Why Marine Diesel Generator Repair Is Critical for Your Vessel

Marine diesel generator repair is essential for maintaining reliable power systems that keep your vessel safe and operational on the water. When your generator fails, it affects everything from navigation equipment to climate control, potentially turning a pleasant day on the water into a dangerous situation.

Essential Marine Diesel Generator Repair Services:

- Fuel System Repair – Cleaning clogged filters, replacing contaminated fuel, fixing injector issues

- Cooling System Service – Replacing worn impellers, clearing blocked intakes, repairing heat exchangers

- Electrical Component Repair – Battery replacement, fixing corroded connections, voltage regulator service

- Engine Component Overhaul – Piston rings, cylinder liners, valves, and valve seats

- Preventive Maintenance – Regular inspections, fluid changes, system testing

Your marine generator powers critical systems including navigation instruments, lighting, refrigeration, and communication devices. As one marine service expert notes, “When a generator malfunctions, it can be a serious nuisance for both you and those around you” – affecting not just comfort but safety at sea.

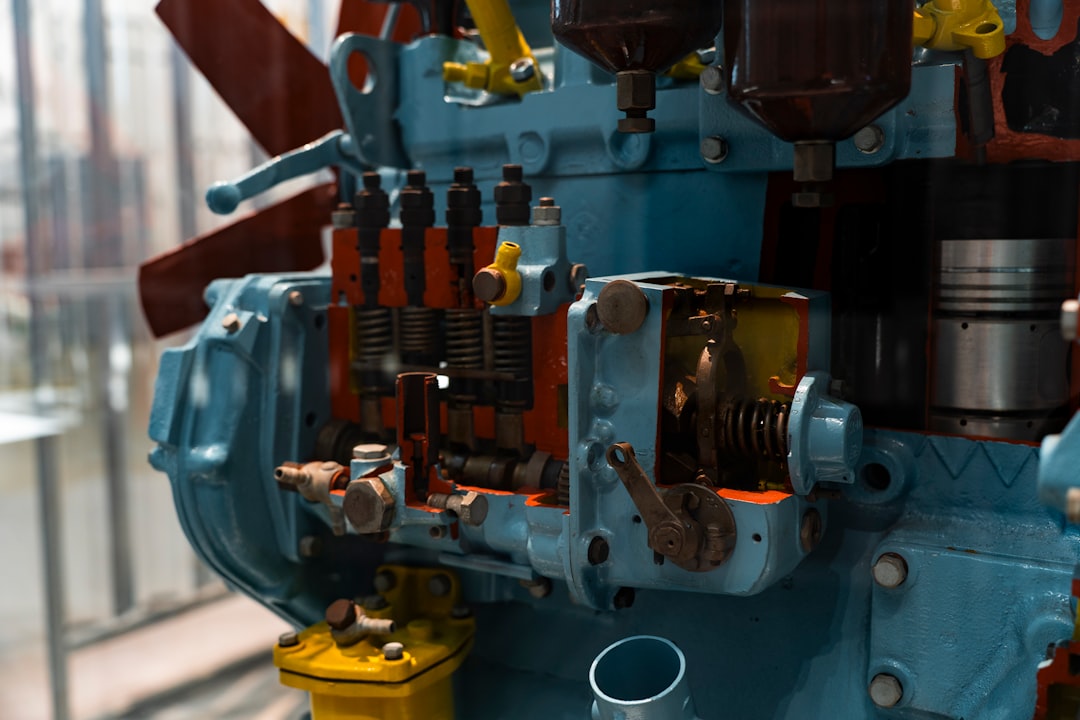

Marine generators face unique challenges that land-based units don’t encounter. Saltwater corrosion, constant vibration, and moisture exposure accelerate wear on components. The demanding marine environment means these generators require specialized knowledge and marine-specific parts for proper repair.

Professional repair becomes crucial because calling a general handyman or automotive technician can be expensive and unreliable. Marine diesel generators need technicians who understand the specific requirements of marine applications and have access to proper diagnostic equipment.

With proper maintenance, a marine generator can last up to 15 years. However, neglecting regular maintenance can turn minor issues into costly repairs that leave you stranded without power when you need it most.

