Why Diesel Engine Power Upgrades Transform Marine and Industrial Performance

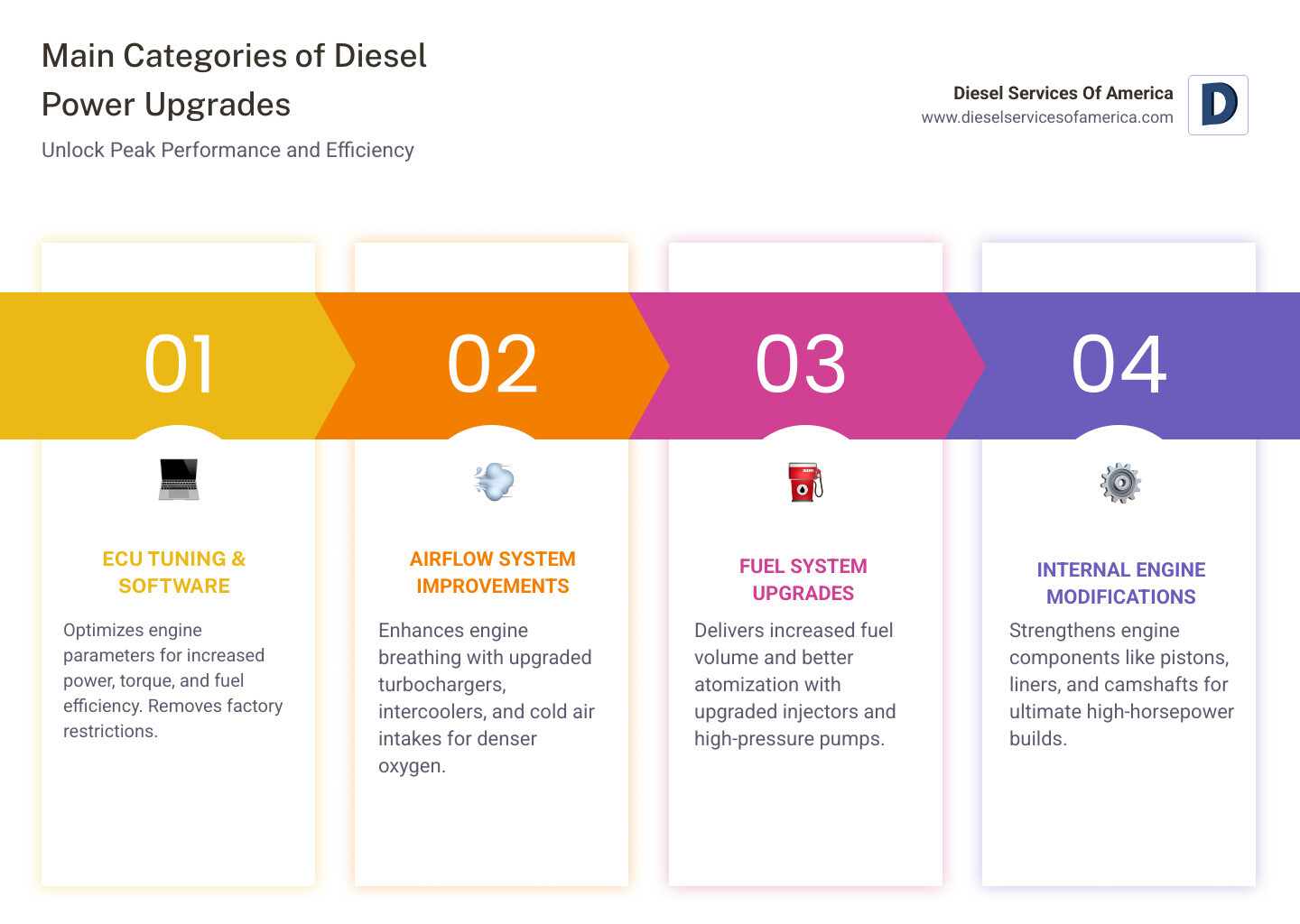

Diesel engine power upgrades are modifications that increase horsepower, torque, and efficiency in marine and industrial diesel engines. These upgrades range from simple ECU tuning to comprehensive internal engine modifications.

