Why Marine Diesel Engines Need Specialized Care

Marine diesel engine repair is critical for vessel reliability and safety. For boat owners and fleet managers facing engine issues, here’s a quick overview of the essentials:

Marine Diesel Engine Repair Essentials:

– Daily Checks: Use the WOBBLES system (Water, Oil, Belts, Battery, Leaks, Exhaust, Sound, Spares)

– Service Intervals: Perform maintenance every 100 hours or seasonally

– Common Issues: Address fuel contamination, cooling system problems, and exhaust concerns promptly

– Professional Help: Call experts for complex issues like internal engine damage or electronic control failures

– Prevention: Regular maintenance prevents costly repairs and breakdowns at sea

The marine environment presents unique challenges for diesel engines. Unlike their land-based counterparts, marine diesel engines operate in harsh conditions with constant exposure to moisture, salt, and vibration. This demanding environment requires specialized knowledge and regular attention.

“An ounce of prevention is worth a pound of cure,” goes the old saying, and nowhere is this more true than with marine diesel engines. With proper maintenance, these workhorses can last over 3,000 hours – but neglect them, and you risk being stranded miles from shore.

Marine diesel engines differ significantly from automotive diesels, featuring specialized cooling systems that use seawater, robust fuel-water separators to combat moisture contamination, and components designed to withstand constant motion. These differences make specialized marine diesel knowledge essential for proper repair and maintenance.

Whether you’re managing a commercial fleet or enjoying weekend cruises, understanding the basics of marine diesel engine repair will save you time, money, and potential emergencies on the water. The most successful vessel operators follow strict maintenance schedules and know when to tackle repairs themselves versus calling in professionals.

Find more about marine diesel engine repair:

– diesel engine oil analysis

– diesel engine vibration analysis

– marine diesel mechanics

Understanding Your Marine Diesel Powerplant

There’s something special about the steady rumble of a marine diesel engine. Whether you’re captaining a commercial vessel or enjoying a weekend on your pleasure craft, that reliable powerplant beneath your feet is the heart of your maritime experience.

Marine diesel engines come in several configurations – inboards nestled deep in the hull, outboards hanging off the transom, auxiliary engines for additional propulsion, and generator sets (gensets) providing electrical power. Each is designed for specific vessel types and purposes.

What makes diesel the preferred choice for serious boaters? It’s all about robustness and that beautiful torque curve. Marine diesels deliver powerful low-end torque that gets your vessel moving efficiently, with remarkable fuel economy compared to gasoline engines. They’re built to last in the challenging marine environment, where reliability isn’t just convenient – it’s essential for safety.

Differences between outboard and inboard engines can affect maintenance requirements significantly, so knowing your specific setup is crucial before tackling any marine diesel engine repair.

Core Components & How They Differ From Automotive Diesels

When it comes to marine diesel engine repair, understanding the specialized nature of these engines is essential. Your boat’s diesel isn’t just an automotive engine dropped into a fiberglass hull – it’s a purpose-built machine.

Block Construction in marine engines features thicker walls and more robust designs to handle constant vibration and provide superior cooling. Many marine diesels employ wet liners that come in direct contact with coolant, improving heat transfer but requiring specialized maintenance approaches.

The cooling system is perhaps the most significant difference. While your car uses air and a closed coolant system, marine diesels typically employ a dual-circuit cooling system. There’s a closed freshwater circuit with antifreeze circulating through the engine, plus a raw water circuit drawing seawater to cool the freshwater through heat exchangers.

That salty, moisture-rich environment also necessitates sophisticated fuel-water separators – both primary and secondary filters with water-separating capabilities that would be overkill on land but are absolutely essential at sea.

Your engine’s raw-water pump with its replaceable impeller is another marine-specific component requiring regular inspection. And don’t forget the water-cooled exhaust systems with specialized risers and mixing elbows designed to prevent water backflow into the engine.

