Understanding Volvo Penta Engine Diagnostics

Volvo Penta engine diagnostics is the process of identifying and resolving performance issues in marine diesel engines using specialized tools and software. If you’re searching for quick guidance on diagnosing your Volvo Penta engine, here’s what you need to know:

Quick Guide to Volvo Penta Engine Diagnostics:

- Tools needed: VODIA diagnostic software or third-party tool (Jaltest, Diacom)

- Hardware required: VOCOM interface (or compatible adapter) and laptop/PC

- Connection method: Locate diagnostic port (typically 8-pin or OBD connector)

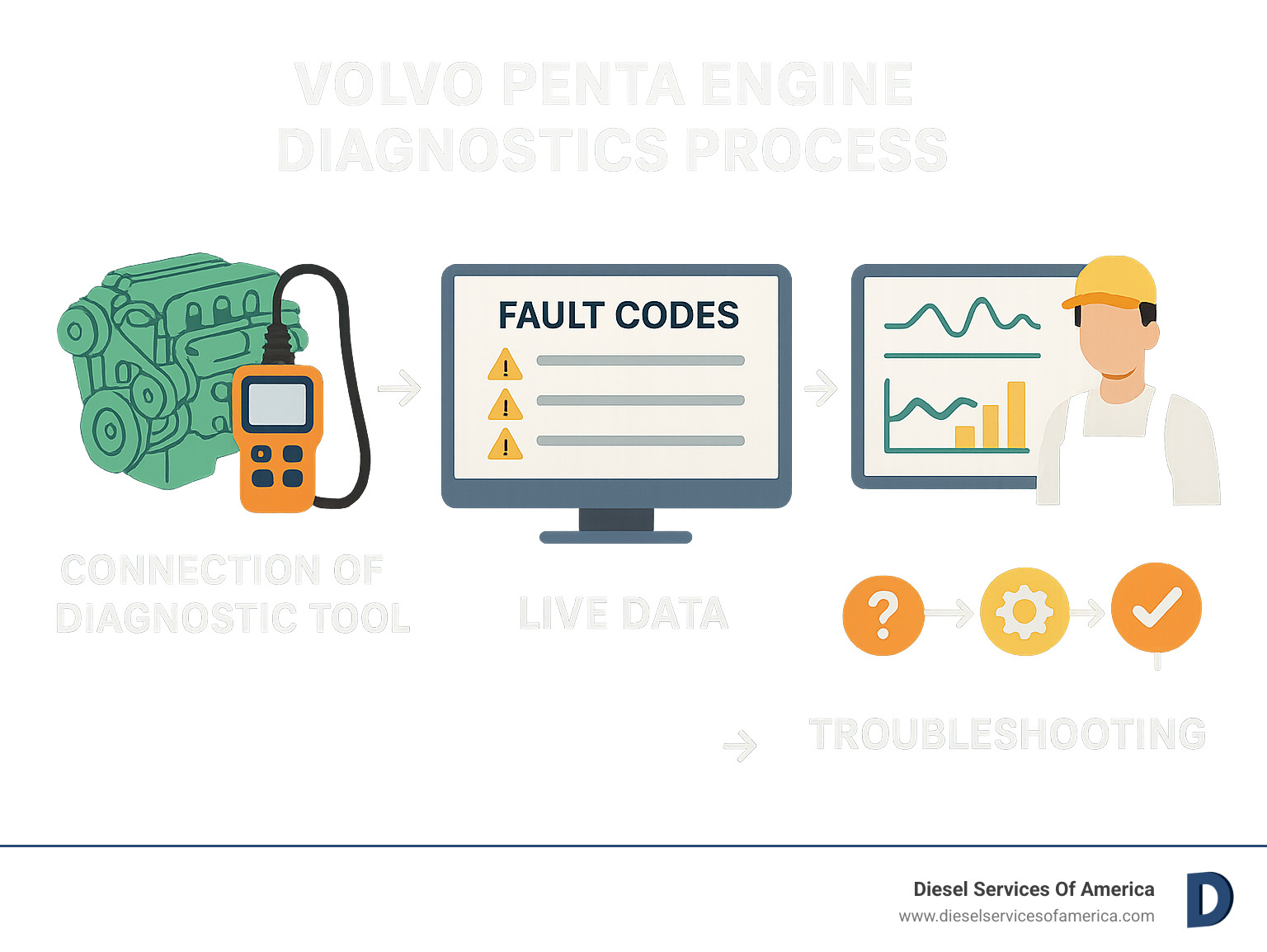

- Basic process: Connect adapter → Run software → Scan for fault codes → Analyze data

- Common functions: Read fault codes, view live data, perform tests, calibrate components

In the challenging marine environment of South Florida and beyond, reliable engine performance is not a luxury—it’s a necessity. When your Volvo Penta marine diesel engine displays warning lights or performs below expectations, proper diagnostic tools become your first line of defense against costly downtime and repairs.