Most Common Diesel Engine Power Upgrades:

- ECU Tuning/Flash – Removes power restrictions, increases fuel delivery (5-35% power gains)

- Turbocharger Upgrades – Forces more air into engine (up to 10x horsepower increase over naturally aspirated)

- Fuel Injector Upgrades – Delivers more fuel for increased power output

- Cold Air Intake Systems – Increases oxygen-rich air flow for better combustion

- Performance Exhaust Systems – Reduces backpressure, improves airflow (10-20 HP gains)

- Intercooler Upgrades – Cools compressed air for denser oxygen content

Whether you’re managing a fleet of commercial vessels in the Caribbean or maintaining a single boat in South Florida waters, the appeal is clear. More power means better performance under load, improved fuel efficiency, and the ability to handle demanding marine conditions.

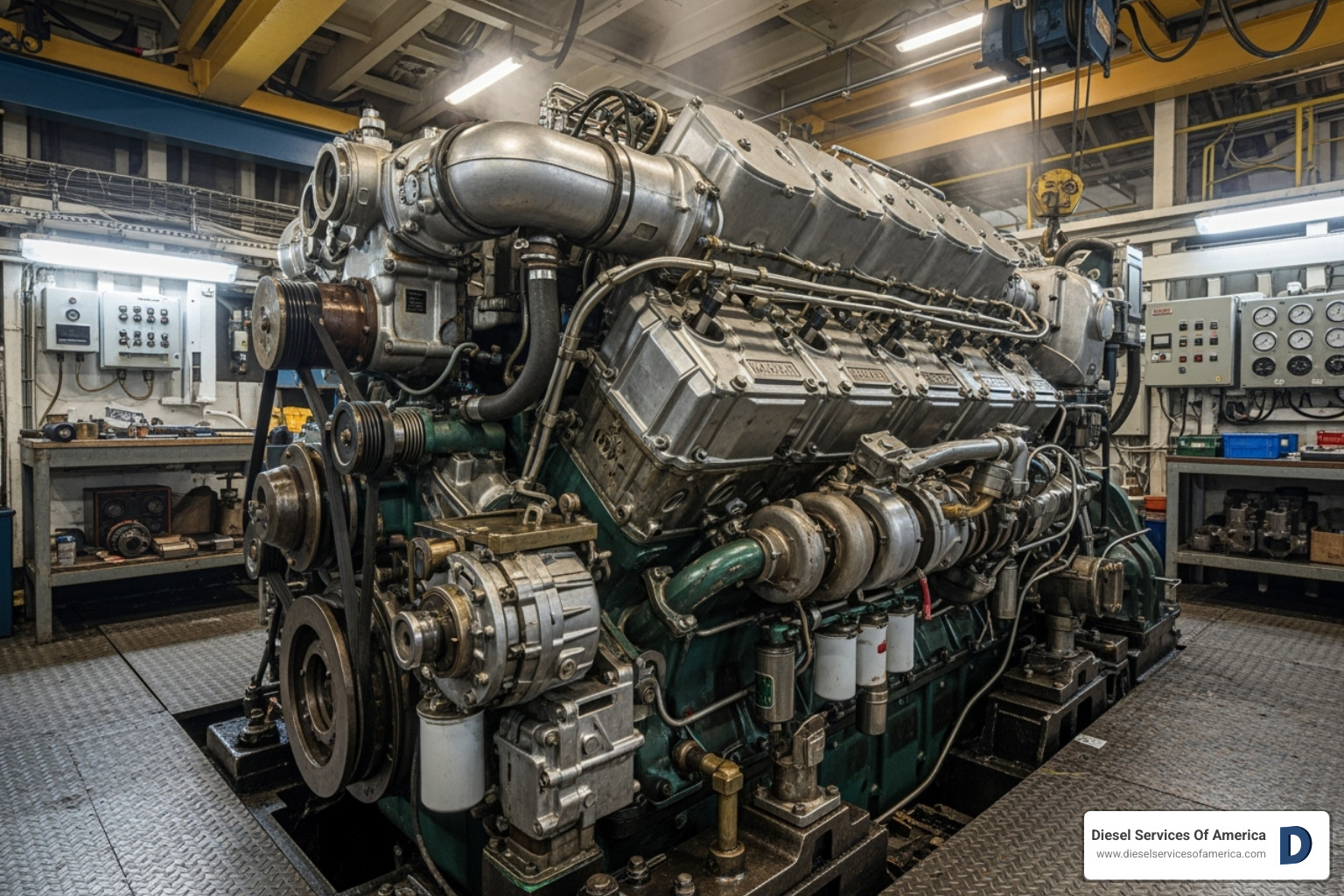

Modern marine and industrial diesels – from CAT 3406s powering commercial fishing boats to MAN engines in luxury yachts – are essentially air pumps. The turbos on these engines can increase efficiency beyond factory levels, making power upgrades both practical and rewarding.