“Marine diesel engines are built like tanks,” says our lead technician at Diesel Services Of America, “but even tanks need proper maintenance to stay battle-ready.”

Service Life Expectations & Hour-Based Benchmarks

With proper care, a quality marine diesel should deliver over 3,000 hours of reliable service. We’ve seen well-maintained engines still running strong well beyond 3,200 hours. The secret? Following these hour-based service benchmarks:

Every 100 Hours or Seasonally: Change oil and filters to remove contaminants and ensure proper lubrication. This is your engine’s most basic need.

Every 200-250 Hours: Replace fuel filters to maintain clean fuel delivery and prevent injector damage.

Every 250-300 Hours: Check and possibly replace your raw water impeller, which can deteriorate from saltwater exposure.

Every 500 Hours: Inspect valve clearances and thoroughly check the cooling system for scale buildup or corrosion.

Every 1,000 Hours: Have fuel injector spray patterns checked for optimal combustion efficiency.

Every 2,000-3,000 Hours: Consider scheduling a major inspection or rebuild assessment to catch wear issues before they become catastrophic.

“The difference between a marine diesel that barely makes it to 1,500 hours versus one that cruises past 3,000 hours comes down to consistent maintenance at these intervals,” our service manager often reminds customers. “Skip these milestones at your peril.”

Want to learn more about extending your engine’s life? Our Marine Diesel Engine Overhaul service can help restore performance and reliability when those hour benchmarks indicate it’s time for major service.

Essential Tools, Spares & Safety Gear Afloat

Ask any seasoned boater what keeps them up at night, and they’ll likely mention engine troubles miles from shore. Being prepared with the right tools and spare parts isn’t just convenient—it’s essential for your safety on the water. Let’s look at what every vessel should have aboard for marine diesel engine repair.

Building a Boat-Ready Repair Toolkit

Your marine toolkit should be thoughtfully assembled, not just a collection of random wrenches tossed in a box. Start with a quality strap wrench, which will become your best friend during oil filter changes, allowing you to remove filters without crushing them. Pair this with a complete socket set that includes extensions for reaching those maddeningly inaccessible bolts hiding in your engine compartment.

An oil extractor pump is worth its weight in gold for clean, spill-free oil changes—especially important in the marine environment where oil spills are both environmentally harmful and dangerous. Keep a reliable multimeter on board for troubleshooting electrical gremlins that inevitably appear at the worst possible moments.

For fuel system maintenance, a vacuum pump will make bleeding air from fuel lines much less frustrating. Don’t forget wire brushes for cleaning corrosion from electrical connections—a common issue in salt environments. A properly calibrated torque wrench ensures you’re tightening critical components to manufacturer specifications, while a specialized fuel filter wrench prevents skinned knuckles when changing filters.

Rounding out your toolkit should be an impeller puller (those rubber impellers can be stubborn!), plus a good flashlight and inspection mirror for peering into the dark recesses of your engine room where problems like to hide.

Essential Spare Parts to Keep Onboard

“The part you don’t have is the part that will fail” seems to be the unwritten law of boating. Smart captains carry critical spares including primary and secondary fuel filters (the CAV 296 type is common on many marine diesels), along with engine-specific oil filters—at least one per engine.

V-belts for your alternator and water pumps are easy to store and can prevent a minor issue from becoming a major problem. An impeller kit complete with gaskets and seals should be considered mandatory—raw water pump impellers have a knack for failing at the worst possible time.

Don’t forget zinc anodes for your cooling system protection—these sacrificial metals prevent corrosion throughout your engine’s cooling passages. Fuel additives help treat and stabilize fuel during periods of disuse, while an assortment of hose clamps, fuses, and small sections of fuel line hose can save the day during emergency repairs.

“We recommend carrying at least 25% more fuel than your planned consumption and a complete set of filters and impellers for every 100 hours of expected operation,” advises our parts department manager at Diesel Services Of America.

