Introduction: The Heart of Your Engine’s Breathing System

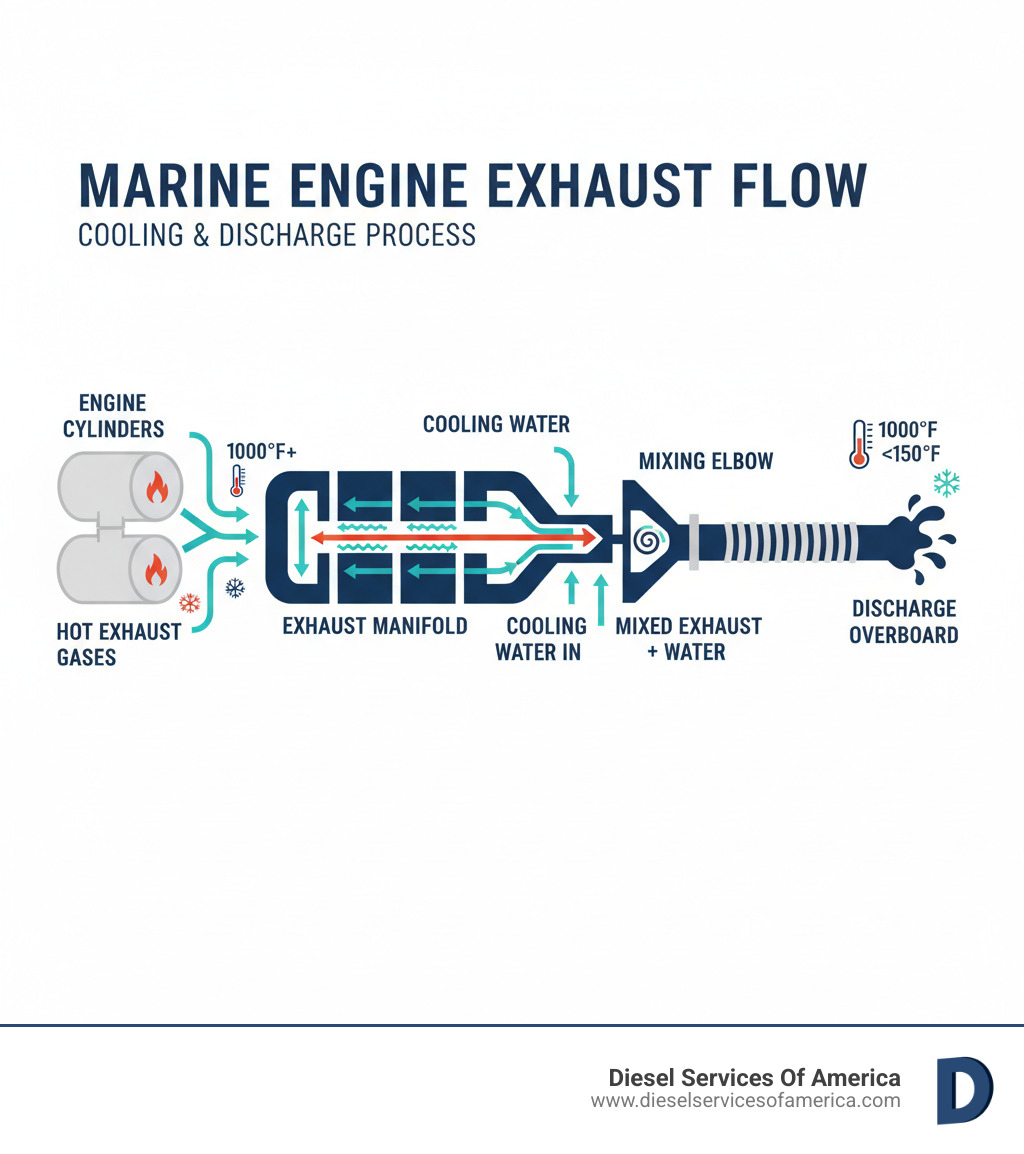

A marine engine exhaust manifold is a critical component that collects hot exhaust gases from each cylinder and cools them with circulating water before discharge. This water-jacketed design is essential for managing temperatures that exceed 1000°F, but it also creates a harsh, corrosive environment.

Manifold failure is the #1 killer of marine inboard engines, primarily because saltwater corrosion can cause water to leak into the engine’s cylinders. This often leads to catastrophic damage to pistons, valves, and cylinder walls.