But here’s what many operators don’t realize: not all upgrades are created equal. A poorly planned modification can reduce engine life, while a properly executed upgrade can actually improve reliability alongside performance.

Foundational Upgrade Paths: Bolt-On vs. Internal Modifications

So, you’re thinking about diesel engine power upgrades for your marine vessel or industrial equipment? That’s exciting! But before we dive in, it’s smart to have a clear game plan. We need to think about your specific power goals, your budget, and most importantly, how these changes will affect your engine’s long-term health and reliability. Choosing between “bolt-on” parts and more involved “internal” engine upgrades often comes down to how much extra power you’re aiming for versus the complexity and cost involved.

Bolt-On Upgrades: The Accessible Path to Power

Bolt-on upgrades are usually the easiest and most cost-effective ways to boost the performance of your marine or industrial diesel engine. They involve adding or replacing parts without needing to take the engine completely apart. Think of them as straightforward improvements that deliver noticeable results.

-

ECU Tuners and Performance Chips: Often the first step for many operators, these are like giving your engine a smarter brain! By reprogramming the Engine Control Module (ECM), we can fine-tune things like how much fuel is delivered, ignition timing, and even how much boost your turbo provides. This can open up hidden power by removing factory limits, potentially increasing horsepower and torque, and sometimes even improving fuel efficiency by 5-10%. Some advanced modules, like the STEINBAUER Power Module, can even deliver up to 20% more power without risking engine safety.

-

Cold Air Intake Systems: Just like we need to breathe well to perform our best, so does your engine! Upgrading the air intake allows more air – especially cooler, denser, oxygen-rich air – to flow into the combustion chamber. This leads to a better, more powerful burn. You might see a boost of 20-30% in horsepower with a good cold air intake. Plus, these systems help keep your engine running cooler, preventing overheating.

-

Performance Exhaust Systems: After all that air goes in and does its job, it needs to get out efficiently! A performance exhaust system reduces “backpressure,” making it easier for exhaust gases to leave the engine. This can add roughly 10-20 horsepower and even shave 1-2% off your annual fuel bill. It’s really important that your exhaust system can handle the increased power safely to maintain optimal airflow and prevent any damage to your engine.

-

Turbochargers: For a significant jump in power, upgrading your turbocharger is key. Turbos work by forcing more pressurized air into the engine, which dramatically increases horsepower. While your stock turbo might increase airflow three to four times, a performance turbo can boost it five to ten times, potentially increasing horsepower by up to 10 times compared to a naturally aspirated engine. This also helps with fuel efficiency by packing more air into each combustion cycle.

-

Intercoolers: When a turbocharger compresses air, that air gets hot. And hot air is less dense, meaning it has less oxygen. An upgraded intercooler cools this compressed air before it enters the engine, making it denser and richer in oxygen. More oxygen means more power! You can also use Water/Methanol injection as a “chemical intercooler.” This can lower intake air temperatures even further, potentially adding an extra 75-100 horsepower.

Ready to explore these bolt-on options for your marine or industrial diesel engine? You can find more information about our comprehensive diesel services, including these upgrades, right here: More info about our diesel services

Internal Engine Upgrades: Forging Ultimate Performance

For those who want the absolute maximum power from their marine or industrial diesel, internal engine modifications are the way to go. These are serious upgrades that require specialized expertise and a significant investment. These changes literally alter the fundamental working parts of the engine.

-

Cylinder Liners and Piston Modifications: One way to gain power is to increase the engine’s “displacement.” This can be done by boring out the cylinder liners and installing larger, oversized pistons. A bigger piston moving in a bigger cylinder means more fuel can be burned, directly increasing horsepower. Even subtle changes, like modifying the weight of the pistons, can fine-tune power delivery and engine balance.

-

Valve Train Components: To make more horsepower, you often need to let your engine “breathe” better at higher RPMs. This means upgrading valve train parts like stiffer valve springs, stronger retainers, and different camshafts and lifters. Sometimes, it even involves removing electronic rev limiters. Performance camshafts, for example, change how much and when the valves open, optimizing airflow for maximum power.

