Maximizing Marine Power: The Efficiency Revolution

Diesel engine efficiency improvements are changing the marine and industrial sectors, offering significant fuel savings and reduced emissions. If you’re looking to boost your vessel’s performance, here’s what you need to know:

| Key Diesel Engine Efficiency Improvements | Potential Benefit |

|---|---|

| High-expansion combustion systems | Up to 14% fuel economy improvement |

| Advanced turbocharging & air systems | 2-5% efficiency gain |

| Synthetic oil replacement | Up to 11% fuel economy boost |

| Friction-reducing technologies | 1-3% efficiency improvement |

| Waste heat recovery systems | 4-7% additional efficiency |

| Regular professional maintenance | Prevents 5-10% efficiency losses |

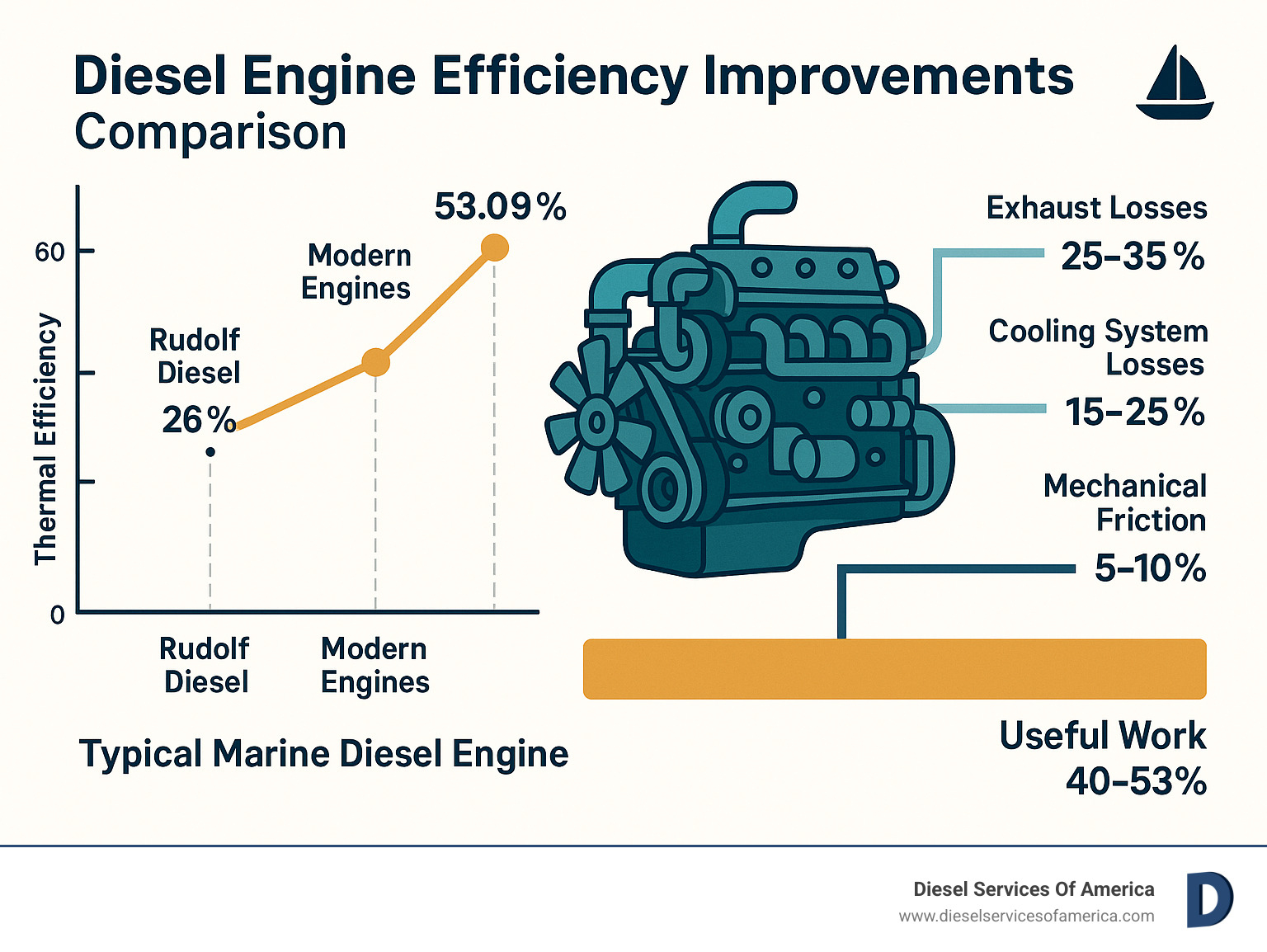

The quest for diesel efficiency has come a long way since Rudolf Diesel’s first engines achieved just 26% thermal efficiency in the 1880s. Today’s marine diesel engines typically operate at 43-46% efficiency, with cutting-edge models breaking the 50% barrier.