The average lifespan is just 5-7 years, depending on water type and storage conditions. In fact, manifolds on dry-stored boats often fail sooner (around 5 years) than those on boats kept in the water (7 years) due to accelerated corrosion from oxygen exposure.

When a manifold fails, saltwater can be drawn into your engine cylinders upon shutdown, causing damage that can cost tens of thousands to repair. The good news is that regular inspection and proactive replacement can prevent this disaster. Understanding how your manifold works and when to replace it is essential for any boat owner in demanding marine environments like South Florida and the Caribbean.

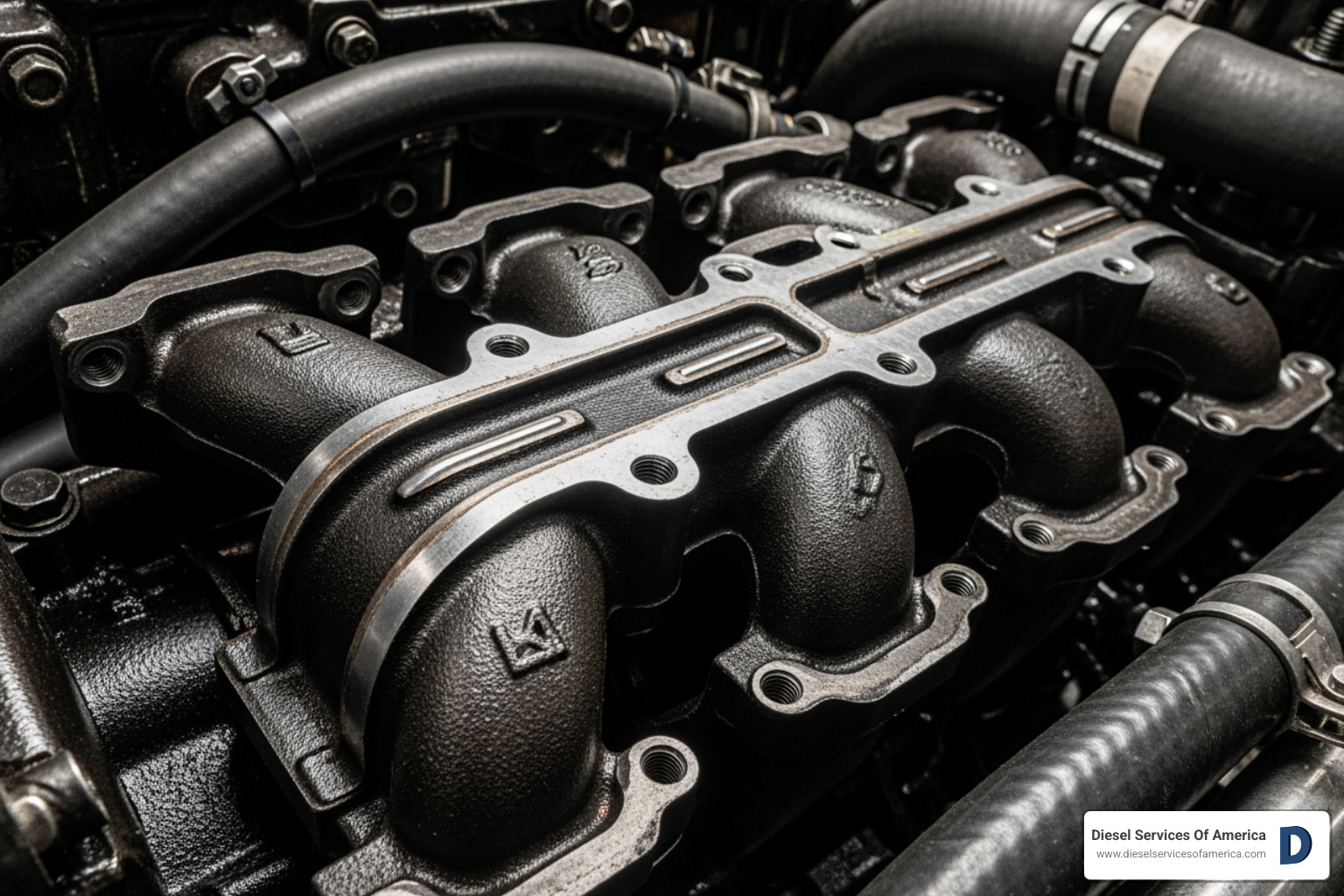

The Anatomy of a Marine Engine Exhaust Manifold

A marine engine exhaust manifold gathers scorching exhaust gases (over 1000°F) from each cylinder and directs them safely out of the boat. Unlike automotive manifolds, it performs a dual role by circulating cooling water through internal passages, or “water jackets.” This process is vital to cool the exhaust, prevent fires, and protect rubber hoses.