Handy marine diesel generator repair terms:

Spotting Trouble: Common Issues and Key Components Prone to Failure

Your marine diesel generator works hard in one of the harshest environments imaginable. Between saltwater spray, constant vibration, and high humidity, it’s remarkable these workhorses keep running at all! But like any hardworking crew member, your generator will eventually start showing signs that it needs attention.

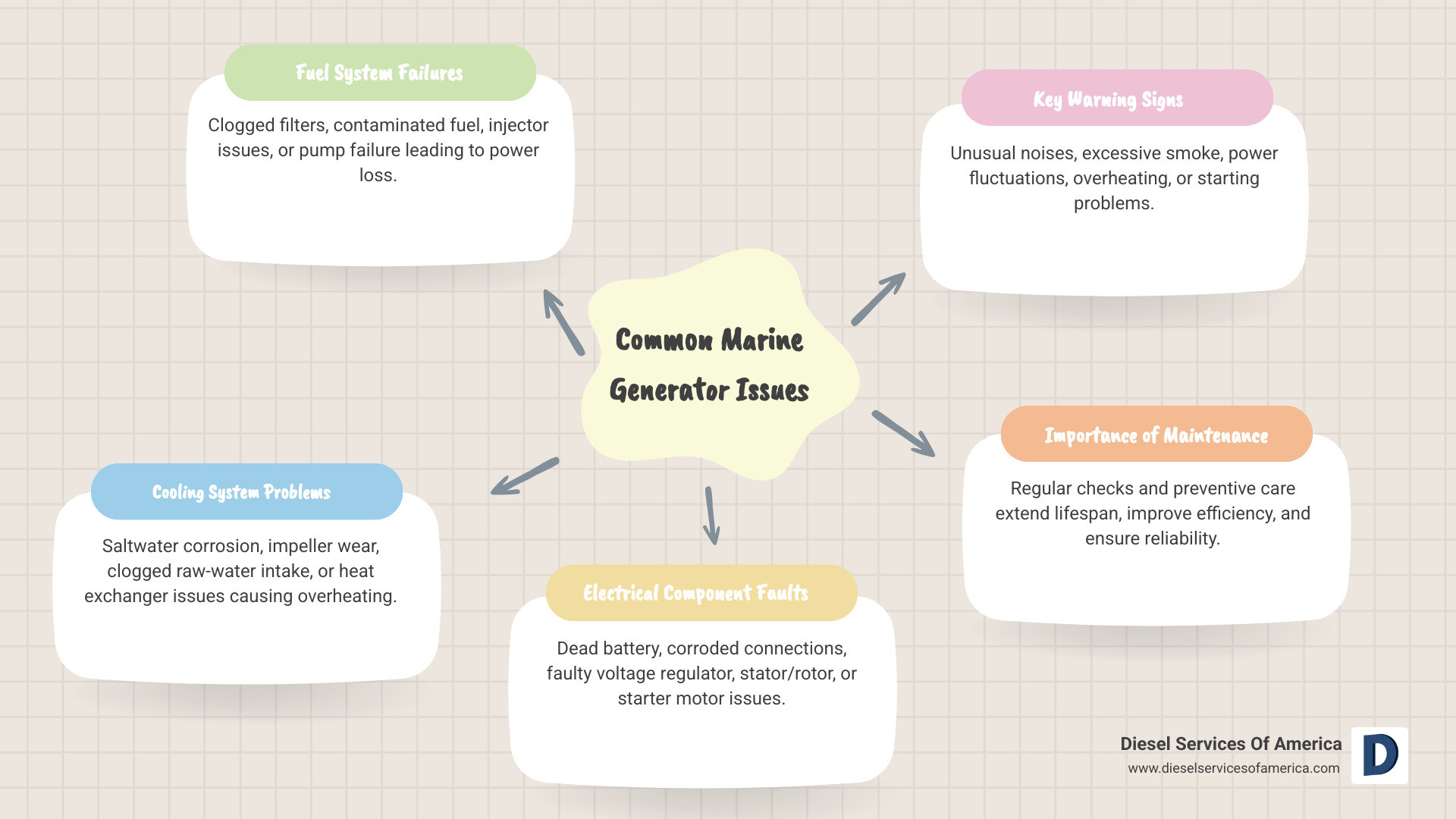

The key is learning to recognize these warning signs before they turn into major headaches. Unusual noises like grinding, knocking, or excessive vibration often signal internal wear. Excessive smoke – especially black or blue clouds – indicates fuel or oil problems. Power fluctuations that cause lights to dim or electronics to act up suggest electrical issues. Overheating and starting problems round out the most common red flags.