Top Safety Precautions Before You Turn a Wrench

Safety isn’t just a buzzword when you’re miles offshore—it’s your lifeline. Before diving into any marine diesel engine repair, familiarize yourself with your engine’s emergency shutdown lever. Know exactly where it is and how it works before you need it.

Always identify all seacocks related to your engine system. In an emergency, knowing which valve stops water from entering can prevent a bad situation from becoming catastrophic. When working on electrical systems, disconnect battery power first—electricity and water make dangerous companions.

Proper PPE isn’t optional—your hands and eyes deserve protection with quality gloves and safety glasses. Keep an appropriate class fire extinguisher within arm’s reach, and ensure adequate ventilation when working in enclosed engine spaces. Marine diesel fumes can quickly overcome you in poorly ventilated areas.

Be mindful of hot surfaces after engine operation—severe burns can happen in an instant. When handling fuel, use absorbent pads to catch inevitable drips and spills. (A cut-off milk carton or even a baby diaper works surprisingly well in a pinch!)

Secure your tools to prevent them from becoming projectiles in rough seas or disappearing into the bilge, never to be seen again. Finally, keep your engine documentation accessible—even experienced mechanics refer to manuals when confronted with unfamiliar systems.

“Never rush repairs on a marine diesel,” emphasizes our safety coordinator. “Taking your time and following proper safety protocols prevents both personal injury and further damage to your engine.” When you’re miles from shore, patience truly is a virtue.

For more information about professional marine diesel engine repair and servicing, visit our Diesel Engine Services page.

Routine 100-Hour Maintenance Checklist

Regular maintenance is the cornerstone of reliable marine diesel operation. Following a consistent 100-hour or seasonal maintenance schedule will significantly extend your engine’s life and prevent costly breakdowns.

Step-by-Step Oil Service

Proper oil changes are fundamental to marine diesel engine repair and maintenance:

- Warm Up the Engine: Run the engine for 5-10 minutes to warm the oil for better drainage

- Shut Down and Prepare: Turn off the engine and place an oil catch container

- Remove the Old Filter: Use a strap wrench to remove the oil filter

- Drain the Oil: Remove the drain plug or use an oil extraction pump

- Replace the Filter: Apply a light coating of clean oil to the new filter gasket before installation

- Refill with Proper Oil: Use manufacturer-recommended oil grade and viscosity

- Check for Leaks: Run the engine briefly and check for leaks around the filter and drain plug

- Proper Disposal: Dispose of used oil and filters at appropriate recycling facilities

“Never skimp on oil quality to save money—it’s false economy that can lead to premature engine wear,” warns our lead technician.

Fuel System Service & Bleeding Sequence

Fuel system maintenance is critical for reliable operation:

- Drain Water Separator: Check and drain water from the fuel-water separator daily

- Replace Primary Filter: Change the primary fuel filter every 250 hours or annually

- Replace Secondary Filter: Change the secondary fuel filter at the same interval

- Inspect Fuel Lines: Check all fuel lines for cracks, chafing, or leaks

- Bleed the System: Remove air from the system following this sequence:

- Loosen bleed screws at the primary filter

- Operate the manual lift pump until fuel flows without bubbles

- Tighten the primary filter bleed screw

- Loosen the secondary filter bleed screw

- Pump until clear of bubbles, then tighten

- Loosen injector line fittings if needed

- Crank engine briefly to purge remaining air

“Air in the fuel system is one of the most common causes of starting problems and poor performance in marine diesels,” notes our fuel system specialist at Diesel Services Of America.

Cooling Circuit Care

The cooling system requires special attention in the marine environment:

- Raw Water Strainer: Clean the seawater strainer before each engine start

- Impeller Inspection: Check the raw water pump impeller every 250 hours or seasonally

- Impeller Replacement: Replace the impeller if cracks, missing vanes, or excessive wear are visible

- Heat Exchanger Anodes: Replace zinc anodes annually or when more than 50% consumed

- Antifreeze Testing: Use a refractometer to check coolant strength and corrosion inhibitor levels

- Cooling Passages: Clean cooling passages every 500 hours or two years

- Belt Tension: Check and adjust water pump belt tension

“In warm, very salty waters like those around Florida and the Caribbean, check zinc anodes every six months instead of annually,” recommends our cooling system expert.

