Why Your Marine or Industrial Diesel Engine’s Oil Tells Its Health Story

Diesel engine oil analysis is a diagnostic process that examines used engine oil to determine the lubricant’s condition and the internal health of your marine or industrial diesel engine. By testing a small oil sample, this powerful maintenance tool reveals wear patterns, contamination, and potential problems before they cause costly breakdowns.

Key Components of Diesel Engine Oil Analysis:

- Wear Metals – Iron, copper, and lead indicating component wear

- Contaminants – Fuel, water, coolant, soot, and dirt

- Oil Properties – Viscosity, Total Base Number (TBN), and oxidation

- Trend Analysis – Tracking changes over time to predict maintenance

- Cost Savings – Preventing major repairs through early detection

For marine fleet managers in Southeast Florida and the Caribbean, oil analysis is an early warning system. Instead of waiting for an engine alarm or catastrophic failure, you get advance notice of developing issues.

“Oil is the lifeblood of your engine, and like a blood test for the skipper, an oil analysis can identify potential problems before they become major ones,” explains one marine surveyor with decades of experience.

As your diesel engine operates, microscopic metal particles from wear and contaminants like fuel or saltwater become suspended in the oil. A lab analysis measures these elements, creating a detailed picture of your engine’s internal state.

For boat owners in South Florida, this means catching issues like fuel injector leaks or saltwater ingress before they destroy expensive components. The cost of analysis—typically $17 to $35 per sample—is minimal compared to a major engine rebuild costing tens of thousands.

The ‘Why’ and ‘What’ of Diesel Engine Oil Analysis

Imagine your marine diesel engine seizing up off the coast of Fort Lauderdale, leading to a $20,000 repair bill. A simple $25 oil test could have warned you months ahead. That’s the power of diesel engine oil analysis—it’s like X-ray vision for your engine.

For marine and industrial operators, preventive maintenance is essential. The Importance of diesel marine engine maintenance is clear when you consider the alternative. Diesel engine oil analysis shifts maintenance from reactive to proactive. Instead of arbitrary schedules, you’ll know exactly when to change your oil based on its actual condition. This approach significantly extends engine life, and engines with documented oil analysis histories command higher resale values.

The analysis focuses on three critical areas: wear metals (component condition), contaminants (engine threats), and oil condition (lubricant effectiveness). It’s a comprehensive blood test for your engine.

Decoding Wear Metals

As your engine runs, microscopic metal particles from internal components suspend in the oil, indicating which parts are wearing and how quickly.

- Iron, the most common wear metal, comes from cylinder liners, piston rings, and crankshafts. Rising iron levels can signal normal aging, but sudden spikes indicate serious problems.

- Copper often points to bearing wear or oil cooler issues. Copper with potassium and sodium usually indicates a failing oil cooler core, a critical issue for marine engines.

- Lead and tin are key to bearing analysis. Liftd levels of these soft metals indicate bearing wear. Early detection can prevent catastrophic bearing failure.

- Aluminum in marine and industrial diesels comes from pistons and bearings. High levels can also signal dirt ingestion, a critical concern for engines in dusty or sandy environments.

Identifying Harmful Contaminants in Marine and Industrial Engines

Contaminants are active threats to your engine’s survival.

- Soot indicates poor combustion efficiency from issues like dirty injectors. High soot levels promote sludge and accelerate engine wear.

- Fuel dilution from unburned diesel thins the oil, reducing its protective ability. The analysis measures this precisely.

- Water ingress is especially troublesome for marine engines. It promotes rust and breaks down additives. Keeping water content below 0.2% is crucial.

- Coolant leaks appear as glycol in the oil. Antifreeze is devastating to oil, and immediate action is required to prevent catastrophic damage.

- Silicon usually means dirt or sand is entering the engine. Proper air filtration is critical for marine engines to prevent this abrasive contamination.

- Sodium and potassium levels are key for marine operators. High sodium with low potassium indicates saltwater contamination. High levels of both usually point to a coolant leak.

Assessing Oil Health and Properties

Even with low wear and contamination, the oil itself can break down. The analysis evaluates key properties to determine its remaining service life.

- Viscosity measures oil thickness. Oil that is too thin or too thick cannot properly protect components.

- Total Base Number (TBN) measures the oil’s ability to neutralize acids from combustion. As TBN drops, protection against acid corrosion decreases.

