Why Finding the Right Diesel Engine Spare Parts Supplier Matters

A diesel engine spare parts supplier can make or break your marine or industrial operation. When a critical component fails, every hour of downtime costs money, especially for fleet managers in Southeast Florida and the Caribbean, where a single day offline can mean thousands in lost revenue.

The right supplier provides more than just parts; they offer authenticity, compatibility, and support. Here are the key factors to consider:

- Parts Quality: OEM or high-quality aftermarket parts with full traceability.

- Availability: A large inventory with access to rare and legacy components.

- Technical Expertise: Factory-trained staff to help identify the correct parts.

- Turnaround Speed: Same-day quotes and expedited shipping options.

- Warranty Coverage: Industry-leading protection on the parts you buy.

- Global Sourcing: A network to find hard-to-locate parts when OEM stock is unavailable.

While OEM parts like those from Cummins represent a benchmark for quality, a specialized supplier can provide that same level of reliability by partnering with the right sources. This guide will help you evaluate suppliers and choose parts that keep your engines running efficiently.

Common Diesel engine spare parts supplier vocab:

- Diesel engine repair service

- Marine diesel engine maintenance

Core Components: Common Marine & Industrial Diesel Spare Parts

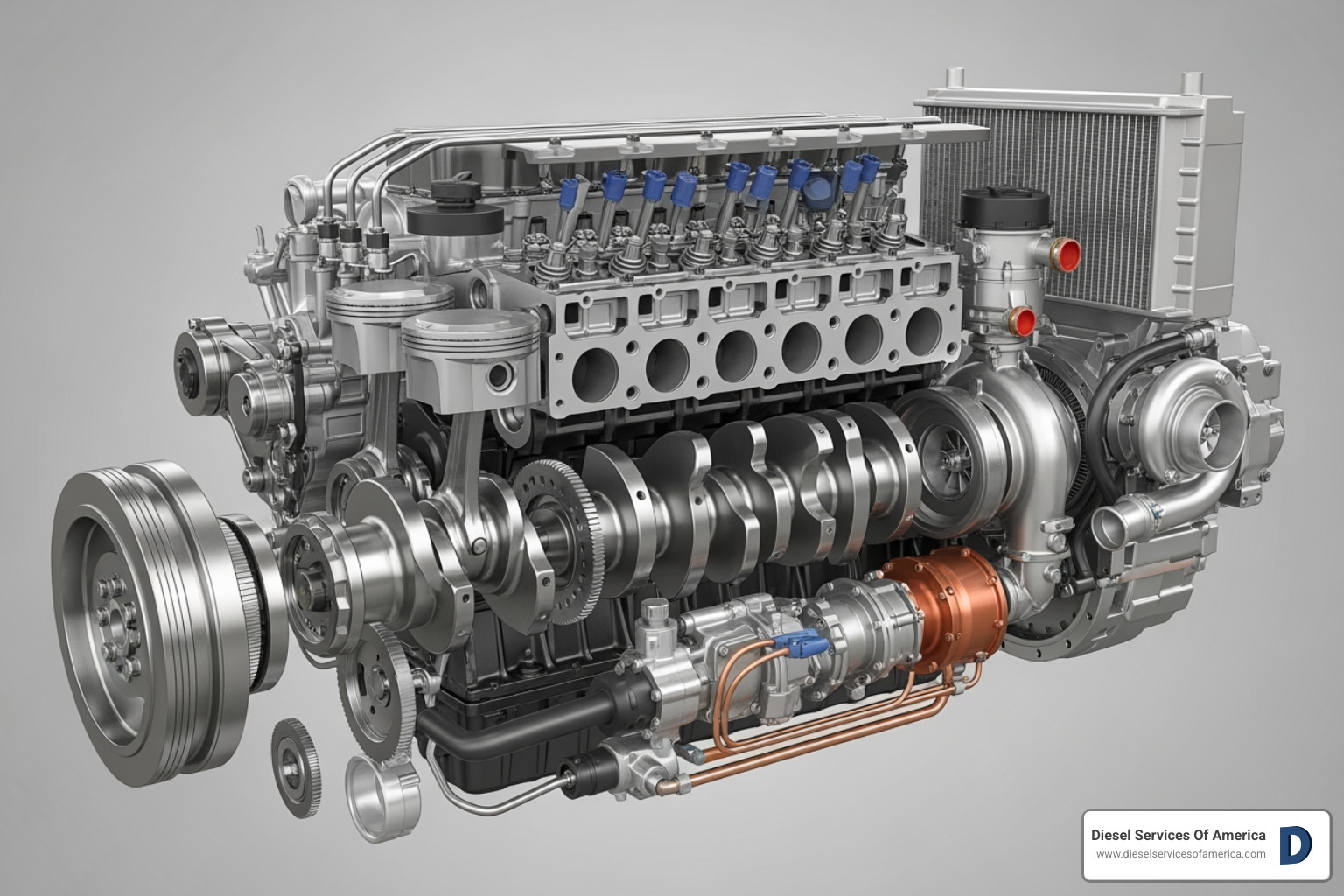

A quality diesel engine spare parts supplier stocks the full range of components your engine needs. When one part fails, the whole operation can stop. Here’s a look at the essential parts for marine and industrial diesel applications.

Engine Block Components

The engine block is the foundation housing the hardest-working parts, which endure extreme temperatures and pressures.

- Cylinder liners, pistons, and rings work together to convert fuel combustion into mechanical energy. Liners form the replaceable walls for the pistons, while rings create a tight seal to control oil and compression.

- The crankshaft translates the pistons’ up-and-down motion into the rotating power that turns a propeller or drives equipment.

- Bearings are crucial for reducing friction between moving parts, allowing the crankshaft and connecting rods to move smoothly.

Fuel & Air System Essentials

A diesel engine is an air pump that requires a precise mix of fuel to operate efficiently.

- Fuel injectors and pumps work in tandem to deliver atomized fuel into the combustion chamber at extremely high pressures. Faulty injectors can cause smoke, poor economy, and rough running.

- Filters for fuel, oil, and air are your engine’s first line of defense against contamination. Clogged filters starve the engine of what it needs, leading to wear and damage.

