Why Intercoolers Are Essential for Marine and Industrial Diesel Engines

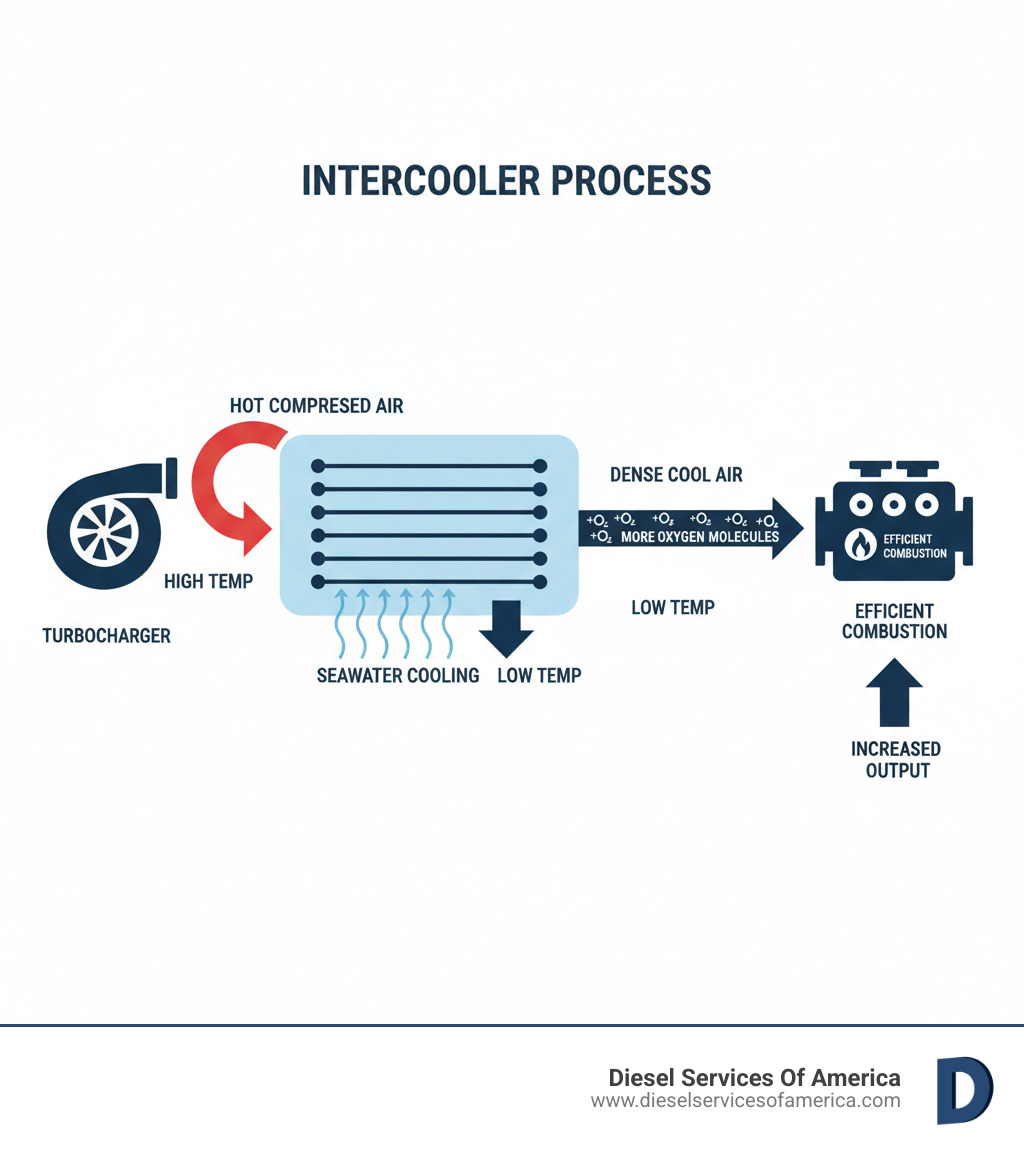

Intercoolers are heat exchangers that cool the compressed air from a turbocharger before it enters the engine. This cooling process increases air density, allowing the engine to burn more fuel efficiently and produce significantly more power.

Quick Answer: What You Need to Know About Intercoolers

- Primary Function: Cool hot, compressed air from the turbo to increase oxygen density.

- Main Types: Air-to-air and air-to-liquid (standard for marine use).

