letter. We also can’t stress enough the importance of keeping a detailed engine logbook. Track every operating hour and every service performed. This simple habit helps you stay on schedule and gives our technicians valuable historical data if something does go wrong.

What are the biggest risks of neglecting a tune-up?

Skipping a routine service to save a few hundred dollars can lead to multi-thousand-dollar repairs. In our marine environment, fuel system contamination and cooling system failure are the biggest risks. Humidity in Southeast Florida promotes water in fuel, leading to microbial growth (“diesel bug”) that can destroy an injection system. Simultaneously, saltwater attacks cooling components, and a worn impeller can fail without warning.

These problems escalate quickly. A failing impeller, a minor part, can cause the engine to overheat in minutes, leading to a cracked block. A repair that could have been prevented with a $50 part can become a $10,000 to $15,000 nightmare.

The cost difference between prevention and repair is staggering. A proper tune up motor diesel service runs around $500 to $1,000 depending on what’s needed. An engine rebuild? You’re looking at five figures, easily. And that’s just the money. For marine applications, there’s something even more important to consider.

Being stranded at sea isn’t just inconvenient—it can be genuinely dangerous. When your engine quits miles offshore, you’re at the mercy of wind, waves, and whoever might be available to tow you back. We’ve had clients call us from some pretty harrowing situations, all because they put off basic maintenance. Your engine’s reliability could literally be a life-or-death matter, and reliability comes from consistent, quality service.

What is the role of the Engine Control Module (ECM) in a modern diesel tune-up?

Most marine diesels built in the last fifteen years have an Engine Control Module (ECM), a sophisticated computer that constantly monitors and adjusts engine performance.

The ECM is essentially monitoring everything, all the time. It’s watching dozens of sensors throughout your engine—tracking temperatures, pressures, speeds, and more—and making thousands of tiny adjustments every minute. It controls your fuel injection timing down to the millisecond, adjusts your fuel rail pressure based on load demands, and manages your turbocharger boost to squeeze out maximum efficiency.

When something goes wrong, the ECM is our first diagnostic tool. Our factory-trained technicians connect specialized diagnostic equipment to read what the ECM has been seeing. Those fault codes tell us exactly what’s happening—whether it’s a failing sensor, an electrical problem, or an actual performance issue. This takes a lot of the guesswork out of troubleshooting, which saves you time and money.

There’s also a performance side to the ECM that’s pretty exciting. Professional ECM tuning—and I emphasize the word “professional” here—can open up significant gains in both power and fuel efficiency. We’re talking about adding 80 to 100 horsepower and nearly doubling torque output in some applications. But this isn’t something you do with a laptop and software you downloaded from the internet. Expert ECM tuning requires deep knowledge of diesel engine operation, specialized calibration software, and an understanding of how to push performance while maintaining reliability and longevity. Done wrong, you can damage your engine. Done right by someone who knows what they’re doing, it can transform how your boat performs.

Protect Your Investment with the Right Products and Service

Your marine or industrial diesel is a significant investment deserving the best care. This guide covered the essential products for a comprehensive tune up motor diesel: fuel treatments to fight contamination, cooling system parts to resist saltwater, and critical replacement items like filters, belts, and hoses.

Having the right products is only half the battle. A proper tune-up combines them with expert labor. Modern diesels are sophisticated machines requiring specialized diagnostic equipment, factory-specific knowledge, and hands-on experience that only specialists possess.

Professional service makes all the difference. At Diesel Services of America, our factory-trained technicians specialize in marine and industrial diesels. We understand the unique challenges of operating in Fort Lauderdale, Southeast Florida, and the Caribbean, from fuel contamination to saltwater corrosion. We know that preventive maintenance saves our clients from massive repair bills.

We make professional service convenient, too. Our dockside service throughout South Florida means we come to you, minimizing your downtime. Need parts shipped anywhere in the world? We’ve got you covered. Whether you’re running a commercial vessel, a pleasure yacht, or industrial equipment, we’re equipped to handle it.

The difference between an engine that lasts 100,000 hours and one that barely makes it to 50,000 often comes down to consistent, quality maintenance. Don’t wait until you’re seeing excessive smoke, experiencing hard starts, or worse—stranded offshore with an overheated engine. Regular service with the right products ensures your diesel runs reliably, efficiently, and safely for decades to come.

Your engine’s legendary longevity isn’t automatic. It’s earned through diligent care, quality products, and expert service. Let us help you protect that investment and keep your diesel running strong.

Contact us for professional marine diesel services and experience the peace of mind that comes from working with specialists who understand your engine inside and out.