Understanding the Critical Role of Engine Cooling Systems

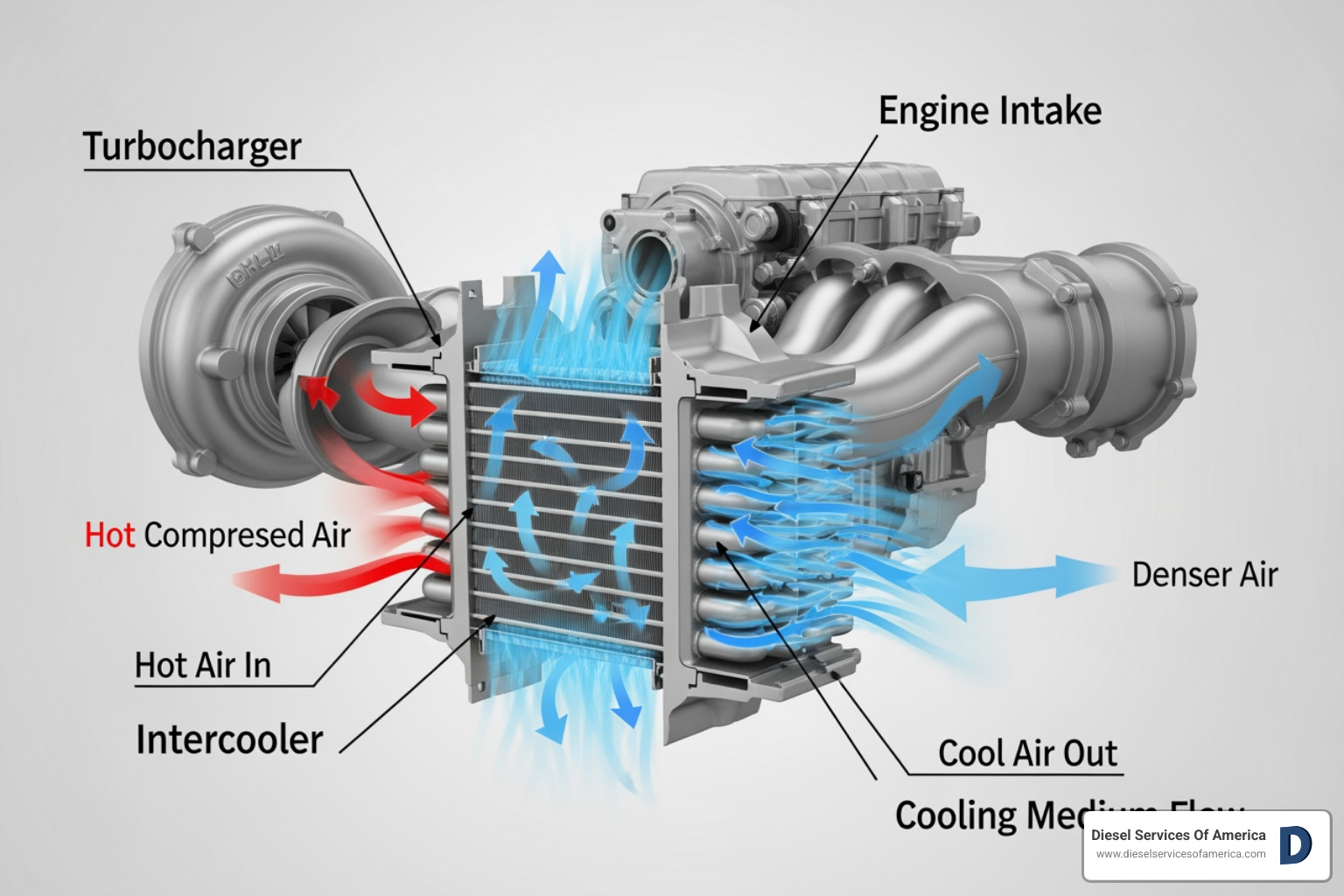

What are intercoolers? An intercooler is a heat exchanger that cools compressed air from a turbocharger before it enters the engine’s intake manifold. By reducing intake air temperature, an intercooler increases air density, allowing more oxygen into the combustion chamber for improved power, efficiency, and reliability.

