When Your Marine Generator Fails at the Worst Moment

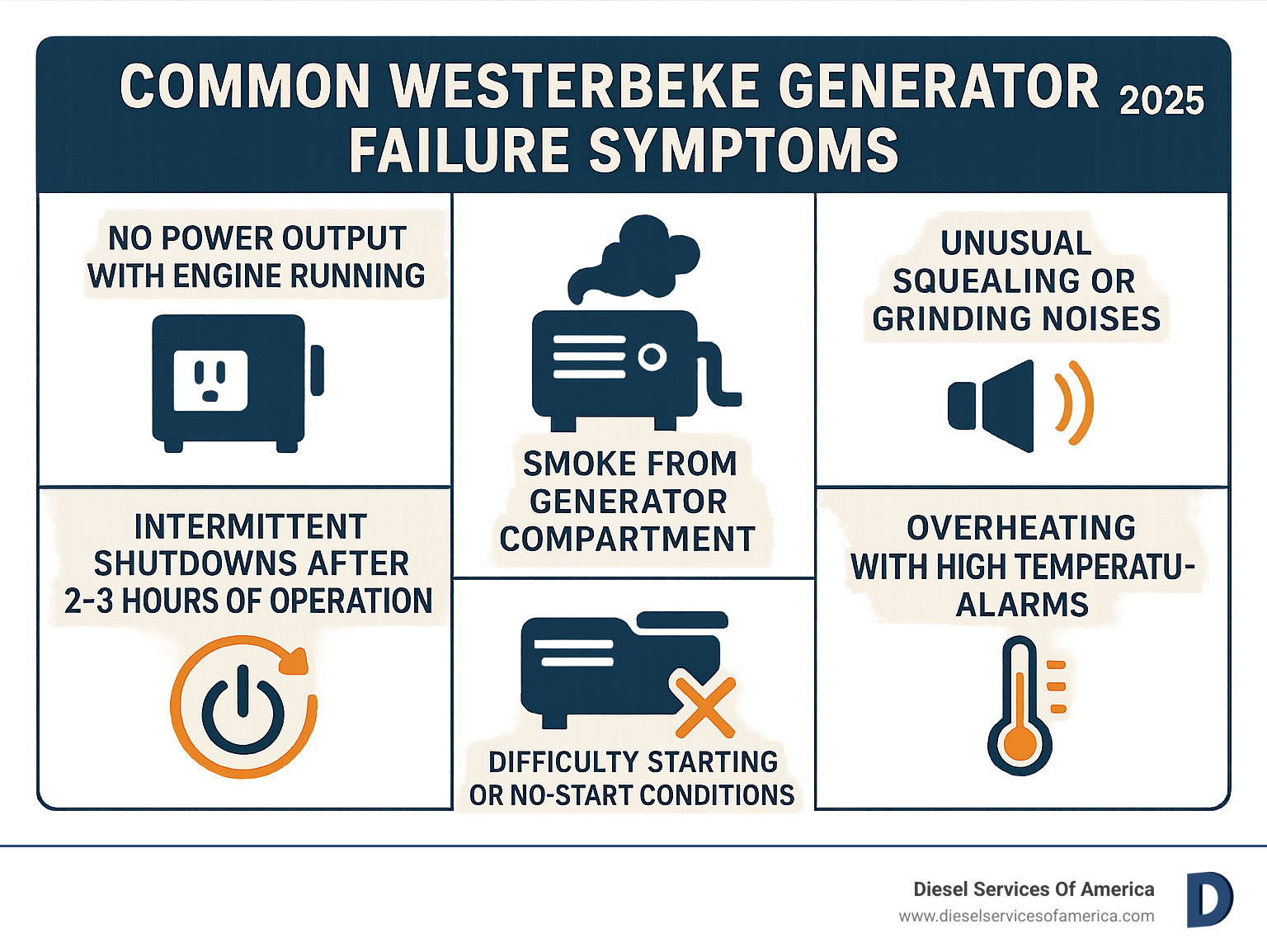

Westerbeke generator repair becomes critical when your onboard power fails. Whether you’re dealing with a generator that smokes with no output, an engine that won’t start, or intermittent shutdowns, finding the right repair solution quickly can mean the difference between a minor inconvenience and a costly emergency.

