Why Diesel Engine Glow Plug Replacement Matters for Marine and Industrial Operations

Diesel engine glow plug replacement is a critical maintenance task for reliable cold starts and optimal performance in marine and industrial equipment. For fleet managers in Southeast Florida or single boat owners, knowing when to replace these parts can prevent costly breakdowns and downtime.

Quick Answer for Diesel Engine Glow Plug Replacement:

- Signs of failure: Hard starting, white smoke, rough idling, misfiring

- Testing method: Use a multimeter to check resistance (should be 0.1-6 Ohms)

- Typical lifespan: Up to 100,000 miles or equivalent engine hours

- Replacement cost: $10-$320 per plug, plus $80-$160+ labor

- Key tip: Replace all plugs at once, even if only one has failed

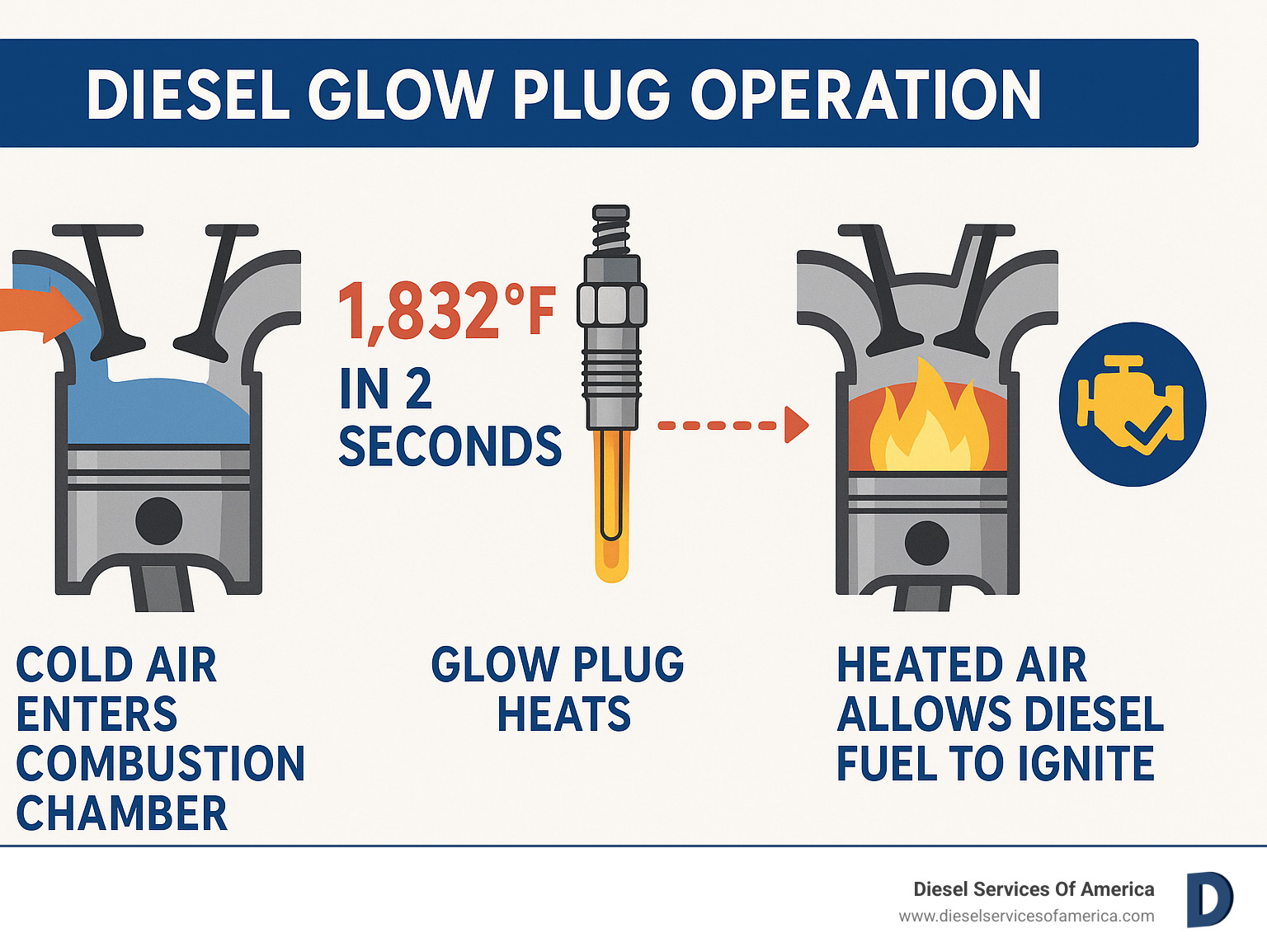

Glow plugs heat the air in a diesel’s combustion chamber to 1,832°F in under two seconds, enabling fuel ignition for cold starts. Even in warm Florida climates, they are essential for proper combustion and reducing engine wear. Modern ceramic glow plugs work almost instantly but wear out over time, especially in harsh marine environments with saltwater corrosion and constant vibration. Timely replacement is critical, as these small components can mean the difference between a smooth start and being stranded.

Basic Diesel engine glow plug replacement terms:

Understanding the Role of Glow Plugs in Marine and Industrial Diesels

When a marine diesel engine cranks but won’t start, a failed glow plug is a common culprit. Diesel engine glow plug replacement is vital because these parts are unique to diesels. Unlike gasoline engines that use spark plugs, diesel engines rely on compression ignition. The engine compresses air to immense pressures, heating it enough to ignite injected fuel spontaneously. However, this process only works reliably when the engine is warm.

Glow plugs solve this problem. These pencil-shaped heaters, located in each cylinder’s combustion chamber, pre-heat the air to 1,832°F in seconds. Without this pre-heating, a cold diesel will struggle to start, run rough, and produce excessive white smoke. Beyond starting, glow plugs are essential for overall engine health and reducing emissions. Proper initial combustion means less unburned fuel, cleaner exhaust, and improved reliability, which is critical for any marine vessel.