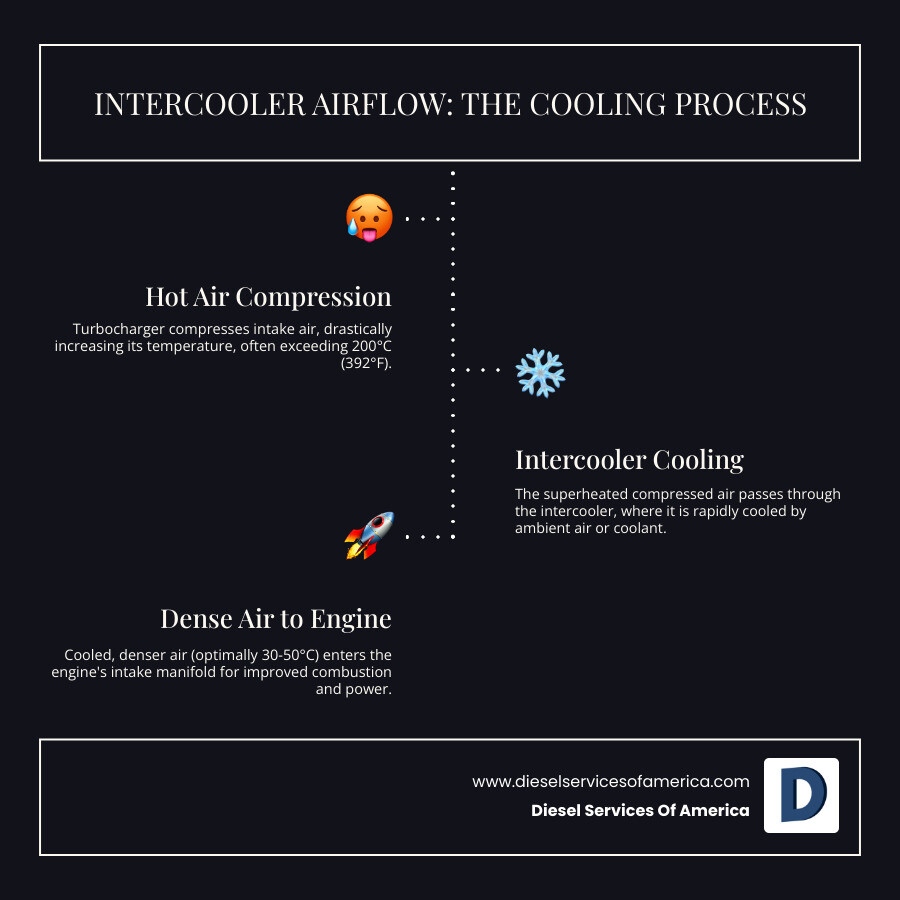

Key Functions of an Intercooler:

- Cools compressed air from turbochargers, which can exceed 200°C (392°F).

- Increases air density by lowering intake temperatures to the ideal 30-50°C range.

- Prevents engine knock by eliminating hot spots in the combustion chamber.

- Improves fuel efficiency through more complete combustion.

- Increases horsepower by allowing more fuel to be burned with denser, oxygen-rich air.

Marine and industrial diesel engines rely on sophisticated cooling systems to manage extreme heat. While radiators handle engine coolant temperatures, intercoolers serve a distinct purpose in forced induction systems. Understanding the distinction between radiators and intercoolers is essential for anyone managing a fleet of marine vessels or industrial diesel equipment. Both are heat exchangers, but they cool different fluids for different reasons.

This guide explains what intercoolers do, how they differ from radiators, and why proper maintenance is critical for engine longevity in marine and industrial applications.

The Role of a Radiator in a Marine Diesel Engine

Before exploring what are intercoolers in detail, let’s review the role of a radiator. Understanding what radiators do clarifies why intercoolers are essential for turbocharged engines.

In marine and industrial diesel engines, the radiator’s job is to prevent the engine block from overheating. It’s the core of a closed-loop cooling system that circulates engine coolant (a water/antifreeze mix) through the engine block and cylinder head.