- Turbochargers force more air into the cylinders, allowing the engine to burn more fuel and generate more power. They are critical for the performance of marine and industrial diesels.

- Gaskets and seals are essential for preventing leaks. A blown head gasket, for example, can cause catastrophic failure.

Cooling & Lubrication Systems

Marine and industrial diesels generate immense heat and require robust cooling and lubrication to survive.

- Water pumps circulate coolant to carry heat away from the engine. Marine engines often use both raw water and freshwater pumps.

- Heat exchangers and oil coolers work like radiators, transferring heat from the engine’s coolant and oil to keep temperatures in a safe operating range.

- Hoses connect these systems and must be durable enough to resist salt water, vibration, and temperature extremes.

- Thermostats regulate coolant flow to maintain optimal engine temperature, preventing both excessive wear from running too cold and overheating from running too hot.

A knowledgeable diesel engine spare parts supplier provides access to all these components, ensuring you get the right part for your specific engine model.

How to Vet Your Next Diesel Engine Spare Parts Supplier

Finding the right diesel engine spare parts supplier is about building a partnership. For commercial vessel operators in the Caribbean or industrial managers in Southeast Florida, downtime means lost revenue. Your supplier is a key part of your maintenance team.

Parts Availability and Sourcing Networks

The best suppliers maintain extensive warehouses stocked with common marine and industrial diesel parts. When they say a part is in stock, it should be on their shelf, ready to ship.

For older or specialized components, a supplier’s global sourcing network is invaluable. A capable supplier doesn’t give up on a rare part; they leverage worldwide connections to find it. This resourcefulness can turn a months-long repair into a week-long project.

Technical expertise is just as important. Look for suppliers with diesel-trained advisors who can help you identify the right part using your engine model and serial number. At Diesel Services of America, our factory-trained technicians have hands-on experience, ensuring you get the correct component the first time. This expertise saves you time, money, and frustration.

For more information about our comprehensive services, including expert technical support, please visit our services page.

Ensuring Quality and Authenticity

Counterfeit parts are a major risk, leading to catastrophic failures. Using substandard components is a safety and financial gamble.

OEM parts are the gold standard, designed by the original manufacturer for a perfect fit and optimal performance. A reputable supplier must also provide traceability—documentation proving a part’s origin and authenticity. This protects you in case of a warranty claim.