- Oxidation and nitration show oil degradation from heat and chemical reactions, which thickens oil and forms deposits.

- Insolubles are solid particles like soot, dirt, and wear metals. High levels mean the filtration system is overwhelmed or the oil has exceeded its useful life.

Understanding these factors turns diesel engine oil analysis reports into actionable intelligence, revealing not just if a problem exists, but its cause and urgency.

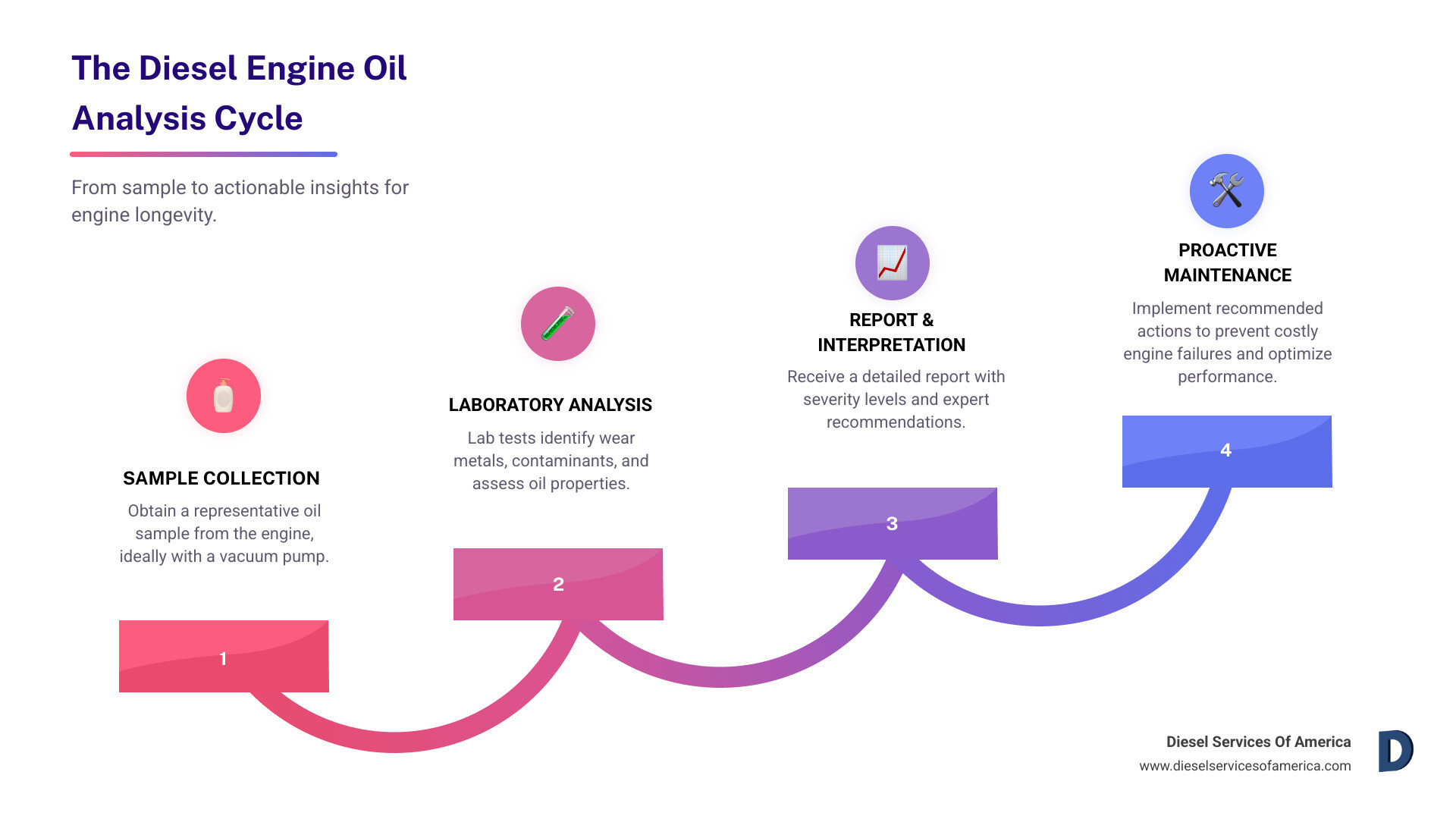

How to Perform an Accurate Oil Analysis: A Step-by-Step Guide

Collecting an oil sample is like a blood test: the sample must be clean and representative to yield accurate results. For diesel engine oil analysis, the sample must truly represent the oil circulating in your engine. Contaminated or poor samples can lead to false alarms or missed problems. Fortunately, getting a clean, accurate sample is straightforward.

