Why “Diesel Tune Ups” Don’t Mean What You Think

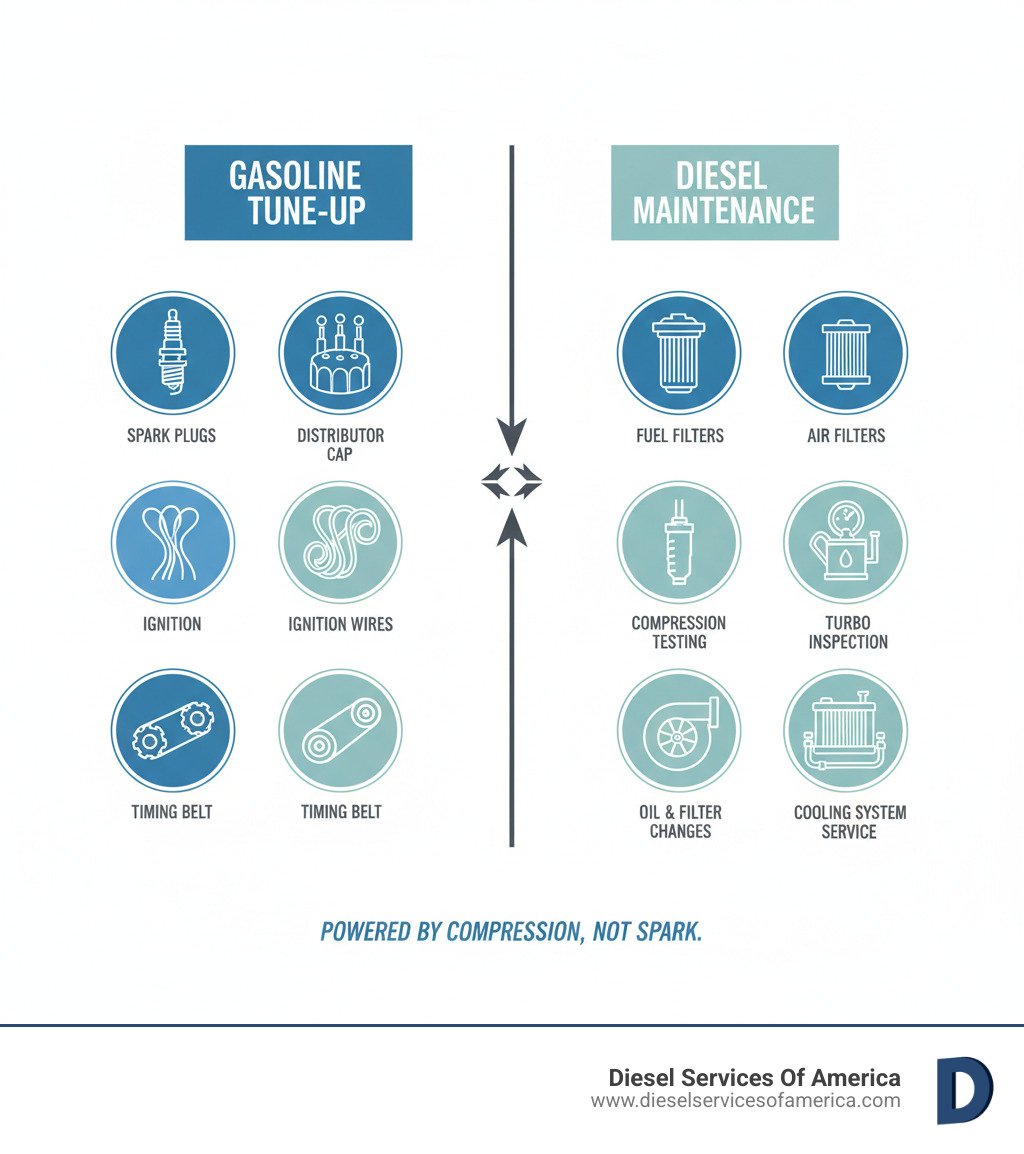

Diesel tune ups are often misunderstood. Unlike gasoline engines, diesels lack spark plugs, distributor caps, or ignition timing that needs adjustment. They use compression ignition, meaning a “tune-up” is actually a comprehensive preventive maintenance service.