As coolant flows through the engine, it absorbs heat from combustion and friction. This hot coolant then travels to the radiator for heat dissipation. Most marine applications use a liquid-to-liquid cooling system. Instead of using air, the engine’s hot coolant passes through a heat exchanger where seawater absorbs the heat and carries it out of the vessel.

This system maintains the engine block temperature in the optimal range for reliable operation. The key distinction is that a radiator cools the engine itself by managing heat from its internal operation. An intercooler, however, cools the intake air before combustion begins. This is the fundamental difference between radiator function vs. intercooler function. Both use heat exchangers, but they cool different things for different reasons.

What are Intercoolers and Why are They Essential for Performance?

An intercooler, also called a Charge Air Cooler (CAC), is the component that makes turbocharging effective. It sits between the turbocharger and the engine’s intake manifold to cool the superheated air coming from the turbo before it enters the combustion chambers.

Modern marine and industrial diesel engines use forced induction to boost performance. The turbocharger compresses massive amounts of air, but this process creates intense heat, which reduces engine efficiency. The intercooler solves this problem by lowering the intake air temperature, changing hot, expanded air into a dense, oxygen-rich charge. The result is more power, better fuel economy, and a cleaner, more durable engine. For anyone serious about Diesel Engine Performance Enhancement, understanding the intercooler is crucial.

The Science: Why Compressing Air Creates Intense Heat

According to the laws of thermodynamics, compressing a gas increases its temperature. A turbocharger spins at incredible speeds (over 300,000 RPM) to force air into a smaller space. This compression can heat the air to over 200°C (392°F), while optimal combustion occurs with intake air between 30-50°C.

Hot air is less dense, meaning it contains fewer oxygen molecules per volume. Sending this superheated air directly to the engine would negate the benefits of the turbocharger’s work, actually reducing power. The higher the boost pressure, the more heat is generated, making an intercooler’s cooling function indispensable. More details on this can be found at The Science Behind How an Intercooler Works.

The Performance Advantage: Cooler, Denser Air for Combustion

The magic of an intercooler is simple: cooler air is denser air. By cooling compressed air from 200°C down to 40-50°C, the air molecules pack together more tightly, delivering significantly more oxygen to the combustion chamber. This dense, oxygen-rich air allows the engine to burn more fuel completely and efficiently.

- Increased horsepower and torque: More oxygen allows more fuel to be burned completely, creating stronger combustion that pushes pistons harder. This is vital for marine engines needing sustained power.

- Better fuel economy: Efficient combustion extracts maximum energy from every gallon of diesel, reducing waste and lowering operating costs for commercial marine operations.

- Engine knock prevention: Hot intake air can cause hot spots in the combustion chamber, leading to premature ignition (detonation). This damaging event can destroy pistons and bearings. By keeping intake temperatures low, intercoolers prevent knock and protect the engine.

- Reduced emissions: Complete combustion means fewer unburned hydrocarbons and particulates in the exhaust, helping engines meet environmental regulations.

The intercooler transforms hot, inefficient air into a dense, powerful charge that open ups the full potential of a turbocharged engine, ensuring the reliable performance that marine and industrial applications demand.

Types of Intercoolers in Marine and Industrial Applications

Not all intercoolers are the same. The two main types, air-to-air and air-to-water, cool compressed air differently. The best choice depends on the specific application, especially in the compact and demanding environments of marine and industrial settings. Most marine diesels we service in Fort Lauderdale use air-to-water intercoolers due to the tight, hot conditions of engine rooms.

Air-to-Air (ATA) Intercoolers

An air-to-air intercooler functions like a small radiator for intake air. Hot compressed air flows through tubes while cooler ambient air passes over external fins, transferring heat away.

- Advantages: Simple design with fewer parts, lower cost, and lighter weight.

- Disadvantages: Requires direct, constant airflow to be effective. This is a major challenge in enclosed marine engine rooms or industrial housings. Their efficiency drops in high ambient temperatures, making them less practical for the hot climates of South Florida and the Caribbean.

For these reasons, ATA intercoolers are rarely used in the marine diesel world.

