Why Understanding Engine Overhaul Benefits Matters for Marine and Industrial Operations

Engine overhaul benefits can transform a declining marine or industrial diesel engine into a powerhouse of performance, saving you significant costs while extending its operational life by years. For fleet managers in the Caribbean or generator operators in South Florida, understanding what an overhaul delivers is key to smart asset management.

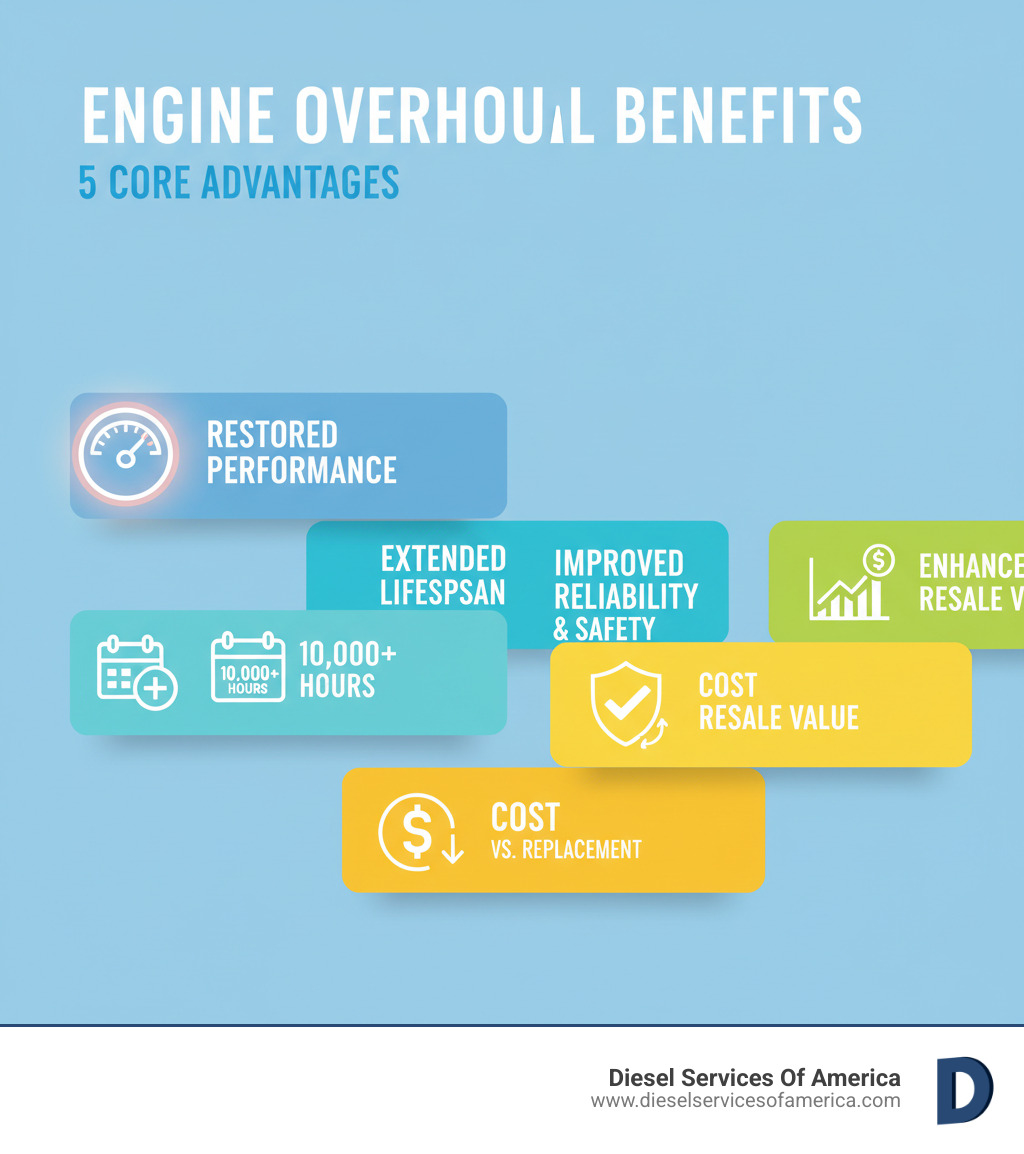

Key Engine Overhaul Benefits:

