Introduction: The Heart of Your Marine & Industrial Engine

When your marine or industrial engine needs specialized care, finding the right crankshaft repair shop is crucial. For fleet managers and boat owners, engine reliability is everything. You need quick, expert service to keep your operations running smoothly.

Here’s what to look for when you need a top-tier crankshaft repair shop:

- Specialized Expertise: The shop should understand marine and industrial diesel engines.

- Comprehensive Services: Look for grinding, straightening, welding, and balancing.

- Proven Experience: A long track record in crankshaft repair means reliability.

- Fast Turnaround: Minimize your vessel’s downtime with efficient service.

- Quality Workmanship: Precision is key for engine longevity and performance.

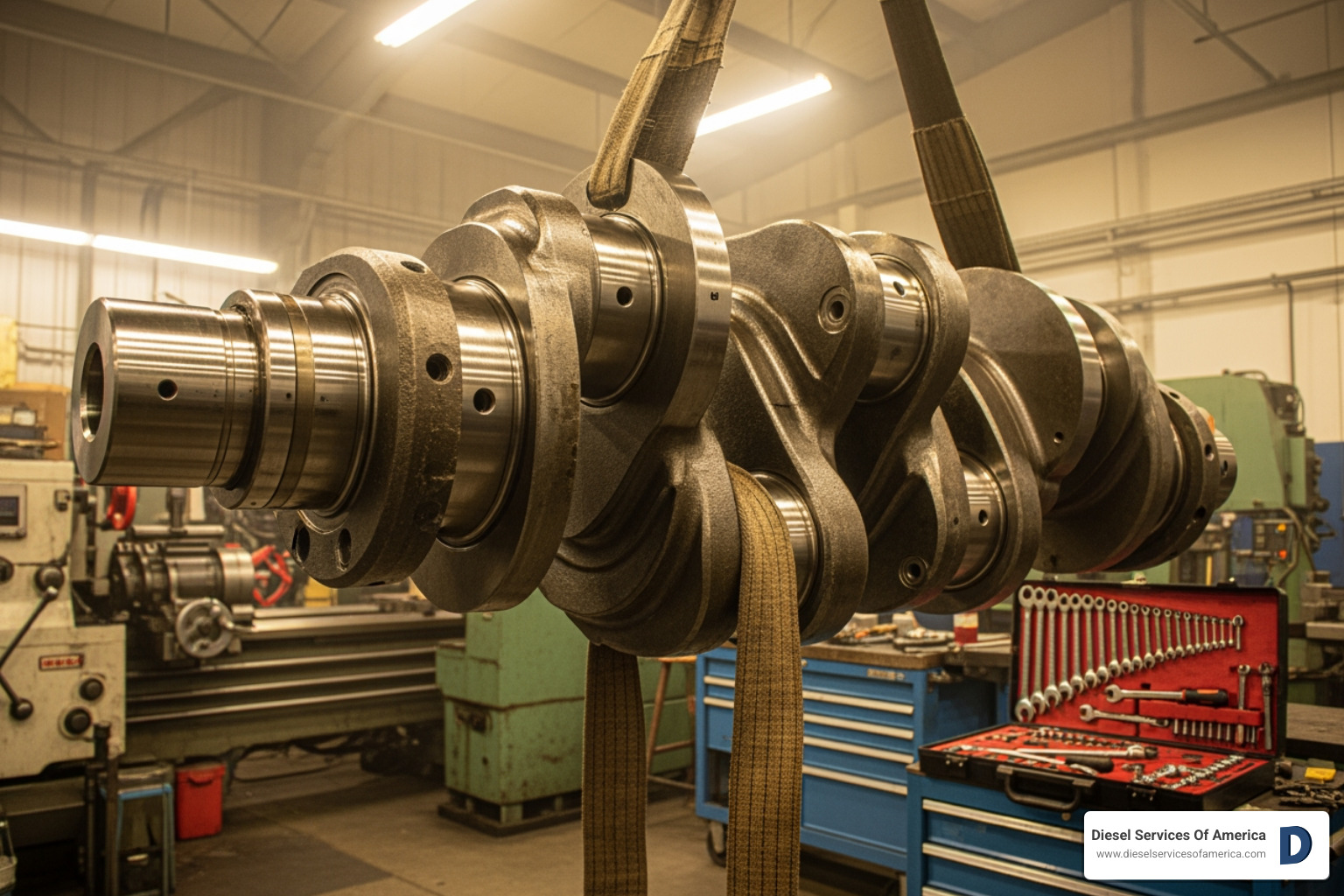

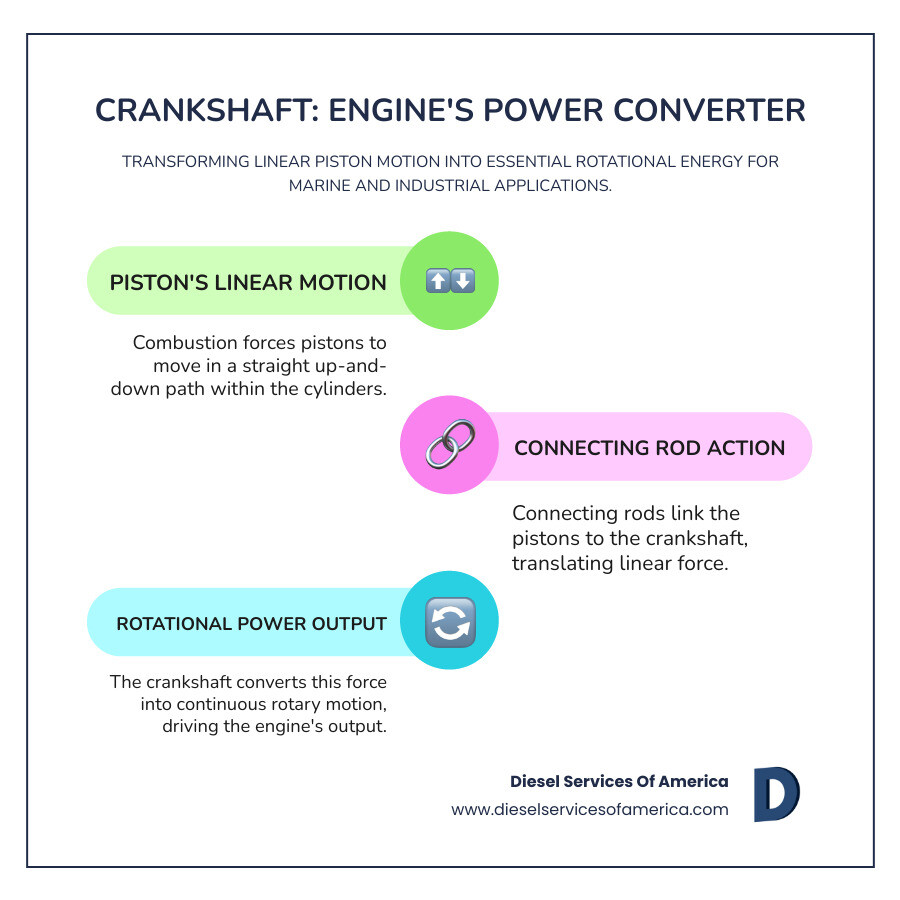

The crankshaft is the central component of any engine. It turns the up-and-down motion of pistons into the rotating power that drives your vessel or equipment. When this vital part is damaged, it can lead to serious issues, from performance loss to complete engine failure. That’s why professional repair is not just an option, it’s a necessity. This guide will help you understand crankshaft repair and how to pick the best shop for your needs.

Understanding Crankshaft Damage and the Need for Repair

The crankshaft is the heart of your marine or industrial diesel engine, converting piston motion into the powerful rotation that drives your vessel or equipment. Even minor damage can impact power, fuel efficiency, and engine life.