In April 2024, Weichai Power unveiled a record-breaking diesel engine with 53.09% thermal efficiency – a milestone that industry experts compare to “a human breaking the 100-meter sprint barrier under nine seconds.” This breakthrough translates to approximately 14% better fuel economy compared to conventional engines.

For marine fleet operators, these advancements mean substantial cost savings. A vessel with an upgraded high-efficiency diesel engine traveling extensive routes can save thousands of gallons of fuel annually, with typical payback periods under three months for efficiency-focused maintenance and upgrades.

“There shouldn’t be a trade-off between protecting the air we breathe and achieving better engine efficiency,” notes Greg Shaver of Purdue University, whose research has informed recent EPA emissions standards. Modern marine diesel efficiency improvements can simultaneously reduce fuel consumption and emissions.

Whether you operate a commercial fleet or a single vessel, understanding these efficiency technologies can significantly impact your bottom line and environmental footprint.

Key terms for Diesel engine efficiency improvements:

– Diesel engine coolant flush

– Diesel engine diagnostic tools

Understanding Diesel Engine Efficiency: Metrics & Benchmarks

Ever wonder how we measure just how efficiently your marine diesel engine turns fuel into power? Let’s break down the numbers that matter and see how today’s engines stack up against their predecessors.

How efficiency is measured

When we talk about diesel engine efficiency improvements, we’re primarily looking at thermal efficiency – the percentage of fuel energy that actually becomes useful work rather than escaping as heat.

Think of thermal efficiency like your engine’s report card. The main grade we look at is Brake Thermal Efficiency (BTE), which measures the actual power output relative to the energy in the fuel. It’s the real-world performance number that matters most to vessel operators.

Other important measurements include Indicated Thermal Efficiency (how efficiently combustion occurs before mechanical losses) and Volumetric Efficiency (how effectively your engine breathes in air).

To get these numbers, engineers use sophisticated dynamometers – essentially treadmills for engines – that measure power output and fuel consumption under various loads and conditions.

“The difference between a 46% efficient engine and one achieving 53% efficiency might not sound dramatic, but in the marine world, it’s revolutionary,” explains our lead technician at Diesel Services Of America. “It’s like getting an extra day of operation for every week at sea without refueling.”

Current state-of-the-art numbers

The journey of diesel engine efficiency improvements tells an impressive story:

| Era | Typical Thermal Efficiency | Notes |

|---|---|---|

| 1890s (Diesel’s first engines) | 26% | Revolutionary for their time |

| 1950s-1970s | 30-35% | Pre-electronic control era |

| 1990s-2000s | 38-42% | Introduction of common rail injection |

| 2010-2020 | 43-46% | Advanced electronic management |

| 2020-2024 | 46-50% | Improved combustion & turbocharging |

| 2024 (Record) | 53.09% | Weichai Power breakthrough |

| Future Target | 55%+ | DOE SuperTruck 2 program goal |

The recent breakthrough by Weichai Power represents a genuine milestone in marine propulsion. Their 53.09% thermal efficiency engine, certified by TÜV SÜD and the China Automotive Technology & Research Center, didn’t just break the 50% barrier – it shattered it.

For perspective, Rudolf Diesel’s original engines from the 1890s converted about 26% of fuel energy into useful work. Today’s standard marine diesel engines typically operate at 43-44% efficiency, with high-performance models reaching 46-48%.

What does this mean for your bottom line? A vessel traveling 250,000 kilometers annually would save approximately 12,000 liters of diesel fuel when upgrading from a standard (45-46% efficient) engine to one with 53% efficiency. That’s serious savings for any marine operation.

Looking ahead, the U.S. Department of Energy’s SuperTruck 2 program has set an ambitious target of 55% thermal efficiency – a goal that seemed impossible just a few years ago but now appears within reach.