“Owning a computer-controlled marine-injected engine without a scan device is unimaginable,” notes one marine technician in our research, highlighting the critical importance of diagnostic capabilities for today’s sophisticated engines.

Modern Volvo Penta engines feature complex electronic systems that communicate valuable information about their operational status. From simple fault code reading to advanced parameter programming, the right diagnostic tools can transform troubleshooting from guesswork to precision science.

At Diesel Services of America, we understand that proper marine engine diagnostics requires specialized knowledge and equipment. Whether you’re managing a fleet of commercial vessels or maintaining your personal yacht, understanding the basics of Volvo Penta diagnostics can save you time, money, and frustration on the water.

Simple Volvo Penta engine diagnostics word guide:

Why Every Captain Should Care About On-Board Diagnostics

There’s something special about being out on the water – the freedom, the peace, the trip. But as any experienced captain knows, that freedom quickly disappears when engine troubles arise. That’s where Volvo Penta engine diagnostics comes in – not just as a fancy tech tool, but as your first mate in keeping your marine journey smooth sailing.

In the salty, humid environment of South Florida and beyond, marine diesel engines face unique challenges that land-based engines never encounter. Your engine is constantly battling corrosion, humidity, and temperature fluctuations that can cause small issues to snowball into major problems.

“I’ve seen it time and again,” says our senior technician at Diesel Services of America. “The captains who invest in diagnostic capabilities rarely find themselves stranded. It’s like having a crystal ball for your engine.”

What makes diagnostics so valuable? It’s all about what you stand to gain:

Maximized uptime means more days enjoying the water and fewer days stuck at the dock waiting for repairs. By catching issues early, you’re preventing the domino effect of small problems becoming catastrophic failures.

Fuel efficiency isn’t just good for your wallet – it’s essential in today’s world. Modern Volvo Penta engine diagnostics can pinpoint exactly where your engine might be wasting fuel, potentially saving you thousands over a season of boating.

For vessels with newer Tier 4 and Tier 5 engines, emissions compliance isn’t optional. Diagnostic tools help ensure your sophisticated emissions systems are functioning properly, keeping you legal and environmentally responsible.

When it comes time to upgrade your vessel, documented diagnostic history significantly boosts your resale value. Potential buyers will pay a premium for vessels with transparent maintenance records showing regular diagnostic checks.

Perhaps most importantly, diagnostic capabilities dramatically improve your safety margins. The ocean doesn’t care about your plans or your schedule – but with proper diagnostics, you’ll rarely find yourself in a dangerous situation due to engine failure.

The warm waters around Florida create an especially challenging environment for marine engines. Salt spray, high humidity, and tropical heat create the perfect storm for accelerated wear and corrosion. Regular diagnostic scans become even more crucial in these conditions, as they can detect problems before they manifest as performance issues.

Think of Volvo Penta engine diagnostics as preventive medicine for your vessel. Just as you wouldn’t wait until you’re seriously ill to see a doctor, you shouldn’t wait for your engine to fail before performing diagnostics. A small investment in diagnostic capability today can prevent major expenses tomorrow.

More info about diesel diagnostics

Mastering Volvo Penta Engine Diagnostics: Tool Landscape

When it comes to Volvo Penta engine diagnostics, the tool options can feel like navigating a complex channel without a chart. Let’s drop anchor and explore what’s available to help you make the best choice for your vessel.

The diagnostic world essentially divides into two harbors: Volvo Penta’s own manufacturer tools and third-party solutions that work across multiple engine brands. Each has its place depending on your needs, budget, and technical comfort level.

What Is Volvo Penta VODIA?

VODIA (Volvo On-board Diagnostics Interface Application) is the crown jewel in Volvo Penta engine diagnostics. Think of it as having the manufacturer’s own technicians right there in your engine room.

“When we’re dealing with complex engine issues, VODIA gives us the most comprehensive access possible,” explains our senior technician at Diesel Services of America. “It’s like having X-ray vision into the engine’s electronic brain.”

VODIA doesn’t just read what’s happening—it speaks the engine’s native language. It provides complete access to all electronic control units, allows you to reprogram engine parameters back to factory specs, and update ECU firmware to the latest versions. The software maintains detailed records of your engine’s performance history, and offers specialized testing capabilities that simply aren’t available elsewhere.