- Restored Performance – Regain original horsepower and torque

- Extended Lifespan – Add thousands of operational hours to your engine

- Improved Reliability – Prevent catastrophic failures and unplanned downtime

- Cost Savings – Save thousands compared to complete engine replacement

- Improved Resale Value – Increase asset value with documented professional service

Over time, every marine diesel engine and industrial generator experiences performance decline as compression drops and fuel efficiency suffers. An engine overhaul is not just a repair; it’s a strategic investment that delivers near-new performance at a fraction of the replacement cost.

For vessel owners and industrial operators in Southeast Florida and the Caribbean, this decision is critical. When your engines power your livelihood, choosing to overhaul can mean getting back to work quickly and avoiding weeks of downtime. An overhaul can save you thousands—if not tens of thousands—compared to re-powering, and is often completed in a fraction of the time.

What is a Marine or Industrial Engine Overhaul?

An engine overhaul is a complete restoration that brings a heavy-duty diesel engine back to factory specifications. It addresses the deep-seated wear that accumulates over thousands of hours, whether the engine is powering a vessel in the Caribbean or a critical generator on a job site.

The process is meticulous and systematic:

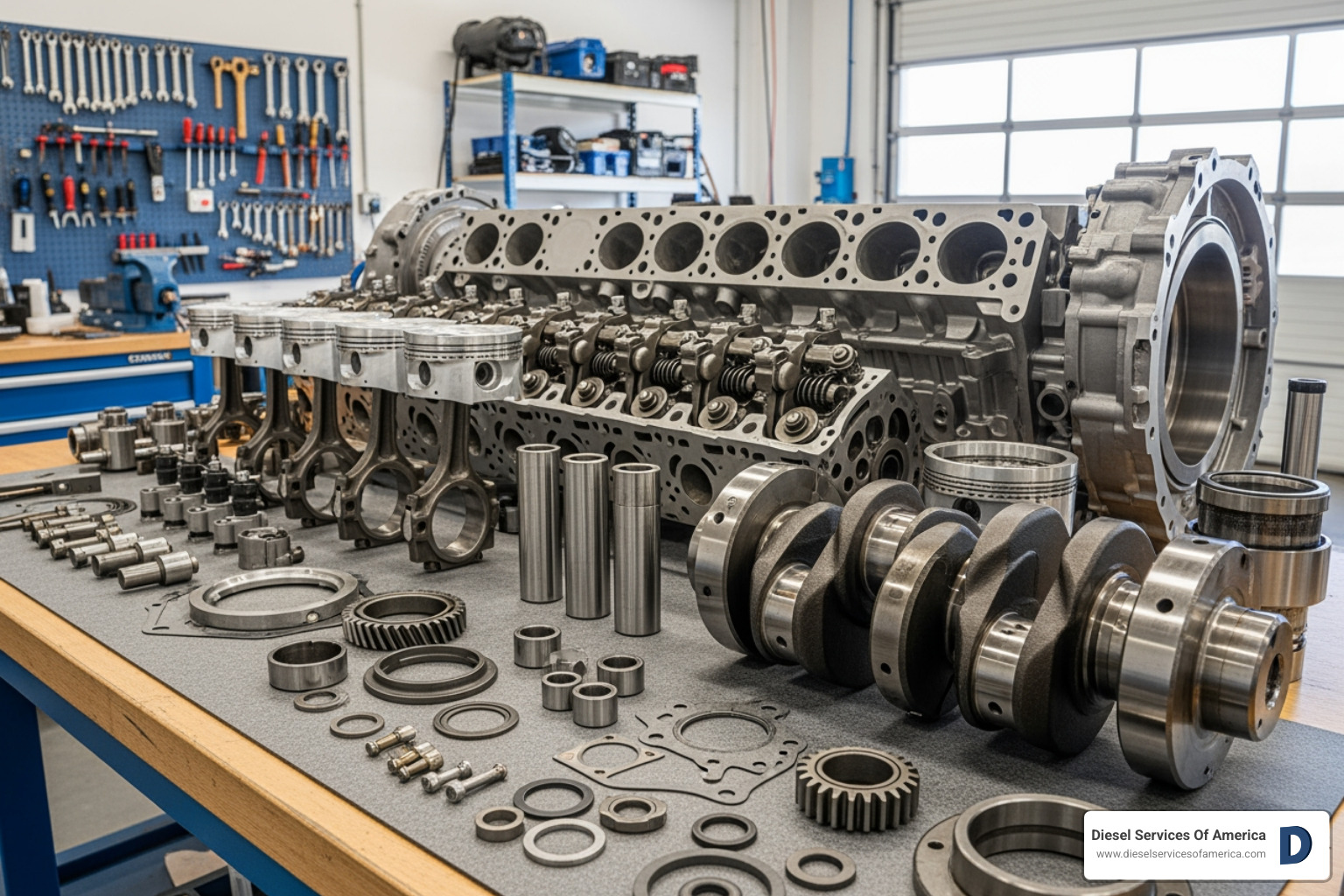

- Disassembly and Cleaning: The engine is completely taken apart. Each component is deep-cleaned to remove deposits and reveal its true condition.

- Inspection: Technicians perform visual checks and use advanced non-destructive testing (NDT) to find hidden cracks or flaws. Critical parts like cylinder bores and crankshafts are measured against manufacturer specifications to identify wear.

- Component Replacement: This is where the key engine overhaul benefits emerge. Worn parts such as pistons, rings, cylinder liners, bearings, gaskets, and seals are replaced with new components to restore performance and prevent leaks.

- Reassembly and Testing: The engine is carefully reassembled to precise factory tolerances. Afterward, it undergoes rigorous testing and a controlled break-in procedure to ensure all new parts function correctly for long-term reliability.

There are two main types of overhauls. An in-frame overhaul addresses components like pistons and liners without removing the engine block, making it faster and more economical for less extensive wear. An out-of-frame overhaul involves removing the entire engine for a complete teardown, allowing for comprehensive work on the block and crankshaft.