After absorbing heat, the cooling water meets the exhaust gases at the mixing elbow (or riser). From there, the cooled mixture of gas and water is discharged overboard. Gaskets and seals are critical for keeping the water and exhaust separated. If a gasket fails, water can enter the engine cylinders, leading to severe damage.

Common Materials and Why They’re Used

The material used in a marine engine exhaust manifold significantly impacts its durability and performance.

| Material | Durability (Corrosion) | Cost | Weight | Heat Management |

|---|---|---|---|---|

| Cast Iron | Moderate | Low | Heavy | Excellent |

| Cast Aluminum | Good (with coatings) | Moderate | Light | Good |

| Stainless Steel | Excellent | High | Moderate | Good |

Cast iron is the most common material due to its low cost and excellent heat management. Its main weakness is a high susceptibility to saltwater corrosion, which ultimately limits its lifespan.

Cast aluminum is a lighter alternative popular in performance applications. It transfers heat well and can resist corrosion if properly coated. Custom aluminum manifolds can also be designed to reduce back pressure, improving engine performance.

Stainless steel is the premium choice for maximum corrosion resistance and longevity. While more expensive upfront, stainless manifolds can outlast cast iron alternatives by years, making them a smart long-term investment for boats operating in saltwater.

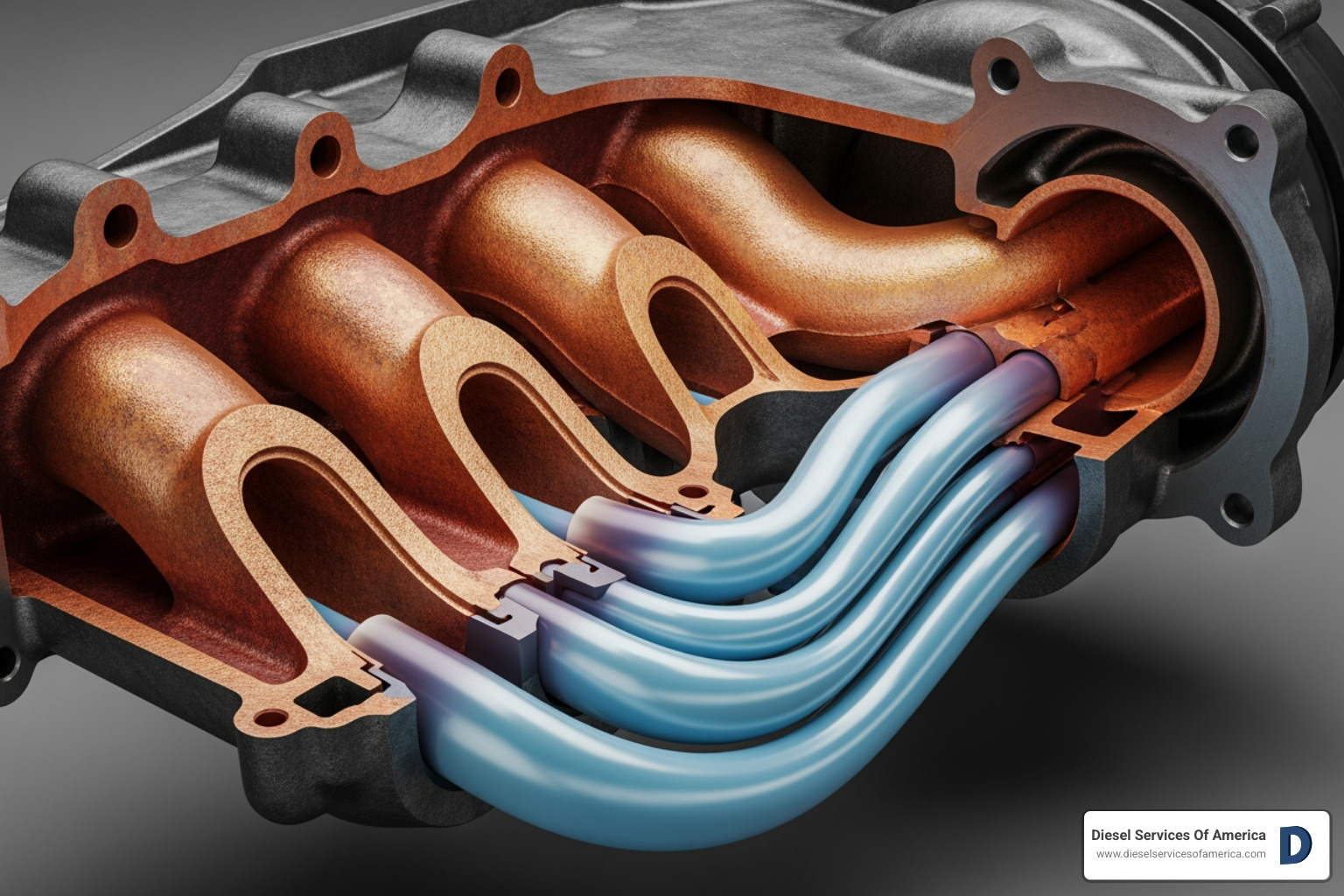

Key Design Differences: Conventional vs. Dry-Joint

A major advancement in manifold technology is the dry-joint design, which offers superior protection against engine damage.

Conventional “wet-joint” designs route cooling water across a gasket surface to get to the mixing elbow. This gasket is under constant assault from heat and corrosion. When it fails, water can leak directly into the engine’s cylinders—a nightmare scenario for any boat owner.

The dry-joint manifold design improves reliability by moving water through a separate passage that avoids the critical exhaust gas seal. With this design, a deteriorating gasket is far less likely to cause water intrusion into the engine. This simple change significantly reduces the risk of catastrophic failure and extends the manifold’s service life, offering peace of mind for operators in demanding saltwater conditions.