Quick Westerbeke Generator Repair Options:

- Emergency Service: Call marine diesel specialists for immediate troubleshooting

- DIY Diagnosis: Check circuit breakers, fuel supply, and basic electrical connections first

- Professional Repair: Generator end rebuilds typically cost $2,500 vs. $12,000+ for replacement

- Authorized Service: Use Westerbeke distributors for genuine parts and warranty protection

- Preventive Care: Regular maintenance prevents 80% of generator failures

Marine generators are complex machines combining diesel engines with electrical equipment. When problems arise, symptoms can range from obvious (smoke) to puzzling (intermittent power loss). One boat owner described a noise “like a belt slipping…coming from in between the motor and the generator end.” This type of issue, often caused by something as simple as a clogged breather screen, illustrates why proper diagnosis is essential before committing to expensive repairs.

Learn more about westerbeke generator repair:

Diagnosing Common Westerbeke Generator Problems

Most Westerbeke generator repair issues follow predictable patterns, and understanding the symptoms can save you time and money. Common signs of a failing marine generator include no power output with a running engine, smoke, unusual noises, difficulty starting, intermittent shutdowns, overheating, or excessive vibration. A marine generator is two systems in one: a diesel engine and an electrical generator, so a problem could be with either. Before attempting any diagnostic work, safety comes first.