Troubleshooting & DIY Marine Diesel Engine Repair

Let’s face it—even with the most diligent maintenance schedule, things can still go wrong when you’re out on the water. The good news? You can solve many common problems yourself if you know what to look for.

Interpreting Smoke & Leaks in Marine Diesel Engine Repair

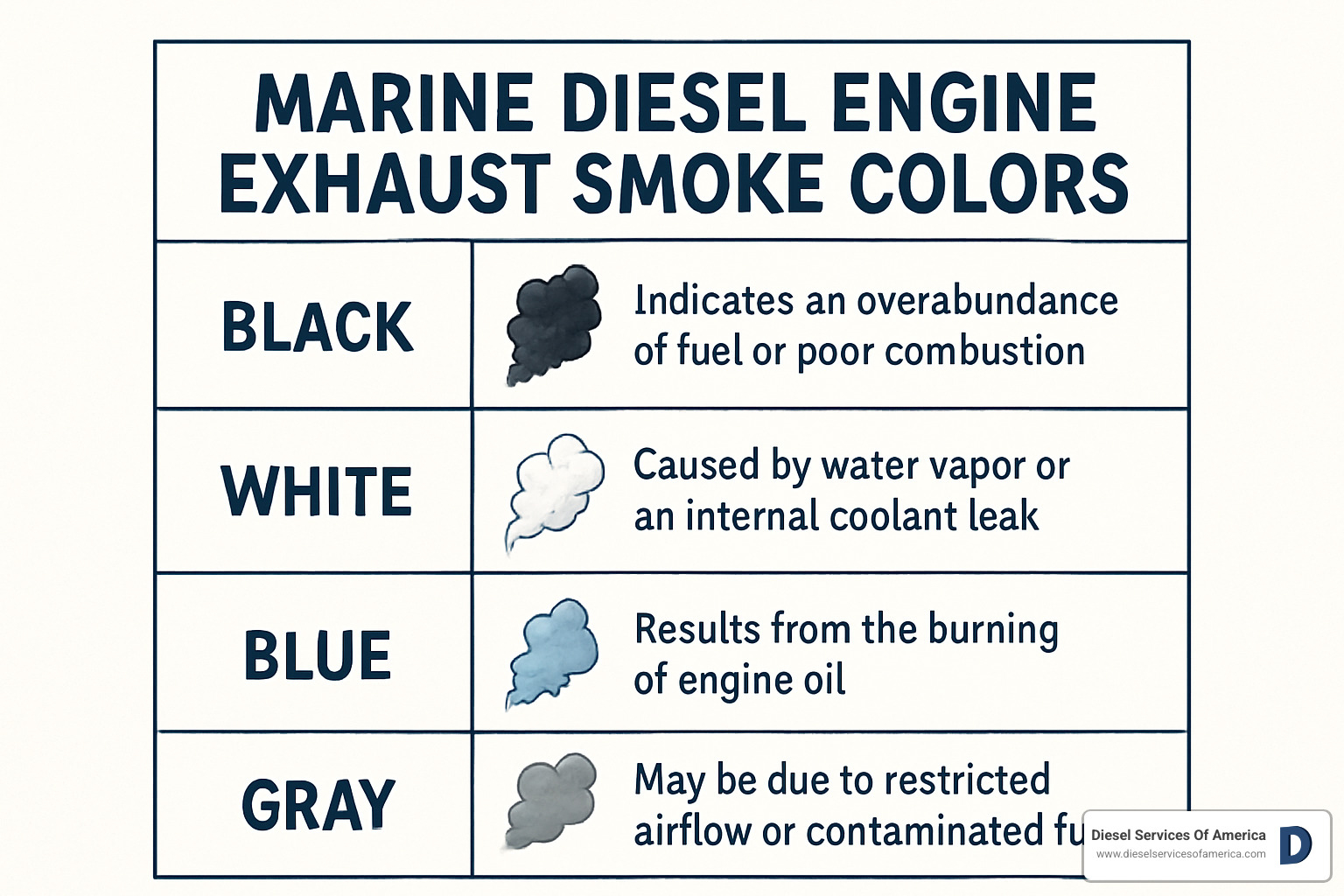

Your engine is actually quite chatty—it communicates through smoke signals! Each exhaust color tells a different story:

Black smoke is essentially your engine saying, “I can’t breathe!” This happens when there’s incomplete combustion, usually because you’re overloading the engine, have a clogged air filter, or your injectors need attention. Think of it as your engine gasping for air while trying to burn too much fuel.

White smoke is the maritime equivalent of seeing your breath on a cold day—water vapor where it shouldn’t be. This usually points to water entering the combustion chamber through a failing head gasket, cracked cylinder head, or seriously mistimed fuel injection. Never ignore white smoke; it’s often a red alert.

Blue smoke means you’re burning oil along with your diesel. Like an aging athlete with worn joints, your engine’s piston rings, valve guides, or seals are probably worn out and letting oil seep into places it shouldn’t go.

Gray smoke typically suggests your fuel timing is off or you’ve picked up some questionable diesel at your last refueling stop. It’s like trying to dance with a partner who can’t keep the beat.

As for leaks, they’re like breadcrumbs leading you to the problem:

Fuel leaks leave yellowish-brown trails and smell distinctly like diesel. They’re often found around filters, injector lines, or the lift pump.

Oil leaks appear as dark brown or black stains with a thicker consistency. They typically originate from gaskets, seals, or the oil filter.

Coolant leaks show up green, pink, or orange (depending on your coolant type) and often have a sweet, syrupy smell that’s unmistakable once you’ve encountered it.

Seawater leaks start clear but leave crusty white salt deposits as they dry, making them easier to spot after the engine cools down.