The system pairs with Volvo’s VOCOM interface devices (the latest being the VOCOM II 88894000) to create that critical bridge between your laptop and the engine’s electronic systems. For captains and fleet managers who demand absolute precision, VODIA 5.2.50 represents the gold standard.

Third-Party Options vs. VODIA: Pros & Cons

While VODIA might be the flagship solution, several worthy alternatives have sailed into the Volvo Penta engine diagnostics market. Each offers a different balance of coverage, convenience, and cost.

Jaltest Marine stands out with impressive coverage of Volvo Penta engines from the oldest Tier 1 models right up to the latest Tier 5 powerplants. With three software updates annually, you’re never far behind the technology curve. Its inclusion of wiring diagrams can be a lifesaver when troubleshooting complex electrical issues. The downside? You’ll make a bigger initial investment, and a few specialized VODIA functions might remain out of reach.

Rinda’s Diacom Marine system wins fans with its user-friendly interface. “I love how Diacom lets me graph engine parameters in real-time,” shares one yacht captain who regularly uses our services. “It makes spotting trends so much easier.” It handles multiple marine engine brands well, though you’ll need specific adapters for different engine types, with the CAN adapter for newer systems running around $249.

For those working in challenging environments, the handheld TechMate Pro offers rugged portability. When you’re balancing on a rolling deck in choppy seas, a compact diagnostic tool can be much easier to manage than a laptop. The trade-off comes in display limitations—you’ll only see data for one engine and fewer parameters at once.

When selecting your diagnostic solution, consider these key factors: Does it fully support your specific Volvo Penta model? How often are updates released? What are both the initial and ongoing licensing costs? And perhaps most importantly—do you need basic fault code reading or more advanced programming capabilities?

At Diesel Services of America, we work with all these platforms daily and can help guide you to the solution that makes the most sense for your vessel and situation. Whether you’re managing a commercial fleet that can’t afford downtime or maintaining your personal cruiser, we’ll help you find the right diagnostic approach.

Scientific research on multi-brand marine scanners

Hardware & Software Requirements for Reliable Connections

When it comes to Volvo Penta engine diagnostics, having the right hardware is just as important as the software you’re using. Think of it like fishing – you need both a good rod and the right bait to catch anything!

The marine environment is notoriously harsh on electronics. Salt spray, humidity, vibration, and the occasional splash can quickly ruin standard equipment. That’s why investing in marine-grade hardware isn’t just recommended—it’s essential for reliable connections and lasting performance.

Laptop & OS Specifications

Your computer is the command center of your diagnostic operations, so choose wisely! For optimal performance with Volvo Penta engine diagnostics software, look for these specifications:

A solid processor (Intel Core i5 or better) will handle diagnostic software without breaking a sweat, while 8-16 GB of RAM keeps everything running smoothly when you’re multitasking. We strongly recommend an SSD with at least 256GB—they’re not only faster than traditional hard drives but also have no moving parts to fail when your boat hits a wave!

Windows 10 or 11 Professional is your best bet for operating system compatibility, as most marine diagnostic software is Windows-based. Your display should have a minimum 1366×768 resolution with an anti-glare coating—you’ll thank yourself when working under the bright Florida sun.

Battery life matters too—aim for at least 4 hours of runtime for dockside diagnostics. Multiple USB ports (including USB 3.0) ensure you can connect all necessary interfaces without hunting for adapters.

“I once tried using a standard laptop near the engine room. Between the heat, humidity, and occasional spray, it didn’t last three months,” shares one of our technicians at Diesel Services of America. “Now I only use IP-rated equipment that can handle marine conditions.”

Many marine professionals choose Panasonic Toughbook models like the CF-54, CF-52, or newer FZ-55. These ruggedized laptops are built to withstand the bumps, splashes, and vibrations that are part of everyday marine diagnostics.

Cables, Adapters & Interfaces You’ll Need

Connecting your computer to a Volvo Penta engine is like solving a puzzle—you need the right pieces! Here’s what typically goes in your diagnostic toolkit:

The VOCOM II Interface (88894000) is the heart of modern Volvo Penta engine diagnostics. This latest genuine Volvo interface connects via USB to your computer and provides a stable, reliable engine connection. It’s absolutely required if you want full VODIA functionality.

You’ll also need specific cables depending on your engine type. Older Volvo Penta engines use an 8-pin diagnostic connector (requiring Volvo 88890306 cable), while newer models may use standard OBD-II ports (Volvo 88890304 cable). Don’t forget the Volvo 88890305 USB cable to connect your VOCOM interface to your computer.