-

Crankshafts and Connecting Rods: When you’re pushing extreme horsepower, the entire rotating assembly—the crankshaft and connecting rods—needs to be incredibly strong. Upgrading these components ensures they can handle the immense forces and higher engine speeds without failing. They are the backbone of your engine’s power delivery.

-

Reducing Friction and Weight: Every little bit helps! Using lighter materials, like aluminum for engine blocks and cylinder heads, can reduce the overall weight of the engine itself, which improves power distribution. Also, reducing internal friction through advanced coatings or specialized lubricants can lead to small but noticeable power gains and better efficiency.

It’s really important to understand that internal modifications come with big considerations. Changing parts from their original factory specifications without proper engineering and knowledge can lead to serious engine problems. It’s crucial to make sure all related components are upgraded to handle the increased stress and to keep a healthy balance within the entire engine system.

Here are some key internal components we often consider for a high-horsepower build:

- Heavy-duty crankshaft

- Forged connecting rods

- Performance pistons (often oversized or with specific dome designs)

- Upgraded cylinder liners (if applicable)

- Performance camshaft

- Stiffer valve springs and retainers

- Stronger head studs and main studs

We truly understand the intricate physics behind these deep modifications – from how altering stroke length impacts power to how different cylinder liners affect compression. For a deeper dive into how changing piston weight can influence engine performance, you might find this study interesting: Altering the weight of pistons for performance

The Core Systems for Diesel Engine Power Upgrades

At the very heart of any successful diesel engine power upgrades project lie three key, interconnected systems: the engine control module, the fuel system, and the air intake system. Thinking about these systems working together is like orchestrating a perfect symphony! Our goal is always to achieve that ideal air-fuel ratio for maximum combustion efficiency, truly open uping every ounce of potential from your marine or industrial diesel engine.

Tuning the ECM: The Brains of the Operation

Think of your Engine Control Module (ECM) as the super-smart brain of your diesel engine. It’s a highly sophisticated computer that’s always watching, always adjusting, making sure everything runs just right. This includes carefully managing the air-fuel mixture, setting the maximum RPMs, and constantly gathering data to keep all systems running smoothly and efficiently.

When we talk about an ECM flash upgrade, we’re talking about expertly reprogramming this onboard computer. This allows us to politely ask the engine to remove power restrictions that were set by the manufacturer. It means we can allow more fuel, increase the air intake, and even dial up the turbo boost. A well-done ECM reprogramming can significantly boost horsepower and torque. Plus, when done correctly, it can even improve your fuel efficiency by a nice 5-10%. It’s a precise art, carefully adjusting factors like the air-fuel ratio, injection timing, and manifold pressure to get those desired power gains.

For a broader understanding of what an Engine Control Unit (ECU), which is essentially the ECM, does, you can explore this resource: What is an Engine Control Unit?

Fuel System Improvements for More Power

It’s simple: power in a diesel engine comes from burning fuel. So, the more fuel we can efficiently burn, the more power we generate! That’s why the fuel system plays such a critical role in any diesel engine power upgrades.

First up are upgraded fuel injectors. Your engine’s stock injectors are only designed for factory power levels. By installing new, higher-capacity fuel injectors, we allow more fuel to reach the engine. This directly translates to more horsepower. Many advanced injectors also feature special nozzles that create more fuel pressure by atomizing the fuel much more finely. This improved atomization leads to a more complete burn and, you guessed it, greater power output.

To support those larger injectors and the increased fuel volume, the high-pressure fuel pump must be up to the task. Upgrading this component makes sure there’s a consistent and ample fuel supply to the injectors, even under heavy load. And in some marine or industrial applications, we might also look at modifying or upgrading fuel rails. This ensures that fuel is distributed evenly to all injectors, preventing any fuel starvation when you’re demanding maximum power.

A very important note: when upgrading the fuel system, always consider supporting modifications. You never want to “over-fuel” the engine without also providing enough air. Doing so can lead to excessive smoke, wasted fuel, and dangerously high Exhaust Gas Temperatures (EGT), which can definitely cause engine damage. The secret is always a balanced increase in both fuel and air.

Mastering Airflow: The Lungs of Your Diesel

Just like we need to breathe well to perform our best, the amount of air entering a diesel engine is just as important as the amount of fuel. More air means more oxygen available for combustion, and that always leads to more power!

Cold air intake systems are a fundamental upgrade, and they do exactly what their name suggests. They funnel more, cooler, and denser air into the engine. Denser air means more oxygen molecules per breath, which is absolutely critical for efficient combustion and increased horsepower.