“When you call us about a leak,” says our diagnostic specialist at Diesel Services of America, “take a quick photo and note its color, location, and when it appears—at startup, under load, or after shutdown. This information is pure gold for speeding up your marine diesel engine repair.”

Bleeding Fuel Lines for Successful Marine Diesel Engine Repair

Air in your fuel system is like vapor lock in your wallet—nothing’s going to flow until you clear it out. If your engine suddenly dies or refuses to start after refueling or changing filters, here’s how to get things moving again:

First, gather clean towels—this will get messy. Locate all the bleed screws on your filters and injection pump. Start at the primary filter by loosening its bleed screw, then pump the manual primer (if equipped) until a steady, bubble-free stream of fuel flows out. Close that screw firmly but not aggressively—you’re not trying to snap it off!

Move to the secondary filter and repeat the process. If your engine has an injection pump with a bleed point, that’s your next stop. For stubborn cases, you might need to crack open the injector lines one at a time while someone cranks the engine (but this is truly a last resort).

“The biggest mistake I see boaters make,” shares our fuel system technician, “is rushing the bleeding process. You need the patience of a fisherman here—complete each step fully before moving to the next, or you’ll just push air bubbles further into the system.”

Quick-Fixes vs Permanent Repairs

Sometimes you need a Band-Aid solution to get back to shore safely, but remember—these are temporary fixes only!

When a raw water impeller shreds, you might limp home on reduced cooling, but make retrieving those broken pieces your top priority once you’re safe. Those rubber fragments can migrate to your heat exchanger and cause major blockages and overheating issues later.

A broken drive belt in remote waters? In a true emergency, you can fashion a makeshift belt from strong cordage like dock line—it won’t last long but might get you to safety.