For the newest Volvo Penta EGC ‘CAN’ systems, you’ll need dedicated CAN adapters (around $249), while engines using the J1939 protocol require specific J1939 adapters.

Don’t underestimate the importance of USB isolation in marine environments. A quality USB isolator protects both your computer and the engine’s electronic systems from electrical noise and potential ground loops—a common issue in marine applications.

Waterproof cases aren’t just nice to have—they’re essential protection for your investment. A good case keeps your equipment dry during unexpected rain or spray and provides shock protection when moving around the vessel.

Comparison: Laptop-Based vs. Handheld Diagnostic Tools

| Feature | Laptop-Based Systems | Handheld Scanners |

|---|---|---|

| Display Size | Larger (12-15″) | Smaller (3-7″) |

| Parameter Display | Multiple parameters simultaneously | Limited parameters per screen |

| Graphing Capability | Extensive, multi-parameter | Limited or none |

| Data Recording | Comprehensive | Basic |

| Durability | Requires protective case | Built-in ruggedization |

| Battery Life | 3-6 hours typical | 8+ hours typical |

| Usage in Rough Seas | Challenging | More practical |

| Software Updates | More frequent | Less frequent |

| Multi-Engine Support | Often supports 2+ engines | Usually single-engine |

| Cost | Higher initial, lower updates | Lower initial, higher updates |

“Diacom on a laptop offers full-parameter graphing and recording, while TechMate Pro handheld is safer and more convenient underway,” explains our marine diagnostic specialist at Diesel Services of America. “It’s like choosing between a Swiss Army knife and a specialized tool—both have their place in your toolbox.”

For our professional work at Diesel Services of America, we’ve found that a combination approach works best: ruggedized laptops with full diagnostic capabilities for comprehensive dockside diagnostics, supplemented by handheld tools for quick checks and underway diagnostics when conditions get rough. This gives us the best of both worlds—depth of analysis when needed and convenience when working in challenging conditions.

Step-By-Step Guide to Running Volvo Penta Engine Diagnostics

Let’s roll up our sleeves and dive into the practical side of Volvo Penta engine diagnostics. Whether you’re a seasoned captain or new to marine engine maintenance, these steps will help you steer the diagnostic process with confidence.

Connecting Your Scanner to the Engine (Volvo Penta Engine Diagnostics)

The first step in any successful diagnostic session is establishing a solid connection between your tools and the engine. Think of it as setting up a conversation between your computer and your Volvo Penta.

Start by making sure your vessel is secured properly. There’s nothing worse than trying to perform delicate diagnostics while your boat is rocking wildly! Next, check that your batteries have plenty of juice – low voltage is the silent saboteur of diagnostic sessions, causing mysterious connection failures and unreliable readings.

Finding the diagnostic port is your next mission. Depending on your Volvo Penta’s age and model, you’ll be looking for an 8-pin connector (older models), a standard OBD-II port (newer engines), or a CAN bus connector (latest models). It’s like finding the engine’s secret handshake spot!

Once you’ve located the port, select the matching adapter for your interface. For most diagnostics, you’ll want the ignition ON but the engine NOT RUNNING – though some specific tests might require the engine to be purring away.

“The connection sequence matters,” explains our senior technician at Diesel Services of America. “Always connect to the engine first, then to your computer. It’s a small detail that prevents a lot of headaches.”

With your hardware connected, launch your diagnostic software and verify communication. Your software should give you a friendly nod that it’s talking to the engine’s control modules. If you’re met with silence, double-check your connections and COM port settings – these are the usual suspects when communication fails.

More info about Volvo Penta Marine Parts

Reading & Interpreting Fault Codes

Now for the detective work – reading and making sense of those fault codes. This is where Volvo Penta engine diagnostics truly shines, changing mysterious engine behavior into actionable information.

Begin by initiating a system scan through your software. The results will typically display in several formats, including SPN/FMI codes (like “SPN 100 FMI 1”), flash codes (such as “2.4”), and thankfully, plain English descriptions that tell you what’s actually happening.

Understanding these codes is like learning a new language. The SPN (Suspect Parameter Number) points to the specific system or component having issues, while the FMI (Failure Mode Identifier) tells you what kind of problem it’s experiencing. For instance, that “SPN 100 FMI 1” we mentioned translates to “Engine Oil Pressure – Data valid but below normal operational range” – immediately directing your attention to oil levels and pressure systems.

Freeze-frame data is your diagnostic time machine, showing exactly what was happening when the fault occurred. Was the engine hot? Running at high RPM? This context can be the difference between a quick fix and hours of frustration.