While the terms “overhaul” and “rebuild” are often used interchangeably, a professional overhaul is a comprehensive restoration to factory specifications. At Diesel Services of America, our overhauls deliver a standard of quality and precision comparable to a remanufactured engine, but with significant savings in cost and downtime.

The Core Engine Overhaul Benefits for Your Operation

A professional engine overhaul offers a powerful alternative to limping along with a failing engine or spending a fortune on a replacement. The engine overhaul benefits go far beyond simple repairs, delivering restored power, increased efficiency, long-term value, and improved safety.

This proactive approach is a strategic investment that keeps you ahead of catastrophic failures, allowing you to plan maintenance instead of reacting to emergencies.

How an Overhaul Restores Performance and Efficiency

An overhaul brings back the smooth, confident power of a new engine by addressing the root causes of performance decline. By replacing worn pistons, rings, and liners, we restore compression to factory specifications, which is the foundation of efficient combustion. This allows for optimal fuel combustion, leading directly to improved fuel economy and reduced emissions. The performance benefits of a professional engine overhaul are immediate, with your engine’s original horsepower and torque returning. This means your workboat or generator can handle demanding tasks with confidence once again.

One of the Key Engine Overhaul Benefits: Extending Engine Lifespan

The financial case for an overhaul is undeniable. You can add thousands of operational hours to your equipment, delaying capital expenditure on a new engine by years. Heavy-duty marine diesels are built for longevity, and an overhaul at the right time makes it possible to reach 20,000, 30,000, or more operational hours. Overhauls are generally less expensive than a complete engine replacement, often by tens of thousands of dollars. This approach maximizes the value of an asset you already own and trust, making it a highly cost-effective solution.

Improved Reliability and Safety

For marine and industrial operators, reliability is essential. An overhaul improves reliability and safety by preventing catastrophic failure. Through systematic inspection and replacement of aging components, we help you minimize unplanned downtime so your vessels stay on schedule and your operations run smoothly. For marine applications, this dependability at sea is critical for ensuring crew safety. The peace of mind from knowing your engine has been professionally restored by factory-trained technicians is invaluable, allowing you to focus on your business, not your equipment.