What a Diesel “Tune-Up” Actually Involves

Instead of a traditional tune-up, diesel engines require preventive maintenance focused on these critical areas:

- Fuel System: Replace fuel filters, drain water separators, inspect/clean injectors

- Air Intake: Replace air filters, check turbocharger health

- Cooling System: Flush coolant, inspect hoses and radiators

- Lubrication: Change oil and oil filters at proper intervals

- Compression: Test cylinder compression, check glow plugs (if equipped)

Marine and industrial diesel engines need systematic maintenance, not a “tune-up” in the gasoline sense. This approach keeps your engine running strong and prevents costly breakdowns. As one diesel service manual states: “Regular maintenance is absolutely imperative if you want a diesel engine to last.”

For marine and industrial applications, this maintenance is even more critical. Engines operate under demanding conditions like high loads, extended run times, and exposure to saltwater. Catching issues early can be the difference between a minor service and a major engine rebuild.

The “Tune-Up” Myth: How Marine Diesels Differ

When we talk about diesel tune ups for marine or industrial engines, we mean a comprehensive maintenance approach, not a quick automotive service. The reason lies in how diesel engines work. Instead of spark plugs, diesels rely on compression ignition. They compress air until it’s hot enough to ignite fuel on contact. No spark plugs, distributor caps, or traditional ignition timing adjustments are needed.

This fundamental difference changes all maintenance requirements. Diesel engines are known for impressive torque production and reliability, but their higher operating temperatures and complex fuel systems demand regular, specialized care. The marine and industrial world operates differently than the automotive one, and your maintenance schedule must reflect that. Learn more about how diesel engines work.

Why Maintenance Needs Are Unique

Marine and industrial diesel maintenance is unique for several reasons. First, engine life is tracked in operating hours, not mileage. Service is typically scheduled every 250 or 500 hours, or annually.

The harsh marine environment is another factor. Saltwater corrosion attacks metal surfaces and electrical connections, while humidity poses a constant threat.

These engines also face high-load demands that automotive engines rarely see, often running at or near full throttle for extended periods. This generates immense heat and stress, breaking down oil faster and taxing the cooling system.

Water in fuel is a constant battle due to condensation in fuel tanks. Water can decrease power, cause rough running, or even lead to catastrophic fuel injector failure.

Because of this fuel system sensitivity, even small amounts of contamination from algae, dirt, or rust can clog injectors and accelerate engine wear. Clean fuel is absolutely critical.

Key Components Requiring Attention

This maintenance focus shift means paying close attention to specific components:

- Fuel injectors spray atomized fuel into the combustion chamber. Their performance is critical for power and efficiency. Regular service ensures all cylinders contribute equally.

- Fuel filters are the engine’s first line of defense. Most diesels have a primary filter (with a water separator) and a secondary filter that need regular replacement based on operating hours.

- Air filters provide clean air for combustion. A restricted filter hurts performance and fuel economy, especially in dusty or salt-spray environments.

- The turbocharger (if equipped) boosts power by forcing more air into the engine. It operates at extreme temperatures and requires proper lubrication and monitoring to prevent failure.

- The cooling system manages the immense heat produced by a diesel under load. The water pump, heat exchanger, hoses, and coolant all require regular inspection to prevent overheating.

- The lubrication system (oil and filters) reduces friction, manages heat, and prevents contamination. Regular oil changes are essential due to high-load operation.

- Glow plugs (on many diesels) aid cold starting by heating the combustion chamber. They are tested as part of a thorough maintenance check.

Warning Signs: When Your Marine Diesel Engine Needs a Tune-Up

Your engine communicates through subtle changes in performance, sound, and exhaust. Catching these warning signs early can prevent a minor issue, like a clogged filter, from escalating into a major repair. If you notice any of the following symptoms with your marine or industrial diesel, it’s time for a professional assessment.

Decoding Exhaust Smoke

Exhaust smoke color reveals what’s happening inside your engine.

- Black smoke indicates a rich fuel mixture (too much fuel or not enough air). Common causes include dirty air filters, faulty injectors, or a failing turbocharger.