“Fault codes are like your engine’s way of leaving breadcrumbs,” says our diagnostic specialist. “They don’t always tell you exactly what part to replace, but they point you in the right direction to start investigating.”

Clearing Codes & Programming Parameters (Volvo Penta Engine Diagnostics)

After you’ve solved the mystery and made repairs, it’s time to clear those fault codes and potentially reprogram parameters. This part follows a simple but important sequence: repair, verify, then erase.

Always complete the necessary repairs first, then run the engine to confirm your fix worked before clearing any codes. Erasing codes before confirming your fix is like deleting the evidence before you’re sure the case is closed!

In most diagnostic software, there’s a straightforward option to clear fault codes. Traditionally, only authorized Volvo Penta workshops with VODIA tools could erase these codes, but many modern third-party tools now offer this capability as well.

If your repair involves parameter programming, you’ll select the parameter to modify, enter the new value (staying within allowable ranges), write the changes to the ECU, and verify they took effect. Think of it as fine-tuning your engine’s personality.

Before disconnecting, export and save a report of your diagnostic session. These records are gold for tracking your engine’s health over time and can be invaluable for warranty purposes or when troubleshooting future issues.

“The diagnostic history is like your engine’s medical record,” our head technician often reminds customers. “The more complete it is, the better we can care for your engine over its lifetime.”

At Diesel Services of America, our factory-trained technicians perform these procedures daily, maintaining comprehensive records of your engine’s diagnostic history. This attention to detail ensures your Volvo Penta performs at its best and provides complete documentation for warranty purposes.

Proper Volvo Penta engine diagnostics isn’t just about fixing current problems – it’s about preventing future ones and extending the life of your marine investment.

Advanced Functions That Take Your Maintenance to the Next Level

Beyond basic fault code reading, modern Volvo Penta engine diagnostics tools offer powerful capabilities that can transform your maintenance approach from reactive to proactive. These advanced functions aren’t just technical bells and whistles—they’re practical tools that help captains and technicians truly understand what’s happening inside their engines.

Live Data & Predictive Maintenance

Imagine having a window into your engine’s inner workings while it’s running. That’s exactly what live data monitoring provides.

“The difference between basic diagnostics and live data monitoring is like comparing a snapshot to a movie,” explains our senior technician at Diesel Services of America. “One gives you a moment in time, while the other reveals the whole story.”

With advanced diagnostic tools, you can watch multiple engine parameters simultaneously on your screen. Your Volvo Penta engine diagnostics tool becomes a comprehensive dashboard showing engine RPM, fuel pressure, oil temperature, coolant readings, and dozens of other vital signs—all updating in real-time.

What makes this truly powerful is the ability to see relationships between different readings. When fuel consumption suddenly increases, is it accompanied by a drop in rail pressure? Does the coolant temperature spike under certain conditions? These correlations often reveal the true story behind performance issues.

The real magic happens when you start recording this data over time. Modern tools can capture performance during sea trials or typical cruising, creating a performance baseline unique to your vessel. When something begins to change—even subtly—you’ll spot it before it becomes a problem.

For South Florida boaters facing our unique combination of heat, humidity, and salt exposure, this predictive approach is invaluable. A slight decline in oil pressure trends might not trigger any alarms but could indicate developing pump wear. Address it during scheduled maintenance, and you’ll avoid that dreaded mid-cruise breakdown.

“We’ve had clients avoid major repairs simply because we caught unusual exhaust temperature patterns during routine diagnostic sessions,” notes our diagnostic specialist. “The engine wasn’t showing any fault codes yet, but the data told us something wasn’t right.”

Performing a Forced Regen on Tier 4/5 Diesels

If you operate a newer Tier 4 or 5 Volvo Penta diesel, you’ve entered emissions control systems and diesel particulate filters (DPF). These systems are fantastic for the environment but add complexity to maintenance—especially when it comes to regeneration.

Volvo Penta engine diagnostics tools give you the power to manage this process proactively through forced regeneration. Think of it as a deep-cleaning cycle for your engine’s exhaust system.

Under normal conditions, your engine should regenerate its DPF automatically during regular operation. But when operating primarily at idle or low loads (common in marina settings), soot can accumulate faster than it burns off. That’s when forced regeneration becomes necessary.

The process itself is straightforward with the right diagnostic equipment. After connecting to the engine and verifying high soot levels, you’ll initiate a controlled burn-off cycle that typically runs for about 40 minutes. During this time, the engine maintains a specific RPM range while exhaust temperatures rise significantly to incinerate accumulated soot.

