Why Diesel Engine Parts Sourcing Makes or Breaks Your Operation

Diesel engine parts sourcing is the strategic process of acquiring components for marine and industrial diesel engines. For fleet managers and boat owners in South Florida and the Caribbean, an effective strategy is crucial for:

- Minimizing downtime with fast access to quality parts

- Ensuring compatibility with specific engine models (Caterpillar, Cummins, Detroit Diesel, MAN, etc.)

- Balancing cost and quality between genuine OEM, aftermarket, or remanufactured options

- Partnering with suppliers who offer technical expertise and reliable delivery

- Calculating the total cost of ownership beyond the initial price

When a vessel or industrial equipment goes down, every hour of downtime costs money. Many businesses struggle with high procurement costs, long lead times, and inconsistent supply. The difference between a quick repair and a costly breakdown is often having the right sourcing strategy in place before you need it.

For marine and industrial use, sourcing isn’t just about finding the cheapest part. It’s about understanding your engine’s performance requirements, navigating environmental regulations, and building relationships with suppliers who deliver quality, especially when operating in remote locations across the Caribbean or Southeast Florida. The stakes are too high to treat parts sourcing as an afterthought.

Diesel engine parts sourcing terms explained:

- Diesel engine repair service

- Marine diesel engine maintenance

Understanding Your Options: Genuine, Aftermarket, and Remanufactured Parts

When sourcing diesel engine parts, your first decision is the type of part to buy. This choice impacts performance, longevity, and total cost. Let’s break down your three main options: genuine (OEM), aftermarket, and remanufactured. Each has its place, and knowing when to use which can save you time, money, and headaches.

The diesel parts market is evolving. Remanufactured parts are gaining traction for offering solid performance without the OEM price, and they are more environmentally friendly. The aftermarket segment is also growing, showing that operators are looking beyond traditional OEM-only sourcing.

Genuine (OEM) Parts

Genuine parts come directly from your engine’s manufacturer (Original Equipment Manufacturer), whether it’s a Caterpillar, Cummins, or Detroit Diesel. As we cover in Basic Information on Engine Diesel Parts, these are the gold standard.

With OEM parts, you get guaranteed compatibility with your specific engine model. The part was designed and tested for your engine, ensuring a perfect fit. The quality and reliability are typically the highest available, as they meet strict manufacturing standards and undergo rigorous testing. They also usually come with a manufacturer’s warranty, providing peace of mind for critical applications. The trade-off is a higher cost, but for essential components where failure is not an option, the price is often justified.

Aftermarket Parts

Aftermarket parts are made by companies other than the original manufacturer. They are designed as replacements for OEM components. The primary advantage is cost savings, which can be significant for fleet maintenance or tight budgets. You may also find wider availability, which is helpful when an OEM part has a long lead time.

However, quality can vary widely. Some aftermarket manufacturers produce parts that meet or exceed OEM specifications, while others do not. A poor-quality part can fail prematurely, leaving you in a worse position. Common aftermarket parts include filters, belts, water pumps, alternators, and starters. For non-critical applications, carefully selected aftermarket parts can be a smart choice, provided you use a supplier who vets their offerings.