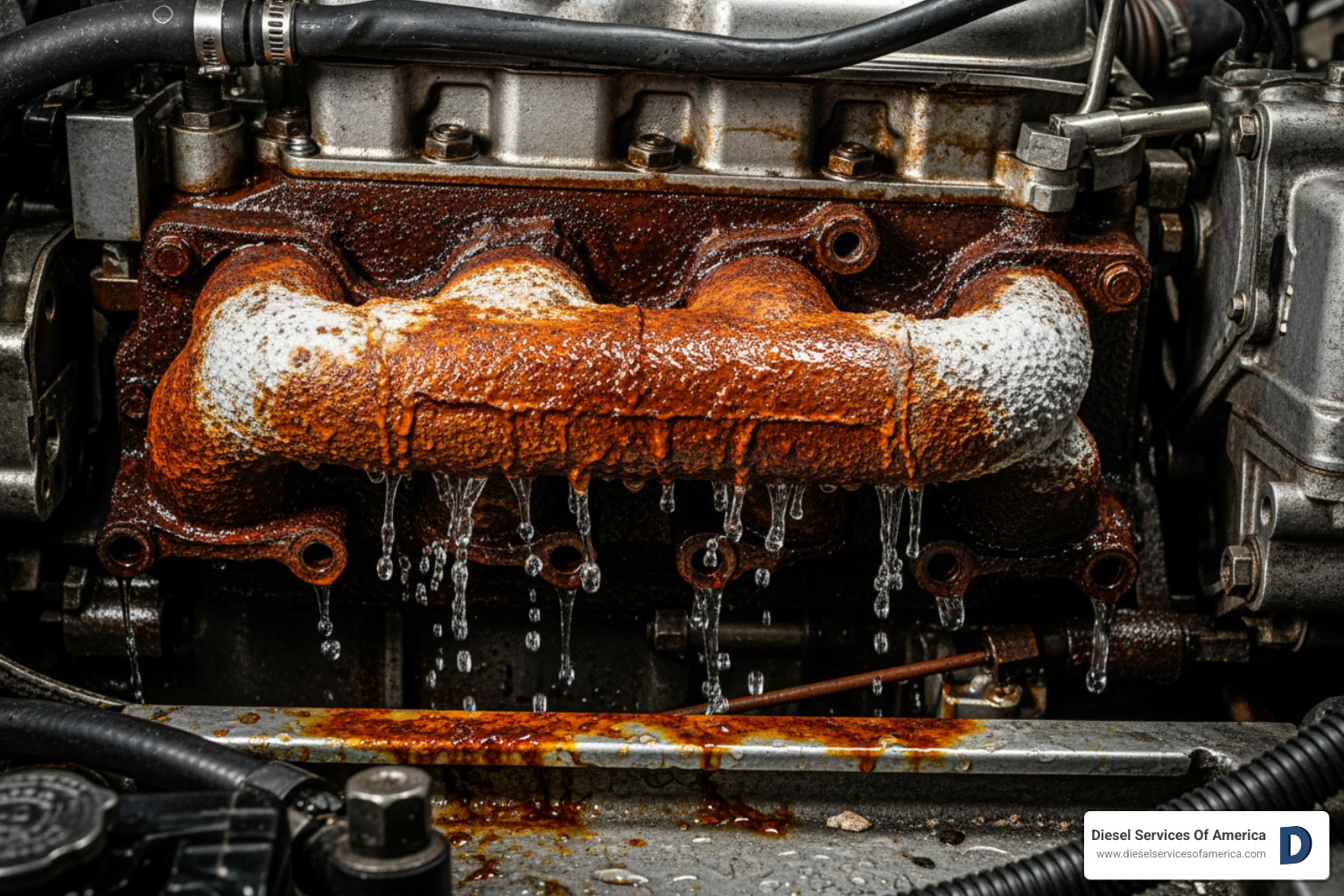

The Silent Killer: Manifold Failure, Causes, and Consequences

Exhaust manifold failure is the #1 cause of catastrophic damage to marine inboard engines. The destruction happens quietly, often while the boat is docked, and you may not see warning signs until it’s too late.

The primary enemy is saltwater corrosion. The combination of hot exhaust and flowing saltwater creates an aggressive chemical reaction that eats away at the manifold’s internal walls. Over time, rust and scale build up, restrict water flow, and can eventually breach the metal. Freshwater systems can also corrode, albeit more slowly, especially if coolant is not properly maintained.

Overheating accelerates this process by causing stress fractures, while condensation damage allows a weak acid to form from residual exhaust gases, eating away at the metal even when the engine is off. The corrosion never sleeps.

Signs of a Failing Marine Engine Exhaust Manifold

Catching a failing marine engine exhaust manifold early can save you from financial disaster. Watch for these warning signs:

- Excessive white steam from the exhaust: A sign that water is leaking into the hot exhaust stream.

- Engine temperature climbing at speed: Indicates restricted water flow due to internal blockages.

- Water in the engine oil: A milky, coffee-colored appearance on the dipstick means water has breached the engine. This requires immediate attention.

- Rust streaks or water drips on the exterior: Visual proof that the manifold is corroded through from the inside.

- Reduced engine performance: Sluggish acceleration or lower top RPM can be caused by back pressure from a blocked manifold.

- Unusually loud exhaust noise: Often points to a crack or a failed gasket.

If you notice any of these symptoms, schedule an inspection immediately.

The High Cost of Neglect

When you shut down an engine with a compromised marine engine exhaust manifold, a vacuum can form in the cooling cylinders. This vacuum can suck saltwater from the leaking manifold directly into the combustion chambers.