Gathering Your Tools and Timing it Right

Your lab will send an oil analysis kit. You’ll also need a clean vacuum pump with fresh tubing, which is crucial for marine engines to avoid saltwater contamination in the sample. You’ll also want clean gloves and a rag.

Timing is critical. The engine must be at normal operating temperature (run for at least 15 minutes) to ensure wear metals and contaminants are evenly mixed in the oil. After an oil change, wait about 50 hours of operation before taking the first sample. For ongoing monitoring, sample every 250 to 500 operating hours.

The Proper Diesel engine oil analysis Sampling Procedure

- Start with a warm engine. Prepare your kit by screwing the sample bottle onto the vacuum pump.

- Use your dipstick to measure the correct tubing depth. Mark the tube where the dipstick ends, then pull back an inch to avoid drawing settled sludge from the bottom of the oil pan.

- Insert the tubing to your marked depth. Use the vacuum pump to draw about two ounces of oil into the bottle (about three-quarters full).

- If using a drain port, let the oil flow for a few seconds to flush out debris before catching a mid-stream sample.

- Fill out the information sheet completely. The lab needs your engine make/model, total engine hours, hours on the oil, and oil type. This context is vital for an accurate diagnosis.

- Seal the sample immediately and clean the vacuum pump, avoiding solvents that could contaminate future samples.

- Ship your sample as instructed. Most labs process samples in 2-3 business days, with faster options available for urgent cases.

This 10-minute process can save you thousands in repairs. For marine operators in South Florida, this small time investment pays dividends in reliability and longevity.

Interpreting Your Diesel Oil Analysis Report

Your oil analysis report is a “health report card” for your engine. The numbers and terms might seem overwhelming at first, but understanding the basics makes reading them second nature. Your diesel engine oil analysis report tells you what’s happening inside your engine, often months before symptoms appear.

Understanding Severity Levels and Trends

Most labs use a color-coded system to flag issues: Normal, Abnormal (monitor), or Critical (investigate immediately). Don’t panic over a single abnormal reading; it needs context, as a recent repair or oil change can cause temporary spikes.

Trend analysis is key. Tracking multiple reports over time provides a complete picture of your engine’s health. A gradual increase in iron, for example, is different from a sudden spike. Establish a baseline for your engine, as each has a unique operating signature, which makes it easier to spot meaningful changes.

Common Problems Revealed by Diesel engine oil analysis

- Fuel dilution is indicated by a significant drop in the oil’s flashpoint. This points to issues like leaky injectors that need immediate attention from our diesel engine repair services.

- Coolant leaks are revealed by liftd sodium, potassium, and glycol. This dangerous mix can be caused by a blown head gasket or cracked oil cooler and can quickly destroy an engine.

- Saltwater ingress, a unique threat for marine engines in South Florida, is identified by high sodium with low potassium. This indicates issues like faulty raw water pump seals.

- Excessive wear appears as consistently high metal levels. For example, rising lead and tin suggest bearing problems. Oil analysis catches these trends before you hear expensive noises.

- Air filtration problems are indicated by high silicon levels. A dirty air filter can allow abrasive particles into the engine, causing significant damage.

- Poor combustion is shown by high soot levels, which can indicate dirty injectors or incorrect timing. Addressing it early prevents oil gelling and sludge.

Regular diesel engine oil analysis guides your maintenance decisions, giving you advance warning to plan repairs conveniently instead of facing emergency breakdowns.

Integrating Oil Analysis into Your Maintenance Program

Diesel engine oil analysis lets you get ahead of problems before they become expensive breakdowns. This shift to condition-based maintenance is a game-changer for marine and industrial operations. Instead of changing oil on arbitrary schedules, you make decisions based on your engine’s actual condition, allowing you to optimize drain intervals.

For operators in South Florida, this means planning maintenance on your schedule, not as an emergency. You can schedule a repair during your off-season instead of during a critical operation.