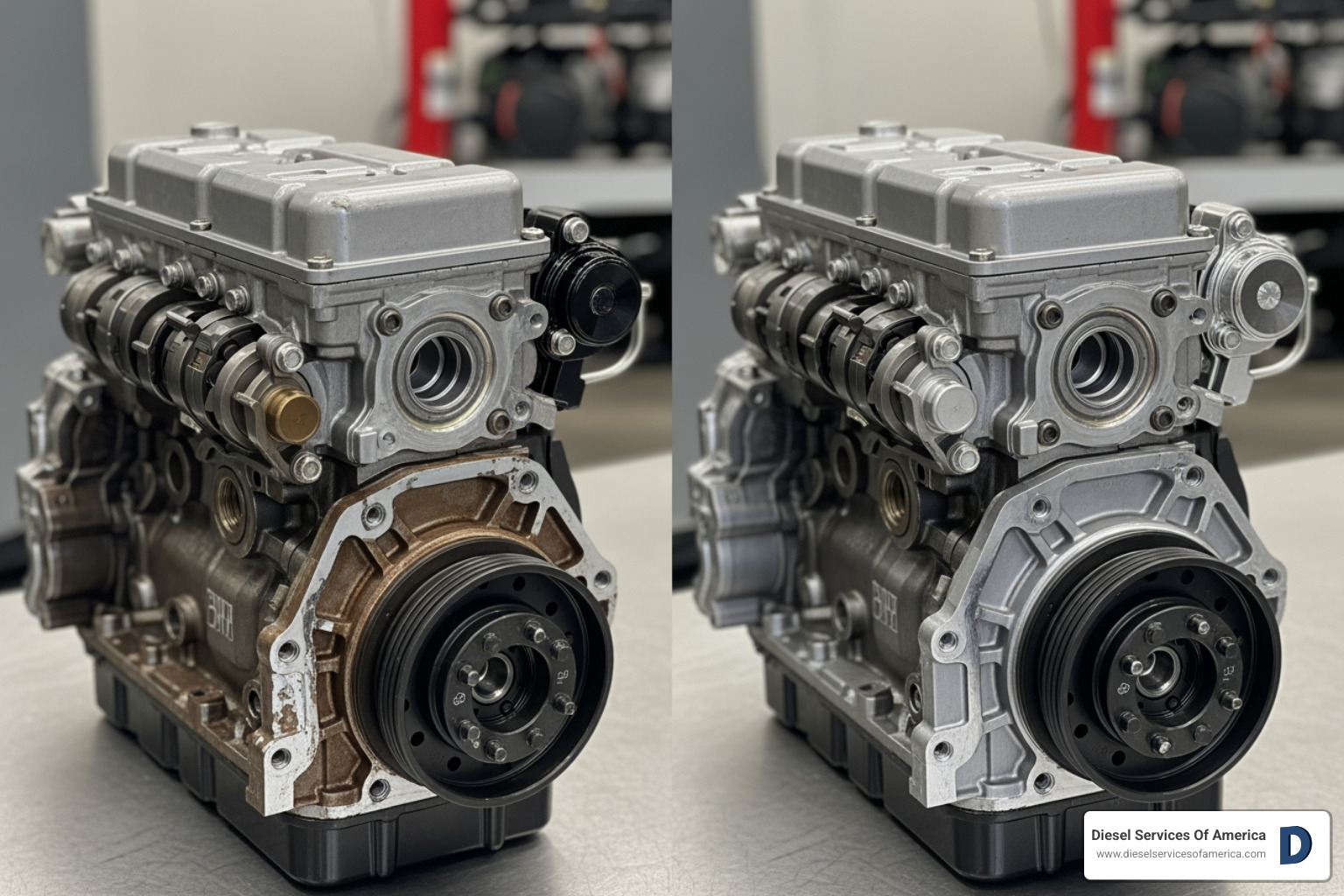

Remanufactured vs. Rebuilt Parts

The terms “rebuilt” and “remanufactured” are often confused, but the difference is significant for engine reliability.

A rebuilt component is repaired. The failed part is replaced, and the unit is reassembled. Other components, even if worn, are often left in place. The quality of a rebuilt part depends heavily on the technician’s skill.

A remanufactured component is completely restored. The entire unit is disassembled, cleaned, and inspected. All components are measured against original OEM specifications, and any part showing wear is replaced, not just the one that failed. The unit is reassembled and tested to meet or exceed original performance standards.

This difference is reflected in the warranty. Remanufactured parts typically come with stronger warranties. For marine and industrial clients, remanufactured components often provide the best balance of performance and value, offering reliability comparable to new OEM parts at a significantly lower cost and with environmental benefits.

Key Factors for Strategic Diesel Engine Parts Sourcing

Sourcing parts for a marine or industrial diesel engine is a strategic decision that impacts your entire operation. A good choice can ensure years of smooth running, while a poor one can lead to costly breakdowns. Effective diesel engine parts sourcing requires looking beyond price to consider quality, performance, long-term value, and regulatory compliance.

Quality, Performance, and Application Needs

The marine and industrial environments are harsh, with exposure to saltwater, vibrations, and heavy loads. Matching parts to your specific application is essential. Whether you choose OEM, aftermarket, or remanufactured parts, the goal is to meet or exceed OEM-quality standards for reliability and proper system integration.