Once inside, saltwater causes catastrophic damage. Rust forms on cylinder walls, pistons, and valves within hours. Piston rings seize, valves fail to seal, and cylinder walls get scored when the engine is next started. This damage destroys the engine’s ability to build compression.

The financial reality is sobering. A proactive manifold replacement might cost a few thousand dollars. An engine rebuild or replacement due to manifold failure can cost $15,000 to $50,000 or more, not to mention weeks or months of downtime. Preventative maintenance always costs less than catastrophic failure.

Proactive Protection: Maintenance and Inspection Essentials

When it comes to your marine engine exhaust manifold, waiting for obvious problems is a costly mistake. Water-cooled exhaust components have a finite lifespan. Based on countless real-world observations in demanding environments like South Florida, you should plan for replacement every 5 to 7 years.

Surprisingly, manifolds on dry-stored boats often last only 5 years, while those on boats moored in water last about 7 years. The repeated wet-dry cycles and increased oxygen exposure during dry storage accelerate corrosion faster than continuous submersion. Proactively replacing your manifold in this timeframe is a small investment compared to the tens of thousands of dollars required for an engine rebuild.

Recommended Maintenance for a Marine Engine Exhaust Manifold

Consistent maintenance can help you catch problems early. Here’s a checklist:

- Visual Inspections: Regularly look for rust streaks, discoloration, or water drips on the manifold and mixing elbow, especially around gaskets and bolts.

- Check Hoses and Clamps: Ensure cooling hoses are pliable, not hard or cracked, and that all clamps are secure to prevent leaks and overheating.

- Check Mounting Bolts: Engine vibration can loosen bolts over time. Check them periodically and tighten to manufacturer specifications to maintain a proper gasket seal.

- Temperature Checks: Use an inexpensive infrared thermometer to check the manifold surface while the engine is running. Hot spots can indicate internal blockages.