At Diesel Services of America, our technicians ensure your engines deliver the job site reliability your business demands. Learn more about our comprehensive marine and industrial diesel engine services and how we keep your operations running.

Overhaul vs. Replacement: Making the Right Financial Decision

Deciding between an overhaul and a complete replacement is a major financial choice. It requires strategic thinking about your budget, downtime, and long-term asset management.

To help you weigh your options, here’s a quick look at how overhauls stack up against replacements:

| Feature | Engine Overhaul | Engine Replacement |

|---|---|---|

| Cost | Generally less expensive (e.g., $3,500 – $9,000 for rebuild/remanufacture for mainstream, thousands less for marine/industrial) | Significantly more expensive (e.g., $8,000+ for mainstream, potentially hundreds of thousands for marine/industrial) |

| Downtime | Often shorter (weeks for marine/industrial) | Can be longer (months for marine/industrial, especially for older models or complex installations) |

| Compatibility | Maintains existing vessel/equipment configuration, avoids modifications | May require extensive modifications to mounts, fuel, exhaust, controls |

| Warranty | Varies by shop/type (e.g., 12 mo/12k miles for rebuild, multi-year for remanufactured) | Typically comes with new engine warranty (e.g., 24 months) |

| Longevity | Adds thousands of operational hours, restores near-new performance | Provides a “fresh start” with full new lifespan |

| Resale Value | Improves with documented service | Can significantly boost resale value, especially if other systems are updated |

Cost and Downtime: Overhaul vs. Replacement

The primary engine overhaul benefits are often cost and time savings. An overhaul is almost always more budget-friendly than a new engine, saving thousands of dollars. Downtime is also a critical factor. An overhaul might take a few weeks, whereas a full re-powering project can stretch into months due to sourcing and complex installation. Replacing an engine can also require extensive and costly modifications to engine mounts, fuel systems, and controls. An overhaul avoids these issues by working with your existing setup, which is why it often makes sense to overhaul instead of re-power a marine diesel engine.

Understanding the Terminology: Rebuilt vs. Remanufactured

While often used interchangeably, these terms have key differences:

- A rebuilt engine involves replacing only broken or heavily worn parts. Quality can vary, and warranties are often limited.

- A remanufactured engine is completely disassembled and restored to original equipment (OE) manufacturer specifications, with all wear items replaced. This process aims for “like-new” quality and typically includes longer warranties.

A high-quality overhaul from a professional shop like Diesel Services of America can achieve results similar to a remanufactured engine by using top-grade parts and adhering to strict standards.

When an Overhaul is the Superior Choice

An overhaul is often the smartest move in several situations:

- Sound Engine Block: The engine’s core structure is undamaged.

- Budget Constraints: You need a cost-effective path to restored performance.

- Minimizing Downtime: Getting back to work quickly is the top priority.

- Maintaining Compatibility: You want to avoid costly modifications to fit a new engine.

- Avoiding Electronic Integration Issues: You prefer to stick with your vessel’s existing, familiar control systems.

- Parts Availability: Components for your older, robust engine are still readily available.

Key Signs Your Diesel Engine Needs an Overhaul

Your marine or industrial diesel engine will usually show warning signs before a major failure. Recognizing these signs allows you to schedule an overhaul proactively, avoiding a catastrophic breakdown that could strand your vessel or shut down your operation.

Telltale Signs of Engine Wear

Watch for these common indicators that your engine needs attention:

- Excessive Smoke: White smoke (coolant/unburnt fuel), blue smoke (burning oil), or black smoke (incomplete combustion) all point to internal issues.

- Noticeable Loss of Power: A sluggish engine or a generator struggling under load often indicates declining compression.

- Increased Oil Consumption & Poor Fuel Economy: If you’re constantly adding oil or your fuel bills are rising, the engine is likely suffering from internal wear.

- Engine Knocking or Tapping Noises: These sounds can indicate serious problems like worn bearings.

- Metal Shavings in Oil Analysis: This is a clear sign that internal components are breaking down.

- Persistent Overheating: Can be caused by excessive internal friction from worn parts.