- Key Benefits: More power, better fuel economy, reduced engine stress, and knock prevention.

- Marine Advantage: Air-to-liquid intercoolers use seawater for superior cooling on vessels.

- Maintenance Needs: Regular cleaning of seawater side (deposits, marine growth) and air side (oil, salt buildup).

- Common Failure Signs: Power loss, black smoke, hissing sounds, high temperatures, leaks.

For operators of marine vessels or industrial diesel equipment in Southeast Florida and the Caribbean, the intercooler is a critical component. It directly impacts your engine’s reliability and performance, whether on a commercial fishing boat, pleasure craft, or industrial generator.

Modern diesel engines use turbochargers to compress intake air, but this process creates intense heat, often raising air temperatures to 3 or 4 times ambient. This hot, less-dense air contains less oxygen, limiting power. The intercooler solves this by cooling the compressed air, creating a denser, oxygen-rich charge for more complete combustion. The result is more horsepower, better fuel efficiency, and a reduced risk of engine knock.

Most marine engines use air-to-liquid intercoolers, which tap into seawater for cooling. This design is compact and highly effective in enclosed engine rooms. However, these units face a harsh environment. The seawater side collects mineral deposits and marine growth, while the air side accumulates oil and salt residue. Without regular maintenance, this buildup reduces cooling efficiency, leading to performance loss.

This guide covers how marine and industrial intercoolers work, why air-to-liquid designs are superior for marine use, how to spot failure signs, and when to consider an upgrade.

How Intercoolers Boost Marine & Industrial Engine Performance

An intercooler is what makes turbocharging truly effective on a marine or industrial diesel engine. While a turbocharger compresses air to force more into the cylinders, this process generates extreme heat—up to 3 to 4 times the ambient temperature. Hot air is less dense and contains fewer oxygen molecules, which limits the engine’s ability to burn fuel and produce power.

The intercooler solves this problem by cooling the compressed air. This makes the air charge denser and richer in oxygen, allowing for more complete fuel combustion. The result is a significant boost in real-world performance, which is essential for reliable operation in the demanding conditions of Southeast Florida and the Caribbean. For a detailed look at this process, check out our guide on How a Turbo Diesel Intercooler Works. You can also learn more about maximizing your system in our Diesel and Turbo section.

The Science of Cooled, Compressed Air

When a turbocharger compresses air, physics dictates that its temperature increases, a principle known as Boyle’s Law. This superheated air is expanded, with oxygen molecules spread far apart. To support efficient combustion, your engine needs those oxygen molecules packed closely together.

The intercooler acts as a heat exchanger, dropping the temperature of the compressed air. As the air cools, the oxygen molecules pack closer together, increasing its density. With each intake stroke, the cylinders fill with significantly more oxygen. This denser air charge allows more fuel to be injected while maintaining the ideal air-fuel ratio, ensuring the fuel burns more efficiently and extracts maximum energy.

Key Benefits for Your Engine

A properly functioning intercooler delivers immediate and long-term benefits for your marine or industrial diesel engine.

-

More Power: Cooler, denser air means more oxygen for combustion, directly increasing horsepower and torque. This is crucial when pushing a loaded vessel or running equipment at full capacity.

-

Better Fuel Economy: More complete combustion means you get more work out of every gallon of fuel. Over time, this leads to significant operational savings.

-

Reduced Engine Stress: Cooler intake temperatures help lower overall engine operating temperatures. This reduces thermal stress on internal components, helping seals and oil last longer.

-

Lower Emissions: Efficient combustion produces fewer unburned hydrocarbons and less particulate matter (black smoke), which is important for regulatory compliance.

-

Knock Prevention: Hot intake air can cause pre-ignition or “knocking,” which can damage pistons and bearings. An intercooler keeps intake temperatures in a safe range, eliminating this risk and ensuring reliable operation.

For more strategies to optimize your marine diesel performance, visit our page on Marine Diesel Engine Performance. To take your engine to the next level, explore our insights on Diesel Engine Performance.