Air-to-Water (ATW) Intercoolers

Air-to-water intercoolers are the workhorses of marine and industrial cooling. They use a liquid coolant to transfer heat. Hot compressed air passes through the intercooler core, heating a liquid coolant. This coolant is then pumped to a separate heat exchanger, where it is cooled by seawater (in marine applications) before circulating back.

- Advantages: Water transfers heat far more efficiently than air, allowing for a much more compact and effective unit. Cooling efficiency is superior and more stable, unaffected by high ambient air temperatures. The intercooler’s flexible placement is a huge benefit in tight engine rooms. They are built with corrosion-resistant materials like copper-nickel to withstand harsh seawater environments, as seen in our specialized Diesel Intercooler solutions.

- Disadvantages: More complex system with a pump, reservoir, and secondary heat exchanger. This results in a higher initial cost and more weight.

Despite the complexity, the superior cooling, compact size, and reliable performance make ATW intercoolers the clear choice for serious marine and industrial applications.

TABLE: Comparing Air-to-Air vs. Air-to-Water Intercoolers for Marine Use

| Feature | Air-to-Air (ATA) Intercooler | Air-to-Water (ATW) Intercooler |

|---|---|---|

| Cooling Medium | Ambient air | Intermediate liquid coolant (e.g., engine coolant, seawater) |

| Heat Transfer | Compressed air directly to ambient air | Compressed air to liquid coolant, then liquid coolant to ambient air/seawater |

| Efficiency | Good, but dependent on ambient air temperature | Excellent, more stable, less affected by ambient air temp |

| Size/Footprint | Generally larger for equivalent cooling | More compact for equivalent cooling |

| Placement | Requires direct airflow, can be restrictive in enclosed spaces | Flexible placement, ideal for enclosed engine rooms |

| Complexity | Simpler system, fewer components | More complex (pump, reservoir, secondary heat exchanger) |

| Weight | Lighter | Heavier due to additional components and fluid |

| Cost | Generally lower initial cost | Higher initial cost |

| Marine Suitability | Limited by enclosed engine rooms and high ambient temps | Highly suitable due to available seawater and compact design |

| Corrosion Risk | Lower, mostly air-side issues | Higher in seawater applications, requires specialized materials |