Common causes of crankshaft damage include oil starvation, where insufficient or poor-quality oil leads to scoring and seizure, and bearing failures, which cause vibration and excessive wear. Overheating can warp or weaken the crankshaft metal, while improper maintenance, like skipping oil changes, can turn small issues into major failures.

Signs of a damaged crankshaft include a noticeable loss of power and excessive vibration. Ignoring these symptoms can lead to catastrophic engine failure, resulting in long downtimes and costly repairs. Acting quickly and seeking professional help from a reliable crankshaft repair shop is key to keeping your valuable engines running strong.

Why Repair is a Cost-Effective Alternative

When a crankshaft is damaged, repair is often a smarter, more affordable choice than replacement, especially for large marine and industrial engines. A new crankshaft can be prohibitively expensive and have long lead times.

Expert crankshaft repair shop services can restore a damaged crankshaft to original factory specifications, saving you tens of thousands of dollars. Repairing also extends the life of your engine and is a more sustainable option, reducing waste and conserving resources.

Preventing Crankshaft Issues Through Regular Maintenance

The best way to avoid costly crankshaft repairs is through diligent maintenance. A healthy oiling system is critical. As experts say, “The lifeblood of a crankshaft is the engine’s oiling system.” This means using the correct lubricant, checking levels, and adhering to your oil change schedule.

Routine engine maintenance should also include checks of the cooling and fuel systems, as failures in these areas can indirectly damage the crankshaft. Always follow the manufacturer’s maintenance guidelines. For prospective vessel owners, a pre-purchase survey can identify potential crankshaft issues before you invest. Proactive care is the key to engine dependability. For more details on keeping your engine in prime condition, explore our [More info about marine diesel engine services](https://www.dieselservicesofamerica.com/marine-diesel-engine-services/).

The Crankshaft Repair Process: From Inspection to Perfection

When a damaged crankshaft arrives at a specialized crankshaft repair shop, it undergoes a methodical restoration process to ensure long-term reliability.