- Frequent Breakdowns: A series of small problems often means multiple components are failing at once.

Acting on these signs early allows an overhaul to fix the root causes before they force a complete engine replacement.

A Key Engine Overhaul Benefit: Enhancing Resale Value

One of the most valuable engine overhaul benefits is a significant boost in resale value. A documented professional overhaul transforms a high-hour engine from a liability into a key selling point.

Potential buyers are cautious about aging engines. Proof of a recent overhaul provides them with confidence in the equipment’s mechanical integrity and future reliability. This documentation shows that you’ve invested in the asset, added thousands of hours back to its lifespan, and maintained it properly. This increased buyer confidence translates directly to a higher asset valuation and justifies a premium asking price, giving you a strong return on your investment.

Diesel Services of America provides the detailed service records that make this possible, ensuring your overhaul pays dividends both in performance and at resale.

Frequently Asked Questions about Engine Overhauls

Considering an overhaul for your marine or industrial engine? Here are answers to the most common questions from operators in Southeast Florida and the Caribbean.

How long does a marine or industrial diesel engine overhaul take?

The timeframe depends on several factors, including the extent of wear, the type of overhaul, and parts availability. An in-frame overhaul is typically faster than a more comprehensive out-of-frame overhaul. While sourcing parts for older or less common engines can add time, a typical overhaul takes weeks, not days. This is still significantly faster than a complete engine replacement, which can stretch into months when factoring in sourcing, delivery, and installation modifications.

Will an overhauled engine be as reliable as a new one?

Yes, when the work is done correctly by professionals. A high-quality overhaul can restore an engine to reliability levels that match or even exceed its original condition. This is achieved through:

- Expert Workmanship: Our factory-trained technicians have specialized experience in marine and industrial applications.

- Quality Parts: We use genuine OEM or premium aftermarket parts that meet or exceed original specifications.

- Adherence to OEM Specs: Every component is reassembled to precise factory tolerances, effectively resetting the engine’s operational life.

- Proper Break-in: A controlled run-in period ensures new components seat correctly for long-term performance.

When these elements combine, an overhauled engine delivers near-new reliability at a fraction of the cost of a new powerplant, which is one of the most valuable engine overhaul benefits.

What is the difference between a top overhaul and a major overhaul?

Understanding the distinction helps you choose the right service:

-

A top overhaul (or “top-end” overhaul) focuses on the upper engine components. It involves reconditioning the cylinder heads and replacing pistons, rings, and valves. The engine’s lower end, including the crankshaft and main bearings, is not serviced.

-

A major overhaul is a complete reconditioning of the entire engine. It includes everything in a top overhaul, plus a full disassembly of the lower end to service the crankshaft, connecting rods, main bearings, and all other internal components. This is the most comprehensive option, returning the entire engine to like-new condition.

For engines with significant hours or multiple signs of wear, we typically recommend a major overhaul to deliver the most lasting benefits.

Learn more about our approach to marine diesel engine overhauls and explore our services here: https://www.dieselservicesofamerica.com/marine-diesel-engine-overhaul-service/.

Conclusion: A Smart Investment in Your Vessel or Equipment

When your marine diesel engine or industrial generator shows its age, an overhaul is more than a repair—it’s a strategic investment. The engine overhaul benefits are clear: restored performance, extended longevity, improved reliability, and substantial cost savings compared to a full replacement.

For commercial operators in Southeast Florida and the Caribbean, these advantages mean a healthier bottom line through less downtime, lower fuel costs, and fewer emergency repairs. For private vessel owners, it means the invaluable peace of mind that comes from knowing your engine is dependable.

At Diesel Services of America, our factory-trained technicians specialize in overhauling marine and industrial diesel engines. We understand the demands of the corrosive marine environment and the need for absolute reliability. We serve clients throughout Fort Lauderdale, Southeast Florida, and the Caribbean, providing the expertise to keep your equipment running at its peak.

Don’t let a declining engine compromise your operations or safety. Your engine is telling you it needs attention, and we’re here to help. Contact us for expert marine and industrial diesel overhaul services today, and let’s discuss how we can breathe new life into your valuable equipment.