If you’re dealing with starting issues, learn more about our marine diesel engine services.

Why Glow Plugs Are Still Essential in Warmer Climates

Even in South Florida’s heat, an engine is considered cold until it reaches operating temperature. The large metal engine block acts as a heat sink, absorbing heat during air compression. This can lower the air temperature just enough to hinder ignition. Glow plugs compensate for this heat absorption, ensuring reliable starts every time.

The benefits include smoother, cleaner operation and reduced engine wear, as the starter and battery aren’t strained. Functional glow plugs also eliminate the embarrassing white smoke from incomplete combustion and improve fuel efficiency.

How Many Glow Plugs Does My Engine Have?

Typically, an engine has one plug per cylinder. A six-cylinder diesel will have six glow plugs. Most modern engines use in-cylinder plugs for precise heating. Some older industrial engines might have a single in-manifold plug (Thermostart system) to heat all incoming air, but this design is less effective and less common today.

While most designs are straightforward, some specialized engines have unique configurations. The best way to be certain is to check your manufacturer’s specifications or consult with our factory-trained technicians, who can identify your engine’s specific needs.

Diagnosing Faulty Glow Plugs: Symptoms and Testing

A failing glow plug can leave your marine engine or industrial generator struggling to start. They often weaken over time, so your need for diesel engine glow plug replacement can sneak up on you. Paying attention to the warning signs is key.

Our technicians begin by checking for diagnostic codes. Modern diesels often have an engine warning light or glow plug indicator to signal a problem with the pre-heating system or glow plug controller, giving us a head start on diagnosis.

Common Signs of Glow Plug Failure

Your engine will signal when its glow plugs are failing. Watch for these symptoms:

- Hard starting: The engine cranks excessively before firing up, or fails to start at all.

- Engine misfiring or rough idling: The engine stumbles or runs unevenly for the first few minutes after starting.

- Excessive white smoke: Thick clouds of white smoke from the exhaust at startup indicate incomplete combustion.

- Black smoke: Less common, but can indicate very poor combustion due to unburnt fuel.