Then there are turbochargers, the true champions of airflow improvement. Turbochargers work by gathering more air and forcing it into the engine’s intake under pressure. This dramatically increases the volume of air, and therefore oxygen, available for combustion. While your basic stock turbos might increase airflow up to four times, performance turbos can achieve even greater gains! This powerful process is eloquently described here: How turbochargers bring more oxygen-rich air to the engine

Finally, after the turbo compresses the air, it gets hot. That’s where intercoolers, also known as charge air coolers, come in. An intercooler’s job is to cool this superheated, compressed air before it enters the engine. Why? Because cooler air is denser, meaning more oxygen molecules packed into the same space. More oxygen directly translates to more power. Reducing the intake air temperature is crucial for making your turbocharger as effective as possible.

Mastering airflow is all about minimizing restrictions and maximizing the density of the air that enters your engine. This holistic approach ensures that your marine or industrial diesel can breathe freely and efficiently, turning more fuel into that usable power you crave.

Supporting the Power: Drivetrain, Maintenance, and Safety

Think of your marine or industrial diesel engine like a high-performance athlete. You can train them to be stronger and faster, but without proper support systems, they’ll break down when it matters most. That’s exactly what happens when we pursue diesel engine power upgrades without considering the bigger picture.

A holistic approach means understanding that your engine doesn’t work in isolation. Every component from the transmission to the cooling system needs to handle the increased demands. System balance isn’t just engineering talk – it’s the difference between reliable power and expensive breakdowns.