Performance metrics like horsepower and torque requirements dictate which components can handle the job. Marine Engine Parts for a high-performance yacht have different tolerances than those for a stationary generator. Fuel efficiency is also tied to part quality; precisely manufactured components help your engine run at peak efficiency, saving significant fuel costs over time. We work with engines from Caterpillar, Cummins, MAN, and more, and respecting each manufacturer’s specifications is key to successful sourcing.

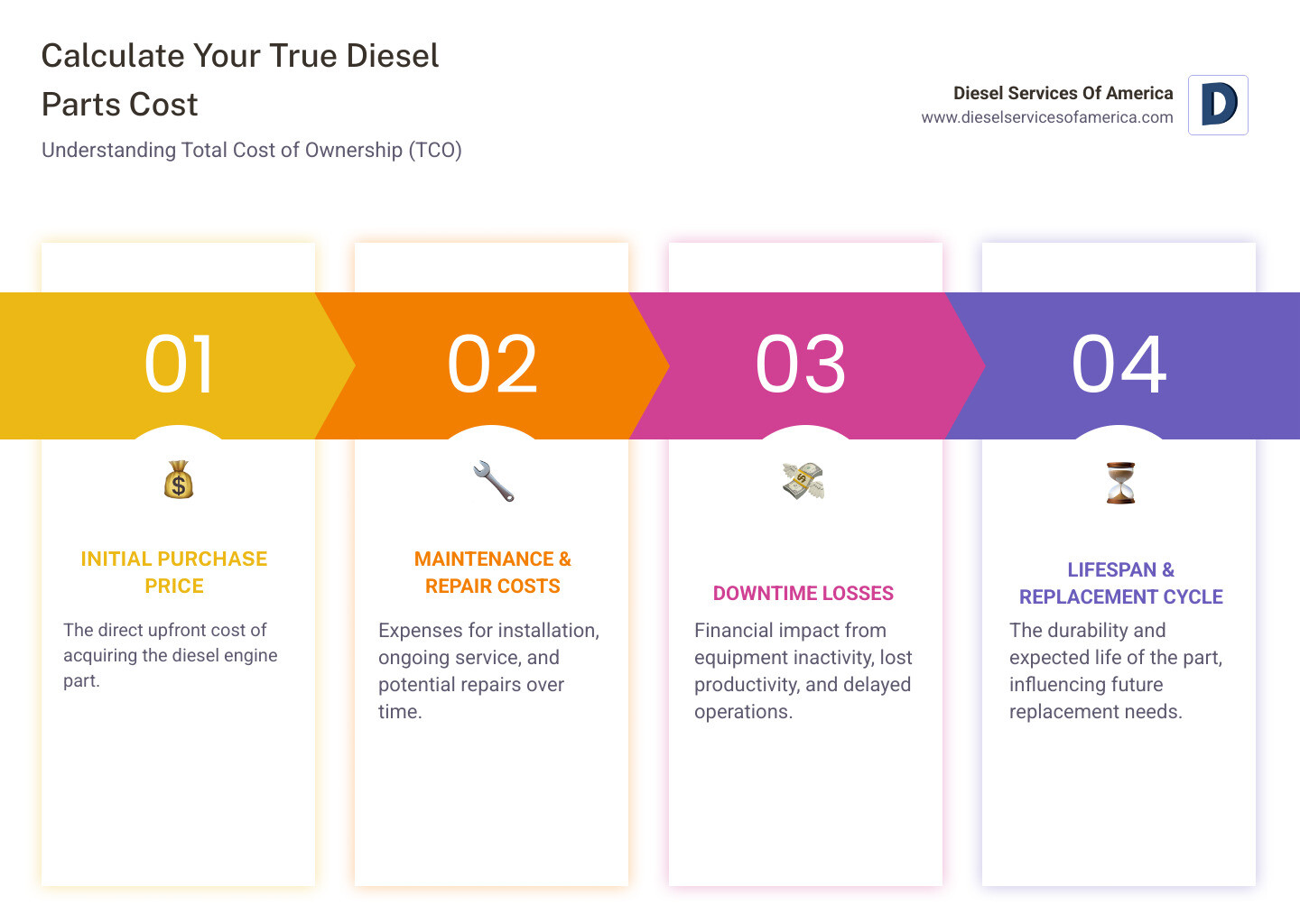

Beyond the Price Tag: Calculating Total Cost of Ownership (TCO)

Focusing only on the initial purchase price is a common mistake. A better approach is to calculate the Total Cost of Ownership (TCO), which includes all expenses over a part’s life.