The marine environment accelerates wear on specific components, making them particularly vulnerable to failure. Understanding which parts are most at risk helps you stay ahead of problems and avoid those dreaded breakdowns when you’re miles from shore. For quality replacement components, check out our Marine Diesel Generator Parts selection.

Fuel System Failures

Think of your fuel system as your generator’s digestive tract – when it’s not working properly, nothing else functions well either. Clogged filters top our list of common culprits. Marine fuel can pick up water, algae, and debris during storage, quickly blocking filters and starving your engine of clean fuel.

Contaminated fuel causes a cascade of problems. You might notice rough idling, inconsistent RPMs, or difficulty starting. Sometimes the generator fires up fine but then sputters and dies under load. This frustrating behavior often points to fuel quality issues.

Injector problems create their own set of headaches. When injectors become fouled or fail completely, fuel doesn’t burn efficiently. You’ll see black smoke, reduced power output, and poor fuel economy. Fuel pump failure, while less common, can leave you completely dead in the water – literally.

These fuel system issues don’t just affect comfort systems like air conditioning. When your marine diesel generator repair involves fuel problems, it can impact critical navigation and safety equipment too.

Cooling System Problems

Overheating will destroy a marine diesel generator faster than almost anything else. Unfortunately, the marine environment seems designed to attack cooling systems at every turn.

Saltwater corrosion relentlessly attacks cooling system components. Hoses, heat exchangers, and raw-water pumps all suffer from this constant assault. Even small pinhole leaks can quickly escalate into major cooling failures.

Impeller wear catches many boat owners off guard. These rubber components look sturdy, but they gradually lose their flexibility and pumping efficiency. A worn impeller might still move some water, but not enough to keep your generator cool under load.

Clogged raw-water intakes from marine growth, plastic bags, or debris will starve your cooling system entirely. Your generator might start and run briefly, then shut down on high temperature alarms. Heat exchanger issues, where internal passages become blocked with scale or corrosion, create similar overheating problems.

When cooling problems strike, quick action prevents catastrophic engine damage. Our team specializes in Diesel Engine Water Pump Repair and can get your cooling system back to peak performance.

Electrical Component Malfunctions

Nothing’s more frustrating than a generator that runs perfectly but produces zero electricity. Or worse – one that won’t even start when you need power most.

Dead batteries and corroded connections top the electrical failure list. Marine environments are particularly harsh on electrical components, with salt air attacking terminals and connections. Even a small amount of corrosion can prevent your generator from starting.

Faulty voltage regulators create erratic power output that can damage sensitive electronics. Your lights might flicker, or you might notice inconsistent charging of your house batteries. Stator or rotor failure can prevent power generation entirely – the engine runs fine, but you get no electrical output.

Starter motor issues leave you unable to even crank the engine. You might hear clicking sounds, or complete silence when you hit the start button. Sometimes the starter engages but lacks the power to turn over the engine.

These electrical problems range from minor annoyances to complete system failures. The challenge is proper diagnosis – what looks like a simple battery problem might actually indicate deeper electrical issues requiring professional marine diesel generator repair.

The Professional Marine Diesel Generator Repair Process: What to Expect

When your marine diesel generator shows signs of trouble, bringing it to certified mechanics is paramount. You don’t want a technician who uses refurbished parts, reuses worn equipment, or rushes through a job just to “get something working” again. Professional expertise ensures optimal performance and less frequent subsequent repairs. We emphasize that professional service is not just a fix, but an investment in your vessel’s reliability and your peace of mind. Our comprehensive Diesel Engine Repair Services cover everything from minor adjustments to major overhauls.