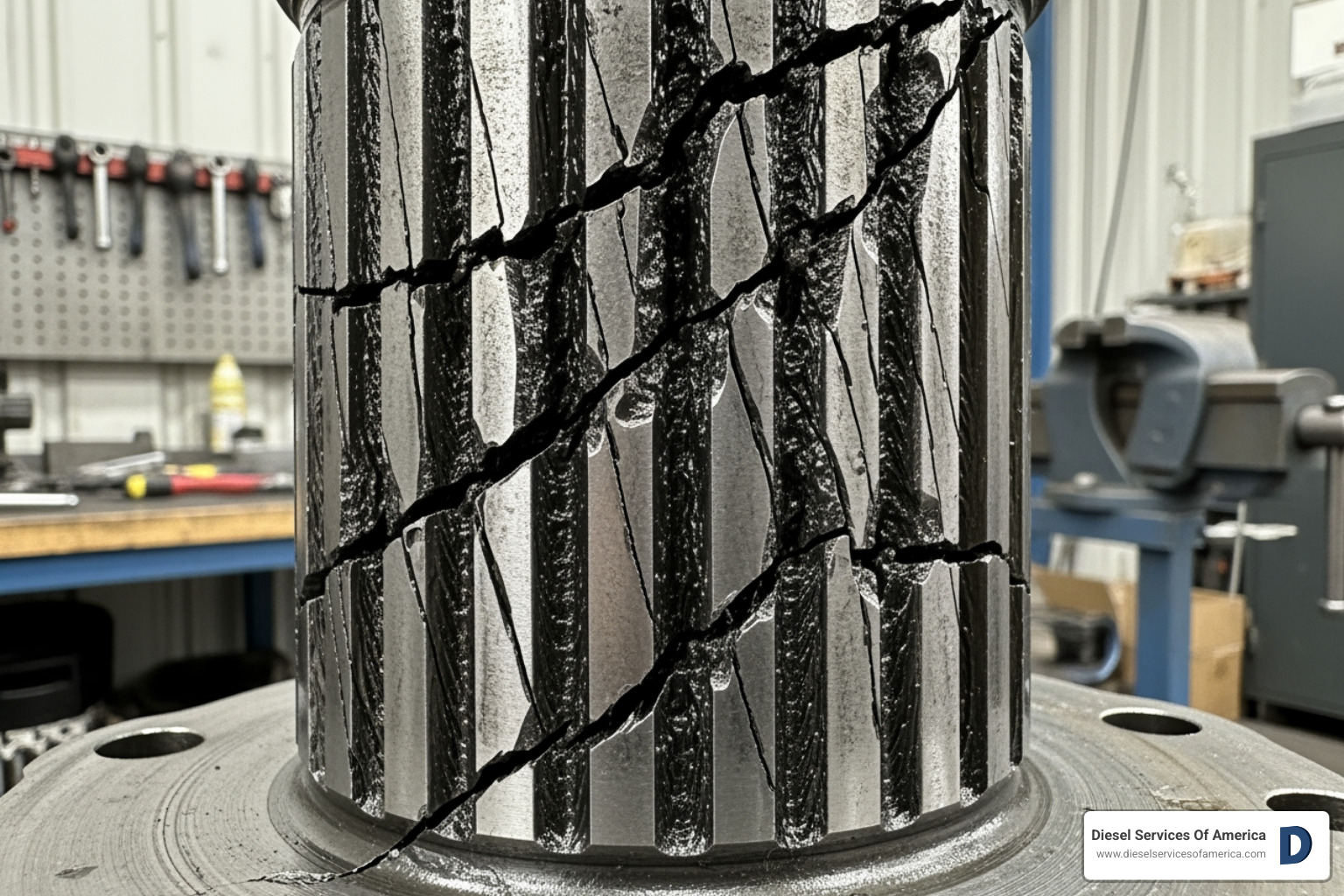

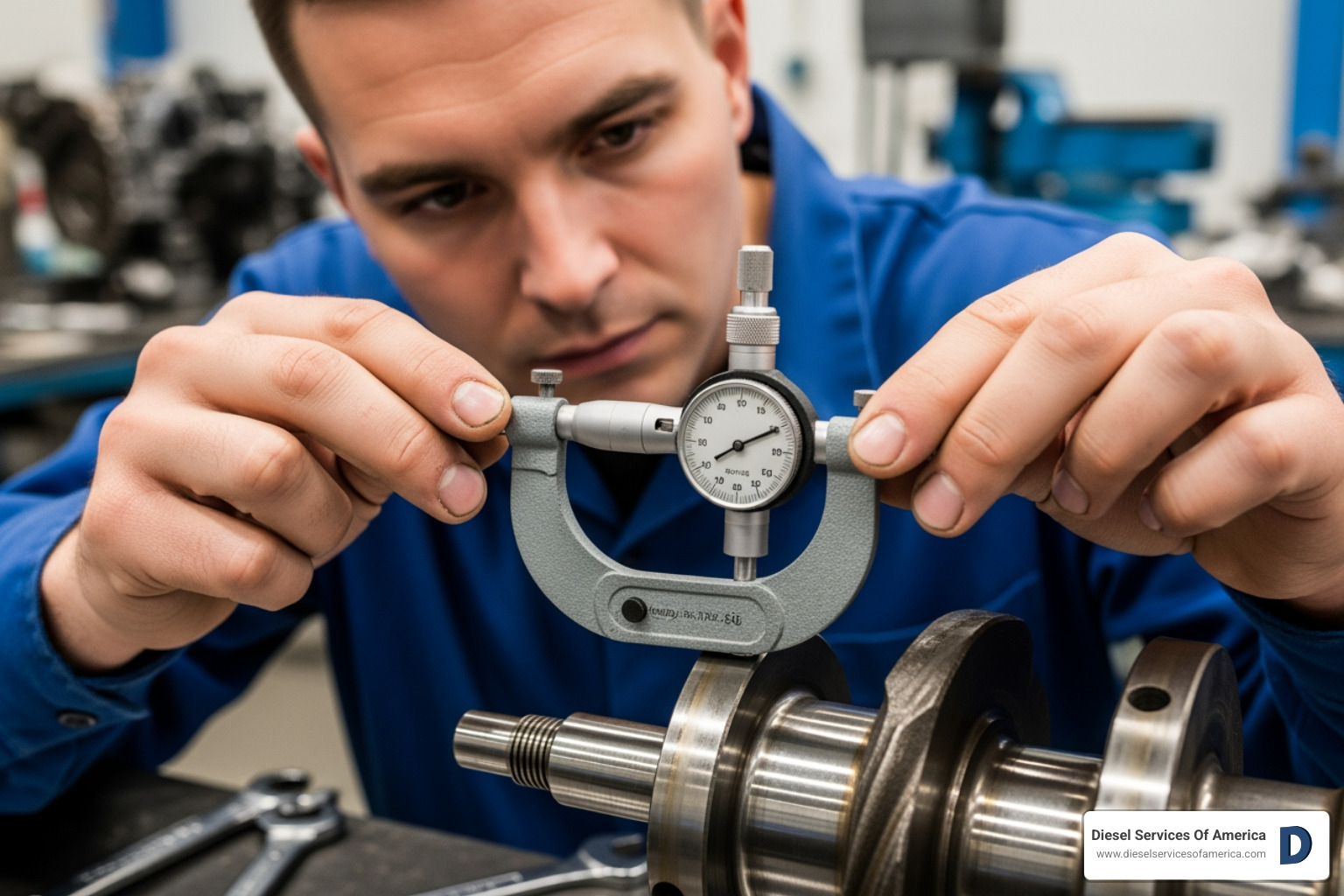

The process begins with a comprehensive initial inspection. Technicians perform a visual check for scoring or cracks and use precision instruments like micrometers to measure journal diameters and run-out. Next, the crankshaft is thoroughly cleaned via thermal cleaning and shot blasting to remove all contaminants. A critical step is magnafluxing for cracks (a form of magnetic particle inspection), a non-destructive test that uses magnetic particles to reveal hairline fractures invisible to the naked eye. This is vital for preventing catastrophic failure in high-stress marine and industrial engines. Finally, a straightness check is performed to detect and correct any bending, which could cause vibration and premature bearing wear. Once these diagnostics are complete, the restoration work begins.

Key Services Offered by a Crankshaft Repair Shop

A quality crankshaft repair shop offers a range of specialized services to address specific types of damage:

- Crankshaft Grinding: Worn or damaged journals are resurfaced to precise undersize dimensions, allowing for new bearings and proper oil clearance. This requires maintaining tolerances measured in thousandths of an inch.

- Journal Welding and Repair: For severe damage, journals are built up with specialized welding techniques, then ground and polished back to their correct dimensions. The process often includes stress-relieving.

- Straightening: Precision presses are used to return a bent crankshaft to its true axis, eliminating vibration and preventing uneven wear.

- Micro Polishing: This super-finishing process creates an exceptionally smooth journal surface, reducing friction and extending bearing life.

- Balancing: The crankshaft and rotating assembly are balanced to eliminate vibrations that can wear out bearings and other engine components.

- Nitriding: A surface hardening heat treatment that diffuses nitrogen into the steel, creating a hard, wear-resistant outer layer for improved durability and fatigue strength, ideal for heavy-duty applications.

You can learn more about these specialized services on our diesel engine crankshaft repair page.

Specialized Techniques for Marine and Industrial Engines

Repairing crankshafts for marine and industrial diesel engines requires techniques that most shops cannot provide. The sheer size of these components often makes on-site machining a necessity. We offer dockside service in South Florida and the Caribbean, bringing our equipment and technicians to your vessel to reduce downtime.