Serious suppliers have strict quality control processes, vetting their supply chains and inspecting incoming parts. High-quality parts are made from materials that withstand extreme stress and have been tested for reliability. A cheap bearing might save you $50 today, but its failure could lead to a five-figure repair bill.

Evaluating Pricing, Support, and Turnaround

When it comes to diesel parts, focus on the total cost of ownership, not just the initial price. A slightly more expensive part that lasts longer and has a strong warranty is the better value.

Quote and shipping speed are critical when you’re facing downtime. A supplier who provides same-day quotes and expedited shipping can get you back in business faster. For our customers in the Caribbean and beyond, worldwide delivery capabilities are essential. The best suppliers have established logistics to ensure parts arrive quickly and reliably, no matter the destination.

OEM vs. Aftermarket Parts: A Critical Decision for Your Engine

When your marine or industrial diesel engine needs parts, you’ll face a choice between genuine OEM components and aftermarket alternatives. This decision affects everything from immediate costs to long-term reliability.

| Feature | Genuine OEM Parts | Aftermarket Parts (High-Quality) | Aftermarket Parts (Low-Quality) |

|---|---|---|---|

| Fit | Perfect, engineered by original manufacturer | Good to excellent, designed to match OEM | Variable, may require modification, poor fit |

| Performance | Optimal, designed for peak engine efficiency | Meets or exceeds OEM standards, reliable | Substandard, can degrade engine performance |

| Warranty | Comprehensive, backed by manufacturer | Reputable suppliers offer strong warranties | Limited or no warranty, difficult to claim |

| Long-Term Value | Improved engine lifespan, fewer complications | Cost-effective, good reliability | Frequent failures, increased operational costs |

| Cost | Typically higher | Generally lower than OEM | Very low, but comes with high hidden costs |

Genuine OEM Parts

OEM (Original Equipment Manufacturer) parts are identical to what was installed when your engine left the factory. They come directly from the engine manufacturer, carrying the full weight of the brand’s engineering and testing.

The perfect compatibility of OEM parts eliminates guesswork, ensuring a perfect fit and optimal performance. This translates to fewer complications, longer engine life, and better overall efficiency. For marine applications in harsh saltwater environments, this certainty is invaluable and helps preserve your manufacturer’s warranty.

The Case for High-Quality Aftermarket Parts

Not all aftermarket parts are created equal. The best ones offer compelling value without compromising your engine’s integrity. Reputable aftermarket brands have earned their standing through proven performance.

Many high-quality aftermarket suppliers meet or exceed OEM standards, sometimes even offering innovative improvements on the original design. This isn’t about cutting corners; it’s about specialized manufacturers pushing boundaries in specific component categories.

These parts provide cost-effective solutions, which is attractive when managing a fleet or multiple industrial engines. A reliable diesel engine spare parts supplier offering quality aftermarket options can reduce your parts budget without causing anxiety over premature failure. A strong warranty, such as 18 months on some premium parts, demonstrates real confidence in the product’s engineering and manufacturing.

The Risks of Low-Quality Components

Cheap parts are expensive in the long run. When tempted by rock-bottom pricing from unknown suppliers, you’re gambling with your engine’s life.

Premature failure is a common issue with inferior components. What looks like a bargain can become a recurring headache when you receive incorrect or poorly made parts that simply don’t perform.

The worst-case scenario is catastrophic engine damage. A failed injector or cracked piston can destroy cylinders or contaminate your entire lubrication system, turning a minor repair into a complete engine rebuild.

Furthermore, installing unapproved parts can lead to voided warranties, leaving you liable for any subsequent damage. The smart approach is to partner with a trusted supplier who offers transparent sourcing, quality guarantees, and technical expertise for both OEM and high-quality aftermarket parts.

The Modern Supply Chain and E-Commerce

The way we find and order diesel parts has changed dramatically. What once took weeks of phone calls and faxes can now be done in minutes, drastically reducing downtime for a vessel in Fort Lauderdale or industrial equipment in the field.

Global sourcing is the backbone of modern parts distribution. A supplier with connections that span continents can procure parts for engines from any manufacturer, whether it’s Caterpillar, Cummins, or Yanmar. This network is especially critical for finding legacy components for older engines after the OEM has discontinued them. A specialized supplier can tap into a global network of distributors and remanufacturers to give an older engine a new lease on life.