“Safety is paramount during forced regeneration,” cautions our lead technician. “Exhaust temperatures increase dramatically, so proper ventilation and monitoring are essential. It’s not a process to start and walk away from.”

Beyond these two key functions, advanced diagnostic tools open up several other capabilities that can dramatically improve your maintenance program:

Cylinder balance testing helps identify performance differences between cylinders, while injector coding ensures replacement injectors are perfectly calibrated to your specific engine. For vessels with Volvo Penta IPS systems, comprehensive steering diagnostics can troubleshoot drive issues before they affect maneuverability.

For Florida boaters who demand reliability in our challenging waters, these advanced diagnostic capabilities aren’t luxuries—they’re essential tools for maintaining peak performance and avoiding costly emergency repairs. At Diesel Services of America, we leverage these advanced functions every day to keep our customers’ vessels running at their absolute best.

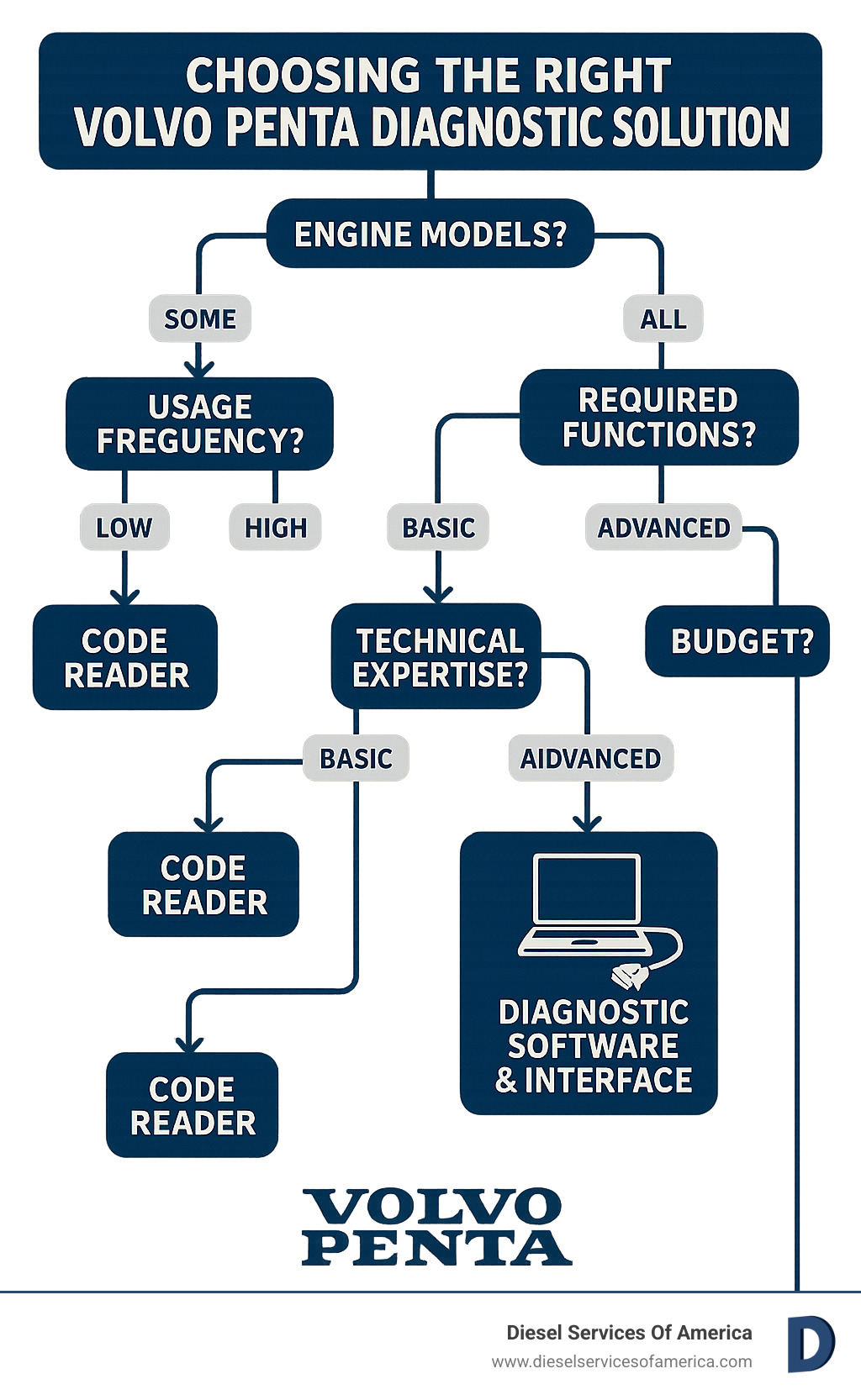

Choosing the Right Diagnostic Solution for Your Engine & Budget

Finding the perfect Volvo Penta engine diagnostics solution doesn’t have to feel like navigating through fog without radar. Let’s chart a clear course through your options, keeping your specific needs and budget in mind.