When the Engine Runs But There’s No Power Output

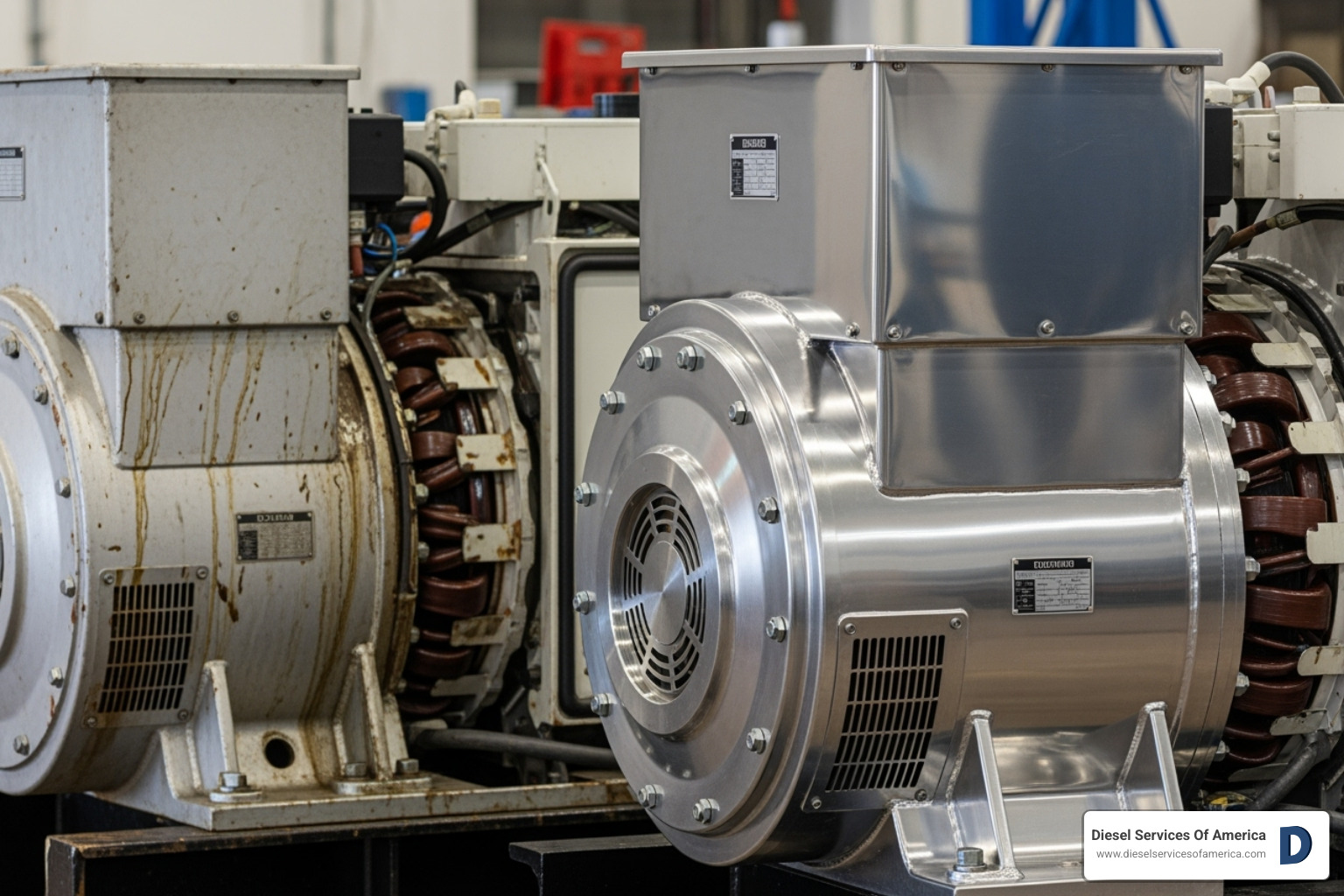

If your generator’s engine runs smoothly but you have no AC output, the problem is likely in the generator end (the electrical portion). Common culprits include:

- Failed diodes: These components are essential for power generation; when they fail, output disappears.

- Worn bearings: Worn bearings can allow the rotor to contact the stator, causing smoke, damage, and power loss. If your generator smoked before failing, this is a likely cause.

- Faulty capacitor: Sometimes, a simple capacitor replacement is all that’s needed to restore power.

- Damaged windings: Vibration can wear through wire insulation, creating shorts that require professional rewinding.

These generator end problems require specialized tools and expertise. Professional Westerbeke Generator Service is essential for these complex, non-DIY repairs.

Engine Starting Issues and Intermittent Shutdowns

A generator that won’t start or shuts down intermittently can be stressful. Here are common causes:

- No-start conditions: Always check the basics first: fuel supply and battery charge.

- Preheat solenoid: This component powers the glow plugs and fuel pump. A faulty solenoid or its fuse/breaker can prevent starting.

- Fuel system problems: A clogged breather screen on the throttle body intake can cause squealing, hard starts, and white smoke.

- Vapor lock: On hot days, fuel can vaporize in the lines, starving the engine. If your generator dies after running for a couple of hours in the heat and restarts after you cool the fuel pump with water, vapor lock is the likely culprit.

- Faulty safety switches: Malfunctioning exhaust temperature, water temperature, or oil pressure switches can trigger false shutdowns.

For detailed diagrams, consult your Westerbeke generator operator’s manual.

Essential Safety Precautions Before Attempting a Westerbeke Generator Repair

Marine generators combine fuel, electricity, heat, and moving parts in a confined space. Respect these hazards to avoid serious injury.

- Carbon monoxide dangers: CO is an invisible, odorless killer. Symptoms include dizziness and nausea; seek fresh air immediately. Ensure proper ventilation and install working CO detectors.

- Electrical shock prevention: Turn OFF the DC breaker or battery switch before work. Use insulated tools and gloves, and remove jewelry.

- Hot engine parts: Allow the generator to cool completely before touching it to prevent severe burns.

- Fuel system safety: Ensure good ventilation, clean up spills immediately, and keep flames away. Check for tight, leak-free fittings.

- Battery safety: Disconnect the negative terminal first and reconnect it last. Wear eye protection and rubber gloves.

- Moving parts: Never service a running engine. Keep guards in place, tie back long hair, and avoid loose clothing.

When in doubt, call a professional. Attempting complex westerbeke generator repair isn’t worth risking your safety.