Intercooler Maintenance and Troubleshooting

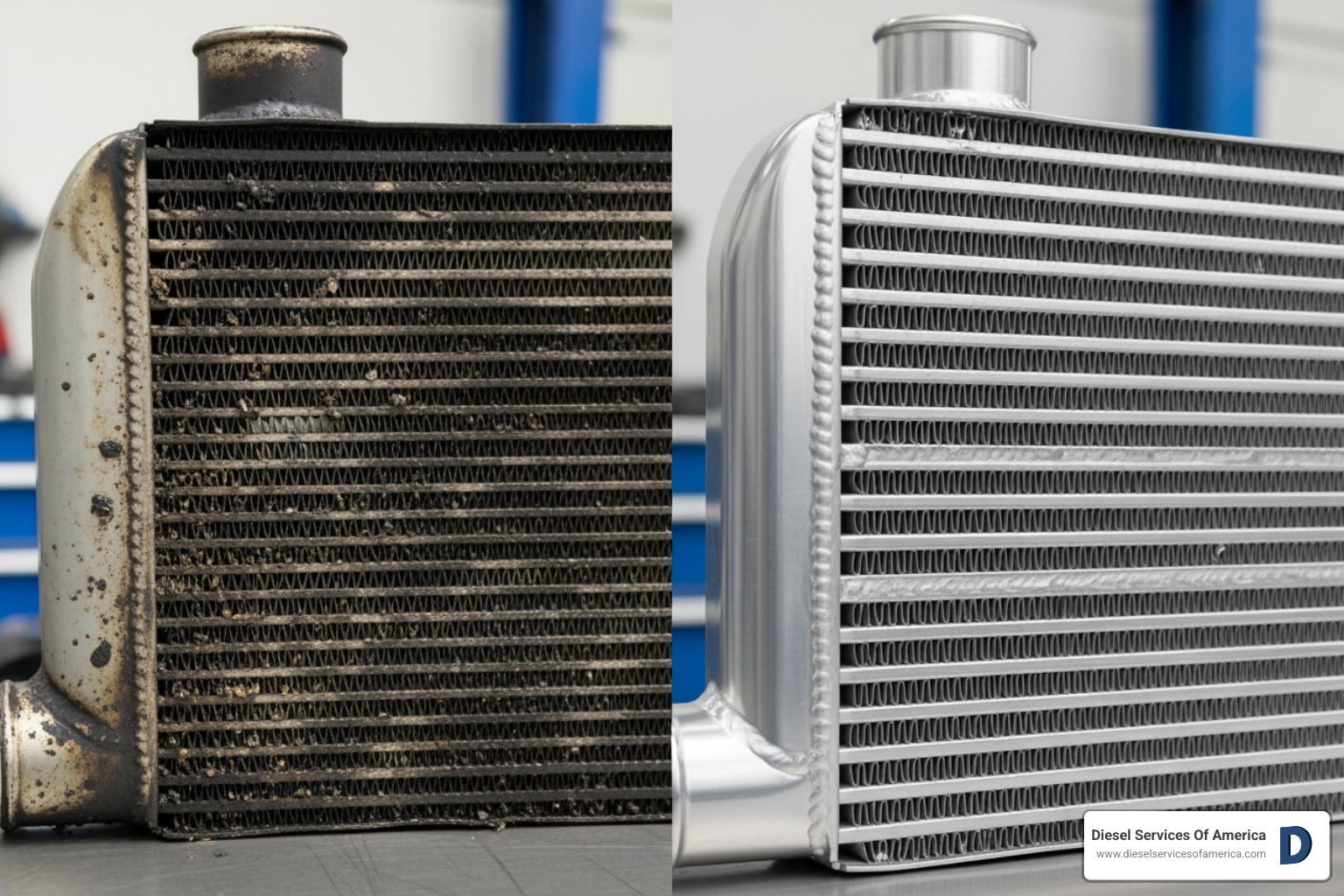

An intercooler works under extreme temperatures and pressures. Without proper care, it will fail, compromising engine performance and reliability. Preventative maintenance is key to protecting your investment, especially for marine and industrial diesels in demanding environments like South Florida and the Caribbean.

What are the signs of a failing intercooler?

A failing intercooler often gives subtle hints before a major breakdown. Look for these common signs:

- Decline in power and acceleration: The engine feels sluggish because it’s not getting dense, cool air.

- Increased black smoke from the exhaust: This indicates incomplete combustion and wasted fuel due to hot intake air.

- Hissing or whistling sounds: These noises suggest a boost leak from a crack or failed seal. Pressurized air is escaping before reaching the engine. Learn more about Understanding Boost Leaks.

- High intake air temperature (IAT) readings: If your engine monitoring system shows IATs consistently above the ideal 30-50°C range, the intercooler is struggling.

- Visible damage or corrosion: Check for bent fins, cracks, loose clamps, or leaks, especially from saltwater corrosion.

- Increased fuel consumption: The engine burns more fuel to compensate for the poor-quality air.

If you notice these symptoms, have your intercooler inspected by a specialist.

Essential Maintenance for Marine Intercoolers

In harsh marine environments, intercooler maintenance is not optional. We’ve seen externally fine intercoolers that were completely choked internally, leading to lost performance and costly engine damage.

- Regular Inspections: Visually check for damage, corrosion, and leaks during routine engine checks.

- 1000-Hour Service: Most marine engine manufacturers (like MAN and Yanmar) recommend a thorough intercooler service around every 1000 operating hours to maintain reliability.

- Airside Cleaning: The airside fins become coated with a sticky mix of oil vapor and soot from crankcase vapors. This buildup acts as an insulator, trapping heat. Professional cleaning with specialized solvents is required to remove it without damaging the core.

- Seawater Side Cleaning: For air-to-water units, the seawater side is prone to salt deposits, marine growth (barnacles, sea grass), and mineral buildup. This restricts water flow and kills cooling efficiency. It requires aggressive cleaning, sometimes with products like “Barnacle Buster,” which must only be used on the raw water side to avoid damaging engine seals.

- Pressure Testing: After any cleaning, pressure testing is essential to find hidden leaks. A small leak can cause significant boost pressure loss.