TCO considers the initial purchase price, maintenance costs, and part lifespan. A cheaper part that fails quickly costs more in the long run due to repeated replacement. The fuel consumption impact is also critical; an inefficient part can drain your operating budget. However, the biggest hidden cost is downtime. Lost revenue from a non-operational vessel or machine often dwarfs the part’s cost. Finally, strong warranty coverage protects you from unexpected repair costs. When you consider all these factors, a higher-quality OEM or remanufactured part is often the most economical choice.

Navigating Environmental Regulations

Environmental regulations have transformed diesel engine parts sourcing. Standards like the EPA’s Tier 4 regulations mandate dramatic reductions in particulate matter and nitrogen oxides. This has fundamentally changed modern diesel engine design.

To meet these emissions reduction requirements, engines now use sophisticated technology like advanced fuel injectors, Diesel Particulate Filters, and Selective Catalytic Reduction systems. Part compatibility is critical: a replacement part in a Tier 4 engine must be designed to maintain the engine’s emission profile. Using an incorrect part risks non-compliance, can damage the emission control system, and lead to expensive repairs. This is especially relevant for engines from manufacturers like John Deere Diesel Engine Parts. Working with knowledgeable suppliers who understand these regulations removes the guesswork from compliance.

Choosing Your Supplier: Finding a Reliable Partner

After understanding part types and key factors, the next step in diesel engine parts sourcing is selecting the right supplier. For marine and industrial applications, your supplier choice is as important as the part itself. A great supplier acts as a partner in keeping your operations running smoothly. If you Need Marine Diesel Engine Parts, choosing the right partner is essential.

Authorized Dealerships and Specialized Suppliers

For those who demand the best, authorized dealerships and specialized suppliers are top choices.

Authorized dealerships offer a direct manufacturer relationship, ensuring you get genuine OEM parts with full backing. This is vital for complex engines requiring specific components, like MAN Diesel Engine Parts. Their factory-trained technicians provide invaluable expertise in identifying parts and troubleshooting. They also offer access to comprehensive inventory, simplifying the ordering process. When seeking Volvo Penta Parts for Sale, an authorized source guarantees compatibility and quality.

Specialized suppliers focus exclusively on diesel parts, bringing deep knowledge across various engine types. They often maintain vast inventories for multiple brands and can provide custom solutions, which is a major benefit for clients managing diverse fleets.

The Importance of Certifications, Warranties, and Expertise

When evaluating suppliers, look for key indicators of quality and reliability.

Start by verifying OEM-quality. Reputable suppliers have stringent quality control measures and should be transparent about their processes. Warranty coverage also reveals a supplier’s confidence in their products; a strong warranty is a statement that they stand behind what they sell. Finally, the value of technical expertise cannot be overstated. A good supplier offers robust technical support, from pre-sales consultation to post-sales installation guidance. Checking a supplier’s reputation and technical capabilities is a crucial part of the vetting process.

Essential Considerations for Your Diesel Engine Parts Sourcing Strategy

Several practical factors will determine your sourcing success.

Availability and lead times are critical when equipment is down. The best suppliers maintain large inventories and have efficient logistics. Options like Overnight Shipping Marine Diesel Parts can be a lifesaver in urgent situations. The ultimate goal is reducing downtime, and a reliable supplier prioritizes fast, accurate order fulfillment. Look for partners with proven track records and decades of experience. Finally, responsive and knowledgeable customer service ties everything together, turning a potentially frustrating experience into a smooth transaction.

Logistics and Supply Chain for Marine & Industrial Parts

For a vessel in the Caribbean or industrial equipment in South Florida, effective diesel engine parts sourcing depends on a sophisticated logistics network. Operations can grind to a halt if a critical component is delayed.

Logistical Best Practices in Diesel Engine Parts Sourcing

Marine and industrial operations are often far from supply centers, creating unique challenges. Smart sourcing requires logistics designed for these situations.