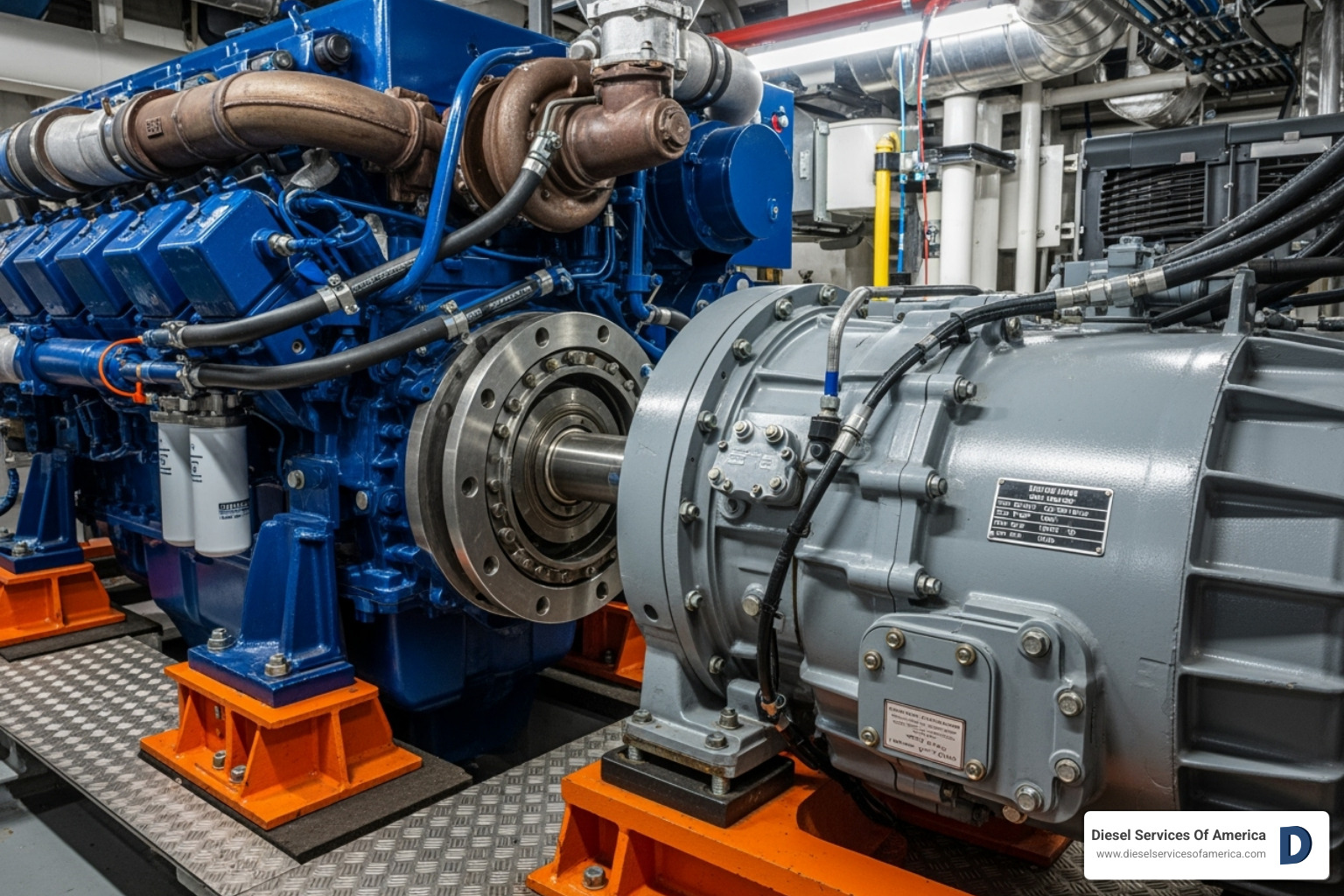

Why Transmission Upgrades are Crucial

Here’s the reality: when you boost your marine diesel’s horsepower by 20%, your transmission doesn’t magically become 20% stronger. The marine gear that handled your stock engine just fine might start slipping, overheating, or worse – failing completely when you need it most.

Handling increased horsepower requires more than wishful thinking. Your transmission’s clutches, bands, and internal components were engineered for specific torque levels. Push beyond those limits without upgrades, and you’re asking for trouble. We’ve seen too many boat owners learn this lesson the expensive way.

Preventing slippage becomes critical when you’re pulling heavy loads or fighting strong currents. Upgraded transmissions feature stronger clutches and improved fluid pathways designed to grip firmly under demanding conditions. The last thing you want is your transmission slipping when you’re trying to dock in rough seas.

Ensuring power delivery means making sure all that beautiful horsepower actually reaches your propeller. A properly matched transmission acts like a skilled translator, converting your engine’s increased output into usable thrust. Always check your transmission’s nominal torque capacity rating against your engine’s new power levels.