- Decreased power and acceleration: The engine feels sluggish as it struggles to run efficiently.

How to Test Your Glow Plugs

Testing glow plugs requires basic electrical tools. The most reliable method is checking resistance with a multimeter. With the engine cool and battery disconnected, locate the plugs and disconnect their wiring.

Set your multimeter to Ohms. Touch one lead to an engine ground and the other to the glow plug terminal. A healthy plug should read between 0.1 and 6 Ohms. A reading of “OL” (open loop) or infinite resistance means the plug has failed.

An amperage draw test is more thorough, measuring the current each plug uses, but requires specialized tools. While DIY testing is possible, professional diagnosis is often faster and safer for complex marine and industrial systems. Our technicians can accurately assess the entire system. For a detailed guide, see our post on How to Remove, Test & Replace Glowplugs in a Diesel Engine.

The Complete Guide to Diesel Engine Glow Plug Replacement

For diesel engine glow plug replacement on marine and industrial equipment, taking shortcuts can lead to expensive mistakes. Proper procedure is essential for these critical engines.

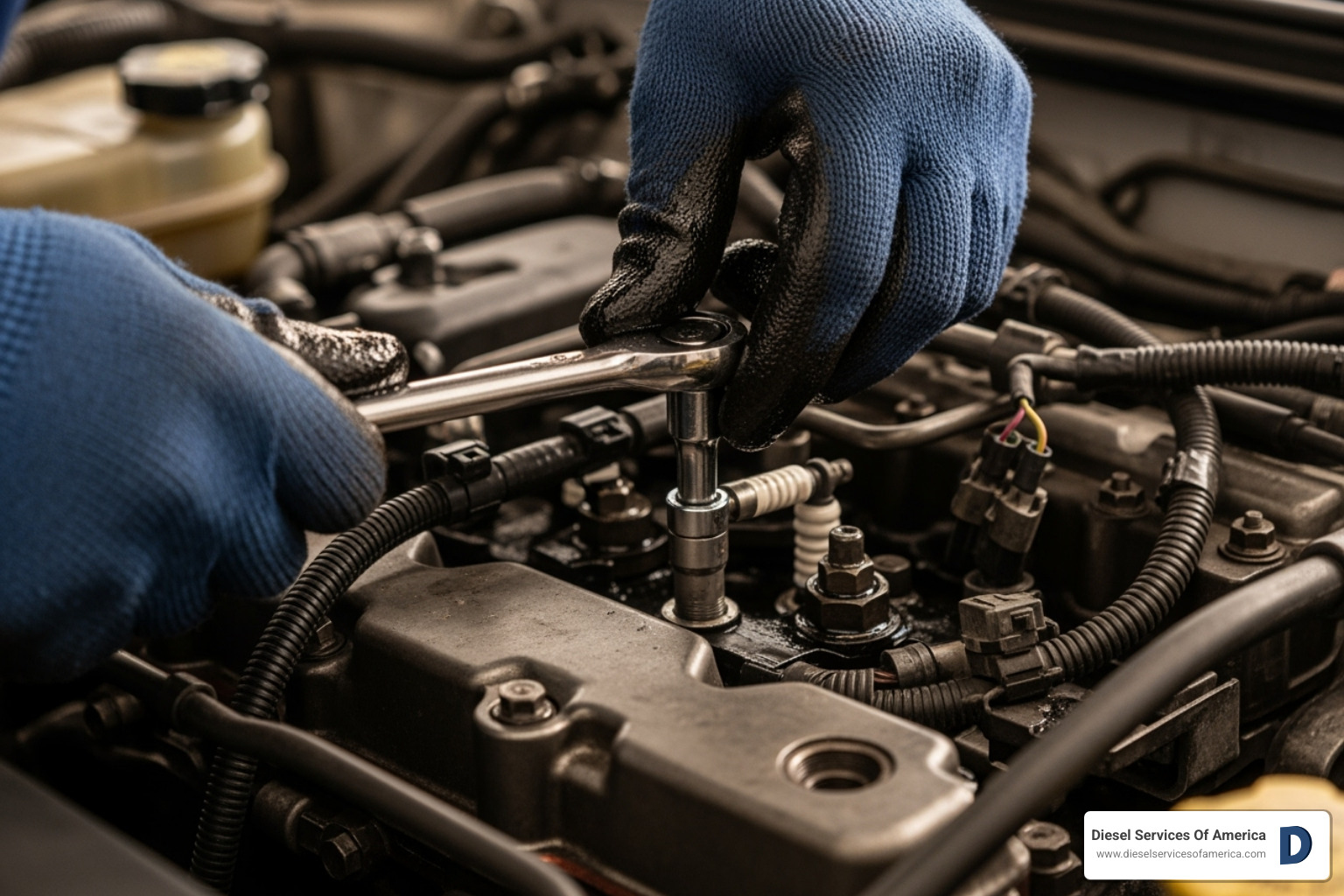

Safety and preparation are paramount. Always disconnect the battery (negative terminal first) and work on a completely cool engine. Use safety glasses and gloves. Essential tools include a quality socket set with deep sockets, a torque wrench, extensions, penetrating oil, anti-seize compound, and compressed air. A glow plug reaming tool is also invaluable for cleaning carbon buildup.