For hose leaks, self-amalgamating tape (which bonds to itself when stretched) or marine-grade epoxy putty can provide a temporary seal. Always carry fuel-grade hose and proper clamps for emergency fuel line repairs—regular automotive hose will deteriorate quickly in a marine environment.

“I always tell our customers that quick fixes are like using duct tape on your boat shoes,” says our service manager. “It’ll get you through the day, but you’ll definitely want proper repairs before your next voyage. Your safety—and your engine’s longevity—depend on it.”

While DIY troubleshooting is valuable, some issues demand professional attention. When metal appears in your oil, temperatures climb beyond 210°F, or you’re dealing with high-pressure system failures, it’s time to call the experts at Diesel Services of America for proper marine diesel engine repair.

Seasonal Care: Fuel Hygiene, Winterizing & Lay-Up

When the boating season winds down or your vessel needs extended storage, proper seasonal care becomes your marine diesel’s best friend. Think of it as tucking your engine in for a good night’s sleep – the better you prepare it, the more refreshed it’ll be when waking up.

Storing Your Engine for Off-Season

Ever notice how quickly problems seem to develop when boats sit idle? That’s no coincidence. Proper storage procedures create a protective cocoon around your diesel during those quiet months.

Start with a fresh oil change before storage – this simple step prevents acidic compounds from silently eating away at your engine’s internals. Think of old oil like food left too long in the refrigerator; it might look fine but it’s definitely not doing any favors.

For your fuel system, fill the tank to about 95% capacity. This might seem counterintuitive, but it actually leaves just enough room for expansion while minimizing the air space where condensation forms. Add a quality fuel stabilizer and biocide – they’re like preservatives that keep diesel fuel from deteriorating and prevent the dreaded “diesel bug” from taking up residence.

“We see it every spring – boats that skipped proper winterizing coming in with mysterious performance issues,” says our fuel specialist. “Marine diesel engine repair costs from fuel contamination alone can run into thousands, all preventable with about $20 worth of additives.”

Your cooling system needs equal attention. Ensure you’ve got the right antifreeze concentration (typically 50/50) to prevent freezing and corrosion. For raw water systems, complete drainage is essential – trapped water can freeze and crack expensive components. In saltwater environments, a freshwater flush before storage prevents corrosive salt crystals from forming.

Battery care is simple but crucial: fully charge, clean terminals, and either disconnect or connect to a quality maintainer. For moisture control, a few desiccant packs in the engine compartment work wonders, while proper ventilation prevents the condensation cycle that leads to corrosion.

Recommissioning in Spring

When springtime arrives and boating beckons, resist the urge to simply turn the key and go. A methodical recommissioning process pays dividends in reliability.

Begin with a careful visual inspection – you’re looking for signs of unwelcome winter guests (rodents love to nest in warm engine spaces), any mysterious leaks, or corrosion that developed during storage. Check all belts closely for cracks, glazing, or stretching – rubber components often reveal problems first.

“The first start of the season should be treated like a first date,” jokes our service manager at Diesel Services Of America. “Take it slow, pay attention to the signals, and don’t rush things.”

Top off all fluids and give special attention to your fuel system. Drain any water from separators (water always finds its way in, regardless of your precautions) and check for the telltale slime that indicates microbial growth. If your filters look suspicious, replace them before that first start – it’s cheap insurance.

Battery service is straightforward but essential: clean terminals, test voltage and capacity, and recharge if necessary. Your raw water system deserves special scrutiny – check that impeller before it leaves you stranded, ensure seacocks operate freely, and clean all strainers.

For the first start, be prepared to bleed the fuel system if necessary. Run at idle while checking for leaks, monitor all gauges carefully, and listen for unusual noises. Your ears are sophisticated diagnostic tools – trust them when they tell you something doesn’t sound right.

Finally, conduct a short sea trial before planning extended voyages. Better to find any issues while you’re near help than when you’re miles offshore.