Essential Maintenance for High-Performance Diesel Engine Power Upgrades

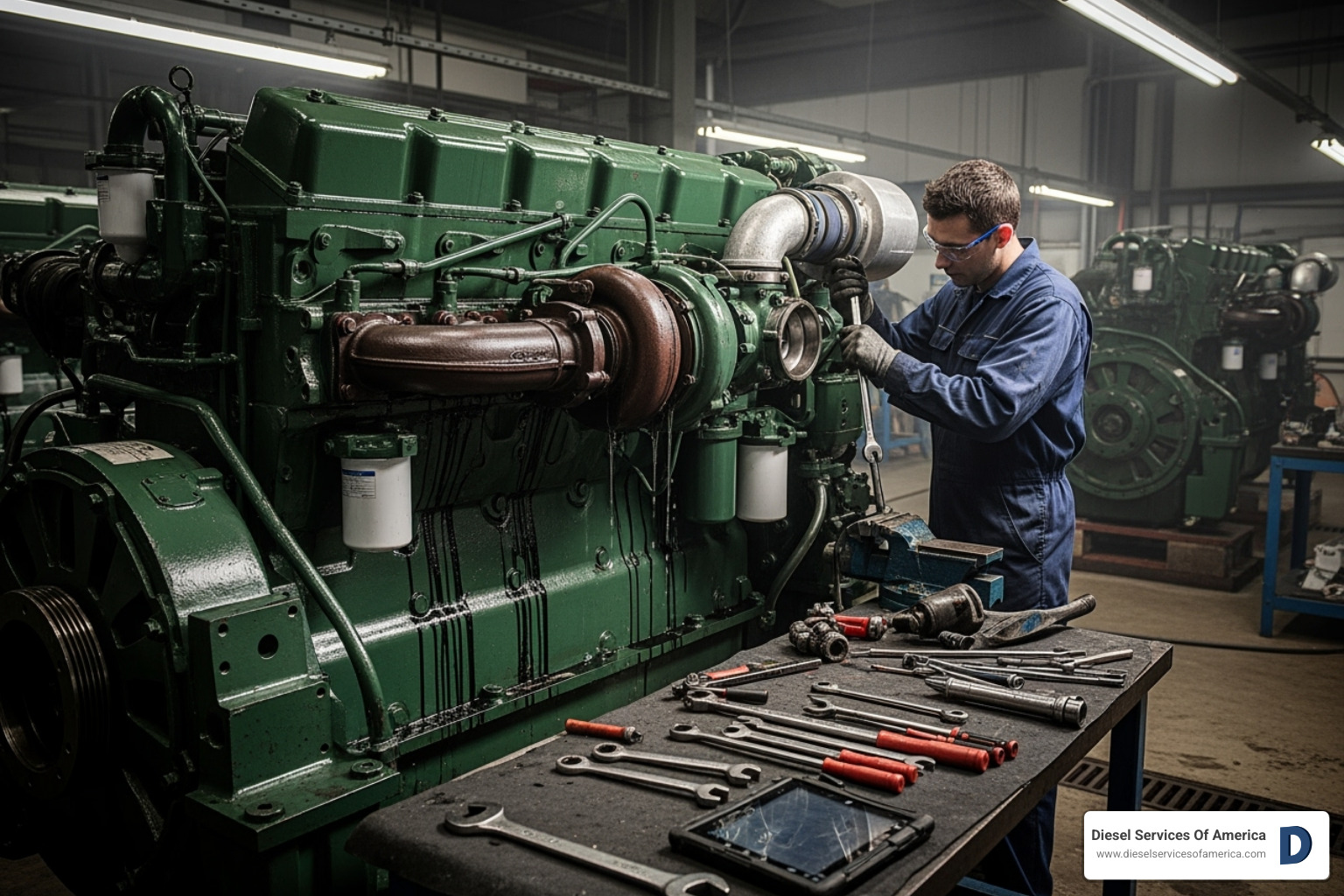

Let’s be honest – modified engines are like professional athletes. They perform at higher levels, but they also need more attention. The maintenance schedule that worked for your stock engine won’t cut it anymore.

High-quality oil and additives become your engine’s lifeline. We’re talking about frequent changes with premium lubricants, not the bargain-basement stuff. Oil additives can work wonders by improving lubricity and removing harmful deposits. Consider bypass oil filters that filter down to 2 microns – they’ll extend your oil life and reduce wear significantly.

Improved cooling systems aren’t optional when you’re making more power. More horsepower equals more heat, and heat is the enemy of engine longevity. Upgrading radiators, intercoolers, and adding transmission fluid coolers helps manage those higher temperatures. Think of it as giving your engine room to breathe.

Regular inspections become your early warning system. Look for leaks, unusual wear patterns, loose connections, and any signs that components are struggling. Catching problems early saves both money and headaches.

Monitoring gauges for critical parameters like Exhaust Gas Temperature (EGT), transmission temperature, and boost pressure let you keep a finger on your engine’s pulse. These aren’t just fancy decorations – they’re essential tools for preventing expensive failures.

Professional dyno tuning fine-tunes everything for peak performance while catching potential issues before they become major problems. It’s like having a personal trainer for your engine, optimizing performance for your specific operating conditions. Schedule a dyno tune for peak performance to get the most from your upgrades.

Legal and Environmental Considerations

Nobody wants to deal with legal headaches, but understanding regulations is part of responsible ownership. The rules around marine and industrial diesel modifications can be complex, and ignorance isn’t a defense.

Emissions systems like EGR (Exhaust Gas Recirculation), DPF (Diesel Particulate Filters), and SCR systems using DEF (Diesel Exhaust Fluid) might seem like performance killers, but tampering with them is illegal and carries serious consequences. For marine and industrial engines, specific maritime and industrial emissions regulations apply.

Legal compliance covers more than just emissions. Noise levels from upgraded exhaust systems, operational permits, and local regulations all matter. The EPA takes engine tampering seriously, with significant penalties for violations. Understanding these regulations protects both you and your business: EPA regulations on engine tampering.

Environmental responsibility goes beyond legal requirements. We believe in modifications that deliver performance without compromising our marine environment. Many modern engines are engineered to perform optimally with their emissions systems intact, proving that power and environmental stewardship can coexist.

The goal is finding that sweet spot where performance gains meet legal compliance and environmental responsibility. It’s not just about what we can do – it’s about what we should do.

Frequently Asked Questions about Diesel Upgrades

Over the years, we’ve worked with countless marine and industrial operators considering diesel engine power upgrades. Whether you’re running a commercial fishing vessel out of Fort Lauderdale or managing industrial generators, the same questions come up time and again. Let’s tackle the big ones.

Will performance upgrades reduce my engine’s lifespan?

Here’s the honest truth: it depends entirely on how you approach it. We’ve seen engines destroyed by weekend warriors who thought bigger was always better, and we’ve also seen properly upgraded engines that outlasted their stock counterparts.