Preparing for a Marine Diesel Engine Glow Plug Replacement

Patience is key, as saltwater corrosion makes marine engine work challenging. Start by thoroughly cleaning the area around each glow plug with brake cleaner and compressed air to prevent debris from entering the cylinder. The most critical step is to soak the plugs with penetrating oil, ideally overnight, to prevent them from breaking during removal. You may need to remove other components for access, so take photos as you go.

Step-by-Step Removal and Installation

- Disconnect Electrics: Carefully remove the electrical connectors or bus bar from each glow plug.

- Remove Old Plugs: Apply steady, even pressure with a deep socket and ratchet. If a plug is stuck, stop, reapply penetrating oil, and wait. Do not force it.

- Clean the Holes: Once the old plugs are out, use a reaming tool to clean carbon deposits from the glow plug holes. This ensures the new plugs seat correctly.

- Install New Plugs: Apply a small amount of anti-seize compound to the threads of the new plugs. Start each plug by hand to avoid cross-threading.

- Torque to Spec: Use a torque wrench to tighten the plugs to the manufacturer’s specification (typically 10-22 Nm or 7-16 ft-lbs). Over-tightening is a primary cause of breakage.

- Reconnect and Test: Reconnect all wiring and components, then reconnect the battery and test start the engine.

For more details, see our Glow Plug Installation and Removal Guide.