For marine and industrial operators, understanding these benchmarks helps you make informed decisions about engine upgrades, maintenance priorities, and long-term fleet planning. The thermodynamic principles may be complex, but the benefits of increased efficiency are crystal clear: more power, less fuel, and reduced operating costs.

Game-Changing Technologies: Diesel engine efficiency improvements from Lab to Deck

The journey from laboratory innovations to practical applications on marine vessels is where the rubber meets the road—or in this case, where engineering meets the waves. Let’s explore the remarkable technologies that have collectively pushed diesel engine efficiency improvements beyond what was once thought possible.

Diesel engine efficiency improvements crossing the 50% barrier

Breaking the 50% thermal efficiency barrier wasn’t just an incremental step—it was a quantum leap that required simultaneous advances across multiple systems. Weichai Power’s record-setting 53.09% efficient engine didn’t happen overnight.

“Four consecutive breakthroughs were due to nearly 4,000 days of engineers’ intellectual dedication and open collaboration with universities and research institutions,” notes Tan Xuguang, Chairman of Weichai Power.

This achievement represents the culmination of high-expansion combustion technology that optimizes chamber geometry to extract maximum energy from each fuel molecule. Paired with mixed-flow pressurization systems that precisely control air delivery, these engines achieve what was once thought impossible.

The development yielded an impressive 176 invention patents and 68 utility model patents. Think about that for a moment—hundreds of innovations working together to achieve gains that sometimes measured just 0.1% at a time, eventually adding up to the breakthrough we see today.

When your vessel is equipped with an engine featuring high-efficiency fuel injection systems operating at pressures up to 2,500 bar, you’re benefiting from ultra-precise fuel atomization that extracts more power from every drop of diesel. Meanwhile, low-resistance friction reduction technologies with specialized coatings minimize energy losses where components meet.

Diesel engine efficiency improvements through waste heat recovery & advanced boosting

Did you know that traditional diesel engines lose 25-35% of energy as exhaust heat? It’s like throwing away a third of your fuel before it does any work. Modern marine engines are changing this equation through clever heat recovery systems.

Organic Rankine Cycle (ORC) technology captures this otherwise wasted exhaust heat to generate additional power, improving overall system efficiency by 4-7%. Think of it as getting free energy that used to literally go up in smoke.

Turbo-compounding takes a different approach, extracting energy from exhaust gases to provide additional mechanical or electrical power. It’s like adding a small bonus engine powered by your main engine’s leftovers.

At Diesel Services Of America, we’ve seen how proper turbocharger service and installation transforms marine diesel performance. Our senior technician often reminds clients: “A properly ‘blueprinted’ turbocharger can restore or even exceed original factory efficiency. When tip-to-blade clearance exceeds .020 inches, efficiency drops noticeably.”

Variable Geometry Turbochargers (VGT) adjust automatically to optimize airflow across all engine speeds and loads, while two-stage turbocharging uses sequential turbochargers to eliminate lag and improve efficiency throughout your vessel’s entire operating range.

Emerging concepts: hybrid combustion & alternative fuels

The marine diesel horizon is expanding with innovations that sound like science fiction but deliver real-world efficiency gains.

Researchers at Argonne National Laboratory have developed Reactivity Controlled Compression Ignition (RCCI) engines that combine gasoline and diesel in a novel combustion process. These hybrid engines achieve diesel-like efficiency with gasoline-like emissions—essentially getting the best of both worlds while eliminating expensive aftertreatment devices.

Partially Premixed Combustion (PPC) creates a more homogeneous air-fuel mixture for cleaner, more efficient combustion. The result? More power with fewer emissions—a win-win for marine operators facing tightening regulations.

Alternative fuels are making waves too. Hydrogen blending adds small percentages of hydrogen to diesel fuel, improving combustion efficiency while reducing emissions. Meanwhile, advanced biofuels designed specifically for high-efficiency diesel combustion offer renewable options without sacrificing the power marine operators depend on.

These emerging technologies from research initiatives like SuperTruck 2 show tremendous promise for marine applications where the combination of high efficiency and clean operation isn’t just nice to have—it’s increasingly essential for both economic and regulatory reasons.