International shipping is at our core. We deliver parts worldwide, navigating complex customs procedures and documentation to prevent delays. For our Caribbean customers, freight consolidation of domestic and overseas freight helps manage costs without sacrificing speed. Our remote customer support team is experienced in assisting operations in challenging locations, ensuring parts get to you efficiently. For emergencies, services like Overnight Shipping Marine Diesel Parts are available. We understand that in your industry, time is money.

Maintaining a Resilient Supply Chain

A resilient supply chain is built on careful planning and strong relationships.

Our inventory management strategy focuses on stocking the parts you are most likely to need from brands like MAN, Volvo Penta, John Deere, and Cummins. Our Fort Lauderdale facility has a comprehensive inventory ready to ship. Strong partnerships with manufacturers and distributors give us reliable access to specialized components. We also take a proactive approach to ordering, anticipating demand for common Types of Marine Diesel Engine Maintenance Parts to prevent stockouts during peak season. For many B2B clients, we act as a sole-source provider, streamlining their procurement process and providing a single, trusted point of contact.

Frequently Asked Questions about Sourcing Diesel Engine Parts

Navigating diesel engine parts sourcing can be complex. Here are answers to common questions from boat owners and fleet managers in South Florida and the Caribbean.

How do I ensure I’m getting OEM-quality parts from a non-dealership supplier?

This is a critical question. To ensure quality, you should:

- Check the supplier’s track record and reputation. Look for decades of experience and positive reviews from others in the marine or industrial sectors.

- Ask about their quality control processes. A reputable supplier will be transparent about how they inspect and vet parts.

- Look for industry certifications. These demonstrate a commitment to meeting high standards.

- Confirm the warranty details. A strong warranty shows the supplier stands behind their products. If a supplier is evasive, consider it a red flag.

What is the difference between a rebuilt and a remanufactured engine?

Though often used interchangeably, the terms describe different processes with different outcomes.

- A rebuilt engine is repaired. Only the specific parts that failed are replaced. Other worn components may remain, potentially leading to future issues.

- A remanufactured engine is completely restored. It’s fully disassembled, and all parts are inspected. Any component that doesn’t meet strict OEM specifications is replaced, not just the ones that broke. The unit is then reassembled and tested to ensure it performs like new.

Remanufactured engines typically offer superior reliability and come with a better warranty, providing near-new performance at a lower cost.

How do environmental regulations like EPA Tier 4 affect my parts choices?

Modern environmental rules like EPA Tier 4 have a direct impact on your parts decisions. These standards require complex emission control systems (e.g., DPF, SCR) that are engineered to work as an integrated unit.

Using an incorrect or non-compliant part in a Tier 4 engine can lead to:

- Non-compliance with regulations and potential fines.

- Poor engine performance and reduced fuel efficiency.

- Damage to expensive emission control components.

- Increased downtime due to diagnostic issues.

For modern engines, especially from brands like John Deere Diesel Engine Parts, choosing genuine OEM or certified OEM-quality parts is essential for both performance and compliance. A knowledgeable supplier can guide you to the correct components.

Conclusion: Your Partner in Performance and Reliability

For marine and industrial operators in South Florida and the Caribbean, diesel engine parts sourcing is a strategic decision that impacts everything from downtime to your bottom line.

As this guide has shown, making the right choice involves more than just price. It means matching the part type—OEM, aftermarket, or remanufactured—to your needs, calculating the total cost of ownership, and navigating complex environmental regulations. Most importantly, it means finding the right partner. A cheap part that fails during a critical job is a liability, not a bargain.

At Diesel Services of America, we understand what’s at stake. Our factory-trained technicians provide the expertise to help you make smart sourcing decisions. We maintain an extensive inventory for the engines you rely on, from Caterpillar and Cummins to Volvo Penta and MAN. Our worldwide shipping and logistics support ensure you get what you need, when you need it, whether you’re in Fort Lauderdale or a remote Caribbean location.

We aim to be more than a vendor; we want to be your partner in performance and reliability. When your engines run smoothly, you can focus on your business.

Ready to experience the difference? Explore our extensive parts department and let our team show you what true partnership looks like.