Key Types of Marine Intercoolers: Air-to-Air vs. Air-to-Liquid

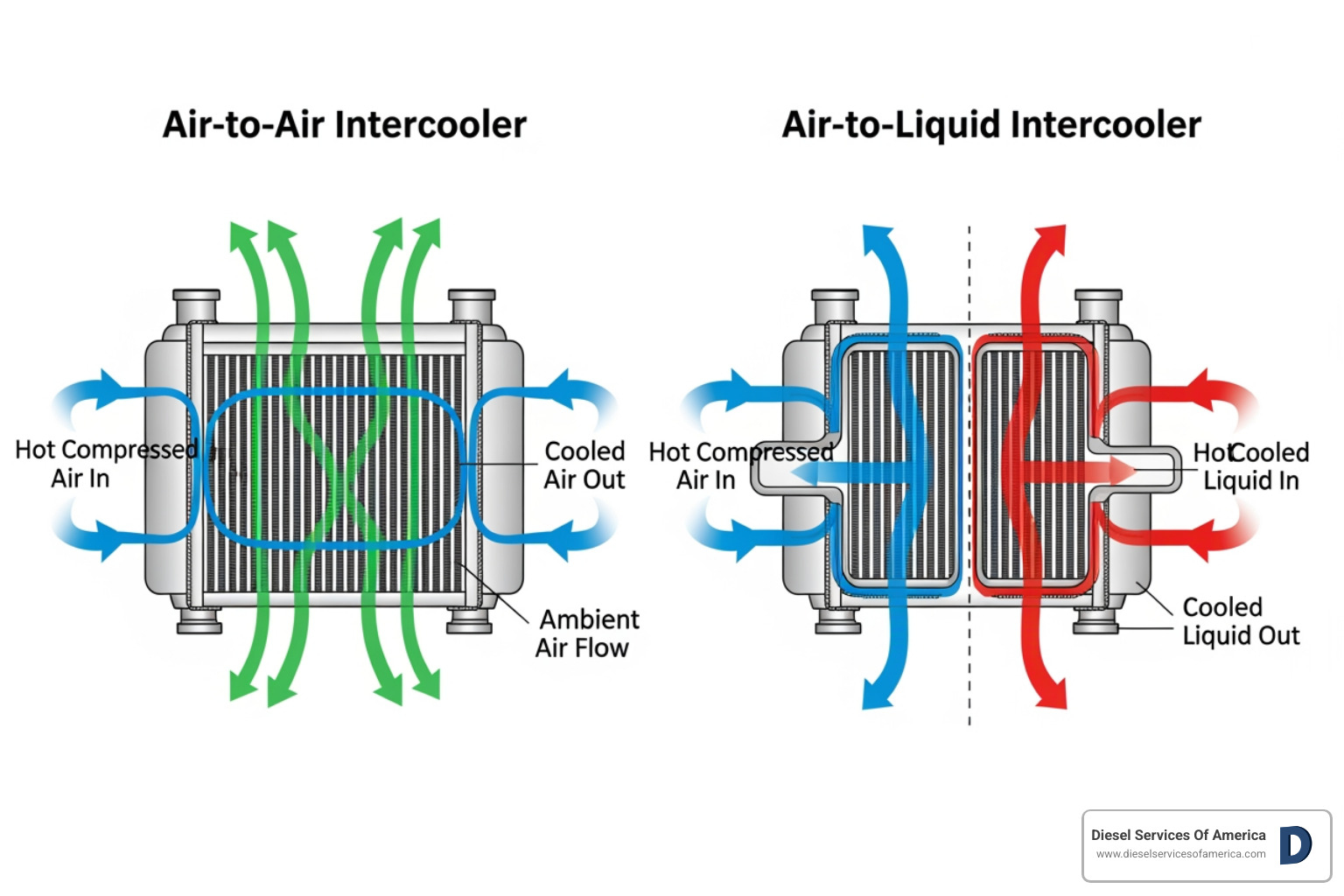

Intercoolers come in two main types: air-to-air and air-to-liquid. Both are heat exchangers designed to cool compressed air from a turbocharger, but they use different methods. For marine and industrial applications, one type is vastly superior.

Air-to-air units use ambient air to cool the charge air, while air-to-liquid systems use a liquid coolant that circulates through a separate cooling circuit. For a deeper dive into the technical principles, Intercooler – Wikipedia offers a comprehensive overview.

| Feature | Air-to-Air Intercooler | Air-to-Liquid Intercooler |

|---|---|---|

| Cooling Medium | Ambient air | Intermediate liquid coolant |

| Efficiency | Good in ideal conditions | Consistently excellent |

| Complexity | Simple, fewer components | More complex system |

| Weight | Lighter | Heavier |

| Cost | Lower | Higher |

| Ideal Application | Open spaces with good airflow | Marine and industrial enclosed spaces |

Understanding these differences is key to engine performance and reliability in the demanding conditions of Southeast Florida and the Caribbean.