Online parts catalogs simplify the search process, allowing you to find components by engine model, serial number, or part number. This, combined with 24/7 ordering convenience, means you can place an order immediately when a breakdown occurs, not just during business hours.

Secure transactions are a hallmark of a reputable online supplier, ensuring your payment and personal data are protected. While technology provides convenience, it’s most effective when backed by real expertise from people who can guide you to the right part the first time. Standard privacy practices, like those outlined in Google’s Privacy Policy, provide a baseline for how customer information should be handled.

Frequently Asked Questions about Diesel Parts

We hear the same questions time and again about marine and industrial diesel engines. Here are answers to the most common concerns.

Why are warranties crucial when choosing a diesel engine spare parts supplier?

A warranty is a supplier’s promise of quality and a crucial way to protect your investment. A strong warranty, such as one lasting 18 months, shows that the supplier is confident in their manufacturing and quality control. It holds them accountable, incentivizing them to source reliable parts and avoid cutting corners. This proof of confidence is essential when purchasing critical components for marine and industrial engines operating in demanding environments like Southeast Florida and the Caribbean.

For more information about our industry-leading warranty coverage, visit our parts department page.

What industries rely most on a reliable diesel engine spare parts supplier?

Several key industries depend on the immediate availability of quality diesel parts:

- Marine Industry: Commercial vessels, cargo ships, and yachts cannot afford downtime. A single day offline can cost thousands in lost revenue or ruin a planned voyage.

- Power Generation: Diesel generators provide primary or backup power for industrial facilities, remote sites, and vessels. Reliability is non-negotiable when the lights need to stay on.

- Industrial & Heavy Machinery: Factories, construction sites, and mines use diesel-powered equipment that operates under extreme stress. Durable, readily available parts are essential to maintain productivity and prevent costly shutdowns.

What are the latest innovations in the diesel parts market?

The diesel parts industry is constantly evolving to improve durability and efficiency. Key innovations include:

- Remanufacturing Advances: Modern processes restore used parts to like-new condition, often with improved specifications, offering a cost-effective and sustainable solution.

- Material Science Improvements: Advanced metallurgy and materials, like specialized steel alloys for cylinder liners and pistons, allow components to withstand higher stress and last longer.

- 3D Printing for Obsolete Parts: Additive manufacturing is emerging as a solution for creating rare or discontinued components for legacy engines, extending the life of older equipment.

- Improved Durability Coatings: Advanced surface treatments are being used to reduce friction, resist corrosion, and extend the lifespan of parts, which is especially valuable in saltwater marine environments.

Conclusion: Partnering for Long-Term Success

We’ve covered a lot of ground together—from the intricate components that keep marine and industrial diesel engines running to the critical factors that separate exceptional diesel engine spare parts suppliers from the rest. If there’s one thing we hope you take away, it’s this: your choice of supplier matters far more than you might think.

Quality, expertise, and availability aren’t just buzzwords—they’re the foundation of engine reliability. When your vessel is docked in Fort Lauderdale waiting for a critical part, or your industrial equipment sits idle in the Caribbean, every hour counts. The right supplier doesn’t just send you parts; they understand the urgency of your situation and the specific demands of marine and industrial diesel applications.

A truly reliable partner brings more to the table than inventory. They offer factory-trained technicians who can identify exactly what you need, a global sourcing network that tracks down even the most elusive legacy components, and quality control processes that ensure every part performs as promised. They stand behind their products with robust warranties and deliver worldwide, so geography never becomes a barrier to keeping your operations running.

Proactive maintenance isn’t glamorous, but it’s what separates successful operations from costly disasters. Having access to high-quality parts—whether genuine OEM or reputable aftermarket—means you’re investing in extended engine life, reduced operational costs, and fewer middle-of-the-night emergencies. It’s about building a relationship with a supplier who views your success as their own.

At Diesel Services of America, we’ve built our reputation on exactly this philosophy. Our commitment goes beyond simply selling parts. With our factory-trained technicians, comprehensive inventory, and worldwide delivery capabilities, we’re here to support your marine and industrial diesel needs with the expertise and reliability you deserve.

Whether you’re maintaining a commercial vessel, managing a yacht fleet, or overseeing industrial machinery, we’re ready to be your trusted partner. Contact us for expert parts support today, and let’s keep your engines running at their best.