These components also demand large-scale grinding equipment capable of handling their massive size and weight while maintaining extreme precision. Furthermore, marine and industrial crankshafts are made from various alloys. As one expert noted, “Crankshafts come in various alloys. If you ‘weld repair’ journals without knowing the alloy, you will have issues down the road.” We identify the material to ensure the correct welding techniques are used for metallurgical integrity.

Our specialization in repairing large four-stroke engines and our experience with brands like MAN, MTU, and Detroit Diesel ensure we understand the unique engineering and specifications of your engine.

Choosing a Reputable Marine & Industrial Crankshaft Repair Shop

Selecting the right crankshaft repair shop is critical for the reliability of your marine or industrial diesel engine. Prioritize shops with proven experience and specialization in heavy-duty diesel mechanics, not general automotive repair. Our team, for example, has over 20 years of experience specifically with marine diesel engines.

Also, look for factory-trained technicians who are certified by manufacturers like MAN and MTU. Their expertise ensures repairs are done to the latest standards. Finally, a top-tier shop will have state-of-the-art equipment, including precision grinders, magnafluxing systems, and balancing machines, to deliver repairs that meet the highest industry standards.

What to Look for in a Top-Tier Crankshaft Repair Shop

Beyond experience, several factors distinguish a top-tier crankshaft repair shop:

- Certifications: Look for authorizations from engine manufacturers, such as our status as an authorized MAN Engines service facility. This indicates the shop meets stringent quality standards.

- Customer Testimonials: Check reviews and references to validate a shop’s reputation for quality and customer satisfaction.

- In-House Capabilities: A facility that performs all services (inspection, grinding, welding, balancing) under one roof ensures consistent quality control.

- Warranty on Work: A reputable shop will stand behind its repairs with a clear warranty, demonstrating confidence in its craftsmanship.

- Comprehensive Services: A shop that offers a full spectrum of engine machining services can provide a more holistic and reliable repair.

Questions to Ask a Potential Crankshaft Repair Shop

To find the best partner for your repair, ask these targeted questions:

- What is your experience with large marine/industrial crankshafts? Ensure they specialize in heavy-duty engines, not automotive ones.

- What inspection methods do you use? Look for a thorough process including thermal cleaning, magnafluxing, and precision measurements.

- Can you handle on-site repairs or offer dockside service? This is a significant advantage for marine applications, minimizing logistics and downtime.

- What is your typical turnaround time? This helps you plan for downtime, though it will depend on the specific repair.

- Do you provide a detailed quote before starting work? Transparency in pricing is a sign of a trustworthy shop.

Cost, Turnaround, and Logistics for Crankshaft Repair

When planning a crankshaft repair, the key considerations are turnaround time, cost, and logistics. Turnaround time varies based on the crankshaft’s size, the extent of the damage, and the specific repair processes required. While a simple repair might be quick, a large marine crankshaft with severe damage will require a more involved timeline. Always get a time estimate from your crankshaft repair shop after they have inspected the component.

For marine clients, shipping and logistics for a heavy crankshaft can be a challenge. We simplify this with dockside service throughout South Florida and the Caribbean, bringing our technicians to your vessel for assessments and some repairs. This, combined with our worldwide parts delivery, minimizes downtime and logistical headaches.

Understanding the Cost of Crankshaft Rebuilding

The cost of crankshaft repair varies significantly and is typically quoted on a per-job basis after a thorough inspection. Several factors influence the final price:

- Size and Complexity: Larger, more complex crankshafts from marine or industrial engines require more time and specialized equipment, increasing the cost.

- Extent of Damage: Minor wear that only needs light grinding and polishing will be less expensive than severe damage requiring welding, straightening, and multiple machining processes.

- Materials and Treatments: The cost of necessary materials, such as undersized bearings or specialized welding alloys, and advanced treatments like nitriding, will be included in the quote.

While repair is a significant investment, it is almost always more cost-effective than purchasing a new crankshaft for a large diesel engine, which can be exceptionally expensive. A detailed quote from a reputable shop will provide a clear breakdown of the expected costs. For more information on our comprehensive approach, visit our page on diesel engine crankshaft repair.