Think of choosing a diagnostic system like selecting the right boat – it needs to match your specific requirements, handling capabilities, and what you can reasonably afford. Start by asking yourself these essential questions: Which engine models do you have? How often will you be running diagnostics? Who’ll be operating the equipment? Do you need advanced functions or just basic fault reading? Will you use it dockside only or out on the water? And of course, what’s your budget looking like?

When it comes to coverage, not all diagnostic tools are created equal. The VODIA system with VOCOM II interface stands as the flagship option, covering virtually every Volvo Penta engine ever made. It’s the complete package, but comes with a premium price tag. Jaltest Marine offers impressive breadth too, covering from older Tier 1 all the way to the latest Tier 5 engines, with the bonus of three annual updates to keep you current. Rinda Diacom provides solid coverage of most modern engines, especially when equipped with the right CAN adapter for newer systems. The TechMate Pro handheld, while more limited, still handles basic diagnostics admirably for supported models.

Your budget considerations should extend beyond just the initial purchase. Volvo Penta engine diagnostics tools have varying cost structures that impact their long-term value. VODIA/VOCOM II systems typically require the highest upfront investment but provide the most comprehensive capabilities. Third-party options like Jaltest and Diacom hit a sweet middle ground on pricing. Handheld scanners generally offer the most affordable entry point for your investment.

Don’t forget to factor in update policies too. Jaltest’s three annual updates keep your system current with the latest engines and features. Some systems require yearly subscriptions to maintain support, while others offer perpetual licenses with optional updates you can purchase when needed. Technical support availability varies widely too – some include training sessions, others offer robust online documentation and user communities where you can find answers.

Here in South Florida’s challenging marine environment, durability matters just as much as function. Laptop-based systems need proper protection from the elements – a quality waterproof case is essential, not optional. Handheld units often come with built-in protection against moisture and impacts. And don’t overlook those critical interface connections – salt spray can quickly corrode unprotected cables and connections, turning your investment into expensive paperweights.

At Diesel Services of America, we’ve helped countless captains and fleet managers find their perfect diagnostic solution. For the occasional private yacht owner who only needs diagnostics a few times a year, a simpler system often makes more sense. Commercial operators with multiple vessels typically benefit from investing in more comprehensive tools that cover their entire fleet.

Many of our Fort Lauderdale customers have found that partnering with us for regular diagnostic sessions can be more cost-effective than purchasing their own equipment. Our factory-trained technicians bring professional-grade tools directly to your vessel, whether you’re docked in Southeast Florida or cruising the Caribbean. This approach gives you access to the most advanced diagnostics without the investment in equipment that might sit unused for months at a time.

The right diagnostic solution isn’t necessarily the most expensive one – it’s the one that best fits your specific needs while providing reliable results when you need them.

Frequently Asked Questions about Volvo Penta Diagnostics

How often should I update my diagnostic software?

Keeping your Volvo Penta engine diagnostics software current is like changing your engine oil—skip it at your peril! Different manufacturers follow different update schedules, and staying current ensures you have access to the latest capabilities.

VODIA typically releases updates quarterly, coinciding with significant engine model introductions. If you’re using Jaltest, you’ll benefit from their three annual updates that keep pace with Volvo Penta’s technological innovations. Diacom users can expect annual or semi-annual updates, with critical patches released as needed throughout the year.

“I can’t stress enough how important these updates are,” says our lead technician. “Last year, we had a customer with a mysterious issue on a newer D6 model that was only diagnosable after a recent software update. Without it, we might have been troubleshooting for days.”

For casual users with older engines, you might stretch the update intervals a bit. But if you’re working professionally or managing multiple vessels, those updates are worth every penny. At Diesel Services of America, we never skip an update—it’s part of our commitment to providing the most accurate diagnostics possible for our South Florida and Caribbean customers.

Can owners access advanced functions or only dealers?

The wall between dealer-only and owner-accessible diagnostic functions has been gradually crumbling over the years. While Volvo Penta once kept a tight grip on advanced capabilities, today’s landscape offers more options for hands-on owners.

Dealer-level access through VODIA still provides the deepest capabilities, particularly for ECU programming and certain calibrations. That’s why many yacht owners in Fort Lauderdale rely on our factory-trained technicians for these specialized tasks.