Determining the Right Analysis Frequency

How often should you test? It depends on engine usage and how critical it is to your operations.

- Annual Analysis: For seasonal boaters, an annual analysis during your yearly service is often sufficient.

- High-Usage Engines (250-500 hours): For commercial and high-usage engines, we recommend testing every 250 to 500 operating hours.

- Post-Repair Verification: After major work, test the oil after about 50 hours to confirm the repair was successful.

- Pre-Purchase Inspections: A single oil sample is invaluable. It can reveal hidden problems like coolant leaks or excessive wear that a visual inspection might miss.

Choosing a Quality Analysis Lab

Choose a lab that understands the unique challenges of marine and industrial diesels.

- Diesel-Specific Testing: The lab must test for Total Base Number (TBN) and offer accurate soot analysis. Confirm these are part of their standard diesel package.

- Clear, Actionable Comments: A great lab explains what the numbers mean for your specific engine and provides detailed recommendations.

- Quick Turnaround Time: Quality labs deliver results in 2-3 business days, which is critical for making timely operational decisions.

- Heavy-Duty Experience: Specialized labs understand the typical wear patterns of marine and industrial engines, allowing them to set appropriate alarm limits and provide relevant advice.

Integrating diesel engine oil analysis into your Diesel Maintenance And Repairs program transforms maintenance from guesswork to informed decision-making. Research, like this study on An Integrated Methodological Approach for Interpreting Used Oil Analysis in Diesel Engines, confirms that systematic oil analysis is a reliable early warning system, giving you confidence in your maintenance decisions.

Frequently Asked Questions about Marine and Industrial Diesel Oil Analysis

Here are the most common questions we get about diesel engine oil analysis from our customers in South Florida and the Caribbean.

How much does diesel oil analysis typically cost?

Diesel engine oil analysis is one of the most cost-effective maintenance tools available. A typical analysis, including lab processing, costs between $17 and $35 per sample. This small investment can catch problems that would otherwise cost thousands to repair. For example, a recent $25 analysis revealed coolant contamination in a generator, leading to a $300 repair instead of a $15,000 engine rebuild. The math is simple: spend a little now to save thousands later.

Can a single oil analysis be useful, or is it only for trending?

While diesel engine oil analysis is most powerful when tracking trends, a single analysis can still provide valuable insights. For pre-purchase inspections, a single sample is a game-changer, revealing red flags like excessive wear or fuel dilution. Single samples also flag critical issues like saltwater contamination or a severe coolant leak, which are immediately apparent. However, the real power is in trend analysis; establishing a baseline and monitoring changes over time gives you a complete picture of your engine’s health.

What’s the most important parameter to watch in a marine diesel engine?

In our experience with marine diesels in South Florida, coolant contamination and saltwater ingress are the two biggest threats.

Coolant contamination appears as liftd glycol, sodium, and potassium. Antifreeze in the oil is like poison, breaking down the lubricant and causing corrosion.

Saltwater contamination is a primary concern for marine engines, identified by high sodium with low potassium. Saltwater in the oil is incredibly corrosive and can quickly destroy an engine.

Fortunately, regular Diesel engine coolant flush services and proper maintenance can prevent these issues. Early detection through oil analysis allows us to address the cause before permanent damage occurs. If left unchecked, both contaminants can lead to a complete engine replacement.

Your Partner in Engine Longevity

For marine and industrial operators, diesel engines are the heart of the operation. At Diesel Services of America, we know diesel engine oil analysis transforms maintenance from a guessing game into a precise science.

Regular oil analysis helps you protect high-value assets. Catching problems early avoids costly downtime and catastrophic failures. It also lets you make informed maintenance decisions, optimizing oil drain intervals based on actual condition, which saves money while ensuring your engine is always protected.

Our factory-trained technicians help you interpret these reports. We explain what the numbers mean for your specific engine and guide you in planning maintenance based on the results. The peace of mind from regular oil analysis is invaluable, giving you advance warning to plan repairs conveniently and avoid emergency breakdowns.

For comprehensive care and expert interpretation of your engine’s health, explore our marine diesel engine services. Our dockside service throughout South Florida means we can be there when you need us, whether it’s for routine maintenance or addressing issues identified through oil analysis. Let us be your partner in keeping your marine and industrial diesel engines running smoothly for years to come.