Finding a “Crankshaft Repair Shop Near Me”

When searching for a “crankshaft repair shop near me,” marine and industrial operators should prioritize expertise over proximity. We serve South Florida, including Fort Lauderdale, and the Caribbean, which are major hubs for marine and industrial operations.

The specialized knowledge and equipment required for heavy-duty crankshafts are not found in most local shops. Choosing an unqualified but nearby shop can lead to subpar repairs and greater costs in the long run. Our factory-trained technicians, state-of-the-art equipment, and deep knowledge of marine and industrial diesel engines like MAN and MTU mean we can handle repairs that others cannot. With our dockside service and parts delivery, we remove many logistical barriers.

When choosing a shop, focus on their track record, certifications, and specialized services. If you have questions about your repair needs, contact us for service inquiries. We provide the expert care your valuable engines deserve.

Frequently Asked Questions about Crankshaft Repair

It’s natural to have questions when your vital marine or industrial engine needs specialized attention. Here are answers to some common inquiries about crankshaft repair.

What is crankshaft grinding and why is it important?

Crankshaft grinding is a precision machining process that resurfaces worn or damaged journals—the surfaces where bearings ride. It is vital for several reasons:

- Restores Proper Bearing Clearance: Grinding allows new, undersized bearings to fit perfectly, ensuring the correct oil film for lubrication.

- Ensures Smooth Operation: A precisely ground crankshaft reduces friction, allowing the engine to run smoothly and efficiently.

- Prevents Catastrophic Failure: By correcting wear and imperfections, grinding prevents serious issues like bearing seizure or a broken crankshaft.

- Extends Engine Life: A properly reconditioned crankshaft can significantly increase the lifespan of your marine or industrial diesel engine.

What types of equipment require crankshaft repair?

Our crankshaft repair expertise is essential for a range of heavy-duty equipment:

- Marine Diesel Engines: We service engines in commercial vessels, mega-yachts, and fishing trawlers. These crankshafts endure continuous high-load operation in harsh marine environments.

- Industrial Power Generation Engines: We work on the large diesel generators that provide reliable power for data centers, hospitals, and industrial sites.

- Large Construction and Agricultural Equipment: Our skills also apply to engines in heavy machinery like excavators, bulldozers, and mining equipment. We service many trusted brands, including MAN, MTU, and Detroit Diesel.

How long does a crankshaft repair take?

The time required for a crankshaft repair depends on several factors:

- Extent of Damage: Minor wear requiring only grinding is much faster to repair than a bent or severely damaged crankshaft needing welding and straightening.

- Size and Complexity: Large crankshafts from marine and industrial engines take longer to process at each stage, from inspection to balancing.

- Shop Workload and Parts Availability: The repair shop’s schedule and the time needed to source specialized parts can also affect the timeline.

While a simple job might take a week, complex repairs on large crankshafts can take several weeks. A reputable shop will provide a realistic timeline after a thorough inspection.

Conclusion: Partnering with the Right Experts for Engine Longevity

Your engine’s crankshaft is its heart; its health is essential for your marine or industrial operations. Choosing the right crankshaft repair shop is a critical decision for ensuring engine longevity.

As we’ve covered, understanding the causes of damage, the benefits of repair over replacement, and the importance of preventative maintenance are key. The repair process itself—from inspection and magnafluxing to precision grinding, welding, and balancing—requires specialized skill and equipment.

Partnering with an experienced shop with factory-trained technicians who understand brands like MAN, MTU, and Detroit Diesel makes all the difference. At Diesel Services of America, we combine this expertise with logistical support like dockside service to minimize your downtime. We are dedicated to providing the precision and quality your high-performance engines demand.

Don’t leave your engine’s most vital component to chance. For expert crankshaft repair services, [Contact Diesel Services of America for expert crankshaft repair](https://www.dieselservicesofamerica.com/contact/) today.