How Air-to-Air Intercoolers Work

An air-to-air intercooler functions like a radiator for your intake air. Hot air from the turbo flows through tubes and fins, while cooler ambient air passes over the outside, carrying heat away. This simple, cost-effective design is common in automotive applications.

However, they are poorly suited for marine use. They require a large volume of consistent airflow, which is difficult to achieve in a cramped, hot engine room. Without it, they suffer from heat soak and lose efficiency. The large size and need for long piping also create installation challenges and can increase turbo lag.

Why Air-to-Liquid Intercoolers Dominate the Marine World

The air-to-liquid intercooler is the clear winner for marine and industrial diesel engines. This design uses a coolant (typically a water/antifreeze mix) to absorb heat from the compressed air. The heated coolant is then pumped to a separate heat exchanger where it is cooled by an external source—for vessels, this is the surrounding seawater.

This system offers several key advantages:

- Superior Cooling: Seawater provides an abundant and consistently cool medium, offering far more effective heat transfer than the hot air in an engine room.

- Compact Design: Air-to-liquid units are much smaller than their air-to-air counterparts, making them easy to install in the tight confines of a vessel’s engine compartment.

- Consistent Performance: Cooling is stable and predictable regardless of vessel speed or engine room temperature, ensuring reliable power whether idling or at full throttle.

- Durability: To survive the harsh marine environment, these intercoolers are built with specialized corrosion-resistant materials. Tubes are typically made from Copper-Nickel alloys, with housings and end caps made of Bronze or other marine-grade materials.

While more complex and expensive upfront, the superior efficiency, compact packaging, and robust construction of air-to-liquid intercoolers make them the standard for any serious marine or industrial application. For more information, visit our Diesel Intercooler page.

Marine Intercooler Maintenance and Recognizing Failure

In the salty, humid environment of Southeast Florida and the Caribbean, your marine intercooler requires regular attention to maintain performance. Preventative maintenance is insurance for your engine’s health, helping you avoid gradual power loss, higher fuel consumption, and costly repairs.

The good news is that catching problems early is straightforward if you know what to look for.

Common Signs of Intercooler Malfunction

When an intercooler starts to fail, your engine will often give you clear signals. Be aware of:

- A noticeable loss of power: The vessel feels sluggish because the engine is receiving less dense, oxygen-poor air.

- Increased black smoke from the exhaust: This indicates incomplete fuel combustion, a direct result of an inefficient air charge.

- Hissing sounds from the engine bay: A distinct whistle or hiss often points to a boost leak in the intercooler or its piping.

- Higher engine operating temperatures: Hotter intake air leads to hotter combustion, putting additional thermal stress on the entire engine.

- Visible corrosion or leaks: In a marine environment, saltwater can cause physical damage to the unit, leading to coolant or boost leaks.

If you notice these symptoms, it’s crucial to act quickly. A minor issue can escalate into major engine damage. Our team at Diesel Engine Repair Service can diagnose and resolve intercooler problems before they become catastrophic.

Essential Maintenance for Peak Condition

Marine intercoolers require maintenance on two fronts: the seawater side and the air side.

-

Cleaning the Seawater Side: This is a unique marine challenge. Mineral deposits (scale) and marine growth like barnacles and algae must be removed. This often requires chemical descaling treatments and physical cleaning to restore proper water flow and heat transfer.

-

Cleaning the Air Side: The internal passages collect oil residue from crankcase vapors and salt particles from the air. This gummy buildup insulates the core and restricts airflow, requiring specialized cleaners to dissolve it.

-

Regular Inspection and Testing: Visually inspect the unit for corrosion and leaks. Pressure testing is essential to find hidden cracks or degraded seals that cause boost leaks. Old gaskets should be replaced during service to prevent leaks and future disassembly problems.

For a thorough cleaning, the heat exchanger core can be removed and ultrasonically cleaned to remove deposits from deep within the passages. We recommend a comprehensive intercooler service at 1000-hour intervals, though harsh conditions may require more frequent attention. Proper maintenance pays for itself in performance, fuel economy, and engine longevity. For more guidance, see The Ultimate Guide to Diesel Engine Repair Services.