For marine and industrial operators looking to stay ahead of the curve, understanding these diesel engine efficiency improvements isn’t just about technical curiosity—it’s about preparing for a future where performance and sustainability go hand in hand.

Minimizing Energy Losses: Components, Maintenance & Operational Best Practices

Even the most advanced marine diesel engine can lose efficiency without proper care. While cutting-edge technologies push theoretical limits, most vessel owners can achieve remarkable gains through smart maintenance and operation. Let’s explore how to keep your engine performing at its best.

Combustion & thermal management

Your engine’s combustion chamber is where the magic happens—and where efficiency can be won or lost.

Running engines at optimal temperatures isn’t just about preventing overheating. Research shows that properly managing piston temperatures can boost efficiency by 2-5% while cutting particulate emissions by up to 27%. This is especially valuable for marine engines that frequently switch between different power demands.

“Many boat owners don’t realize how much fuel gets wasted during cold starts and light operation,” explains our technical director at Diesel Services Of America. “Those first 15 minutes of warm-up might only be a small part of your day, but they have a huge impact on efficiency and engine life.”

Modern thermal management goes beyond simple thermostats. Variable cooling systems adjust flow based on actual needs rather than engine speed. Insulated exhaust components keep heat where it belongs, improving combustion efficiency. And optimized warm-up procedures can get your engine to ideal operating temperature faster and more efficiently.

These approaches not only save fuel but can extend your engine’s lifespan by reducing thermal stress and preventing incomplete combustion issues.

Air, fuel & lubrication systems

Think of your marine diesel as an athlete—it needs clean air, quality fuel, and proper lubrication to perform at its best.

On the air side, high-flow filters that don’t restrict airflow make a noticeable difference. Clean, efficient intercoolers ensure proper charge air density. And well-designed intake manifolds distribute air evenly to all cylinders.

For fuel systems, maintaining common-rail injectors at their 2,500 bar pressure capability ensures optimal atomization. Regular injector cleaning preserves precise spray patterns, while timely fuel filter replacement prevents contamination that can reduce injection precision.

One of the simplest yet most effective upgrades is switching to synthetic oil, which can improve fuel economy by up to 11%. These advanced lubricants reduce internal friction and maintain their protective properties longer, especially in the demanding conditions marine engines face.

“We’ve seen boats gain 5-7% in fuel economy simply by upgrading to premium synthetic oil and sticking to a proper filtration schedule,” our service manager notes. “It’s often the easiest way to boost efficiency without major modifications.”

Friction & parasitic losses

Every marine diesel engine fights an internal battle against friction and parasitic loads that can steal 10-15% of output power. Winning this battle means more power reaches your propeller.

Low-viscosity oils provide adequate protection with less resistance. Advanced coatings like diamond-like carbon (DLC) on critical components reduce wear and friction. Roller bearings can replace plain bearings in high-load applications, while optimized piston rings maintain sealing with minimal drag.

Beyond friction, parasitic loads drain power too. Variable-flow oil pumps deliver precise pressure based on need, not engine speed. Electric water pumps run only when needed rather than constantly. And accessory electrification can replace power-hungry belt-driven components.

For older marine engines, “blueprinting” components to tighter-than-factory tolerances can restore or even improve efficiency. This precision machining is particularly effective for turbochargers, where housing erosion gradually increases clearances and reduces performance.

Vehicle-level tactics

Marine efficiency extends beyond the engine room to the entire vessel’s operation.

Hull cleaning might seem basic, but removing marine growth can reduce drag by 5-15%—a significant fuel saver. Properly sized propellers transfer engine power more effectively, while trim and ballast management ensures your vessel moves through water with minimal resistance.

How you operate your vessel matters too. Finding your optimal cruise speed often saves more fuel than running at maximum power. Smart route planning that accounts for currents and conditions can significantly reduce fuel consumption. And proper weight distribution minimizes resistance and maximizes efficiency.

When you combine engine improvements with vessel optimization, the results can be dramatic—often reducing fuel consumption by 20-30% compared to poorly maintained systems. That’s why at Diesel Services Of America, we take a holistic approach to marine diesel efficiency.

For professional help maintaining your marine diesel at peak efficiency, consider our Regular Maintenance for Your Diesel Engine services. Our factory-trained technicians can identify efficiency losses and implement proven solutions to keep your vessel performing at its best.