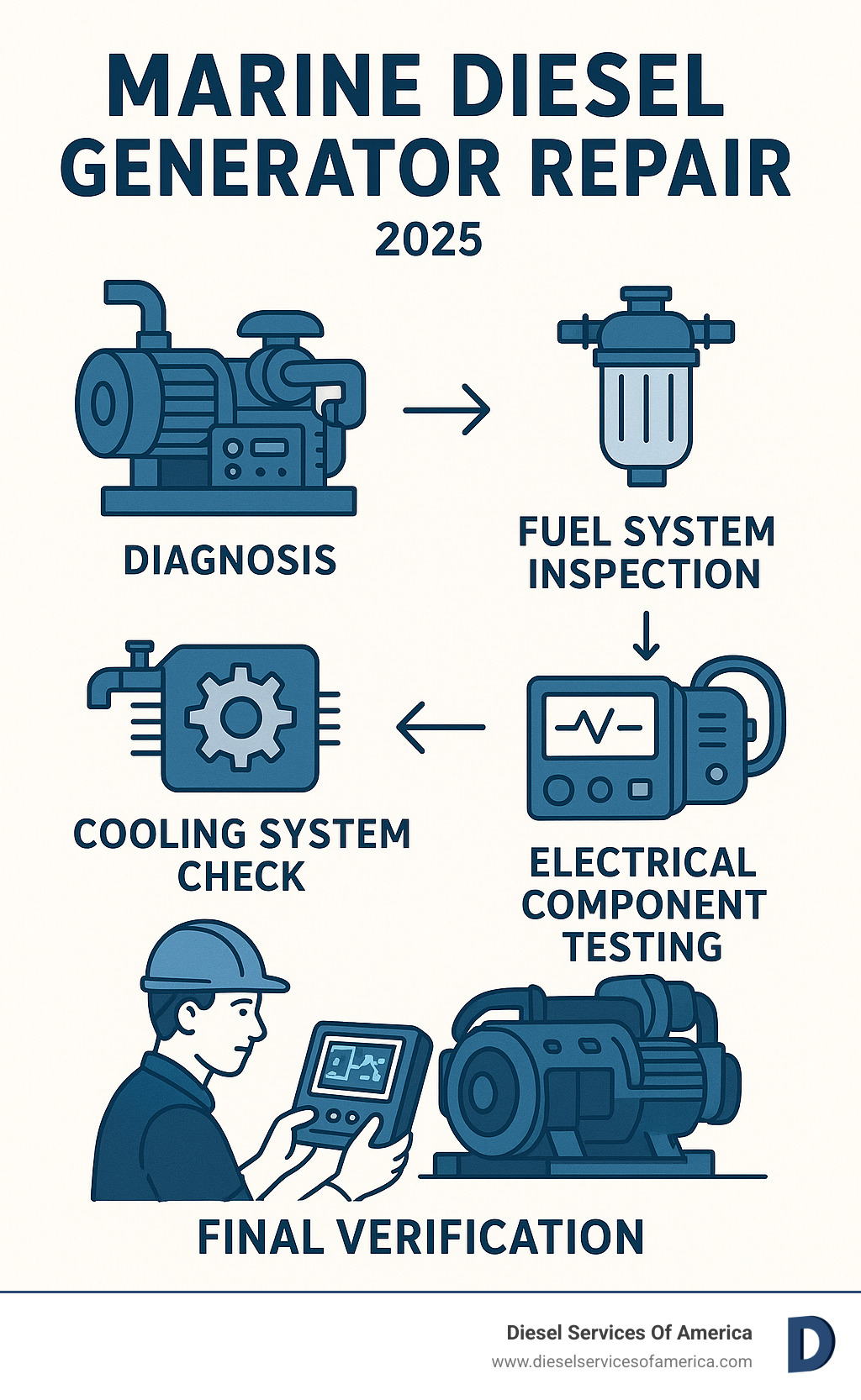

Step 1: Comprehensive Diagnosis

The foundation of any successful marine diesel generator repair is a thorough and accurate diagnosis. When you bring your generator to us, we begin with a visual inspection, looking for obvious signs of wear, leaks, or damage. But we don’t stop there. Our factory-trained technicians use advanced diagnostic equipment to perform comprehensive system testing. This includes fault code analysis, which helps us pinpoint specific electronic issues, and often, load bank testing. Load bank testing simulates real-world operating conditions, allowing us to assess your generator’s performance under various loads and identify weaknesses that might not appear during a simple idle test.

Understanding the nuances of diesel engine diagnostics, including interpreting vibrations and sounds, is key to our process. We leverage our expertise, similar to the insights shared in Vibration Nation: Understanding Diesel Engine Diagnostics, to ensure no stone is left unturned. This meticulous approach ensures we identify the root cause of the problem, rather than just treating the symptoms.