- Flush the System: Flushing the system with freshwater after each saltwater use is one of the best ways to slow internal corrosion.

- Schedule Professional Inspections: Have a factory-trained technician inspect your exhaust system every 1-2 years. A professional can spot hidden corrosion before it becomes a critical failure.

Performance Released: How Manifolds Impact Your Engine

Your marine engine exhaust manifold is more than just an exhaust pipe; it’s a key factor in your engine’s performance and efficiency. The central concept is engine back pressure—the resistance exhaust gases face when trying to exit.

Excessive back pressure forces the engine to work harder to push out exhaust, which wastes energy. This leads directly to lost horsepower and poor fuel efficiency, as the engine burns more fuel for the same output. It’s like trying to exhale through a narrow straw.

A well-designed manifold, however, provides a smooth, unrestricted path for exhaust gases. This allows the engine to “breathe” easily, resulting in more power, better fuel economy, and cleaner combustion. Upgrading from a deteriorating stock manifold to a high-performance or custom-fabricated design can make an engine feel more responsive and run cooler. For commercial or recreational vessels, these improvements directly impact operational costs and capability.

Advanced Designs and Specific Engine Considerations

Modern manifold designs, particularly those made from cast aluminum, offer significant advantages. Their smoother internal passages are engineered to minimize turbulence and restriction. This reduced back pressure allows the engine to draw in a denser air-fuel charge on each intake stroke, resulting in improved power output.

Different engines also have unique requirements. Propulsion engines, which operate at varying loads and RPMs, need manifolds that perform well across a wide range. Generator engines, which run at a constant speed, require exceptional reliability and consistent cooling.

Custom fitting for hose routing is another critical consideration in tight engine rooms. A properly designed manifold accounts for the placement of cooling lines and exhaust hoses, preventing future issues like chafing or restricted maintenance access. This attention to detail ensures the entire system works as an integrated, reliable unit.

Frequently Asked Questions about Marine Exhaust Manifolds

We’ve answered thousands of questions about the marine engine exhaust manifold in our Fort Lauderdale service bay. Here are the most common ones:

What is the average lifespan of a marine exhaust manifold?

The average lifespan is 5 to 7 years. This varies based on key factors:

- Material: Cast iron corrodes faster than stainless steel or coated aluminum.

- Environment: Saltwater use is much harsher than freshwater.

- Storage: Dry storage (5-year average) is surprisingly harder on manifolds than in-water mooring (7-year average) due to increased oxygen exposure during wet-dry cycles.

Given the risk of failure, we recommend proactive replacement within this timeframe.

Can I replace just the mixing elbow?

Yes, and it’s a common repair. The mixing elbow is often the first part to fail because it endures extreme thermal shock where hot exhaust meets cooling water. However, if the elbow has failed, the manifold has been exposed to the same harsh conditions and is likely near the end of its life. Replacing only the elbow may be a temporary fix, and you could end up paying for the same labor again soon. A thorough inspection of the manifold is crucial.

What happens if my exhaust manifold fails?

A failed marine engine exhaust manifold can destroy your engine. The most common failure involves water leaking into the engine’s cylinders, especially after shutdown when a vacuum effect can suck water in. This leads to catastrophic internal damage:

- Rapid rust formation on cylinder walls, pistons, and valves.

- Seized piston rings and pitted valves, causing loss of compression.

- Scored cylinder walls when the engine is started.

The result is often a bill for a complete engine rebuild or replacement, costing tens of thousands of dollars.

Conclusion: Safeguard Your Investment with Expert Care

Your marine engine exhaust manifold is a critical component standing between reliable operation and catastrophic engine failure. It manages extreme heat and corrosive saltwater, but has a finite lifespan of just 5-7 years. As we’ve shown, manifold failure is the #1 killer of marine inboard engines, capable of allowing saltwater to flood your cylinders and cause tens of thousands of dollars in damage.

The good news is that this disaster is preventable. By watching for warning signs and following a proactive replacement schedule, you can protect your engine and your wallet. The cost of preventative maintenance is always a fraction of an emergency engine rebuild.

In the demanding waters of South Florida and the Caribbean, saltwater corrosion is a relentless threat. That’s why having factory-trained technicians who understand these unique challenges is essential to protecting your investment. At Diesel Services Of America, we specialize in keeping marine diesel engines running reliably. We’ve seen the consequences of manifold failure and have helped countless owners avoid them through proper maintenance.

Don’t wait for a disaster. Contact us for complete marine diesel services and let our experienced technicians give your exhaust system the expert attention it deserves.