Economics, Environment & The Road Ahead

The economic and environmental impact of diesel engine efficiency improvements goes well beyond just saving fuel, particularly in the marine sector where regulations are tightening and operators face mounting pressure to reduce emissions.

Diesel vs Alternative Powertrains in Heavy-Duty Marine & Industrial Roles

While battery-electric and hydrogen fuel cells grab headlines, diesel engines maintain clear advantages for marine and industrial applications that are hard to ignore:

Diesel fuel packs a powerful punch with approximately 45.5 MJ/kg energy density – that’s 65-90 times more energy per kilogram than typical lithium-ion batteries. This massive difference explains why diesel remains the practical choice for long-range marine operations where weight and range matter.

“The reality is that global marine fueling infrastructure is built around diesel,” explains our lead technician at Diesel Services Of America. “Alternative fueling or charging stations remain limited in most ports, and the retrofit economics strongly favor incremental diesel improvements for existing vessels.”

Marine operations often involve extended periods at steady load – precisely where optimized diesel engines shine brightest. While harbor operations with variable loads might benefit from hybrid systems, the reliability of diesel for emergency power requirements remains best.

Real-world data tells the story: diesel engines still power roughly 90% of America’s freight movement, with modern marine diesel engines operating 30% more efficiently than their gasoline counterparts. This isn’t likely to change overnight.

“We’ll see a technology mix evolve,” our engineering team predicts. “High-efficiency diesel will remain dominant for long-range vessels, while alternatives will gain ground in specific niches like harbor craft and short-haul ferries where their limitations matter less.”

Emissions compliance without sacrificing efficiency

Historically, emissions controls often came with an efficiency penalty, forcing a choice between environmental compliance and performance. Today’s technologies are eliminating this painful trade-off:

Modern Selective Catalytic Reduction (SCR) systems can slash NOx emissions by over 90% with minimal efficiency impact. When combined with well-designed Diesel Particulate Filters (DPF) and advanced Exhaust Gas Recirculation (EGR) systems with precise cooling and control, these technologies work together to meet stringent emissions standards while maintaining or even improving efficiency.

Advanced control strategies make a huge difference too. Variable Valve Actuation enables cylinder deactivation during idling and low-load operation, reducing both emissions and fuel consumption. Intelligent thermal management systems speed up catalyst warm-up to reduce cold-start emissions, while model-based controls use predictive algorithms to optimize combustion in real-time.

The upcoming EPA heavy-duty regulations (effective 2027) have been shaped by research showing that advanced technologies can simultaneously improve efficiency and reduce emissions – a regulatory approach that encourages innovation rather than forcing compromises.

Future targets & research roadmap

The journey toward diesel efficiency continues with ambitious targets on the horizon:

The U.S. Department of Energy’s SuperTruck program has set an impressive 55% brake thermal efficiency goal, while industry analysts project commercial marine engines could eventually reach 58-60% system efficiency when combined with waste heat recovery systems.

Emerging technologies promise to push these boundaries even further. Digital twins – virtual models that optimize engine operation in real-time – are beginning to make their way from research labs to commercial applications. AI-improved controls using machine learning algorithms continuously adapt to changing conditions, while sustainable biofuels designed specifically for high-efficiency diesel engines offer a path to carbon-neutral operation without requiring all-new infrastructure.

“We’re witnessing a fascinating convergence of mechanical engineering, materials science, and digital technology,” notes our technical director. “The marine diesel engines we’ll be servicing in 2030 will likely achieve efficiency levels that seemed impossible just a decade ago.”

The U.S. diesel engine market is projected to grow by 5.2% annually, driven by demand for cleaner, more efficient technologies. For marine operators working with Diesel Services Of America, this means continued access to innovations that improve both environmental performance and operational economics.

The future of marine diesel isn’t about choosing between efficiency and environment – it’s about achieving both through smart technology and proper maintenance. Our specialized diesel engine performance improvement services help vessel operators stay ahead of this curve.

Frequently Asked Questions about Diesel Engine Efficiency Improvements

What is the single biggest contributor to diesel engine efficiency losses?