Step 2: DIY vs. Professional Marine Diesel Generator Repair

While the idea of a quick DIY fix might be tempting, especially when you’re eager to get back on the water, the complexities of marine diesel generators often make professional intervention the wiser choice. Here’s why:

| Feature/Aspect | DIY Risks The following diagram illustrates the key components of a marine diesel generator and their interactions within the system:

The Power of Prevention: Essential Maintenance for Longevity

The harsh marine environment doesn’t have to be the enemy of your generator’s longevity. With consistent and proactive maintenance, you can significantly extend your unit’s lifespan, improve fuel efficiency, reduce emissions, and ensure rock-solid reliability when you need it most. Think of regular maintenance as giving your generator the care it deserves – a little attention now saves major headaches later!

Regular maintenance is your ticket to spending more time enjoying the water and less time dealing with breakdowns in port. Our Generator Maintenance services are specifically designed to keep your marine unit running at peak performance, season after season.

Your Regular Maintenance Checklist

Effective marine diesel generator repair starts with prevention, not reaction. Rather than waiting for problems to surface, smart boat owners follow a systematic approach to generator care that addresses the most critical components.

Oil and coolant levels deserve your attention before every outing. Just like your main engines, your generator’s diesel engine depends on proper lubrication and cooling to function reliably. Check these levels regularly and top off as needed – it’s a simple step that prevents expensive damage.

Belt and hose inspection should become second nature during your routine checks. Look for cracking, fraying, or looseness in belts, and watch for bulges or leaks in hoses. These components work hard in the marine environment, and catching wear early saves you from unexpected failures.

Your sea strainer cleaning routine directly impacts cooling system performance. Marine growth and debris love to collect in raw water intake strainers, restricting the cooling water flow your generator needs. Regular cleaning prevents the overheating issues that can sideline your vessel.

Filter replacement – both fuel and oil – ranks among the most critical maintenance tasks. Clogged filters are a leading cause of generator problems, so following your manufacturer’s recommended intervals isn’t just suggested, it’s essential for fuel system health and overall reliability.

Battery testing and connection maintenance ensures your generator starts when you need it. A fully charged battery with clean, tight connections eliminates one of the most common starting problems we see in marine applications.

Leak detection during regular inspections catches small problems before they become major issues. Check around your generator and surrounding areas for any signs of fuel, oil, or coolant leaks. Early detection can prevent minor drips from turning into environmental hazards or costly repairs.

For more detailed guidance custom to marine diesel applications, our Top 5 Marine Diesel Maintenance Tips provides additional insights from our factory-trained technicians.

Preparing for Long Trips or Storage

Pre-trip preparation can make the difference between a memorable voyage and a disappointing breakdown. We recommend visiting your boat at least one week before departure to review your generator’s operator manual and perform all necessary services. This includes replacing filters, checking zincs, inspecting belts, and ensuring your battery is fully charged.

During your pre-trip inspection, tighten all hose clamps and fittings, check fluid levels, and start the generator to listen for unusual noises or spot potential leaks. Most importantly, run your generator under load for at least 30 minutes with all expected electrical loads operating. This real-world test ensures your unit can handle the demands of your upcoming trip.

Extended storage and winterization require specific procedures to protect your investment. An oil change before storage removes contaminants that could cause problems during the off-season. Check and adjust coolant levels for appropriate temperature protection in your climate.

Fuel stabilization becomes critical during storage periods, preventing diesel bug growth and fuel degradation that can clog your fuel system. Remove the raw water impeller and drain the sea water side of your heat exchanger and muffler to prevent freeze damage and corrosion – two expensive problems that proper winterization prevents.

When returning your generator to service after storage, replace fuel filters and inspect all electrical connections before starting. These simple steps help ensure a smooth transition back to active service.

Always consult your specific generator’s operator manual for precise instructions, or check our guide on Preparing Your Marine Diesel Vessel for Spring for comprehensive seasonal preparation tips.

Frequently Asked Questions about Marine Generator Care

We love chatting with boat owners about their generators! After years of working on marine diesel systems here in Fort Lauderdale, we’ve heard just about every question imaginable. Let’s tackle the big ones that come up time and again.