Optimizing Performance: Intercooler Sizing and Upgrades

If you’re seeking more power, efficiency, or reliability from your marine or industrial diesel engine, upgrading your intercooler is a strategic move. A stock intercooler can become a bottleneck, especially after other engine modifications. A high-performance unit not only open ups hidden potential but also protects your engine investment.

Many operators in Fort Lauderdale and the Caribbean want to maximize their engine’s output. Upgrading the intercooler is a key step in achieving that goal.

How Intercooler Size Affects Performance

When it comes to intercoolers, size involves a trade-off. A larger core offers more surface area for heat exchange, resulting in cooler, denser intake air. This is crucial for handling the heat from high boost levels and resisting “heat soak” during sustained high-load operation.

However, an excessively large intercooler can be detrimental. It may cause a pressure drop, meaning less boost reaches the cylinders. It can also increase turbo lag, as there is more volume to fill with compressed air. The goal is to match the intercooler’s capacity to your engine’s output and performance goals, achieving maximum cooling with minimal airflow restriction. Our expertise in Diesel Engine Power Upgrades can help you find this balance.

When to Consider an Intercooler Upgrade

Upgrading your intercooler is a smart move in several scenarios:

-

After Engine Power Modifications: If you’ve upgraded your turbo, injectors, or tuned the engine for more power, the stock intercooler may not be sufficient. A performance unit ensures your cooling system can handle the increased heat load.

-

Replacing a Failing Unit: If your current intercooler is corroded, leaking, or inefficient, it’s the perfect time to upgrade. High-quality aftermarket units often use superior materials and designs that outperform and outlast OEM parts.

-

For Commercial and Industrial Use: Where reliability is paramount, an upgraded intercooler provides an extra margin of safety. Better cooling reduces thermal stress, minimizing the risk of costly downtime during critical operations.

-

To Maximize Efficiency: A more efficient intercooler provides denser air for more complete combustion, leading to better fuel economy and lower emissions. Over thousands of hours, these savings add up.

Aftermarket intercoolers from reputable brands are a sound investment for demanding applications. For more strategies, explore our Diesel Engine Optimization Guide.

Frequently Asked Questions about Marine Intercoolers

We get a lot of questions about intercoolers from our clients in Fort Lauderdale and throughout the Caribbean. Here are some of the most common ones.

Why is an intercooler so important for a marine turbo-diesel engine?

An intercooler is critical because it cools the hot air from the turbocharger. This creates a denser, oxygen-rich air charge that allows the engine to burn fuel more efficiently. The result is more power, better fuel economy, and reduced engine stress—all essential for reliable marine operation.

What are the main differences between maintaining a car intercooler and a marine intercooler?

Marine intercooler maintenance is far more demanding. While both require cleaning oil residue from the air side, marine units are typically seawater-cooled. This means you must also deal with the seawater side, which involves descaling mineral deposits and removing marine growth like barnacles and algae. The corrosive saltwater environment also necessitates regular inspection of specialized materials like Copper-Nickel tubes and bronze housings.

Can a faulty intercooler cause serious engine damage?

Yes, absolutely. A clogged intercooler can cause overheating and power loss, but a leaking one is far more dangerous. If the coolant side leaks, seawater can enter your engine’s cylinders. Since water doesn’t compress, this can hydro-lock the engine, leading to bent rods, a cracked cylinder head, or a destroyed block. This catastrophic failure is preventable with regular inspection and maintenance. If you’re concerned about your intercooler’s condition, contact us for expert intercooler service and parts to have our factory-trained technicians inspect it.

Conclusion

Your intercooler is an unsung hero, essential to your marine or industrial diesel engine’s power, efficiency, and reliability. For operators in the harsh environments of Southeast Florida and the Caribbean, a well-maintained intercooler is the difference between dependable performance and costly breakdowns. It turns hot, compressed air from the turbo into the dense, oxygen-rich charge your engine needs to perform at its best.

Neglecting this component means leaving power on the table and risking serious engine damage. At Diesel Services of America, our factory-trained technicians understand these systems inside and out. We provide the expert service, quality parts, and honest advice needed to keep your diesel engines running strong.

Don’t let a compromised intercooler hold your operation back. Whether you need routine maintenance, an overhaul, or an upgrade, we’re ready to help.

Contact us for expert intercooler service and parts

Ready to optimize your diesel performance? Visit our main site:

Diesel Services Of America

Explore our marine diesel engine services:

Marine Diesel Engine Services

Find our full range of services:

Our Services

Get in touch with our team today:

Contact Us