The Critical Decision: Repair vs. Replacement

When your Westerbeke generator fails, you face a critical choice: invest in westerbeke generator repair or buy a new unit? The decision involves weighing today’s bill against long-term reliability and future costs. If the diesel engine is strong but the electrical end has failed, repair is often the best path. However, if the engine and electrical system are both failing, replacement may be more sensible.

Analyzing the Cost: Repairing vs. Buying New

The cost difference between repair and replacement can be significant. A major westerbeke generator repair, like a complete generator end rewind, typically costs around $2,500. In contrast, a new Westerbeke generator can cost $12,000 to $20,000+, plus installation.

| Factor | Repair (e.g., Generator End Rebuild) | Replacement (New Unit) |

|---|---|---|

| Total Cost | ~$2,500 – $5,000 (Major Repair) | ~$12,000 – $20,000+ |

| Downtime | Moderate (waiting for parts/rebuild) | Moderate to High (installation) |

| Warranty | Limited (on repaired parts) | Full (on new unit) |

| Long-Term Reliability | Varies (depends on repair quality, age of other components) | High (for new unit) |

A practical advantage of repair is avoiding the physical removal challenge. Removing a 150-pound generator end is often more feasible than removing the entire unit from a cramped engine room. Of course, minor repairs like replacing a sensor or capacitor cost only a few hundred dollars, making repair the obvious choice.

How Age and Hours Influence Your Choice

Age and operating hours are key factors in the repair vs. replace decision.

- Low-hour generators (under 1,000 hours) are excellent candidates for repair. At this stage, the diesel engine is barely broken in. If the engine runs well, fixing a specific electrical problem makes financial sense.

- High-hour generators (over 2,000 hours) need more thought. Many Westerbeke units use robust Mitsubishi engines that can last over 15,000 hours with good maintenance.

The crucial factor is separating engine health from generator end health. If a high-hour engine is healthy (starts easily, good oil pressure, no smoke), repairing the electrical side is often the smart move. However, if the engine is hard to start, burning oil, or losing power, it’s likely time for a complete Westerbeke Diesel Generator replacement.

An honest assessment is required: good engine with electrical issues means repair. A failing engine means replacement. When both are marginal, consult an experienced marine diesel technician.

A Guide to Professional Westerbeke Generator Repair

While some maintenance is DIY-friendly, complex westerbeke generator repair requires professional expertise. Marine generators merge diesel mechanics with complex electrical systems, and issues with the generator end, fuel system, or diagnostics demand specialized knowledge.

Finding a Reputable Service for Your Westerbeke Generator Repair

Choosing the right service provider is crucial for a lasting repair. Look for:

- Authorized dealers: Westerbeke recommends service by authorized distributors who have access to the latest technical documents and training. Use the Westerbeke Distributor Locator to find one.

- Factory-trained technicians: They understand the unique quirks of Westerbeke systems, from wiring to ECU diagnostics.

- Marine diesel specialization: Marine environments—with salt air, vibration, and confined spaces—require specific expertise that general mechanics lack.

Before calling, locate your model and serial number on the generator’s data plate to ensure the correct parts are ordered. When searching for Westerbeke Generator Repair Near Me, choose a company that understands the marine environment.

The Value of Using Genuine Westerbeke Parts

Using genuine Westerbeke parts is essential for reliability and safety. Here’s why:

- Warranty protection: Non-genuine parts can void your warranty, a costly gamble.

- Performance and safety: Genuine parts are engineered to exact specifications, ensuring safe and proper operation.

- Perfect compatibility: Authentic parts fit seamlessly, reducing installation issues.

- Avoiding premature failure: Genuine parts are built to withstand the marine environment, saving you money on repeat repairs.

At Diesel Services of America, we use only authentic components in our work on Westerbeke Marine Diesel Engines. Our factory-trained technicians know that quality parts are critical for your vessel’s safety and reliability.

Preventative Maintenance to Avoid Future Repairs

The best westerbeke generator repair is the one you never have to make. Preventative maintenance provides peace of mind and helps you avoid being stranded without power. A few hours of care each season can prevent the vast majority of emergency repairs.