How long do marine generators last?

This is probably the question we hear most often, and honestly, it’s a bit like asking “how long is a piece of rope?” The answer really depends on how well you treat your generator.

With proper care and regular maintenance, most marine generators will serve you faithfully for 10 to 20 years. We’ve seen some well-maintained units push even beyond that! The secret ingredient? Consistent preventive maintenance performed by qualified technicians who understand marine applications.

Think of your generator like a good friend – treat it well, and it’ll be there when you need it most. Usage hours play a huge role in determining lifespan. A generator that runs constantly will naturally wear faster than one used occasionally for weekend trips. But here’s the twist – generators that sit unused for months can actually develop more problems than those used regularly!

The marine environment is tough on equipment. Salt air, moisture, and constant vibration all take their toll. That’s why quality service from experienced marine technicians makes such a difference in extending your generator’s life.

What is the single most common problem with marine generators?

After decades in this business, we can tell you without hesitation: neglected maintenance is the generator killer. It’s not glamorous, but it’s the truth.

Most of the marine diesel generator repair calls we get could have been prevented with regular upkeep. We see it all the time – a generator that worked perfectly last season suddenly won’t start, or it’s smoking like a barbecue pit. Nine times out of ten, it comes down to skipped maintenance.

Fuel system contamination is particularly nasty in marine applications. When fuel sits untreated for months, it can develop what we call “diesel bug” – a slimy mess that clogs everything. Saltwater corrosion is another relentless enemy, attacking cooling systems and electrical connections with surprising speed.

Here’s a fun fact: impeller failure is incredibly common, yet completely preventable. These little rubber components are like the heart of your cooling system, but they’re often forgotten until they fail. A simple inspection during routine maintenance can save you from an expensive overheating situation.

Is it worth repairing an older marine generator?

This question usually comes up when someone’s facing a hefty repair estimate on their trusty old generator. We get it – nobody wants to throw good money after bad.

The cost-benefit analysis is key here. As a general rule, if the repair costs less than half the price of a replacement generator, it’s often worth fixing. But that’s just the starting point of our conversation.

Availability of parts is crucial, especially for older units. Some vintage generators are like classic cars – finding original parts becomes a treasure hunt. We always check part availability before recommending major repairs.

The overall condition of your vessel matters too. If you’re planning to upgrade your boat soon, a temporary fix might make more sense than a full overhaul. On the flip side, if your generator’s engine block is sound and you love your current setup, a professional assessment can often reveal that a well-executed repair will give you many more years of reliable service.

We believe in honest recommendations. Our factory-trained technicians will give you the straight story about whether your generator is worth saving or if it’s time to start shopping for a replacement. Sometimes the most expensive option is doing nothing at all!

Conclusion

Your marine diesel generator is more than just a piece of equipment – it’s your lifeline to comfort, safety, and peace of mind on the water. When you understand the warning signs of trouble and know how to spot potential problems before they become major headaches, you’re already ahead of the game.

Professional marine diesel generator repair isn’t just about fixing what’s broken; it’s about ensuring your generator performs reliably when you need it most. Whether you’re anchored in a secluded cove or navigating challenging waters, knowing your electrical systems will work flawlessly makes all the difference between a memorable voyage and a stressful emergency.

The real secret to generator longevity lies in prevention over repair. Regular maintenance might seem like a chore, but it’s actually your best investment in uninterrupted boating enjoyment. Think of it this way – a few hours of maintenance can save you days of frustration and potentially dangerous situations at sea.

When problems do arise, having access to factory-trained technicians who understand the unique challenges of marine environments becomes invaluable. The harsh saltwater conditions, constant vibration, and demanding operating requirements of marine generators require specialized knowledge that goes far beyond general diesel repair.

At Diesel Services of America in Fort Lauderdale, we’ve built our reputation on understanding exactly what your marine diesel generator needs to perform at its best. Our factory-trained technicians specialize exclusively in marine and industrial diesel applications, bringing decades of experience to every repair. We offer dockside service throughout South Florida and the Caribbean, plus worldwide parts delivery – because we know generator problems don’t wait for convenient timing.

Don’t let generator troubles turn your next trip into a survival story. Contact us for expert marine diesel generator repair and experience the confidence that comes with knowing your power systems are in the most capable hands.