Proper seasonal care might seem tedious, but it’s far less painful than unexpected marine diesel engine repair when you should be enjoying time on the water. As our technicians often remind customers, “The hour you spend on proper storage saves ten hours of troubleshooting later.”

For more detailed guidance on seasonal care, check out our Marine Diesel Maintenance Tips Part 4 and learn about The Effects of Diesel Fuel Contamination from our trusted industry partners.

When to Call a Pro & Training Paths

While DIY maintenance is valuable, knowing when to call in professional help is equally important for effective marine diesel engine repair.

DIY Limits & Emergency Scenarios

Consider professional assistance in these situations:

- Overheating Beyond 210°F: Persistent overheating may indicate serious cooling system issues

- Metal in Oil: Metallic particles in oil suggest internal engine damage

- High-Pressure Injector Faults: Modern common-rail injection systems operate at extremely high pressures and require specialized tools

- Electronic Control Issues: Diagnostic software and expertise are needed for electronic engine management problems

- Major Fluid Leaks: Significant oil or coolant leaks often require specialized equipment to address

- Abnormal Vibrations: Could indicate serious internal issues or alignment problems

- Excessive Smoke: Persistent smoke despite basic troubleshooting

- Loss of Compression: Indicates valve or piston ring issues

- Major Overhauls: Rebuilds and major repairs typically require professional facilities

- When Repair Costs Exceed Replacement: Sometimes replacement is more economical than repair

“We recommend establishing a ‘labor-hour threshold’ before starting complex repairs. If you exceed this threshold, it may be more cost-effective to call in professionals,” advises our lead technician.

Becoming a Certified Marine Diesel Mechanic

For those interested in pursuing marine diesel mechanics professionally:

- Education Options:

- Technical schools offering specialized marine programs

- Universal Technical Institute (UTI) and similar programs

- Community college courses in diesel technology

-

Manufacturer-specific training programs

-

Apprenticeship Paths:

- Work with established marine diesel mechanics

- Seek entry-level positions at marinas and boatyards

-

Volunteer with boat maintenance teams

-

Certifications:

- American Boat and Yacht Council (ABYC) certification

- Manufacturer-specific certifications (MAN, Caterpillar, Cummins, etc.)

-

Association of Diesel Specialists certification

-

Career Outlook:

- Median annual salary for marine diesel mechanics was $49,990 in May 2023

- Growing demand for skilled technicians

- Opportunities in recreational, commercial, and military sectors

“Continuous education is essential in this field. Engine technology evolves rapidly, and staying current with training is crucial for success,” notes our human resources director at Diesel Services Of America.

Frequently Asked Questions about Marine Diesel Engine Repair

How often should a marine diesel engine be serviced?

The golden rule for marine diesel engine repair is consistency. Your engine needs attention every 100 hours of operation or once per season—whichever happens first. Think of this basic service as your engine’s regular health check-up.

During these routine check-ups, we typically handle the essentials: fresh oil and new filters, a thorough inspection of your fuel filters (replacing as needed), checking those critical belt tensions, cleaning out your raw water strainer, and a careful once-over for any leaks or developing issues.

As your engine accumulates more hours, it deserves more comprehensive care. At the 250-hour mark, we dig a little deeper. When you hit 500 hours, the service becomes more extensive, and the 1,000-hour service is truly thorough. Your engine’s service manual outlines the specific requirements for each of these milestones.

“I’ve seen engines last twice as long when owners stick to their maintenance schedule,” our service coordinator often tells customers. “Regular maintenance might feel expensive in the moment, but it’s just pocket change compared to the repairs that come from neglect. A well-loved marine diesel can faithfully serve you for decades.”

What causes most breakdowns at sea?

After years of emergency calls at Diesel Services Of America, we’ve identified clear patterns in what strands boaters. The top culprits are:

Fuel system issues lead the pack, accounting for about half of our emergency calls. This includes contaminated fuel, clogged filters, or air bubbles working their way into the fuel system—all preventable with proper maintenance.