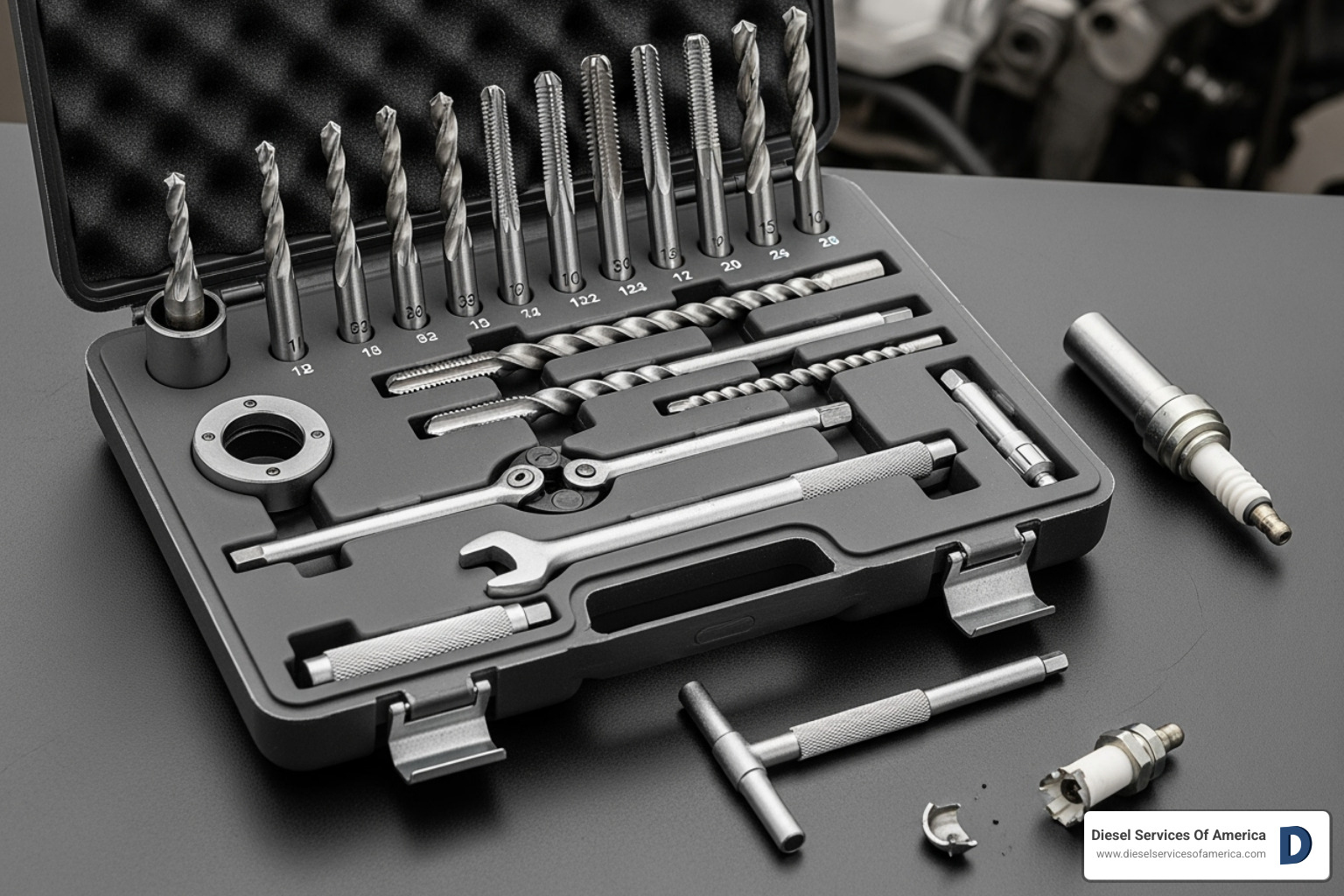

Challenges in Diesel Engine Glow Plug Replacement: Stuck and Broken Plugs

Even with careful prep, plugs can get stuck or break due to carbon buildup, swollen tips, or corrosion. A snapped glow plug leaves part of its body in the cylinder head, creating a serious problem.

Broken plug extraction requires specialized tools to remove the fragment without damaging the cylinder head. In a worst-case scenario, the cylinder head must be removed for repair. If you encounter a stuck plug or one breaks, know when to call for help. Our technicians have the tools and experience for these difficult extractions. Learn more at our services page.

Glow Plug Lifespan, Costs, and Types

Understanding glow plug lifespan helps with maintenance planning. Quality glow plugs can last up to 100,000 miles or an equivalent 3,000-5,000 engine hours. However, lifespan in marine and industrial settings is affected by several factors:

- Engine Hours & Usage: Frequent starts and cycles, common in charter boats and industrial equipment, cause more wear.

- Cold Start Frequency: Each cold start puts stress on the heating elements.

- Fuel Quality: Poor quality diesel causes carbon buildup, leading to premature failure.

- Overall Engine Condition: Issues like worn injectors or poor compression put extra strain on glow plugs.