Your Regular Maintenance Checklist

Most boat owners can handle these routine tasks with basic tools.

- Regular oil changes: Follow the manufacturer’s hour-based schedule. Consider seasonal oil analysis to monitor internal wear.

- Fuel filter inspection: Check and replace fuel filters regularly to prevent restrictions caused by contamination or condensation.

- Air cleaner: Keep the air filter and the breather screen on the throttle body intake clean to ensure engine efficiency.

- Seawater pump impeller: This critical component prevents overheating. Replace it annually or as recommended as cheap insurance against engine damage.

- Drive belt tension: Check belts for proper tension (about 3/8 to 1/2 inch of deflection) to prevent slipping or premature bearing wear.

- Battery terminals: Keep terminals clean and tight to prevent corrosion and ensure reliable starting.

Long-Term Care and Scheduled Service

These critical tasks ensure long-term reliability.

- Catalyst replacement: On equipped models, replace the catalyst every 2,000 hours and verify CO levels seasonally or every 500 hours.

- Valve clearance adjustment: Proper valve clearance (e.g., 0.20mm intake, 0.30mm exhaust) is essential for engine performance.

- Timing belt: Replace the timing belt after 1000 hours or during overhauls to prevent catastrophic engine failure.

- Coolant system: Flush the system periodically to prevent corrosion and ensure efficient cooling.

Even if you’re handy, professional service intervals are invaluable. Our factory-trained technicians can spot potential problems that owners might miss. Understanding the Importance of Westerbeke Diesel Generator Service is about protecting your investment and ensuring reliable power. A little attention now prevents major headaches later.

Frequently Asked Questions about Westerbeke Generators

Here are answers to the most common questions we receive about Westerbeke generators.

What are the first things to check if my Westerbeke generator has no output?

First, check the circuit breakers on the generator and your boat’s main electrical panel; a tripped breaker is a common culprit. Next, confirm the engine speed with a tachometer. It must be at 1800 RPM (for 60Hz) or 1500 RPM (for 50Hz) for proper output. If these are correct, you likely have a generator end problem, such as a failed capacitor, faulty diodes, or damaged windings. Diagnosing these issues requires specialized tools and professional knowledge.

How much does it cost to repair a Westerbeke generator?

The cost varies widely. Minor repairs, like replacing a sensor or capacitor, might cost a few hundred dollars. A major repair, such as a complete generator end rewind, typically runs around $2,500. In contrast, a brand-new Westerbeke generator can exceed $12,000, plus significant labor costs for removal and installation in a tight engine room. This cost difference is why many customers choose to repair a generator that has a healthy engine.

Can I repair the generator myself?

While we encourage owners to handle basic maintenance like oil changes, filter replacements, and impeller inspections, we strongly recommend professional service for more complex issues. Electrical diagnostics, fuel system repairs, and work on the generator end involve high voltage and require specialized training and tools. A DIY mistake can be costly, dangerous, and may void your warranty. For complex westerbeke generator repair, our dockside service in South Florida provides expert help at your location, saving you time and hassle.

Conclusion

When Westerbeke generator repair is needed, understanding the warning signs is the first step. The choice between repair and replacement becomes clearer with an honest assessment: a strong, low-hour engine often makes a $2,500 generator end rebuild a smart choice over a $12,000+ replacement. However, for a high-hour unit with multiple problems, a new generator may be the better investment.

Preventative maintenance like regular oil changes and clean filters prevents most major issues. An ounce of prevention is worth a pound of cure, especially when the cure involves heavy lifting in an engine room.

At Diesel Services of America, our factory-trained technicians specialize in marine and industrial diesel systems. We understand the challenges of the marine environment and have seen everything from simple fixes to complex rebuilds. We offer dockside service throughout South Florida and the Caribbean, plus worldwide parts delivery to ensure you get genuine Westerbeke components.

Don’t let generator problems ruin your time on the water. For expert marine generator repair and service, contact our team today. We’ll help you get back to enjoying your boat with reliable power.