- Blue smoke means oil is burning in the combustion chamber, typically due to worn piston rings or valve seals. This is a sign of internal engine wear.

- White smoke that persists after warm-up usually indicates either a coolant leak into the combustion chamber (from a blown head gasket) or incomplete combustion due to timing, compression, or injector problems.

Addressing Performance and Starting Issues

Your engine provides other clues when it needs attention:

- Reduced power under load: The engine feels sluggish and struggles to maintain speed. This often stems from clogged fuel injectors, restricted air filters, or turbocharger issues.

- Decreased fuel efficiency: If you’re burning more fuel for the same work, something is wrong. Poor combustion from dirty filters or injector problems is a likely cause. A proper diesel tune up can often pay for itself in fuel savings.

- Hard starting: The engine cranks excessively before starting. This can be caused by weak batteries, faulty glow plugs, contaminated fuel, or even corroded electrical connections.

- Rough idling: An uneven idle often points to fuel delivery problems, such as a malfunctioning injector or air in the fuel system.

- Excessive vibration: Beyond normal operation, this can suggest failing engine mounts, driveline issues, or a misfiring cylinder.

- Strange engine noises: Knocking, ticking, or grinding sounds should never be ignored. They can indicate serious internal problems that are less expensive to fix when caught early.

- Overheating: A temperature gauge climbing into the red is a critical warning. Shut down the engine immediately to prevent catastrophic damage like cracked heads or a warped block.

Core Components of a Marine Diesel Tune-Up

When we talk about a comprehensive diesel tune-up for your marine or industrial engine, we’re talking about a systematic approach to keeping your powerplant healthy. It’s not a quick oil change and air filter swap—it’s a thorough inspection and service of every system that keeps your engine running reliably, season after season.

Think of it this way: your diesel engine is a finely-tuned machine where every component depends on the others. The fuel system feeds the fire, the air intake supplies oxygen, and the cooling system prevents everything from melting down. When one system falters, the others suffer. That’s why our approach at Diesel Services Of America addresses all these critical areas together.

The Fuel System: Your Engine’s Lifeline

The fuel system is where most diesel problems begin and where maintenance is most critical. Your engine depends on clean, precisely delivered fuel.

- Fuel filter replacement is essential. Most diesels have a primary and secondary filter that we replace at recommended operating hour intervals. In marine environments, more frequent changes are often necessary.

- Water separation is vital in marine applications. We regularly check and drain water separators to prevent water from damaging sensitive fuel injectors.

- Fuel injectors are precision components that atomize fuel in the combustion chamber. We service them at specific intervals (e.g., ~1,000 hours for turbocharged engines) to ensure proper spray patterns and even power delivery. We also check injector timing for optimal performance.

Using high-quality fuel and additives between services helps maintain system health.

Air, Boost, and Cooling: The Support Systems

Your engine’s air intake and cooling systems are just as important as the fuel system.

- Air filter inspection is done at every service. A clogged filter reduces power and fuel economy by forcing the engine to work harder.

- The turbocharger boosts power and efficiency but operates under extreme stress. We inspect for leaks, listen for unusual noises, and check boost pressure. Proper cool-down procedures (idling for 30-60 seconds before shutdown) are crucial for turbo longevity.

- The cooling system works overtime on marine and industrial diesels. We recommend changing coolant every two to five years to prevent corrosion. We also inspect the radiator (or heat exchanger), hoses, thermostat, and water pump to prevent overheating, which can cause catastrophic engine damage.

The Proactive Approach: Benefits of Regular Diesel Tune Ups

Regular diesel tune ups are not just about preventing problems; they’re about making your engine run better, last longer, and save you money. The vessels and equipment that receive regular preventive maintenance rarely have emergencies. The choice is simple: pay a little now or pay a lot later.

Key benefits include:

- Improved fuel economy: A well-tuned engine burns fuel more efficiently, and the savings can often offset the cost of the service.

- Reliability: Regular maintenance builds confidence that your engine will start every time and perform flawlessly, which is critical on the water or on a job site.

- Extended engine lifespan: Consistent care catches wear early and can add many years to your engine’s working life, protecting a significant financial investment.