Cooling system failures come next, with impeller breakdowns, blocked raw water intakes from debris or marine growth, and heat exchangers corroded by saltwater.

Electrical problems frequently disable vessels, particularly battery failures, alternator issues, and wiring corroded by the harsh marine environment.

Belt failures can cascade into major problems, as they drive critical components like water pumps and alternators.

Operator oversight rounds out the top five—simply running out of fuel, forgetting to check oil levels, or ignoring those early warning signs that something’s not quite right.

Our emergency team has an interesting observation: “Many breakdowns happen within the first hour after a long period of inactivity. It’s almost as if the engine is protesting being awakened from hibernation without proper preparation. This really highlights why thorough recommissioning procedures matter.”

Which spare parts are absolutely essential to carry onboard?

When you’re miles from the nearest marina, your spare parts kit becomes your lifeline. For vessels venturing beyond easy reach of service facilities, we recommend a carefully curated collection of essentials:

Fuel and oil filters top our must-have list—pack a complete set of primary and secondary fuel filters and at least one oil filter per engine. These simple items prevent the most common breakdown causes.

Raw water impellers deserve special attention—carry one per engine plus additional spares for extended journeys. When these fail, overheating quickly follows.

Belts for all your engine’s components should be on board, properly sized and ready for emergency replacement.

Your emergency kit should also include zinc anodes to protect cooling systems, some basic gasket material for emergency repairs, fuses and relays specific to your electrical system, short sections of fuel line hose, various hose clamps, and enough engine oil for at least one complete change.

“The true value of carrying these spares becomes crystal clear when you’re offshore with a problem that a $20 part could fix,” says our parts manager with a knowing smile. “That’s when boaters really understand why we emphasize preparedness. The peace of mind alone is worth the investment.”

Conclusion

There’s something deeply satisfying about understanding and caring for your marine diesel engine. It’s not just about avoiding breakdowns—it’s about developing a relationship with the powerplant that carries you and your loved ones safely across the water.

Throughout this guide, we’ve explored the specialized knowledge, tools, and preventive mindset needed to keep your marine diesel running smoothly. From those essential WOBBLES daily checks to seasonal maintenance routines, you now have a solid foundation for extending your engine’s life far beyond the average.

Marine diesel engine repair isn’t just a technical challenge—it’s an investment in your vessel’s reliability and your peace of mind while on the water. Whether you’re checking zinc anodes, changing filters, or troubleshooting that mysterious noise, each maintenance task contributes to the thousands of trouble-free hours your engine can deliver.

The most successful approach combines your own informed DIY maintenance with professional service at strategic intervals. Think of it as a partnership—you handle the routine care, and the experts step in for the specialized work that requires advanced training and equipment.

At Diesel Services Of America, we understand that your marine diesel engine isn’t just a piece of machinery—it’s the beating heart of your vessel and your trips. Our factory-trained technicians specialize in marine diesel engine repair with the expertise that comes from years of hands-on experience in South Florida’s demanding marine environment.

We’re proud to offer comprehensive services that evolve with your needs:

- Dockside service throughout South Florida and the Caribbean

- Worldwide parts delivery for vessels in remote locations

- Complete engine rebuilds when your trusty powerplant needs renewal

- Emergency repairs when the unexpected happens

- Customized maintenance programs for your specific vessel and usage pattern

The sea doesn’t forgive poor preparation, but it richly rewards those who respect its power and plan accordingly. By combining your newfound knowledge with professional support when needed, you’re setting yourself up for years of reliable cruising.

For more information about our marine diesel services in Fort Lauderdale and beyond, contact us today to schedule your next service or consultation. Whether you’re planning routine maintenance or facing a challenging repair, our team is ready to help ensure your maritime journey continues without interruption.

After all, the best boating stories are rarely about engine troubles—they’re about the amazing places your well-maintained diesel takes you.