Different Types of Glow Plugs for Your Diesel Engine

Choosing the correct glow plug type is crucial for performance. The two main types are metal and ceramic.

| Feature | Metal Glow Plugs | Ceramic Glow Plugs |

|---|---|---|

| Material | Metal heating element (e.g., nickel-chromium) | Ceramic heating element (e.g., silicon nitride) |

| Operating Temp. | Up to 1,832°F (1000°C) | Up to 2,192°F (1200°C) or higher |

| Heat-up Time | A few seconds | Less than 2 seconds (very rapid) |

| Durability | Good, but can be susceptible to swelling/breakage | Excellent, more resistant to heat and corrosion |

| Voltage | Typically 12V or 24V | Often lower voltage (e.g., 5V, 7V) requiring specific controllers |

| Common Use | Older engines, some current applications | Modern, high-performance diesel engines |

Ceramic glow plugs are the modern standard, offering faster heat-up times, higher temperatures, and better durability than older metal glow plugs. Most modern engines use a parallel wiring system, where one failed plug doesn’t affect the others. Older serial systems are like old Christmas lights; if one fails, the circuit is broken. Always use the exact type of plug specified for your engine to avoid damage.

What is the Estimated Cost of Replacement?

Costs for Diesel engine glow plug replacement vary widely.

- Parts Cost: Individual plugs range from $10 for basic metal types to $320 for high-end ceramic plugs, depending on the engine and need for marine-grade components.

- Labor Cost: Labor typically starts at $80 to $160 but can be much higher for marine and industrial engines due to difficult access, often requiring 3+ hours of work.

- Total Cost: A professional replacement often costs $300 or more. For larger engines or those needing premium ceramic plugs, the total can exceed $800 to $1,500.

While DIY is tempting, the risk of breaking a plug makes professional installation a wise investment for critical equipment.

Frequently Asked Questions about Glow Plug Maintenance

Here are answers to common questions we receive about glow plug maintenance at our Fort Lauderdale service center.

Should I replace all glow plugs at once or just the faulty one?

Always replace all of them at once. Glow plugs wear at a similar rate. If one has failed, the others are likely near the end of their service life. Replacing them all simultaneously ensures uniform heating for smooth starts, improves engine performance, and saves on future labor costs. It’s smart preventative maintenance that prevents being stranded by another failed plug weeks later.

What happens if I ignore a bad glow plug?

Ignoring a bad glow plug leads to escalating problems. Initially, you’ll experience hard starting, which strains the starter and battery. This is followed by incomplete combustion, causing excessive white smoke, rough running, and engine misfires. The biggest concern is a loss of reliability, which is unacceptable for commercial marine or industrial operations. Over time, this can cause damage to the fuel system and other engine components, turning a small issue into a costly repair.

What are the correct torque specifications for glow plugs?

Proper torque is critical to avoid breaking plugs or damaging the cylinder head. Specifications vary by manufacturer but are typically between 10 to 22 Newton-meters (Nm), or about 7-16 ft-lbs. Using the wrong torque is a common cause of major problems. Over-tightening can snap the plug, while under-tightening can lead to poor performance and failure. Our technicians use calibrated tools and have access to the exact specifications for your engine, making professional installation the safest choice.

Ensure Your Engine’s Reliability with Proper Maintenance

Reliable engine starting is non-negotiable when you’re at sea or running critical industrial equipment. While it may seem minor, diesel engine glow plug replacement is an essential maintenance task for ensuring that reliability. Functional glow plugs do more than aid cold starts; they promote efficient combustion, reduce emissions, and minimize engine wear.

In the demanding worlds of marine and industrial operations, reliability means uptime and productivity. Regular inspection and timely replacement of glow plugs is a smart investment in the uninterrupted performance of your valuable assets. Staying ahead of glow plug issues prevents emergency calls, reduces downtime, and ensures you can depend on your equipment.

At Diesel Services of America, our factory-trained technicians have helped operators throughout Fort Lauderdale and Southeast Florida keep their engines running strong for years. We understand the unique challenges of marine environments, from saltwater corrosion to constant vibration.

We offer comprehensive dockside service in South Florida and the Caribbean, plus worldwide parts delivery. Don’t let a failing glow plug become a major problem. Our team has the specialized tools to handle even the most challenging replacement jobs, including stuck or broken plugs.

Contact our marine diesel experts today to ensure your engine’s reliability for years to come. Your peace of mind is worth it.