- Gasket and O-Ring Replacement: Always replace all seals during service. Old seals become hard and brittle, and are a common source of leaks after reassembly.

Skipping this maintenance allows debris to harden like concrete, making disassembly difficult and potentially causing damage. Regular cleaning can keep an intercooler functioning perfectly for years, avoiding costly replacements. Our team at Diesel Services of America specializes in this work, as shown in our video on Marine Diesel Engine Intercooler Cleaning and Maintenance.

Frequently Asked Questions about Intercoolers

Here are answers to common questions we get from clients about what are intercoolers and how they work in marine and industrial applications.

How does intercooler size affect performance?

A larger intercooler offers more surface area for cooling, which can lower air temperatures further and create denser air for more power. However, “bigger” isn’t always better.

- Pressure Drop: A very large intercooler can increase resistance, causing a drop in boost pressure by the time the air reaches the engine. This can reduce performance and cause turbo lag.

- Physical Constraints: In the tight confines of a marine engine room, a larger unit may not fit or could create weight balance issues.

The key is proper sizing for your application. An ideal intercooler balances maximum cooling efficiency with minimal pressure drop. This is why working with experienced technicians is crucial. While a bigger intercooler can add horsepower, as discussed in Will a Bigger Intercooler Add Horsepower?, marine applications have unique constraints.

What is the difference between an intercooler and an aftercooler?

In the vast majority of modern single-turbo marine and industrial engines, the terms “intercooler” and “aftercooler” are used interchangeably. They both refer to the heat exchanger that cools compressed air before it enters the intake manifold.

The distinction only matters in rare multi-stage compression systems, where two or more turbochargers operate in series. In that context, an intercooler sits between the turbo stages, and an aftercooler sits after the final turbo stage. For most engines we service, whether you call it an intercooler, aftercooler, or Charge Air Cooler (CAC), it’s the same component.

What are the latest advancements in intercooler technology?

Intercooler technology is constantly evolving to improve efficiency, power, and emissions. Key advancements include:

- Integrated Intake Manifolds: Designers are building the intercooler directly into the intake manifold. This shortens the air path, reduces pressure drop, and creates a more compact engine package—a major benefit in tight marine engine rooms.

- Improved Core Designs: Modern bar-and-plate core construction offers a larger heat transfer surface area with smoother airflow, providing better cooling with less restriction than older tube-and-fin designs.

- Advanced Materials: For marine use, new corrosion-resistant alloys and coatings are being developed to better withstand the harsh saltwater environment, improving long-term reliability.

- Compact Designs: Innovations continue to deliver more cooling capacity in smaller footprints, which is critical for retrofits and space-constrained applications.

These innovations, some of which are covered in Latest Innovations in Automotive Cooling, are making modern diesel engines more powerful and reliable.

Conclusion: Maximizing Your Engine’s Health and Power

To recap, radiators and intercoolers are both vital heat exchangers, but they serve different functions. The radiator cools the engine block itself, while the intercooler cools the compressed intake air from the turbocharger.

Understanding what are intercoolers is key to getting the most from your marine or industrial diesel engine. By cooling intake air to the optimal 30-50°C range, the intercooler delivers dense, oxygen-rich air that results in more power, better fuel economy, and cleaner combustion.

However, these benefits depend on proper maintenance. Regular cleaning of the airside and seawater side, along with pressure testing and seal replacement, is essential. A neglected intercooler will compromise your engine’s performance and longevity.

At Diesel Services of America, our factory-trained technicians understand the unique challenges of marine and industrial engines in South Florida and the Caribbean. We know that maintaining your cooling systems—both radiators and intercoolers—is essential preventative care that keeps your operations on schedule and your repair costs down. We specialize in the complete service of marine and industrial diesel engines, from routine intercooler cleaning to comprehensive system overhauls.

Ready to give your engine the expert care it deserves?

Connect with Diesel Services of America today:

Explore our specialized Diesel Intercooler services to learn more about our maintenance and repair capabilities. For comprehensive engine care, visit our Expert Marine Diesel Services page. You can also browse our full range of capabilities on our services page, or get in touch directly through our contact page. Learn more about our company and commitment to excellence at dieselservicesofamerica.com.