However, modern third-party tools have significantly narrowed the gap. As an owner, you can now handle many useful functions yourself, including fault code reading and clearing, live data monitoring, basic system tests, and even some parameter adjustments.

“One of our regular customers, a retired engineer with a 58-foot sportfisher, handles all his basic diagnostics with a Jaltest system,” shares our service manager. “He only calls us in for the complex stuff—it’s saved him time and given him more confidence in his vessel.”

If you’re considering investing in your own equipment, swing by our shop in Fort Lauderdale. We’re happy to discuss which functions you’ll be able to access yourself versus which might still require our specialized tools and training.

What’s the best way to protect my equipment in a salt-spray environment?

Florida’s marine environment is brutal on electronics—just ask anyone who’s had their smartphone die after a day on the water! For valuable diagnostic equipment, protection isn’t optional; it’s essential.

First and foremost, invest in quality waterproof, hard-shell cases for your laptop and interfaces. When not actively diagnosing, everything should be sealed away from the elements. Look for equipment with appropriate IP ratings—IP65 is good, but IP67 or IP68 is better for serious marine use.

Cable and connector care might seem mundane, but it’s critical. We’ve seen $5,000 diagnostic setups rendered useless by corroded connectors. Apply dielectric grease to electrical connections, clean and thoroughly dry connectors after each use, and store cables in sealed containers. A quick visual inspection before each use can save tremendous headaches.

“The saltiest environments I’ve worked in were the Caribbean islands,” recalls our veteran technician. “We developed a ritual: after each job, everything gets a wipe-down with a barely damp microfiber cloth to remove salt residue, followed by compressed air to clean ports and connections. It’s added years to our equipment’s life.”

When actively performing diagnostics, position your equipment away from direct spray, use protective covers, and consider a dedicated diagnostic cart that keeps everything organized and protected. Some of our customers have even retrofitted Pelican cases with custom foam inserts to create all-in-one diagnostic stations that can be quickly deployed and packed away.

At Diesel Services of America, we’ve learned these lessons through years of dockside service in Fort Lauderdale’s challenging environment. Our equipment protection protocols ensure we arrive at your vessel with fully functional diagnostic tools, ready to solve your Volvo Penta challenges without equipment failures slowing us down.

Conclusion

Mastering Volvo Penta engine diagnostics isn’t just for the professionals—it’s becoming an essential skill for anyone who takes their time on the water seriously. Whether you’re cruising the Intracoastal Waterway in Fort Lauderdale or island-hopping across the Caribbean, understanding your engine’s electronic systems can save you from that sinking feeling when something goes wrong miles from shore.

The world of marine diagnostics has evolved dramatically. What was once the exclusive domain of dealerships has now opened up to captains and boat owners who want to take a more active role in maintaining their vessels. From reading those mysterious fault codes to performing advanced parameter adjustments, today’s diagnostic tools give you unprecedented insight into what’s happening below deck.

At Diesel Services of America, we’ve seen how proper diagnostics can transform vessel maintenance from reactive emergency repairs to proactive care. Our approach combines the best of both worlds—cutting-edge technology with good old-fashioned expertise.

When you work with our team, you’re getting more than just a service call. You’re partnering with technicians who understand both the technical side of Volvo Penta engine diagnostics and the real-world challenges of operating in South Florida’s demanding marine environment. We bring professional-grade equipment right to your dock, along with the knowledge to interpret what your engine is trying to tell you.

What sets us apart? It’s our comprehensive diagnostic process that leaves nothing to chance:

• We begin with thorough system scans that catch both active issues and potential problems developing beneath the surface.

• We analyze live data parameters to optimize performance for your specific operating conditions.

• Every finding gets documented in detail, and we take the time to explain exactly what’s happening in plain English—no technical jargon unless you really want it!

• When repairs are needed, we use only genuine parts installed by technicians who know your engine inside and out.

• We don’t consider the job done until we’ve verified everything with post-repair testing and sea trials when necessary.

As one of our long-time customers put it, “They don’t just fix the problem—they make sure it won’t happen again.” That’s because we understand that in the marine world, downtime isn’t just inconvenient—it can be costly and potentially dangerous.

Whether you choose to invest in your own diagnostic equipment or prefer to have our team handle your maintenance needs, understanding the importance of proper engine diagnostics is the first step toward maximizing your vessel’s reliability, performance, and value.

After all, in the challenging waters of South Florida and beyond, there’s simply no substitute for knowing exactly what’s happening with your engines—before small issues become big problems.

More info about Authorized Volvo Penta Experts