The Financial Case for Maintenance

Consider the costs. A professional diesel tune-up might cost $500 to $2,000. An engine rebuild can be $15,000 to $30,000, and a full replacement can exceed $50,000. Regular maintenance prevents these catastrophic failures.

Minimizing unplanned downtime is another crucial financial benefit. For a charter boat or industrial equipment, downtime means lost revenue and a damaged reputation. Preventive maintenance keeps you operational.

What a Professional Diesel Tune-Up Involves

While some basic checks can be done by owners, a comprehensive professional service goes much deeper.

| DIY Checks | Professional Service |

|---|---|

| Visual inspection (leaks, belts, hoses) | Compression testing (per cylinder) |

| Fluid level checks (oil, coolant) | Fuel injector testing, cleaning, and replacement |

| Basic filter changes (air, primary fuel) | Fuel system bleeding and timing adjustments |

| Battery terminal cleaning | Diagnostic scanning for ECM errors and sensor data |

| Water separator draining | Valve clearance adjustments |

| Turbocharger boost and wastegate inspection | |

| Cooling system flush, pressure test, and component checks | |

| Electrical system analysis (alternator, grounds, battery load) | |

| Load testing with a dynamometer (where applicable) |

Our factory-trained technicians use specialized diagnostic equipment for tasks like compression testing, reading ECM data, and fuel injector servicing. This work requires precision and experience to ensure it’s done correctly, following manufacturer-recommended schedules custom to your engine’s specific operating conditions.

Frequently Asked Questions about Marine Diesel Tune-Ups

We hear the same questions from boat owners and equipment operators who want to properly care for their engines. Here are answers to the most common concerns.

How often does a marine diesel engine need a tune-up?

Service intervals are based on operating hours and calendar time, not mileage. A typical schedule is:

- Oil and Filter Changes: Every 250-500 operating hours.

- Comprehensive Service: Every 1,000 hours or annually. This includes fuel filter replacement, air filter checks, and cooling system inspection.

- Injector Service: Often required at the 1,000-hour or two-year mark for turbocharged engines.

- Coolant System Flush: Every 2-5 years.

If your engine operates under severe duty (constant high loads, harsh environments), these intervals should be shorter. Always consult your manufacturer’s recommendations.

Can I perform a diesel tune-up myself?

It depends on your skill and tools. DIY tasks can include visual inspections, fluid checks, cleaning battery terminals, and changing accessible air and oil filters.

However, tasks like fuel injector servicing, timing adjustments, compression testing, and advanced diagnostics require specialized tools and expertise. An incorrect adjustment can cause expensive damage. If a task isn’t detailed in your owner’s manual, it’s best to call a professional.

What is the most critical part of a diesel tune-up?

Fuel system integrity is the single most critical aspect. A diesel engine requires a constant supply of clean, water-free fuel delivered by healthy injectors.

This means using clean fuel, maintaining primary and secondary fuel filters, and ensuring injectors are functioning correctly. A failure in any part of this system can quickly lead to reduced power, increased smoke, and even severe internal engine damage. Consistent fuel system maintenance is the key to engine longevity and is the primary focus of effective diesel tune ups.

Conclusion: Keep Your Engine Running Strong

The bottom line is that diesel tune ups are about systematic, proactive maintenance, not spark plugs. In demanding environments like Fort Lauderdale, Southeast Florida, and the Caribbean, this care is essential for engine longevity.

Your diesel engine communicates its needs through performance, sounds, and smoke. Learning to listen and acting on these cues protects your investment and ensures reliability on the water or on the job.

Regular maintenance maximizes fuel efficiency, extends engine life, and provides the peace of mind that your equipment will perform flawlessly. That confidence is invaluable when you’re miles from shore or in the middle of a critical operation.

At Diesel Services Of America, our factory-trained technicians understand the unique demands on marine and industrial diesel engines. We’ve seen how proper care allows engines to run strong for decades. We provide expert service, from routine filter changes to complex fuel system diagnostics.

Don’t wait for warning signs to become major problems. Schedule your marine diesel maintenance today and let us help you keep your engine running strong for years to come.