The difference comes down to three critical factors. Quality parts make all the difference – cheap modifications are expensive in the long run. Professional installation ensures everything works together harmoniously, rather than fighting against each other. And proper maintenance becomes even more important when you’re asking more from your engine.

When we upgrade a marine diesel properly, we’re not just slapping on parts. We’re creating a balanced system where the engine can handle increased loads more easily. A CAT 3406 that used to strain at 75% load might now cruise comfortably at that same output level.

The key is operating within safe limits and monitoring your engine religiously. We always tell our clients: respect the upgrade, and it will respect your wallet.

What is the most cost-effective first upgrade for a marine diesel?

For most marine and industrial applications, ECU tuning wins hands down. We can often open up 15-25% more power with just a software modification. No wrenches, no major installation time, and the results are immediate.

Think about it – your MAN or MTU engine already has the hardware capability. The manufacturer just dialed it back for emissions, warranty concerns, or market positioning. It’s like having a racehorse that’s been told to trot.

After ECU tuning, we typically recommend a cold air intake system. Marine engines love cool, dense air, and in South Florida’s heat, every degree matters. Following that, a performance exhaust system helps that engine breathe out as well as it breathes in.

These three modifications work together beautifully and give you the foundation for any future upgrades. Plus, your fuel efficiency often improves, which helps offset the investment cost.

How do I know which upgrades are right for my engine?

This is where experience really matters. A upgrade path that works perfectly for a CAT 3208 powering a sportfisher might be completely wrong for a MAN engine in a commercial workboat.

We start by understanding your specific situation. Are you looking for more speed to get to the fishing grounds faster? Need more power to handle heavier loads? Want better fuel economy for long-range cruising? Your application drives everything – propulsion engines have different needs than generator sets.

Engine model is equally important. We know the quirks of different manufacturers. CAT engines respond differently to modifications than MAN or MTU engines. Some have robust fuel systems that can handle significant upgrades, while others need supporting modifications first.

Here’s what we’ve learned after thousands of marine diesel services: there’s no one-size-fits-all solution. That’s why we always start with a thorough assessment of your current engine condition and an honest conversation about your performance goals.

Our factory-trained technicians have worked on everything from small pleasure craft to commercial vessels throughout Southeast Florida and the Caribbean. We understand the unique demands of marine environments and can recommend a custom upgrade path that delivers results without compromising reliability.

The best upgrade is the one that matches your needs, your budget, and your engine’s capabilities. Let’s figure that out together.

Your Partner for Peak Marine Diesel Performance

We’ve journeyed through the exciting world of diesel engine power upgrades together, exploring everything from simple ECU tuning that can boost your horsepower by 35% to comprehensive internal modifications that completely transform your engine’s capabilities. We’ve finded how bolt-on upgrades like turbochargers and cold air intakes offer accessible paths to more power, while internal modifications open the door to ultimate performance.

But here’s what we’ve learned along the way: achieving real, lasting performance gains isn’t just about bolting on parts or flashing your ECM. It’s about understanding how every component works together – from your fuel system upgrades to your transmission, from your cooling system to your maintenance schedule.

The difference between a successful upgrade and an expensive mistake often comes down to expertise.

That’s exactly where Diesel Services Of America comes in. We’re not just another repair shop – we’re your partners in open uping your marine or industrial diesel’s true potential. Located right here in Fort Lauderdale, our factory-trained technicians live and breathe marine and industrial diesel engines every day.

Whether you’re running a commercial fishing vessel in the Caribbean, managing a fleet of industrial generators, or maintaining a luxury yacht, we understand the unique demands your engines face. Our expertise spans everything from diesel engine power upgrades and ECU tuning to complete engine repowers and rebuilds.

What sets us apart? We offer worldwide parts delivery and dockside service throughout Southeast Florida and the Caribbean. That means when you need performance upgrades or maintenance, we come to you – whether you’re docked in Fort Lauderdale or anchored in the Bahamas.

We believe in doing things right the first time. Every upgrade we recommend is carefully matched to your specific engine model, application, and performance goals. No cookie-cutter solutions, no shortcuts that compromise reliability.

Ready to transform your diesel’s performance? Our team is standing by to discuss your specific needs and create a custom upgrade path that delivers the power gains you want with the reliability you need.

Contact our marine diesel experts in Southeast Florida for a consultation and let’s make your diesel performance dreams a reality.