The largest energy thief in your marine diesel engine is heat rejection – with most of that valuable energy escaping through your exhaust and cooling systems. When we break down where your fuel’s energy actually goes:

- Exhaust energy loss: 25-35% of fuel energy

- Cooling system loss: 15-25% of fuel energy

- Mechanical friction: 5-10% of fuel energy

- Useful work: 40-53% of fuel energy (the part that actually propels your vessel)

Today’s cutting-edge efficiency improvements target this waste heat aggressively. Waste heat recovery systems can recapture 4-7% of otherwise lost energy, essentially giving you free power. Meanwhile, advanced combustion designs are reducing how much heat escapes in the first place.

“Understanding your engine’s energy balance is like reviewing your financial statements,” explains our diagnostic specialist at Diesel Services Of America. “Once you see where your fuel dollars are leaking away, we can plug those energy leaks and improve your bottom line.”

Can maintenance alone deliver noticeable efficiency gains?

Without question! Proper maintenance prevents efficiency losses of 5-10% or more in marine diesel engines – that’s thousands of gallons of fuel saved annually for commercial vessels.

Regular oil changes with the correct grade prevent efficiency-robbing friction increases. Making the switch to synthetic lubricants can boost fuel economy by up to 11% while providing superior protection. Many of our clients implement oil analysis programs that optimize change intervals for maximum protection and efficiency.

Your fuel system needs similar attention. Clean injectors ensure proper fuel atomization for complete combustion. Regular fuel filter replacement prevents pressure drops that compromise injection quality. Maintaining your water separator prevents combustion problems and corrosion that can permanently damage efficiency.

Don’t forget your air system! Clean air filters ensure proper air-fuel ratios for optimal combustion. Turbocharger inspection and service maintains the boost pressure that modern marine diesels depend on. And intercooler cleaning ensures you’re getting maximum air density for complete fuel combustion.

We’ve worked with vessels where comprehensive maintenance restored 7-9% fuel efficiency in neglected marine engines – that’s equivalent to major hardware upgrades, but at a fraction of the cost.

How soon can fleets recoup investment in high-efficiency upgrades?

The payback on diesel engine efficiency improvements often surprises our clients – many upgrades pay for themselves remarkably quickly, especially for vessels in regular service.

When we perform turbocharger blueprinting (typically $1,500-3,000 per turbocharger), we usually see efficiency improvements of 2-5%. For vessels in regular service, that investment pays for itself in under 3 months of normal operation.

Fuel system upgrades ranging from $3,000-8,000 (depending on engine size) deliver efficiency improvements of 3-7% with payback periods of just 3-6 months for commercial vessels with regular routes.

For operators ready for more comprehensive improvements, a full efficiency upgrade package ($10,000-25,000 for medium-sized marine engines) can boost efficiency by 8-14% with payback periods of 6-12 months for vessels with high utilization.

“We’re not just selling parts and service – we’re selling fuel savings,” says our fleet service coordinator. “For vessels operating 2,000+ hours annually, even substantial investments in efficiency technology typically pay for themselves within a year.”

The math is straightforward: if your vessel consumes 50 gallons of diesel per hour, a 10% efficiency improvement saves 5 gallons hourly. At $4 per gallon, that’s $20 every hour in real savings – or $40,000 annually for a vessel operating 2,000 hours. Those numbers make efficiency improvements one of the smartest investments any fleet operator can make.

Conclusion

The pursuit of diesel engine efficiency improvements continues to transform marine and industrial power systems. From Rudolf Diesel’s original 26% efficient engines to today’s record-breaking 53.09% thermal efficiency, the journey represents over a century of engineering innovation.

For marine vessel operators, these advancements translate to substantial benefits:

– Reduced fuel costs

– Extended range and endurance

– Lower emissions and environmental impact

– Improved compliance with increasingly stringent regulations

At Diesel Services Of America, we bring these efficiency technologies to our marine and industrial clients throughout Southeast Florida and the Caribbean. Our factory-trained technicians specialize in implementing proven efficiency improvements through both maintenance excellence and strategic upgrades.

Whether you’re operating a single vessel or managing a fleet, the economics of diesel efficiency have never been more compelling. With proper maintenance and targeted improvements, modern marine diesel engines can deliver performance that was unimaginable just a decade ago.

For more information about maximizing your marine diesel efficiency, contact our team at Diesel Services Of America. We provide comprehensive marine diesel services in Southeast Florida and worldwide parts delivery to keep your engines operating at peak efficiency.

The future of marine propulsion is more efficient, cleaner, and more economical – and we’re here to help you steer this evolving landscape with expert service and support.